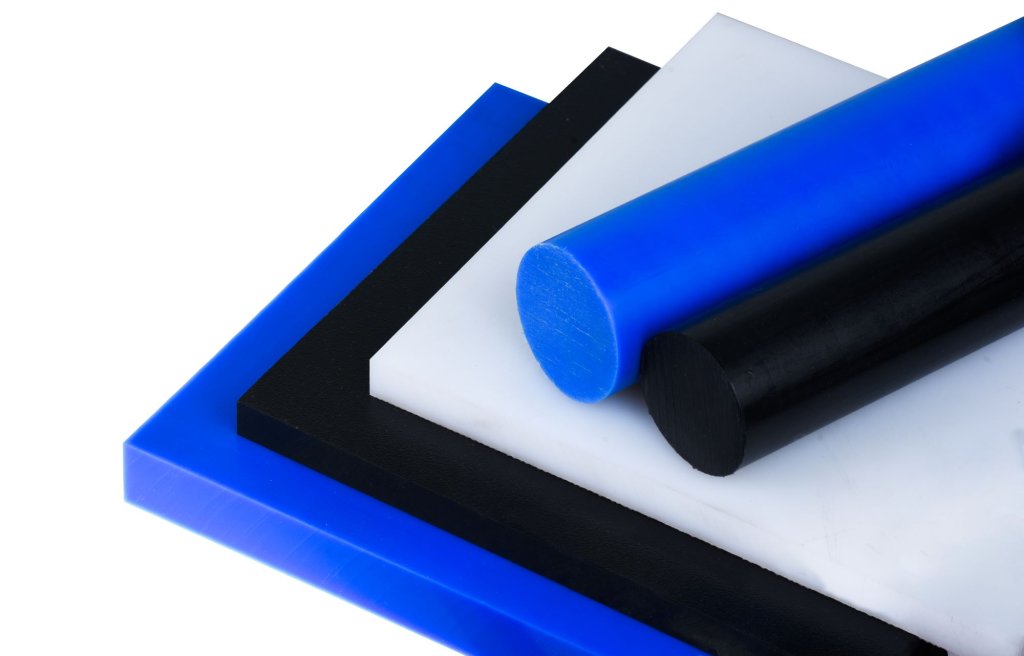

PTFE plastic sheet and rod offer unmatched chemical resistance, high temperature performance, and low friction properties for industrial, electrical, and mechanical applications.

PTFE (Polytetrafluoroethylene)

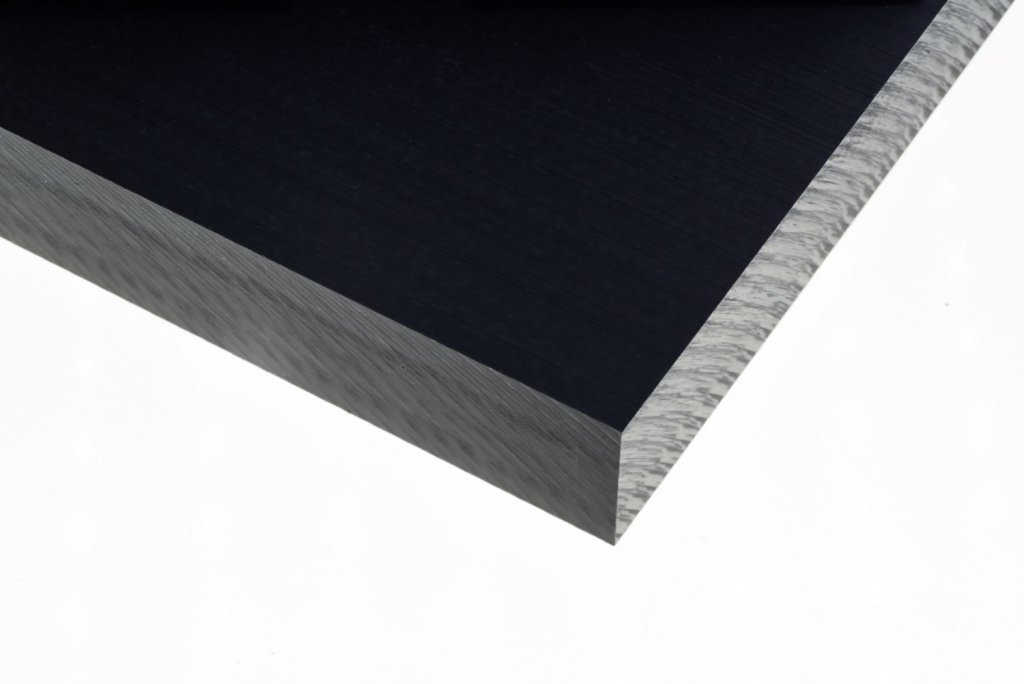

Durable plastic sheet and rod with superior chemical and thermal resistance.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of PTFE (Polytetrafluoroethylene)

Common Properties

- Common Brand Names Fluorosint®, Ketron®, Semitron®, Teflon®

- Typical Thickness Size 0.031 - 4 in

- Typical Lengths 48 - 120 in

- Typical Widths 12 - 48 in

- Friendly Names PTFE Plastic

- Common Profiles Sheet, Rod

- Typical Rod Diameter 0.125 - 8 in

Physical Properties

- Density 0.9-2.2g/cm³

- Water Absorption 0.01-1.5%

- Moisture Absorption at Equilibrium 0.1-0.8%

- Linear Mold Shrinkage 0.2-1.5%

- Melt Flow 0.1-50g/10 min

Electrical Properties

- Dielectric Strength 19kV/mm

- Dielectric Constant 2.1dimensionless

- Dissipation Factor 0.0002dimensionless

- Volume Resistivity 1.0E+18ohm·cm

- Surface Resistivity 10000000000000ohm/sq

- Arc Resistance 300seconds

Mechanical Properties

- Hardness, Rockwell R 90Rockwell R

- Tensile Strength, Ultimate 21MPa

- Tensile Strength, Yield 14MPa

- Elongation at Break 300%

- Elongation at Yield 5%

- Modulus of Elasticity 500MPa

- Flexural Yield Strength 11MPa

- Flexural Modulus 600MPa

- Compressive Yield Strength 14MPa

- Bearing Yield Strength 10MPa

- Shear Strength 15MPa

- Izod Impact, Notched 3.5kJ/m²

- Izod Impact, Unnotched 9kJ/m²

- Gardner Impact 15J

- Falling Dart Impact 75J

- Instrumented Impact Total Energy 12J

Regulations

- FDA

- ASTM/Mil-Spec

- USDA

- 3-A Dairy

- Canada AG

- D635 Self Extinguishing

- RoHS Compliant

- REACH Compliant

Literature and Data Sheets

- All Suppliers

- Mitsubishi Chemical Advanced Materials

- Gapi USA

- Saint-Gobain

- Piedmont Plastics

- Vital Polymers

-

Fluorosint 135 PTFE Mitsubishi Chemical Advanced MaterialsView

-

Fluorosint 207 PTFE Mitsubishi Chemical Advanced MaterialsView

-

Fluorosint 500 PTFE Mitsubishi Chemical Advanced MaterialsView

-

Fluorosint HPV PTFE Mitsubishi Chemical Advanced MaterialsView

-

Fluorosint MT-01 PTFE Mitsubishi Chemical Advanced MaterialsView

-

Gapi PTFE Gapi USAView

-

MCAM Fluorosint® 135 PTFE Mitsubishi Chemical Advanced MaterialsView

-

MCAM Fluorosint® 500 Abradable Plumer Labyrinth Seal Mitsubishi Chemical Advanced MaterialsView

-

MCAM Fluorosint® 500 PTFE Diffusers and Shrouds Mitsubishi Chemical Advanced MaterialsView

-

MCAM Ketron® PEEK/PTFE Mitsubishi Chemical Advanced MaterialsView

Get a Quote for PTFE Plastic at Piedmont Plastics

PTFE, short for polytetrafluoroethylene, is a high-performance fluoropolymer prized for its exceptional chemical resistance, thermal stability, and low coefficient of friction. Available in sheet and rod form, PTFE is a versatile engineering plastic used in industries ranging from chemical processing to electrical insulation. Its unique properties make it one of the most reliable materials for challenging environments. Contact Piedmont Plastics today to request a quote for PTFE sheet or rod.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of PTFE Plastic

PTFE is engineered to withstand extreme operating conditions. Its combination of chemical inertness, thermal performance, and lubricity sets it apart from other engineering plastics.

Key features include:

Exceptional chemical resistance to acids, solvents, and bases

High continuous service temperature range (up to 500°F/260°C)

Extremely low coefficient of friction for self-lubricating performance

Excellent electrical insulation properties

Non-stick surface with minimal moisture absorption

Outstanding dimensional stability across a wide temperature range

Benefits and Advantages

Common Applications

PTFE plastic is a versatile material used in demanding environments where chemical resistance, thermal stability, and low friction are essential. Its reliability makes it a preferred choice across industries such as chemical processing, electrical, aerospace, food production, and automotive.

Chemical Processing Equipment: Gaskets, seals, and linings resistant to aggressive chemicals

Electrical Insulation: High dielectric strength for wiring, cable insulation, and circuit boards

Mechanical Components: Bearings, bushings, and wear parts with self-lubricating properties

Food & Beverage Processing: Components that require cleanliness, moisture resistance, and non-contamination

Aerospace and Automotive: Seals, washers, and parts that must endure wide temperature variations

Related Products

-

UHMW PE

UHMW from Piedmont Plastics offers superior durability, low friction, and wear resistance, ideal for conveyors, liners, and food-grade industrial parts.

-

PEEK (Polyetheretherketone)

PEEK is a high-performance material with chemical resistance and performs well in high temperatures.

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

-

Cast Nylon

Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

Frequently Asked Questions About PTFE

Below are some commonly asked questions about PTFE plastic and how it performs in various environments.

PTFE is used for various industrial or mechanical applicaitons, including seals, gaskets, bearings, electrical insulation, and chemical processing components.

PTFE can withstand continuous service temperatures up to 500°F (260°C) without losing strength.

Yes. PTFE offers unmatched resistance to nearly all industrial chemicals, solvents, and acids.

Yes, but PTFE's low stiffness and tendency to deform (creep) can make holding tolerances difficult. With sharp tools and proper machining practices, it can be fabricated into parts successfully. We recomend following manufactuerer guidlines when customizing your material. Piedmont Plastics also offers custom cutting services and fabrication assistance.

Piedmont Plastics is a leading PTFE distributor with over 50 locations across North America, making it easy to source material locally.

PTFE (polytetrafluoroethylene) is the generic name for the material, while Teflon® is a well-known brand name for PTFE products. They refer to the same type of plastic, but PTFE is the correct generic term used in industry.

Why Buy from Piedmont Plastics?

Piedmont Plastics provides customers with high-quality PTFE sheet and rod, supported by unmatched service and industry expertise.

Nationwide network of branches: Local inventory for quick turnaround

Custom cutting and fabrication services: Tailored to your exact specifications

Deep industry expertise: Guidance from knowledgeable plastics professionals

Wide product selection: A one-stop-shop for performance plastics

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745