Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

Acetal

Acetal is a strong, low-friction performance plastic used for precise, high-performance applications, such as bearings, bushings, gears, and automotive parts.

Product Overview

Widely used for:

Performance Characteristics:

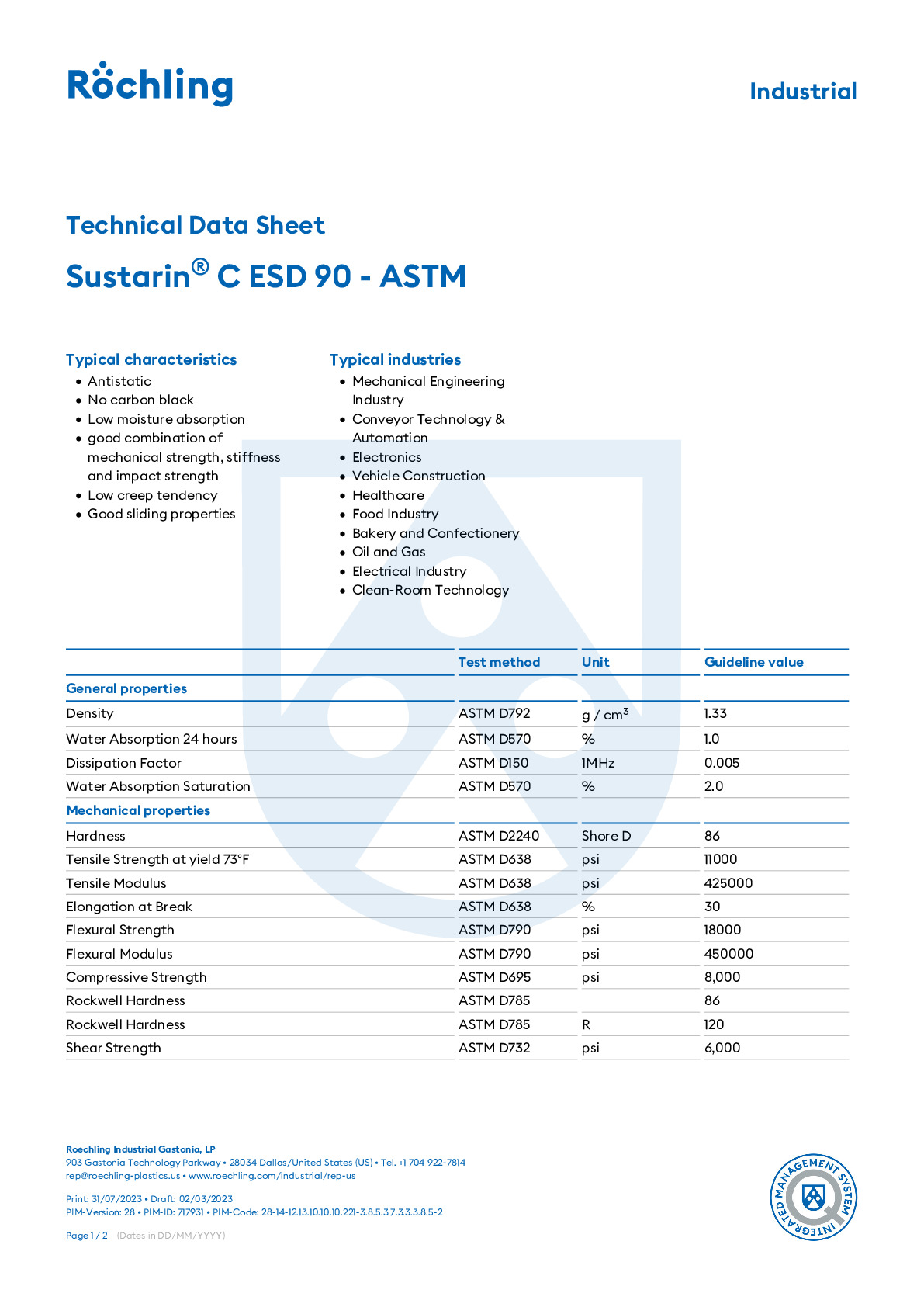

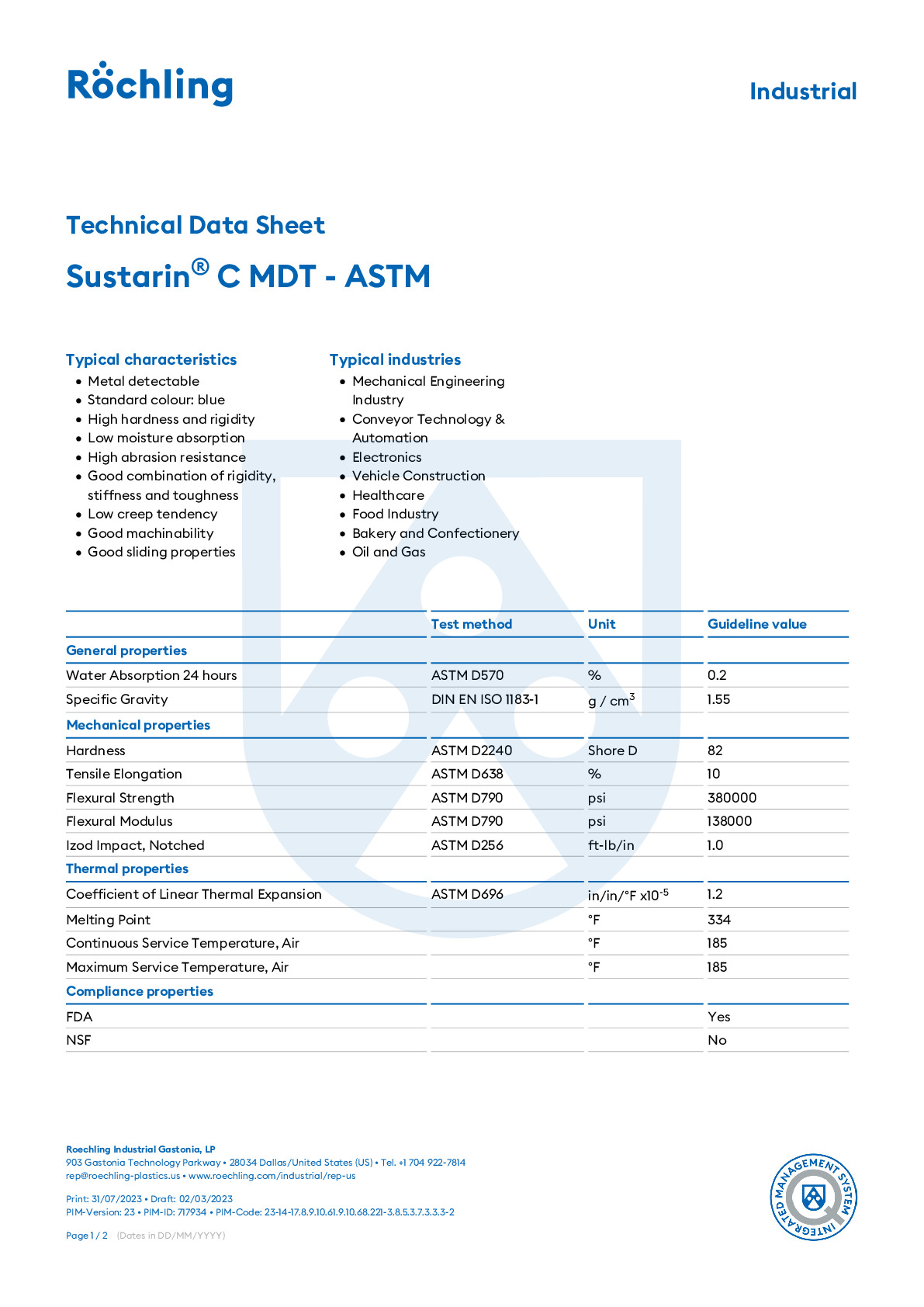

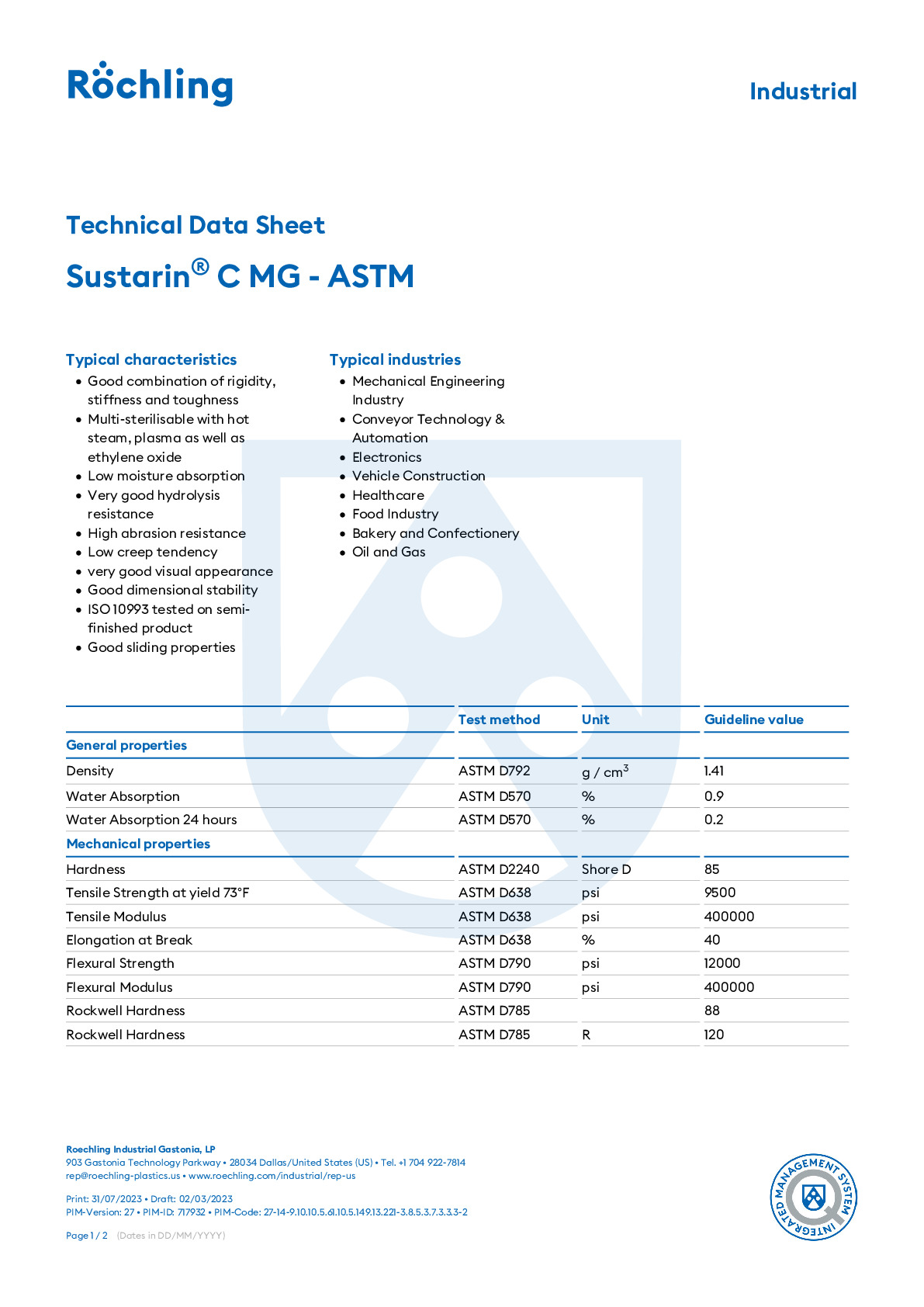

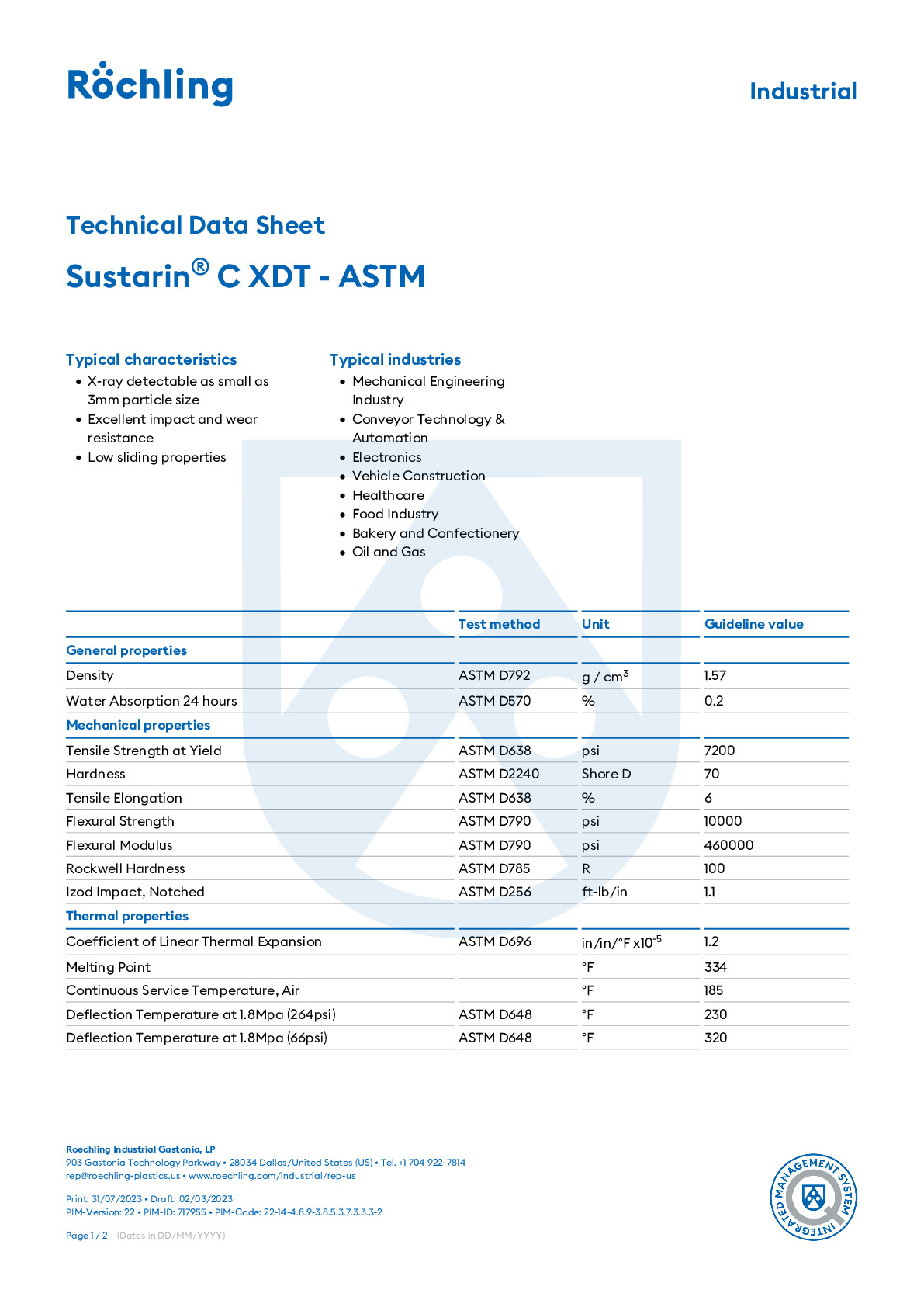

Typical Properties of Acetal

Common Properties

- Typical Lengths 48, 96 in

- Common Profiles Sheets, Rods, Tubes

- Typical Thickness Size 0.125, 0.25, 0.5, 1, 2 in

- Friendly Names POM, Polyoxymethylene, Polyacetal

- Common Brand Names Delrin®, TECAFORM®, ACETRON®, SUSTARIN®

- Typical Widths 24, 48 in

Electrical Properties

- Dielectric Strength 500 V/mil

- Electrostatic Discharge (ESD) Sensitivity Insensitive none

- Surface Resistivity 1.0e15 ohm

- Comparative Tracking Index (CTI) 600 V

- Arc Resistance 120 seconds

- Dissipation Factor 0.002 none

- Volume Resistivity 1.0e14 ohm-cm

- Thermal Coefficient of Dielectric Constant 200 ppm/°C

- Dielectric Constant 3.7 none

- Breakdown Voltage 15 kV

Mechanical Properties

- Tensile Strength, Ultimate 69 MPa

- Modulus of Elasticity 2800 MPa

- Flexural Modulus 2700 MPa

- Elongation at Break 30 %

- Tensile Strength, Yield 63 MPa

- Falling Dart Impact 100 J

- Flexural Yield Strength 96 MPa

- Izod Impact, Notched 1.2 kJ/m2

- Hardness, Rockwell R 120 scale

- Compressive Yield Strength 78 MPa

- Instrumented Impact Total Energy 15 J

- Elongation at Yield 10 %

- Bearing Yield Strength 118 MPa

- Shear Strength 80 MPa

- Gardner Impact 200 J

- Izod Impact, Unnotched 5.4 kJ/m2

Physical Properties

- Moisture Absorption at Equilibrium 0.10-2.50 %

- Melt Flow 0.10-120 g/10 min

- Water Absorption 0.01-1.50 %

- Density 0.90-2.20 g/cm³

- Linear Mold Shrinkage 0.002-0.020 in/in

Regulation Properties

Thermal Properties

- CTE, linear 90-110 µm/m°C

- Minimum Operating Temperature in F -40 °F

- Max Continuous Operating Temperature in F 180-200 °F

- Vicat Softening Point 150-165 °C

- Deflection Temperature at 0.46 MPa (66 psi) 100-140 °C

- Thermal Conductivity 0.3 W/m·K

- CTE, linear, Transverse to Flow 90-105 µm/m°C

- Deflection Temperature at 1.8 MPa (264 psi) 80-125 °C

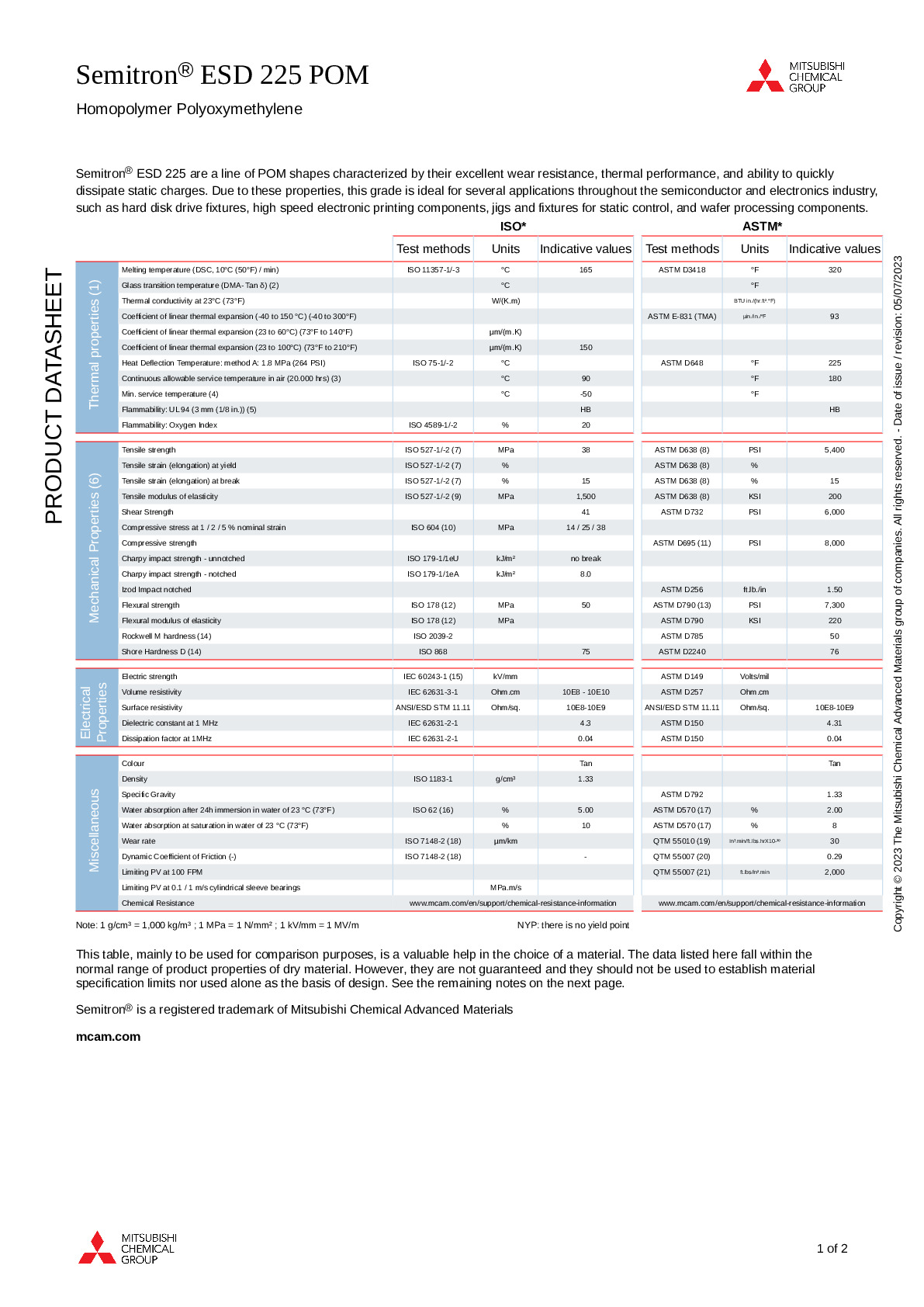

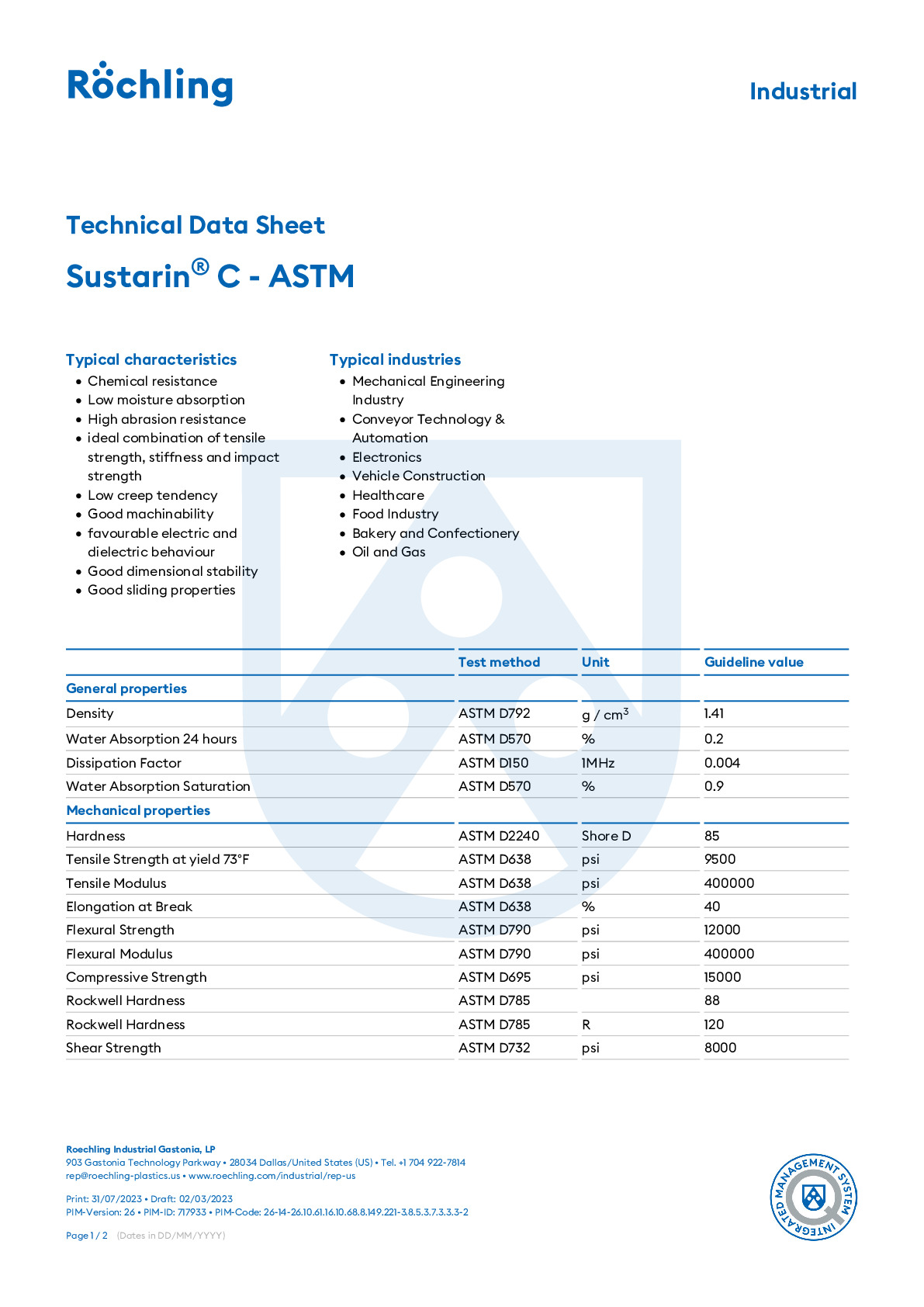

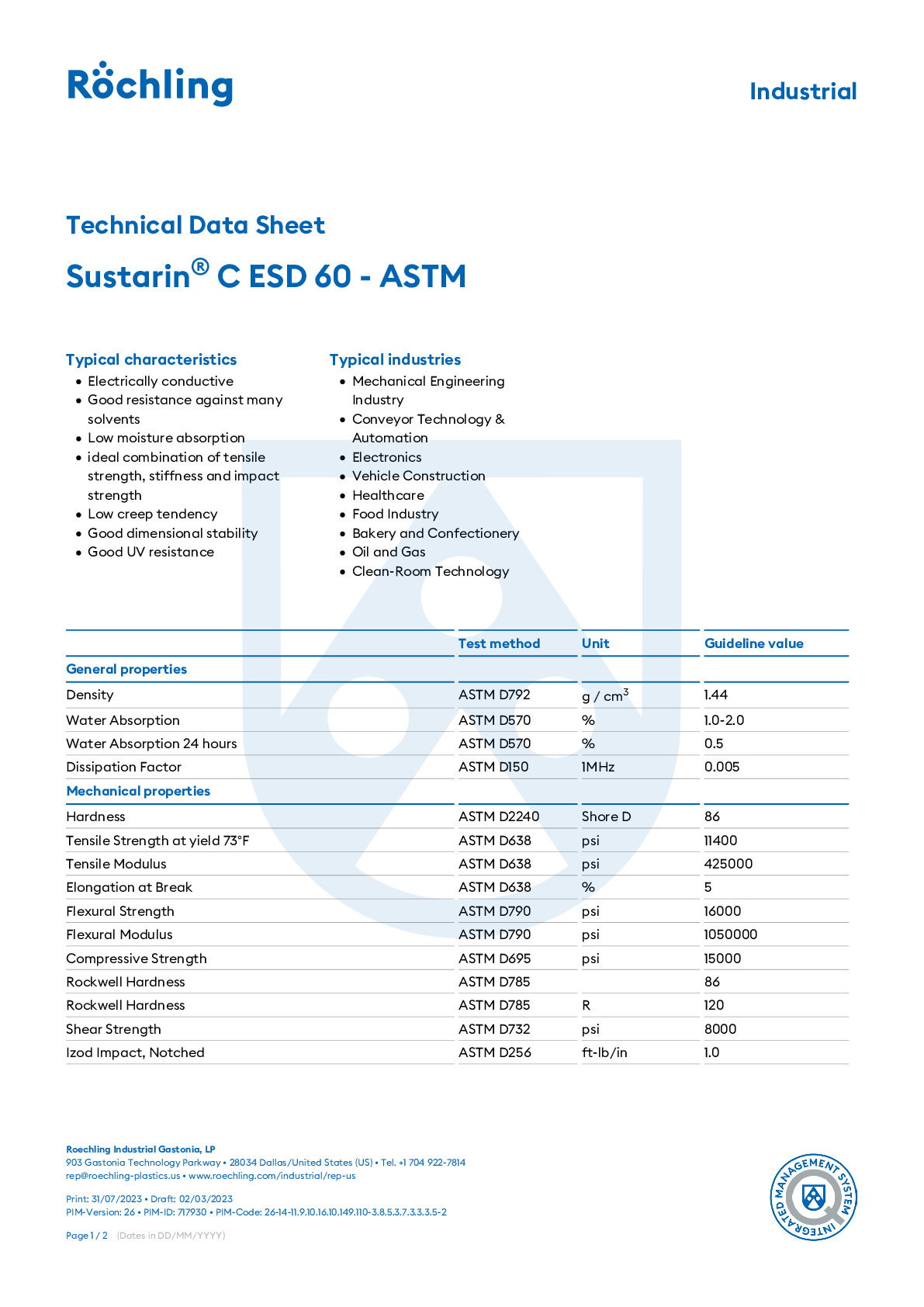

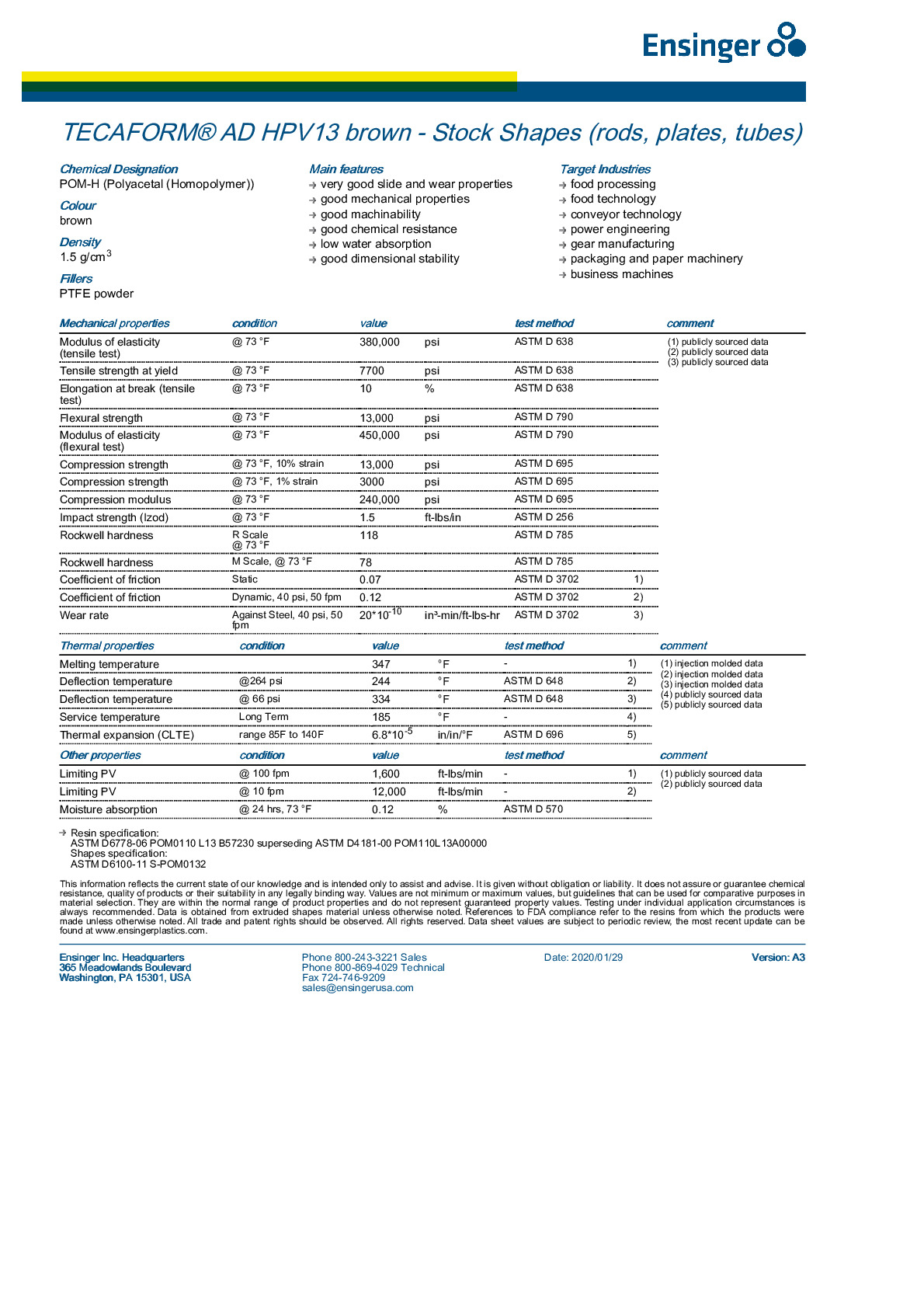

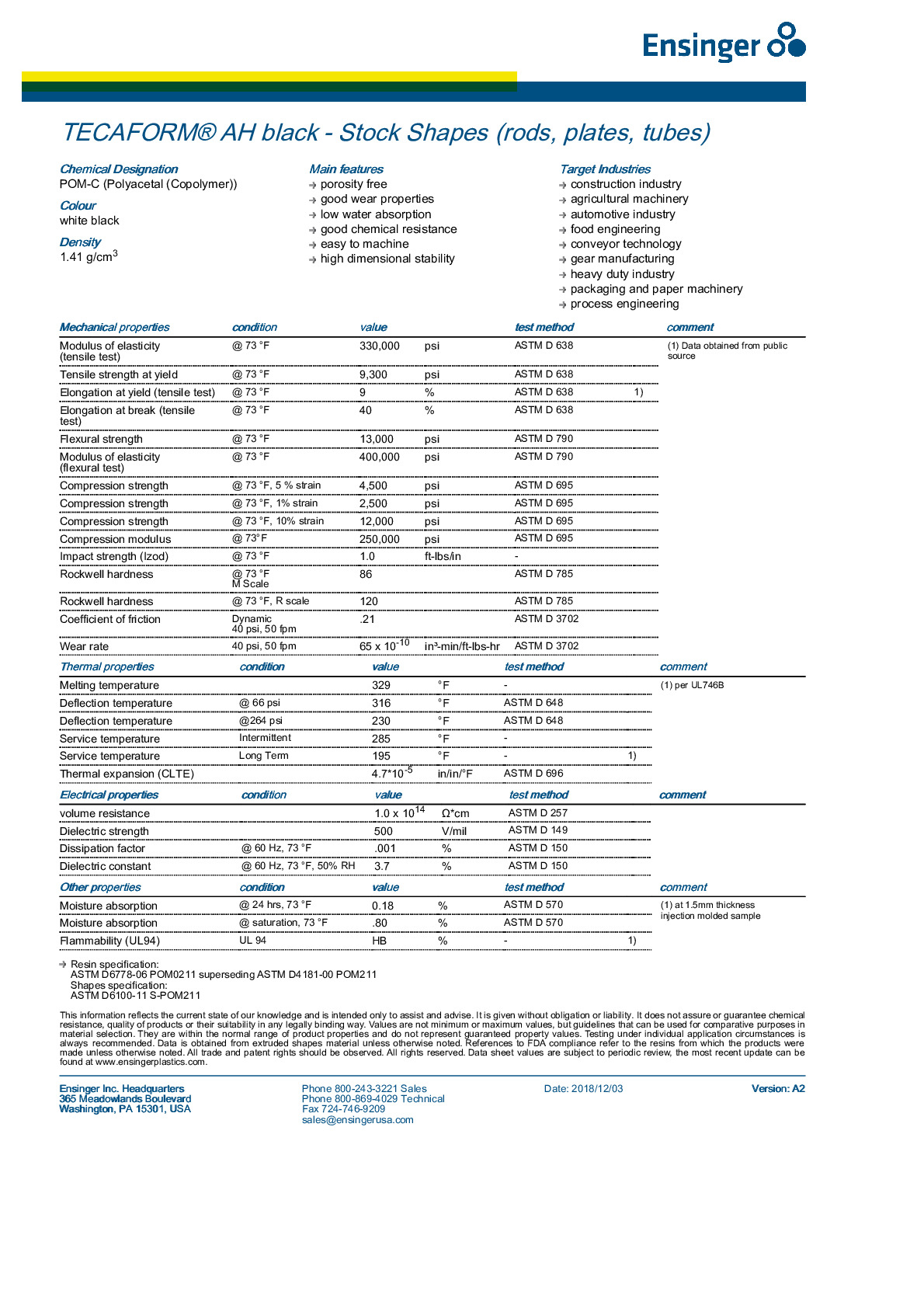

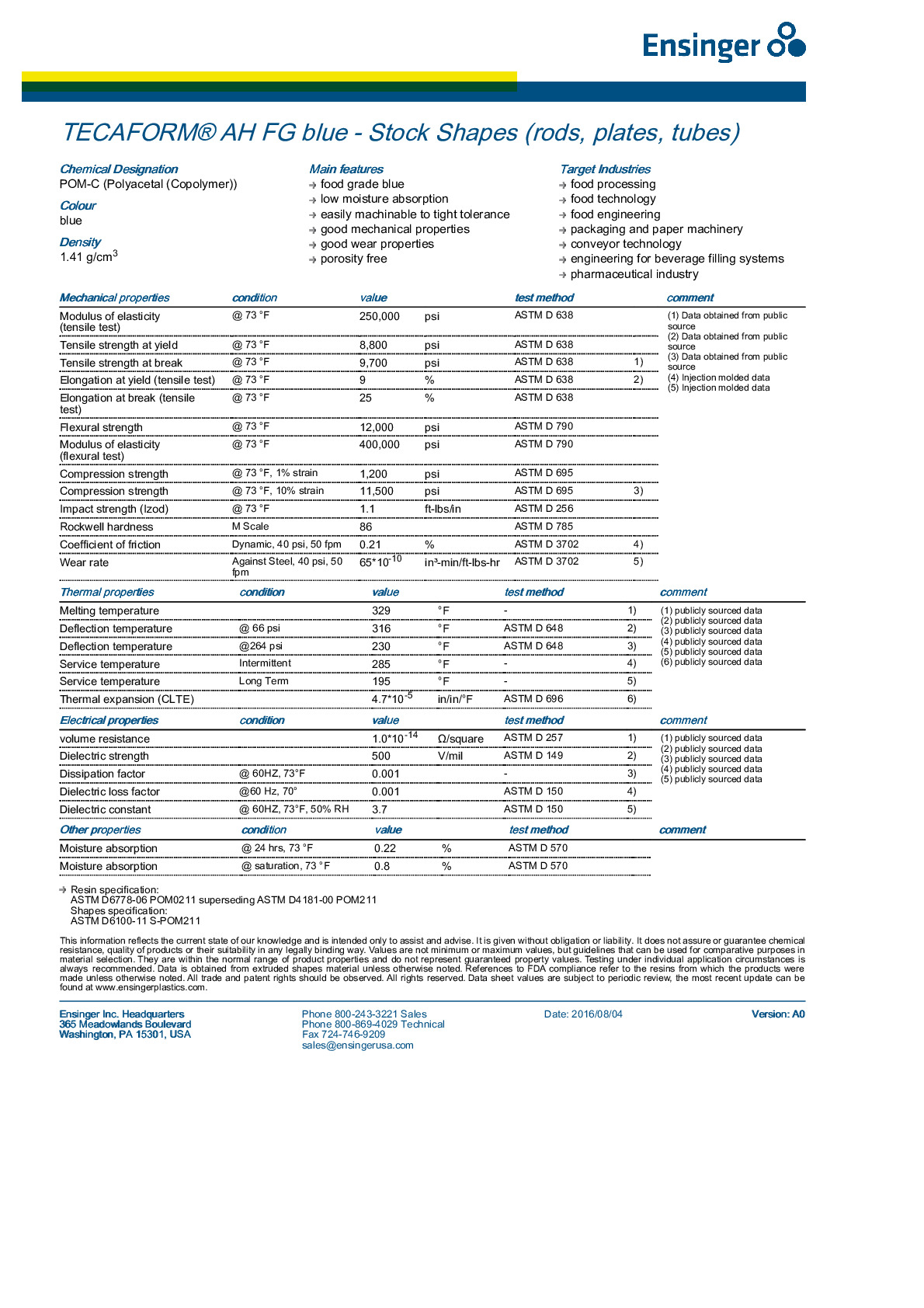

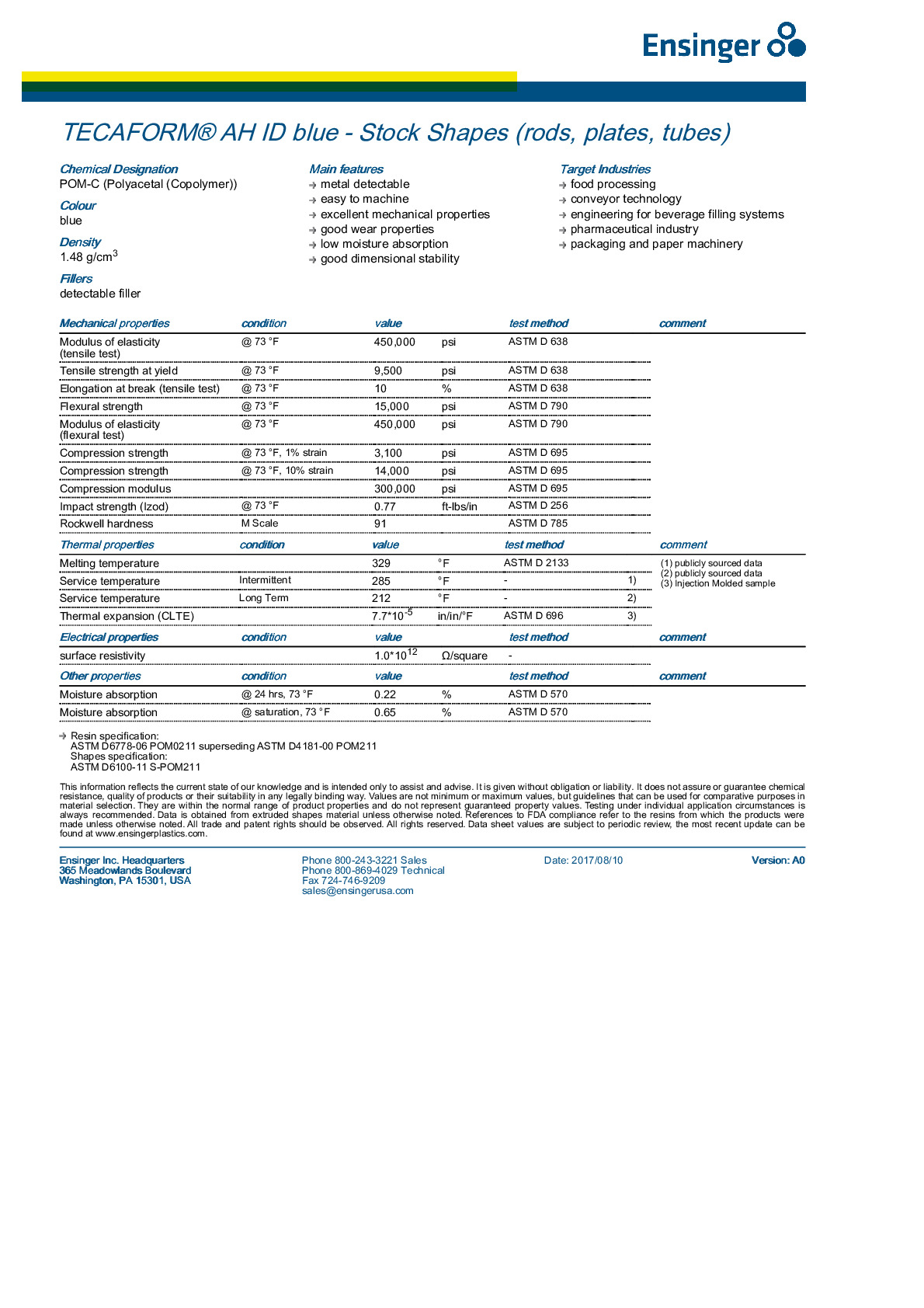

Literature and Data Sheets

-

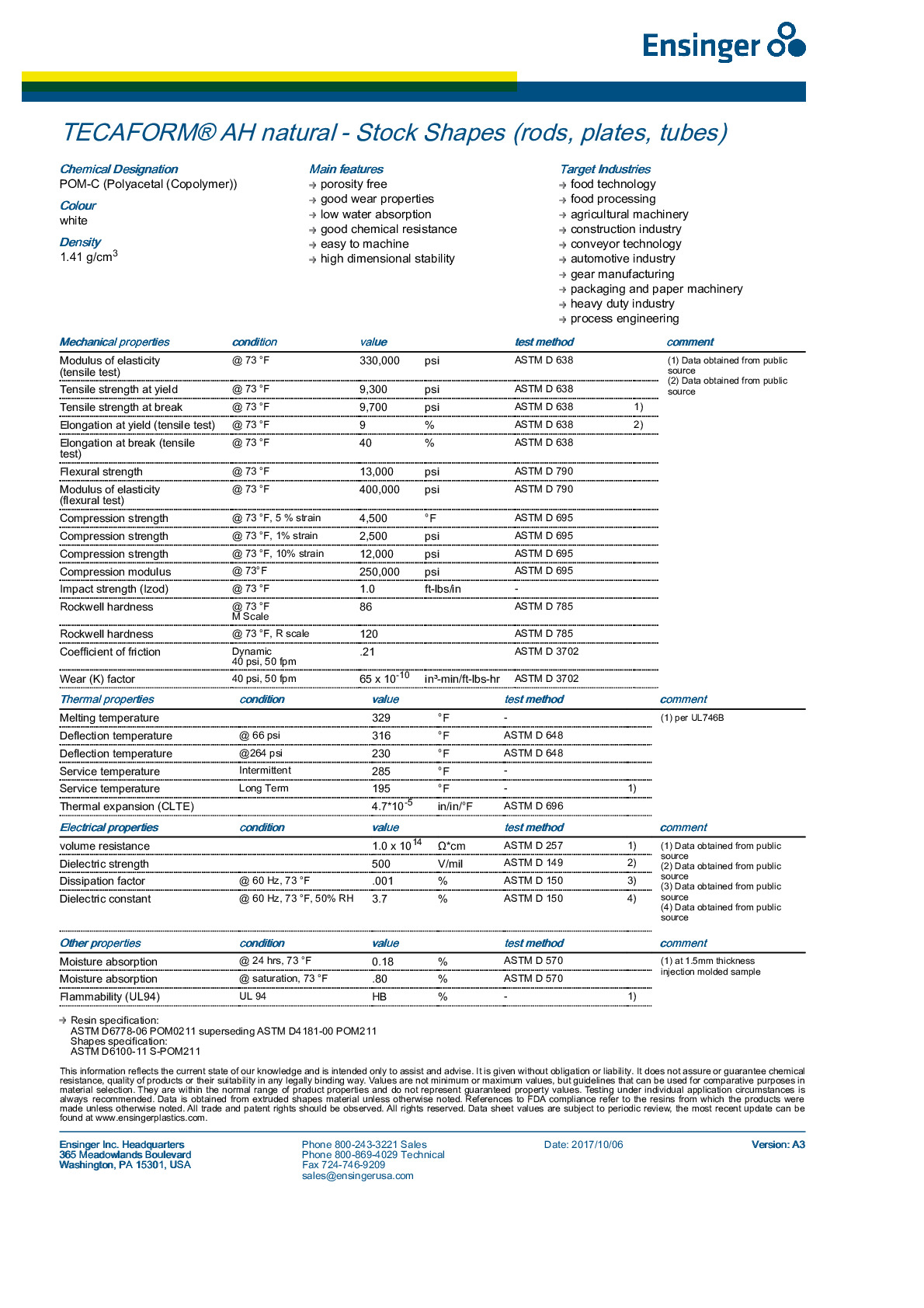

Acetron AF Blend / Ertacetal H-TF POM-H Mitsubishi Chemical Group

Acetron AF Blend / Ertacetal H-TF POM-H Mitsubishi Chemical Group -

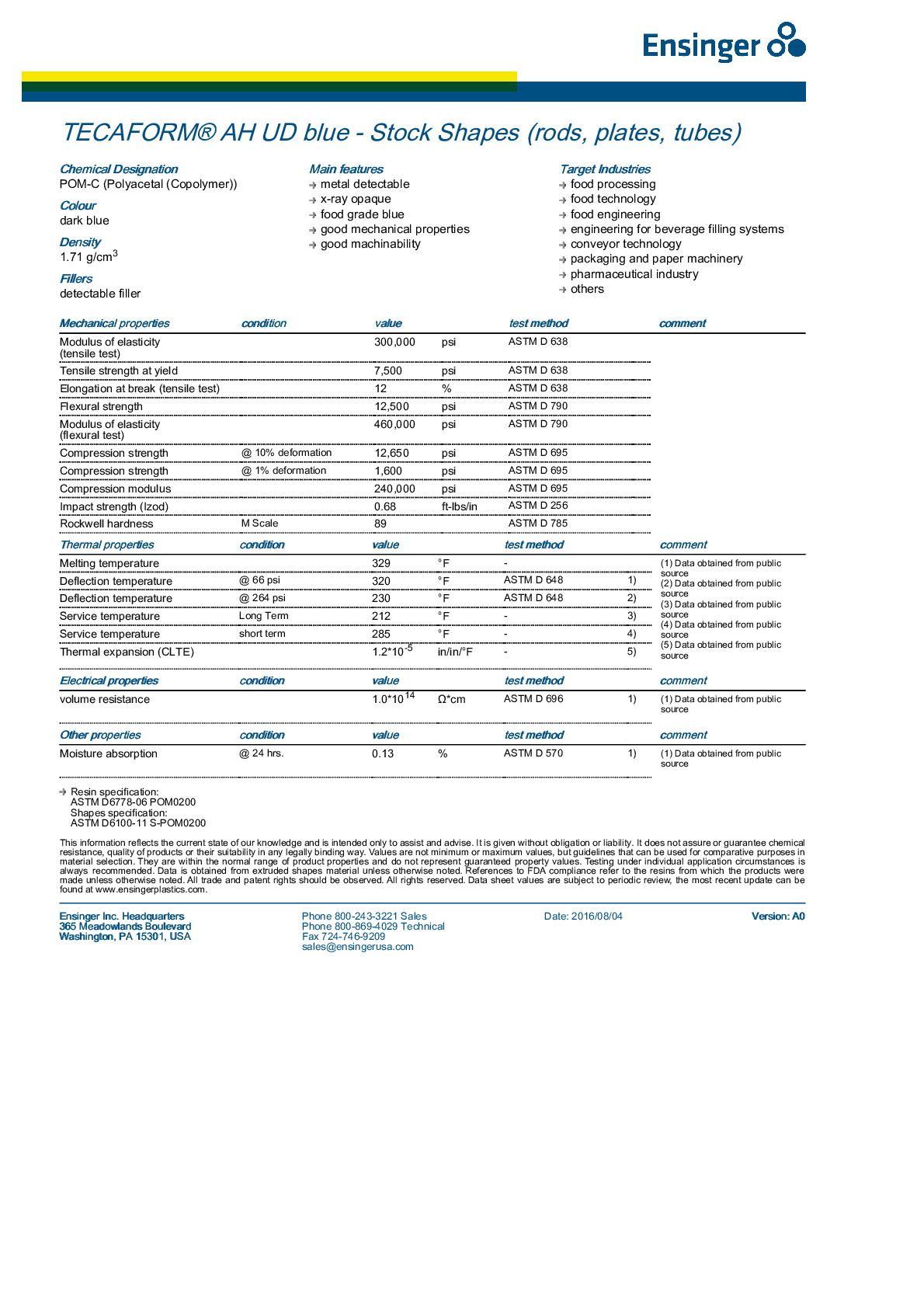

Acetron C Sterra POM-C Mitsubishi Chemical Group

Acetron C Sterra POM-C Mitsubishi Chemical Group -

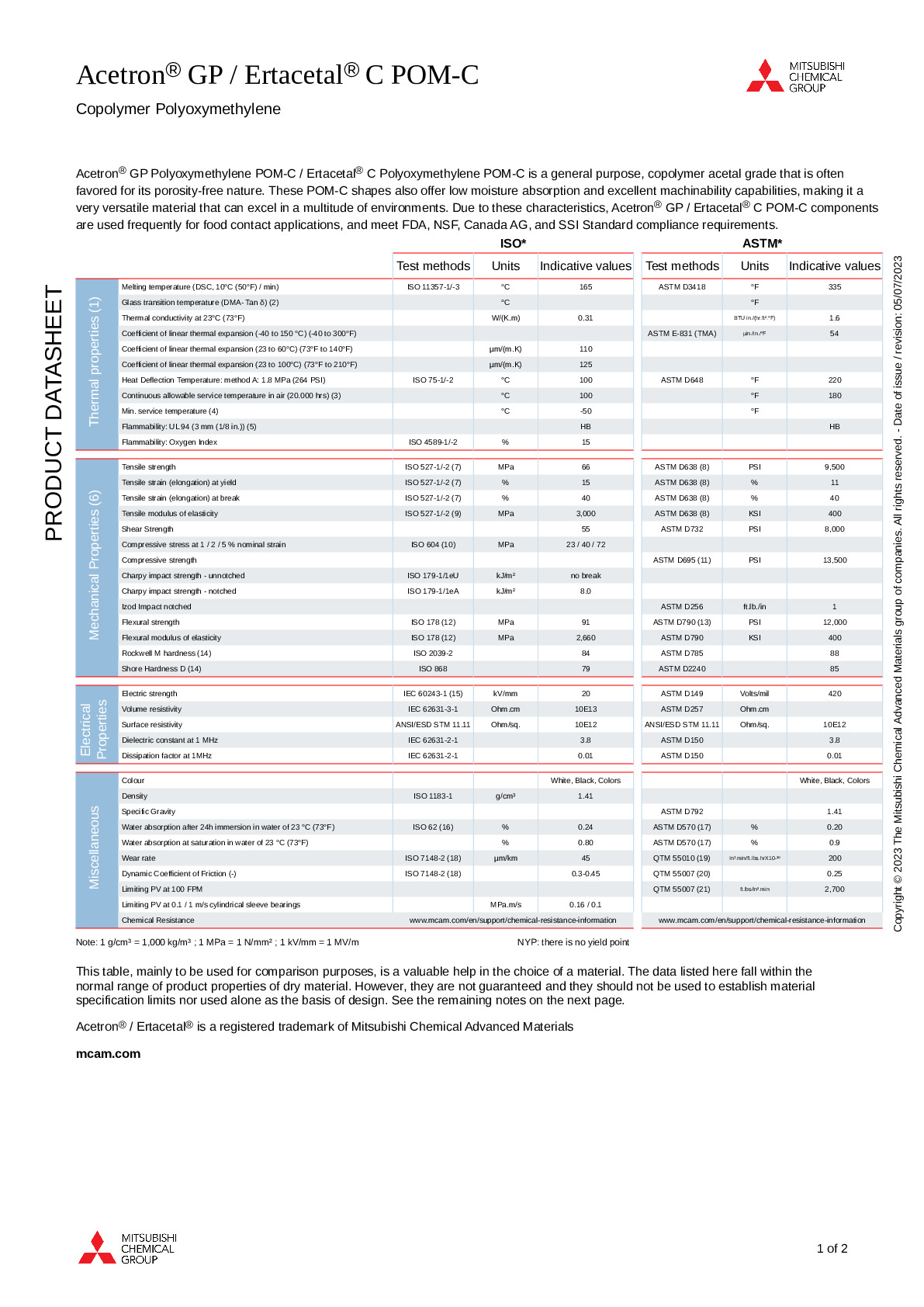

Acetron GP / Ertacetal C POM-C Mitsubishi Chemical Group

Acetron GP / Ertacetal C POM-C Mitsubishi Chemical Group -

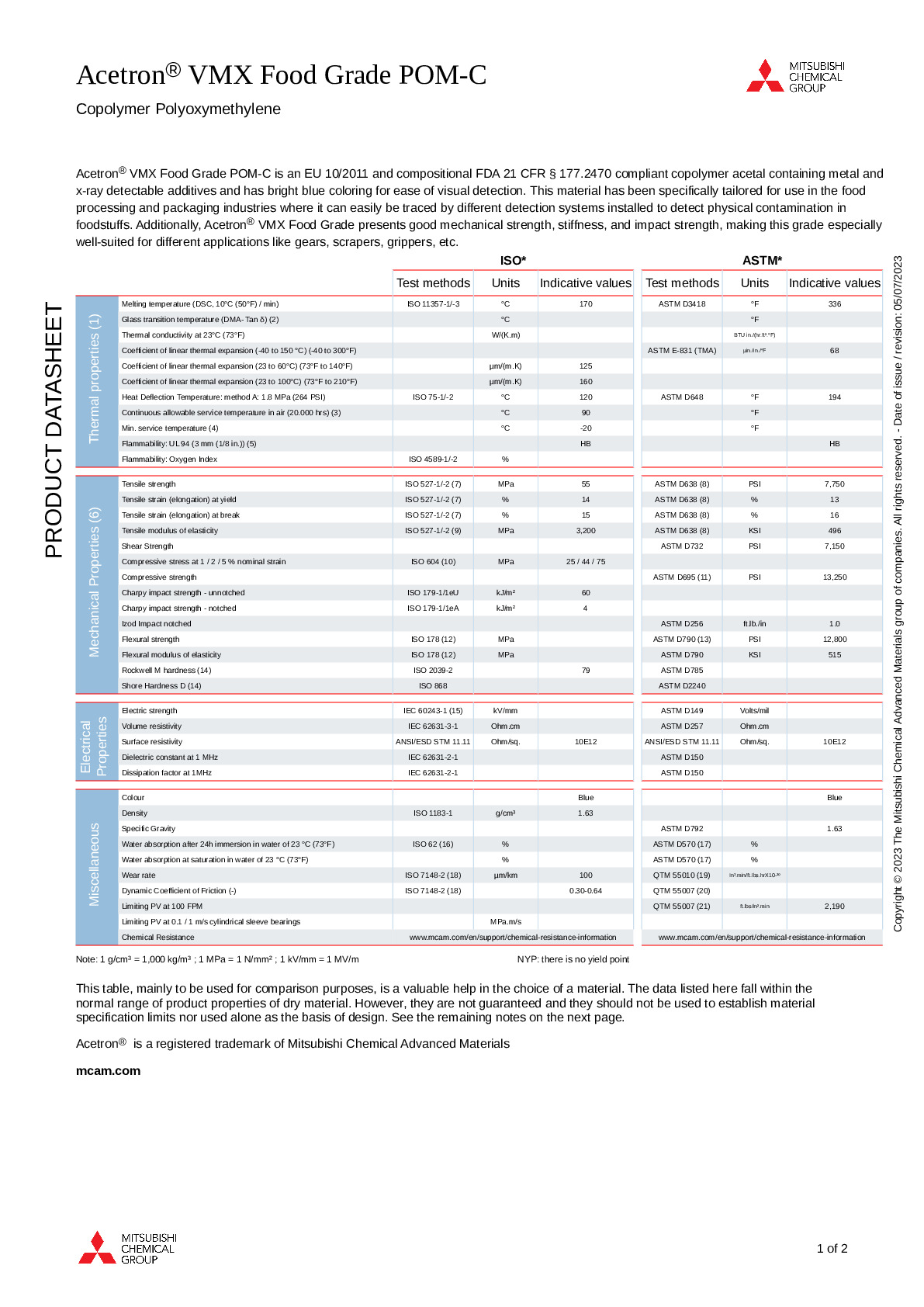

Acetron VMX Food Grade POM-C Mitsubishi Chemical Group

Acetron VMX Food Grade POM-C Mitsubishi Chemical Group -

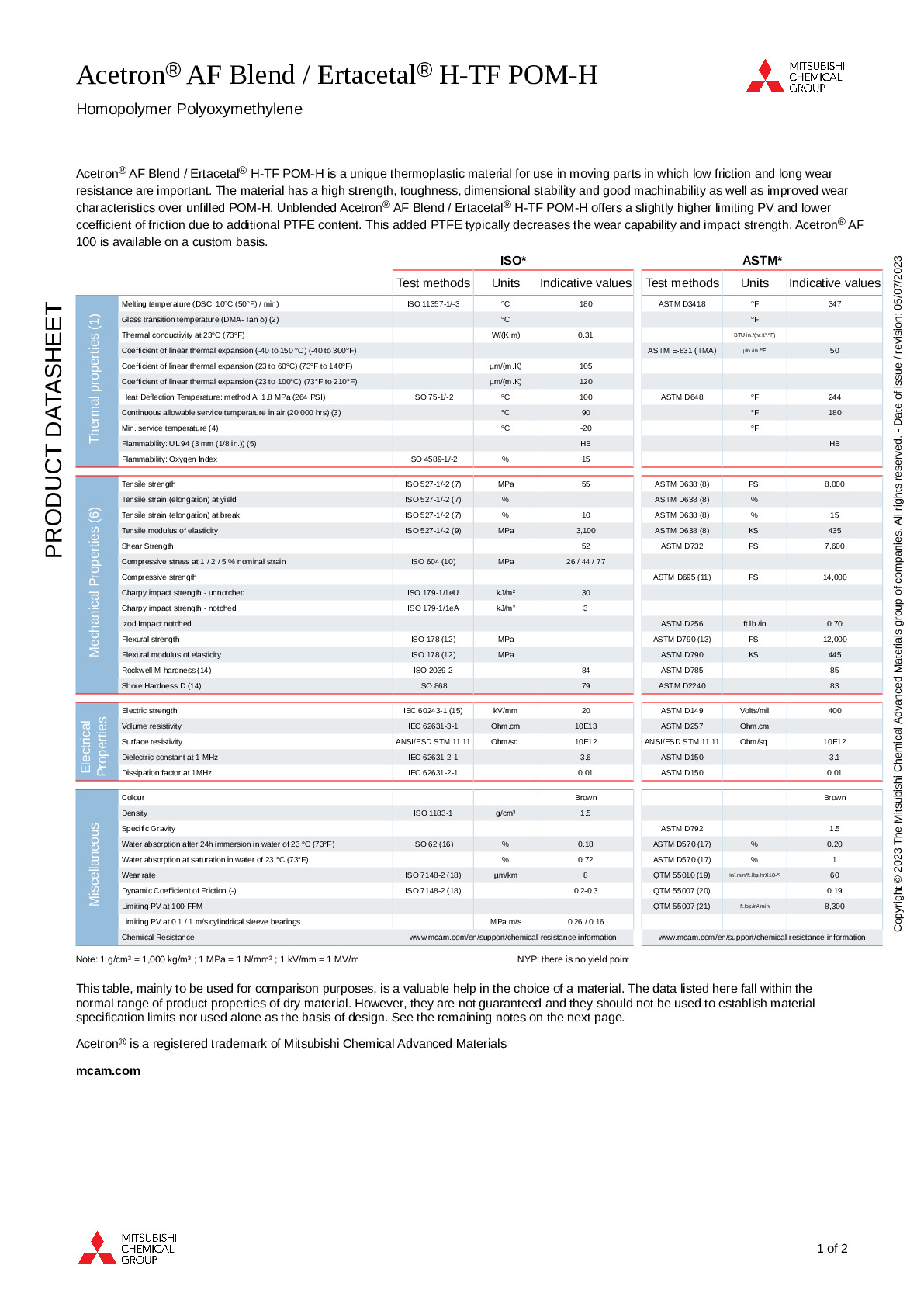

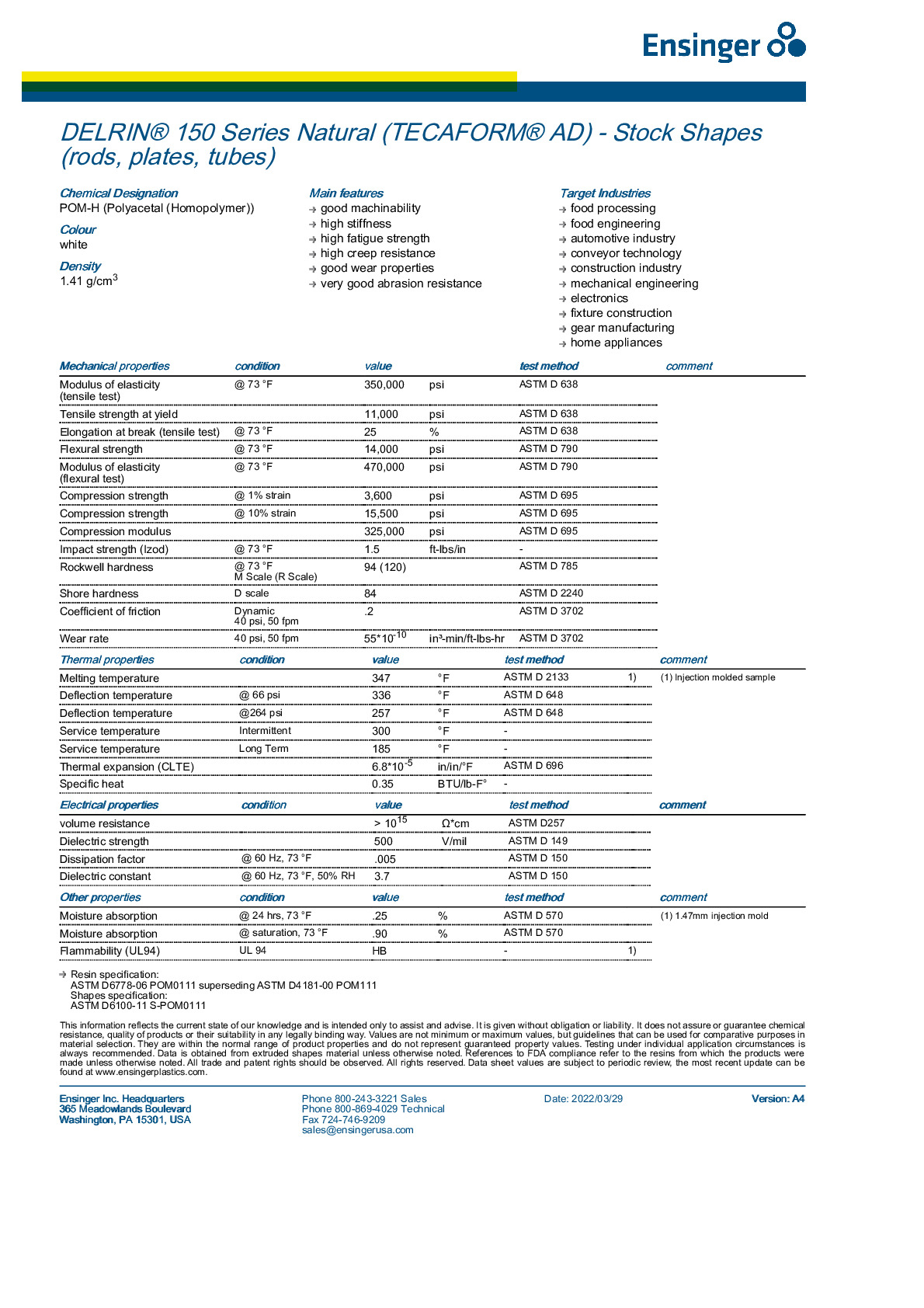

Delrin 150 black (TECAFORM AD) Ensinger

Delrin 150 black (TECAFORM AD) Ensinger -

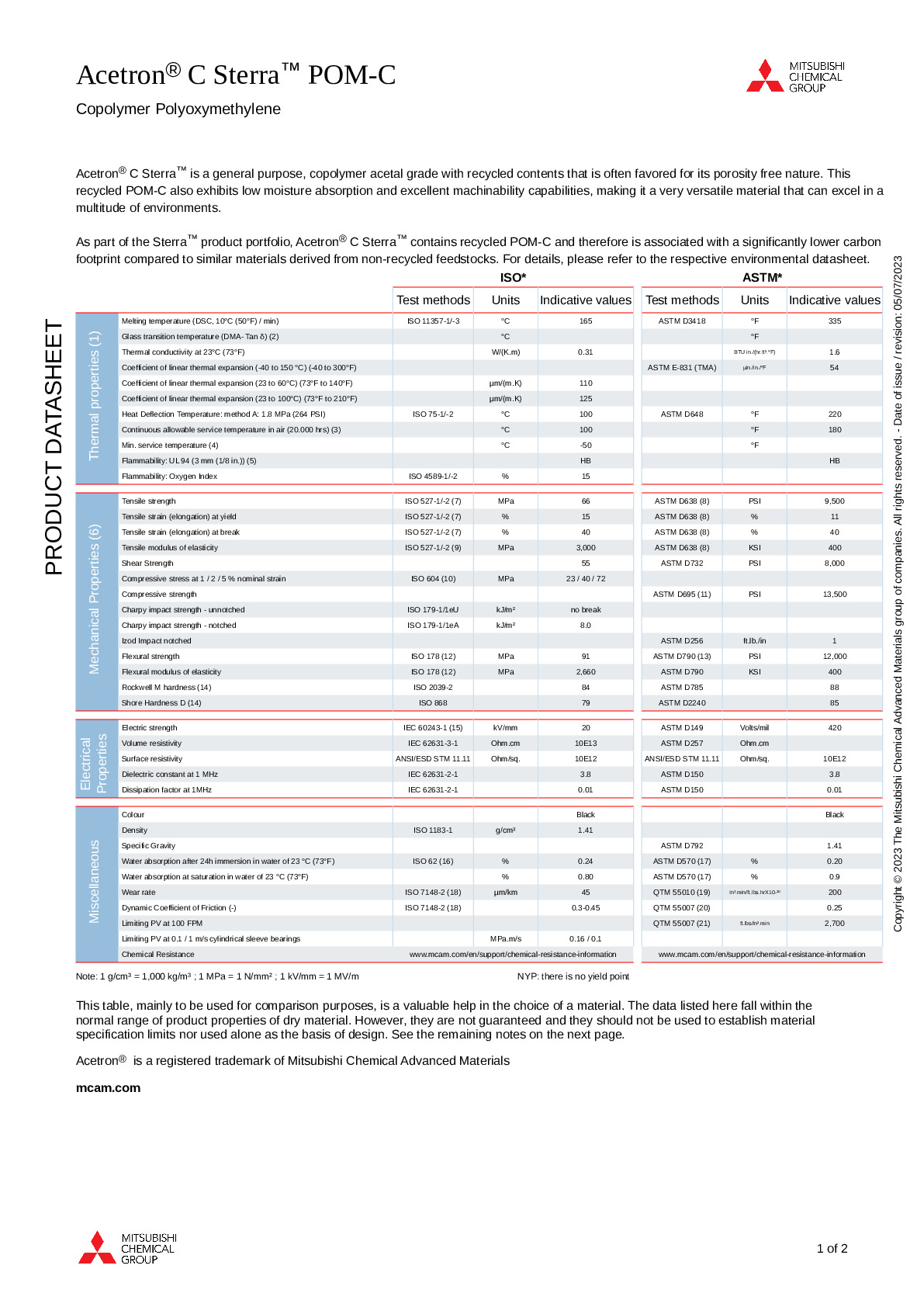

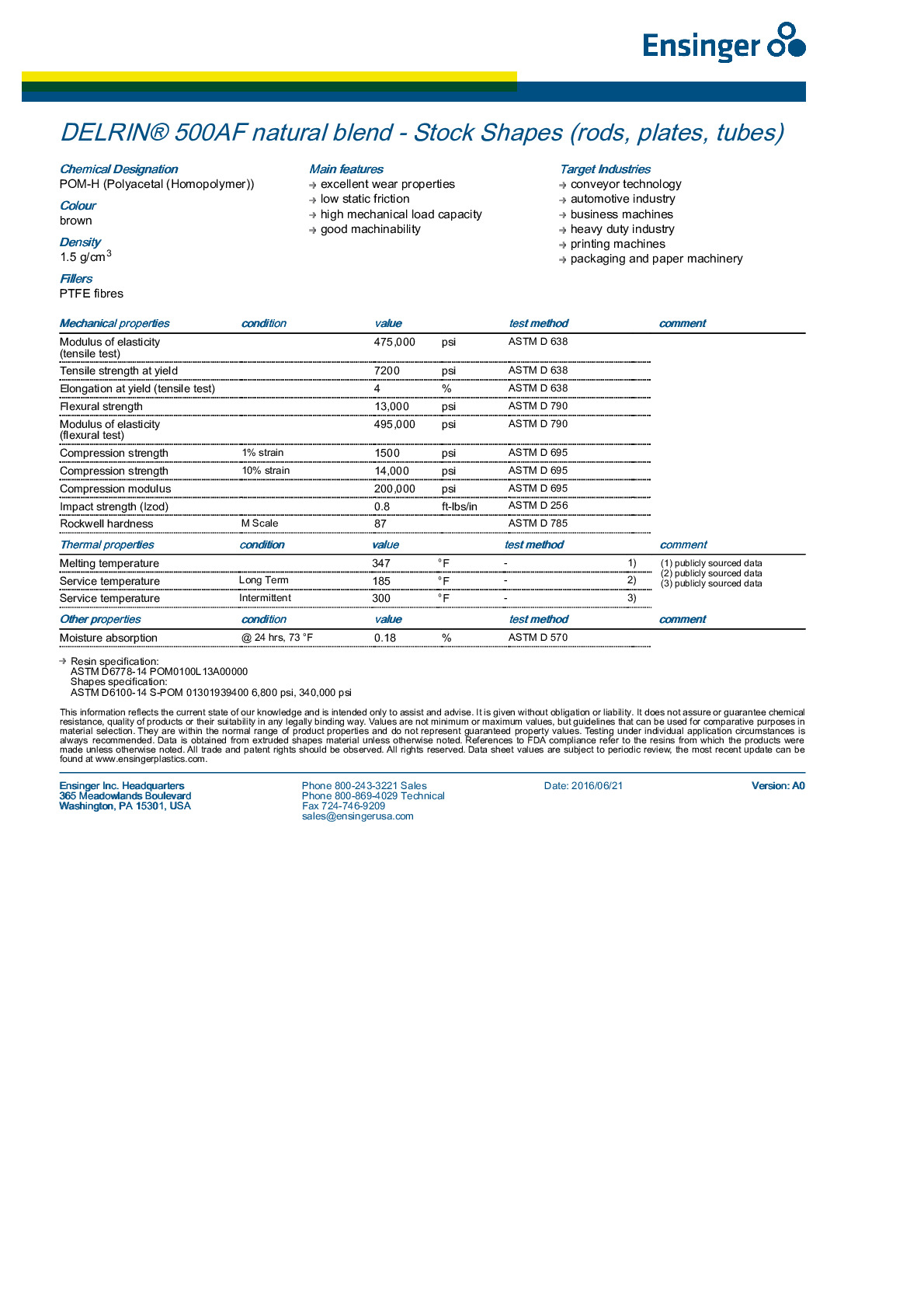

Delrin 500AF brown Ensinger

Delrin 500AF brown Ensinger -

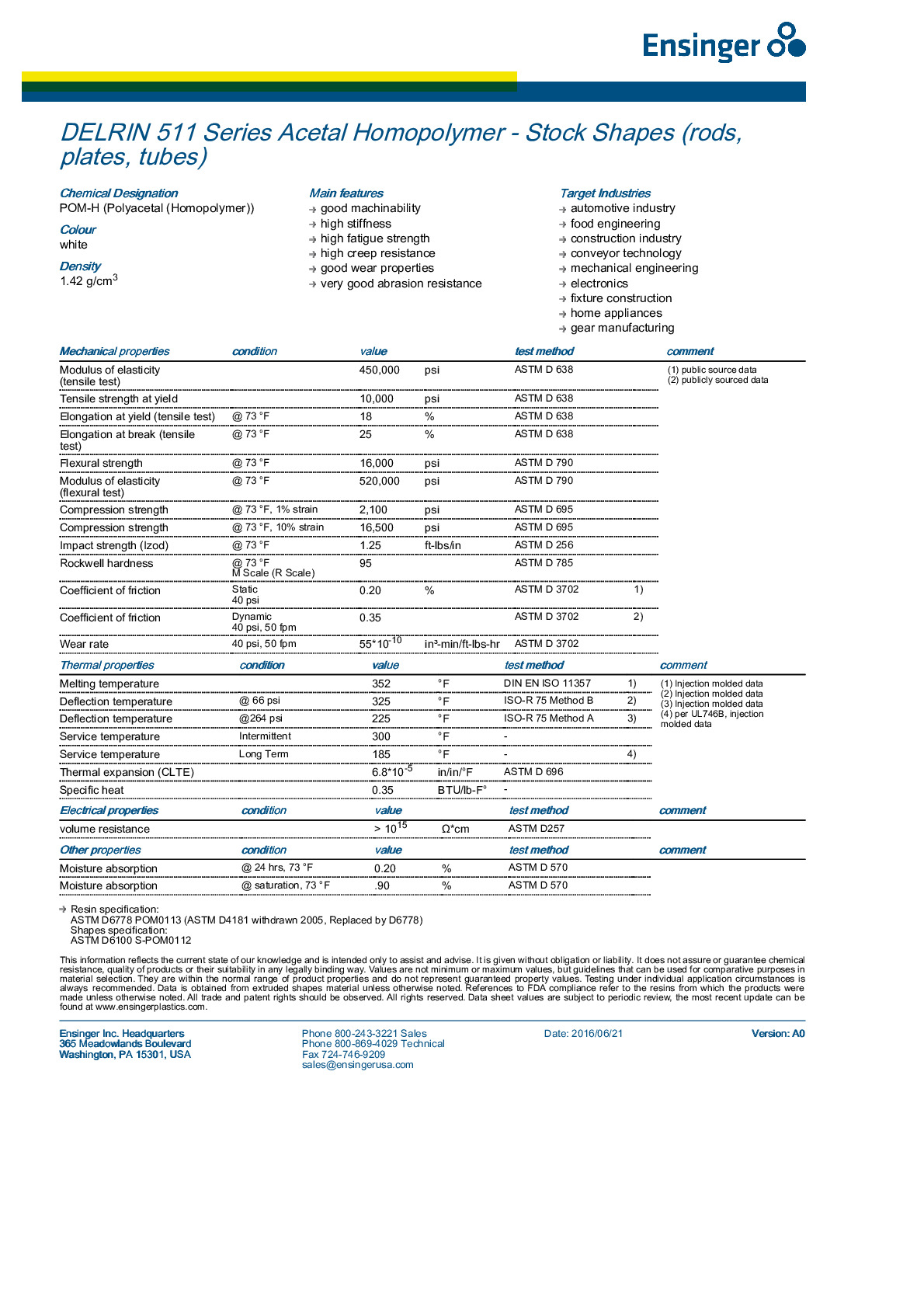

Delrin 511 Ensinger

Delrin 511 Ensinger -

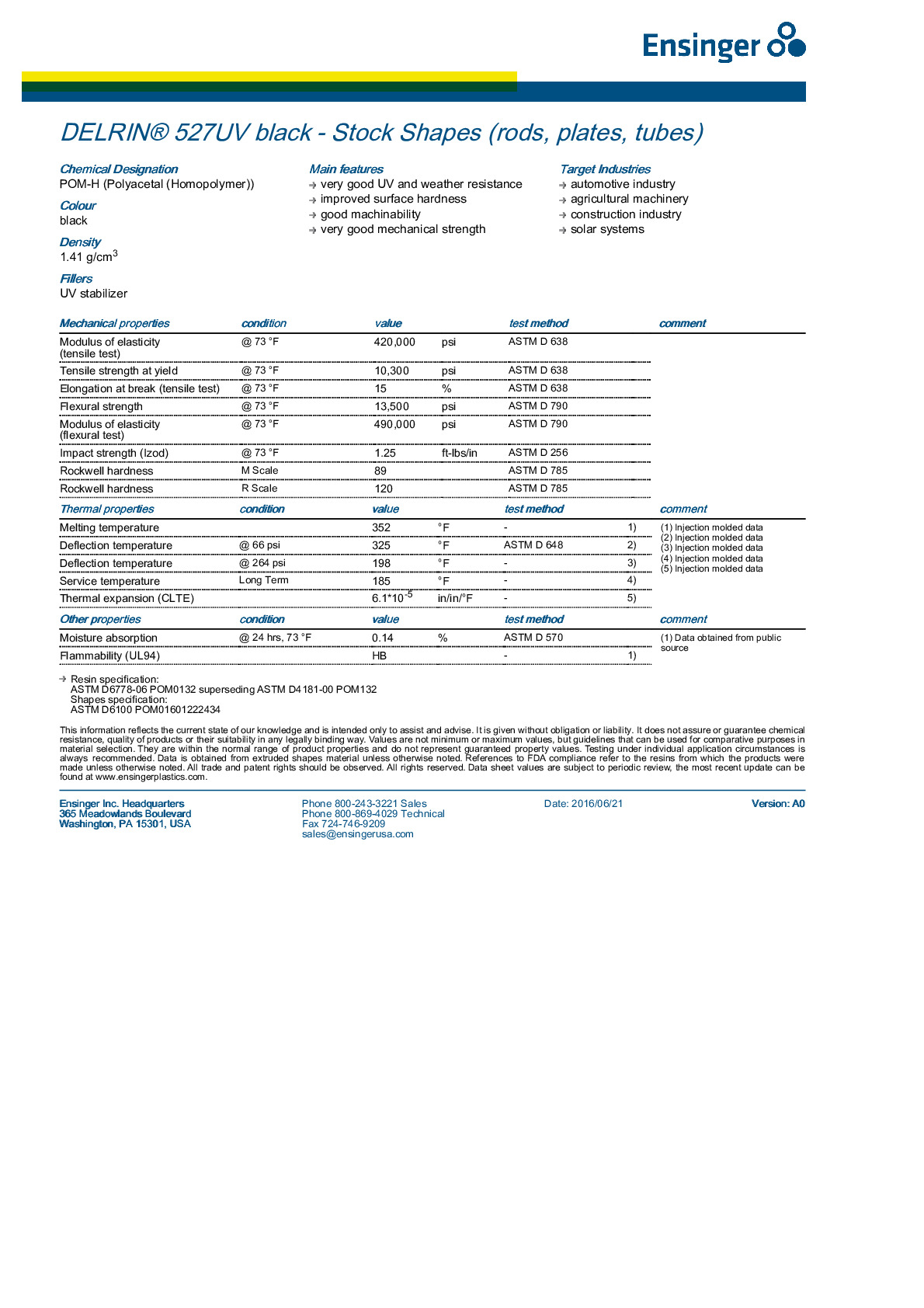

Delrin 527UV black Ensinger

Delrin 527UV black Ensinger -

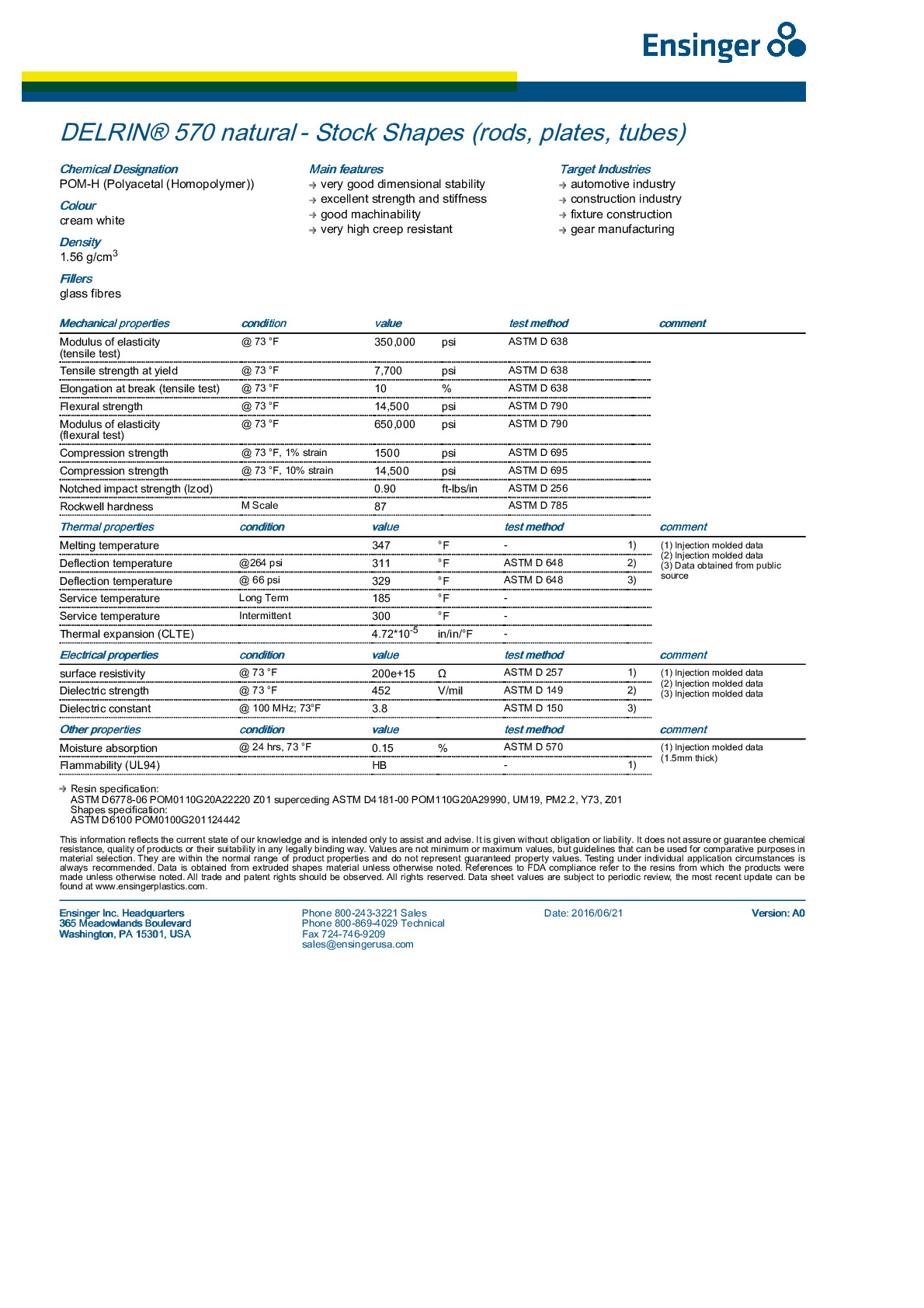

Delrin 570 Ensinger

Delrin 570 Ensinger -

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics -

MCAM Acetron® MD POM-C Mitsubishi Chemical Group

MCAM Acetron® MD POM-C Mitsubishi Chemical Group -

MCAM Ertracetal® POM-H / Acetron® POM-H Aircraft Landing Gear Greaser Plug Mitsubishi Chemical Group

MCAM Ertracetal® POM-H / Acetron® POM-H Aircraft Landing Gear Greaser Plug Mitsubishi Chemical Group

Acetal Plastic Sheet, Rod, and Tube Solutions at Piedmont Plastics

Acetal, also known as Polyoxymethylene or POM, is a high-performance engineered plastic known for its excellent strength, stiffness, and durability. As a semi-crystalline material, acetal offers easy machinability, making it a top choice for creating complex parts that need tight tolerances. Its versatility, low friction, and good wear resistance also make it ideal for parts that move or slide against other surfaces. Whether you need strong components for industrial equipment or precision parts for manufacturing, acetal plastic delivers reliable performance in demanding environments.

At Piedmont Plastics, we offer a wide selection of acetal plastic sheet, rod, and tube to meet your project needs. Our acetal products are perfect for applications like gears, bearings, bushings, conveyor parts, and fittings. Thanks to its strength and stability, acetal is commonly used in industries such as automotive, food processing, medical equipment, and electronics.

As a trusted plastic sheet, rod, tube, and film distributor, Piedmont Plastics has the materials and expertise to help you find the right solution. Our industrial market experts are ready to assist you in selecting the best acetal products for your specific applications.

Ready to get started? Shop for acetal plastic sheet, rod, and tube today at Piedmont Plastics and experience the difference that high-quality performance plastics can make for your project!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Acetal

Acetal has many qualities that make it a terrific choice for your application, including:

High Strength: Acetal is a low friction plastic that offers a thinner, lighter, and more flexible design than leading market products.

Ease of Manufacturing: Designed to replace metals, acetal is easily fabricated for a variety of industrial and commercial applications.

Versatility: With its combination of stiffness, strength, durability, and lubricity, acetal is one of the most widely used thermoplastics for manufacturing.

Low Coefficient of Friction: Its excellent wear properties and low moisture absorption allow it to be used in many industrial applications, especially those in overly wet or dry environments.

Chemical Resistance: Acetal is chemically resistant to solvents and even offers good electrical properties. Acetal also has a continuous use temperature range of up to 180° F (82° C).

Acetal is available in homopolymer (POM-H) and copolymer (POM-C) options. Commonly referred to by its brand name Delrin®, homopolymer acetal offers greater room temperature strength, stiffness, and toughness, whereas copolymer acetal performs extremely well in continuous high heat and hot water environments.

Benefits of Using Acetal

Applications of Acetal Sheet, Rod, and Tube

Acetal is a versatile material that is useful in a variety of industries. Common applications include:

Bearings and Bushings: Acetal's low friction and wear resistance make it well-suited for these industrial components.

Seals and Gaskets: Durable and tough, acetal is widely used in seals and gaskets, offering excellent resistance to high compressive loads as well as protection against most chemicals and solvents.

Conveyor Systems: Easily machined and available in a wide range of grades, acetal offers natural lubricity and a low coefficient of friction for smooth, quiet operation.

Automotive Parts: Acetal is used in engine manifolds and vehicle tanks because of its durability and heat resistance.

Food Processing Equipment: Thanks to its FDA compliance and moisture resistance, acetal is a preferred material for food applications.

Frequently Asked Questions

Acetal is a popular engineering material known for its strength, stability, and versatility. Below are some of the most frequently asked questions about acetal to help you better understand its properties, uses, and advantages.

Acetal (POM) is a high-strength engineering thermoplastic renowned for its stiffness, low friction, and excellent dimensional stability. It's widely used in precision parts requiring tight tolerances and durability.

Delrin® is a brand name for homopolymer acetal, while generic acetal may refer to either homopolymer or copolymer types from other manufacturers.

There are two primary types of acetal. The first is homopolymer acetal (e.g., Delrin®), which offers slightly higher mechanical strength and stiffness but may exhibit centerline porosity. The second is copolymer acetal, which provides improved chemical resistance and reduced porosity, making it suitable for applications involving moisture or chemicals.

Yes, many grades of acetal plastic are FDA-compliant and suitable for direct food contact in processing and packaging equipment.

Acetal has better dimensional stability and machinability than UHMW, and absorbs less moisture than nylon, making it more stable in humid environments.

Yes, acetal is known for its excellent machinability. It can be easily cut, drilled, and milled to precise dimensions, making it ideal for custom parts requiring tight tolerances. Piedmont Plastics can cut acetal to size and assist with fabrication upon request.

Why Buy Acetal from Piedmont Plastics?

Piedmont Plastics is the go-to source for acetal and other performance plastic materials. Backed by the expertise of our industrial market team, we are fully equipped to provide tailored solutions for your mechanical applications.

Learn more about why you should choose Piedmont Plastics as your acetal supplier:

Extensive Product Range: Our large inventory features a wide selection of acetal sheet, rod, and tube, available in a variety of dimensions, thicknesses, diameters, and colors to meet the demands of your application.

Custom Cutting and Fabrication: We can easily fabricate acetal to meet your exact specifications using our cut-to-size services.

Trusted Expertise: With years of hands-on industry experience, our knowledgeable team is ready to help you select the acetal materials for your specific needs.

Nationwide Availability: Thanks to our expansive network of locations across North America, our performance plastics are always close at hand to support your projects.

Superior Quality: Dedicated to delivering excellence, we ensure our acetal products consistently meet or exceed the highest industry standards for performance and reliability.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745