Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

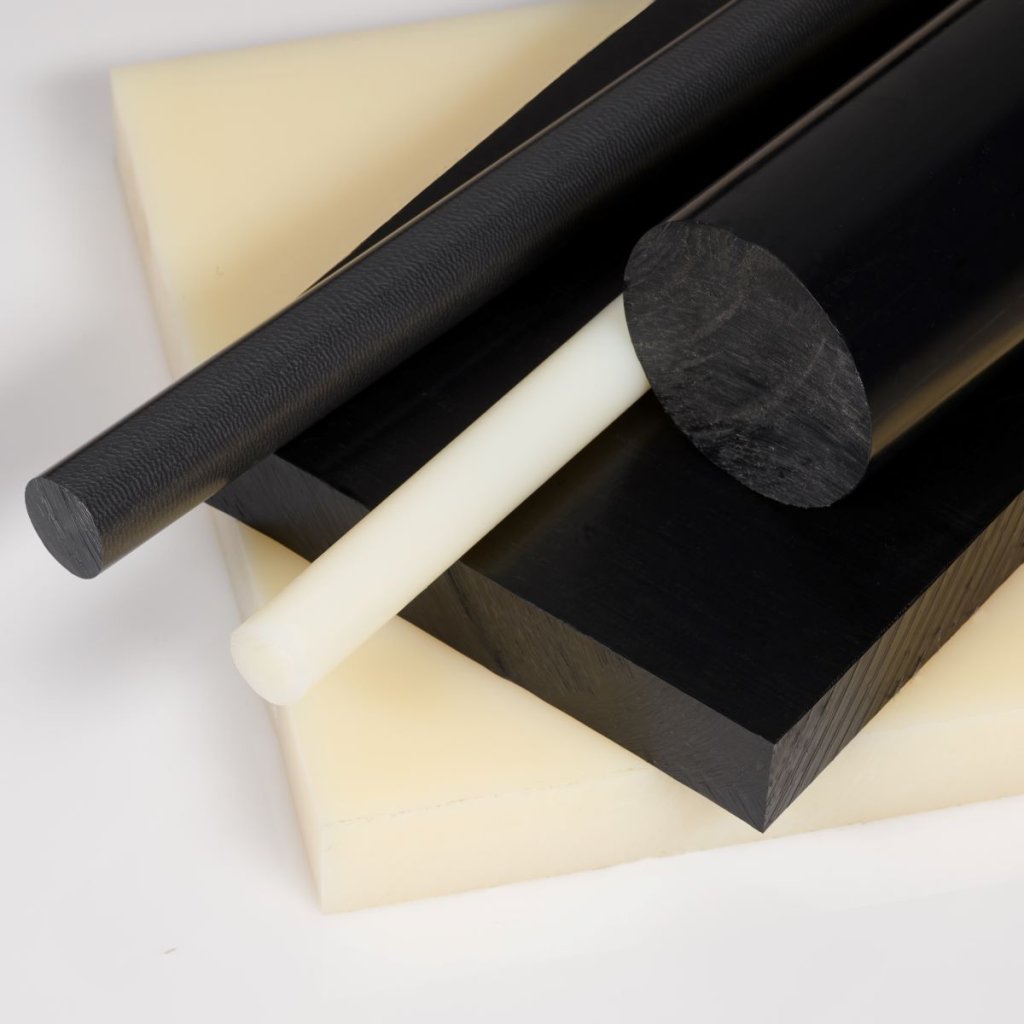

Cast Nylon

Durable, versatile, self-lubricating engineering plastic for industrial applications.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Cast Nylon

Common Properties

- Typical Thickness Size 0.25 - 4.0 in

- Typical Lengths 48-120 in

- Common Brand Names NYCAST®, NYLOIL®, Sustamid®, Nylatron™, Erthalon™, TECAST®

- Typical Widths 24-48 in

- Common Profiles Sheet, Rod, Tube

- Friendly Names Nylon 6, PA6, Polyamide 6

Mechanical Properties

- Instrumented Impact Total Energy 35 J

- Shear Strength 60 MPa

- Izod Impact, Unnotched 10 kJ/m²

- Hardness, Rockwell R 120 -

- Flexural Modulus 2800 MPa

- Modulus of Elasticity 2900 MPa

- Falling Dart Impact 30 N

- Flexural Yield Strength 115 MPa

- Tensile Strength, Yield 80 MPa

- Bearing Yield Strength 150 MPa

- Compressive Yield Strength 110 MPa

- Gardner Impact 34 J

- Izod Impact, Notched 4 kJ/m²

- Tensile Strength, Ultimate 83 MPa

- Elongation at Break 60 %

- Elongation at Yield 20 %

Physical Properties

- Linear Mold Shrinkage 0.2-2.5 %

- Moisture Absorption at Equilibrium 0.1-1.5 %

- Density 0.9-1.4 g/cm³

- Water Absorption 0.01-0.3 %

- Melt Flow 2-20 g/10 min

Regulation Properties

Thermal Properties

- CTE, linear 80 µm/m-°C

- Intermittent Service Temperature 330 ˚F

- Thermal Conductivity 0.31 W/m-°K

- Max Continuous Operating Temperature 194 °F

- Deflection Temperature at 0.46 MPa (66 psi) 190 °C

- Minimum Operating Temperature -40 °F

- Deflection Temperature at 1.8 MPa (264 psi) 90 °C

- Vicat Softening Point 215 °C

- CTE, linear, Transverse to Flow 120 µm/m-°C

- Continuous Service Temperature 230 ˚F

- Flammability, UL94 HB

Literature and Data Sheets

-

Cast Nylons NYCAST® 12 Cast Nylons Limited

Cast Nylons NYCAST® 12 Cast Nylons Limited -

Cast Nylons NYCAST® 6PA MoS2 Cast Nylons Limited

Cast Nylons NYCAST® 6PA MoS2 Cast Nylons Limited -

Cast Nylons NYCAST® 6PA XHA Cast Nylons Limited

Cast Nylons NYCAST® 6PA XHA Cast Nylons Limited -

Cast Nylons NYCAST® 6PA Cast Nylons Limited

Cast Nylons NYCAST® 6PA Cast Nylons Limited -

Cast Nylons NYCAST® CP 6/12 Cast Nylons Limited

Cast Nylons NYCAST® CP 6/12 Cast Nylons Limited -

Cast Nylons NYCAST® CP 6PA MP MPB Cast Nylons Limited

Cast Nylons NYCAST® CP 6PA MP MPB Cast Nylons Limited -

Cast Nylons NYCAST® NYLOIL FG Cast Nylons Limited

Cast Nylons NYCAST® NYLOIL FG Cast Nylons Limited -

Cast Nylons NYCAST® NYLOIL Cast Nylons Limited

Cast Nylons NYCAST® NYLOIL Cast Nylons Limited -

Cast Nylons NYCAST® RX/GX/BX Cast Nylons Limited

Cast Nylons NYCAST® RX/GX/BX Cast Nylons Limited -

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics -

NYLOIL Cast Nylons Limited

NYLOIL Cast Nylons Limited -

Röchling SUSTAMID® 6G OL Röchling Engineering Plastics

Röchling SUSTAMID® 6G OL Röchling Engineering Plastics

Order Cast Nylon at Piedmont Plastics

Cast nylon, also known as nylon 6 or polyamide 6 cast (PA6 C), is an engineering plastic with superior performance and versatility. It’s manufactured through a casting process that boosts its mechanical strengths, like toughness and stability, making cast nylon a great choice for industrial and mechanical applications.

Able to be cast in large or custom diameter rods, tubes, and sheets, nylon 6 is highly resistant to wear, abrasion, and impacts, which can extend the lifespan of various products and components. One of the best advantages of cast nylon is its durability and how well it works with minimal lubrication, helping to cut down on maintenance costs and equipment downtime. Near net casting allows for better yields and more cost-effective parts.

Cast nylon is often used to make gears, bearings, and rollers and is crucial in areas like the automotive, electronics, and industrial machinery sectors where strong materials are needed. Nylon 6 can replace metal bearings and bushings to reduce weight, minimize lubrication needs, decrease wear and noise, and lower labor and downtime costs. It's also easy to shape and machine, which makes it a versatile option for customized projects. This adaptability and strength ensure that cast nylon can meet the tough demands of engineers and designers who need dependable and effective materials.

Whether you're in need of cast nylon rod for structural components, cast nylon tube for fluid handling systems, or cast nylon sheet for large scale industrial projects, Piedmont Plastics offers expert guidance and a comprehensive selection of products to meet your specific needs. We can even provide customized services to meet your project’s exact specifications.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Our Cast Nylon

Cast nylon possesses many features that make it a top choice in numerous applications. Here’s a closer look at the key attributes of this versatile material:

High Impact and Wear Resistance: Cast nylon boasts excellent resistance to impacts, wear, and tear without deforming or cracking under stress. This makes it suitable for components that undergo intense friction, constant movement, and frequent shocks.

Self-lubricating: Cast nylon has a low coefficient of friction, reducing the need for additional lubrication and minimizing maintenance requirements.

Easy to Machine: This material can be easily cut, drilled, and shaped with standard metalworking tools, allowing for high precision and complex designs in manufacturing without the need for specialized equipment.

Corrosion and Chemical Resistance: Unlike metals, cast nylon does not rust or corrode, making it an excellent choice for applications exposed to corrosive substances, chemicals, or environments.

High Compression Strength: Cast nylon can withstand high compressive loads, which is crucial for structural components that must support substantial weight or force without compromising their integrity.

High Heat Tolerance: Cast nylon maintains its form and function under elevated temperatures, which is beneficial for applications involving heat-intensive processes.

Light Weight: The lightweight characteristics of cast nylon make it easier to install, fabricate, and transport, thus also providing cost savings.

FDA Compliance: Certified grades of cast nylon are safe for direct contact with food.

These features collectively make cast nylon an adaptable and effective material across a spectrum of applications, ensuring both performance and durability in the most demanding conditions.

Advantages of Cast Nylon

Common Uses of Cast Nylon

Cast nylon's robust properties make it a key material for parts and components in a variety of industrial applications. Here's how cast nylon is specifically utilized across different sectors:

Construction Equipment: Components like bushings, gears, and structural supports made from cast nylon withstand the rigors of construction environments, offering longevity and resistance to heavy loads.

Food Processing and Bottling Systems: Cast nylon is used for wear-resistant liners, scrapers, and gears for food processing. Parts such as star wheels, guides, and conveyor rollers that reduce friction and wear are commonly used in bottling and canning equipment.

Agricultural Machinery: Durable parts like pulleys, slide plates, and chain guides made from cast nylon help agricultural machinery perform optimally under harsh conditions.

Mining Equipment: In mining, cast nylon is used for sheaves, bearings, and wear pads that can handle the extreme stress and abrasiveness.

Material Handling: Conveyor components, rollers, and bearings crafted from cast nylon enhance the efficiency and durability of material handling systems.

Oil & Gas Processing: Cast nylon is utilized for seals, gears, and washers in oil and gas processing equipment, where its resistance to chemicals and high compressive strength are essential.

Paper Processing and Logging: In the pulp and paper industry, cast nylon parts such as suction box covers, doctor blades, and bearings withstand the demanding conditions of paper production processes.

Automotive Production: Within automotive manufacturing, cast nylon is used for components like bearing cages, thrust washers, and various under-hood parts.

These specific uses of cast nylon in parts and components across industries underscore its essential role in enhancing functionality and extending the life of critical machinery and systems.

Frequently Asked Questions

Have questions about cast nylon? Our FAQ section provides clear answers to help you understand its key benefits, applications, and how it can enhance your projects.

Extruded nylon is formed by pushing melted nylon through a die, offering higher strength, rigidity, and tighter tolerances. Cast nylon is made by pouring liquid nylon into molds, resulting in better wear resistance and low internal stress.

Cast nylon is a high-performance engineered plastic material. It's commonly used as a replacement material for metals like bronze, steel, brass, and aluminum due to its strength, wear resistance, and versatility in industrial applications.

Yes, some grades of cast nylon are FDA or USDA approved and considered food-safe. These certifications make food-grade cast nylon ideal for direct contact with food, allowing its use in food processing and packaging applications.

Yes, cast nylon can be easily machined, cut, and fabricated into custom shapes, making it a versatile choice for manufacturers and engineers. We recomend you follow manufactuer guidlines when customizing your material. Piedmont Plastis will also cut your cast nylon to size upon request.

Piedmont Plastics is a trusted nylon supplier with branches nationwide. Find your nearest location to order cast or extruded nylon for your project.

Acetal has better dimensional stability and machinability than UHMW, and absorbs less moisture than nylon, making it more stable in humid environments.

Why Buy Cast Nylon from Piedmont Plastics?

At Piedmont Plastics, we are committed to delivering value-added services and high-quality cast nylon products to meet your specific needs. Here's why you should choose us as your preferred supplier:

Extensive Product Selection: We offer a wide range of cast nylon products, including sheets and rods, in various sizes and grades to cater to diverse applications.

Custom Cutting and Fabrication Services: Our state-of-the-art CNC equipment and fabrication services enable us to provide customized cast nylon parts that meet your precise specifications.

Expertise and Experience: With decades of experience in the plastics industry, our knowledgeable staff can assist you in selecting the right cast nylon product for your project.

Nationwide Branch Network: Our vast network of branches across the country makes it convenient for you to access our cast nylon products and other performance plastic materials.

Quality Assurance: We are dedicated to maintaining the highest standards of quality, ensuring that you receive cast nylon products that meet or exceed industry standards.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745