PVDF plastic offers exceptional purity, chemical resistance, and mechanical strength. Available in sheet and rod form for chemical processing, electrical, and industrial applications.

PVDF (Polyvinylidene Fluoride)

A high-performance PVDF sheet and rod for chemical and industrial use.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of PVDF (Polyvinylidene Fluoride)

Common Properties

- Typical Lengths 48 in

- Typical Widths 24 in

- Typical Thickness Size 0.5, 0.75, 1, 2, 2.5, 3, 4 in

- Typical Rod Diameter 0.187 - 6 in

- Common Profiles Sheet, Rod

- Typical Rod Length 4 ft

- Friendly Names Polyvinylidene Fluoride

- Common Brand Names Kynar®, SustaPVDF, TECAFLON®, KYTEC®

Electrical Properties

- Volume Resistivity 10000000000000 ohm-cm

- Surface Resistivity 1.0E+14 ohms

- Thermal Coefficient of Dielectric Constant 0.0011 /°C

- Breakdown Voltage 220 MV/m

- Arc Resistance 120 seconds

- Dielectric Constant 8.4

- Dielectric Strength 20 kV/mm

- Electrostatic Discharge (ESD) Sensitivity Low

- Comparative Tracking Index (CTI) 600 volts

- Dissipation Factor 0.02

Mechanical Properties

- Elongation at Break 100 %

- Gardner Impact 12 J

- Modulus of Elasticity 2000 MPa

- Instrumented Impact Total Energy 8 J

- Bearing Yield Strength 120 MPa

- Izod Impact, Unnotched 20 kJ/m²

- Elongation at Yield 10 %

- Tensile Strength, Ultimate 50 MPa

- Compressive Yield Strength 70 MPa

- Falling Dart Impact 15 J

- Izod Impact, Notched 5 kJ/m²

- Tensile Strength, Yield 40 MPa

- Flexural Modulus 1600 MPa

- Flexural Yield Strength 70 MPa

- Hardness, Rockwell R 90 R scale

- Shear Strength 30 MPa

Physical Properties

- Moisture Absorption at Equilibrium 0.03 – 0.05 %

- Melt Flow 2 - 30 g/10 min

- Density 1.76 – 1.79 g/cm³

- Water Absorption 0.1 - 2.0 %

- Linear Mold Shrinkage 0.2 - 2.0 %

Regulation Properties

Thermal Properties

- Vicat Softening Point 130 °C

- Max Continuous Operating Temperature in F 275 - 300 °F

- Flammability V-0 UL94

- Thermal Conductivity 0.19 W/(m·K)

- Deflection Temperature at 1.8 MPa (264 psi) 100 °C

- CTE, linear 80-120 µm/(m·°C)

- CTE, linear, Transverse to Flow 95-130 µm/(m·°C)

- Deflection Temperature at 0.46 MPa (66 psi) 110 °C

- Minimum Operating Temperature in F -60 °F

Literature and Data Sheets

-

GEHR KYNAR PVDF® Gehr Plastics

GEHR KYNAR PVDF® Gehr Plastics -

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics -

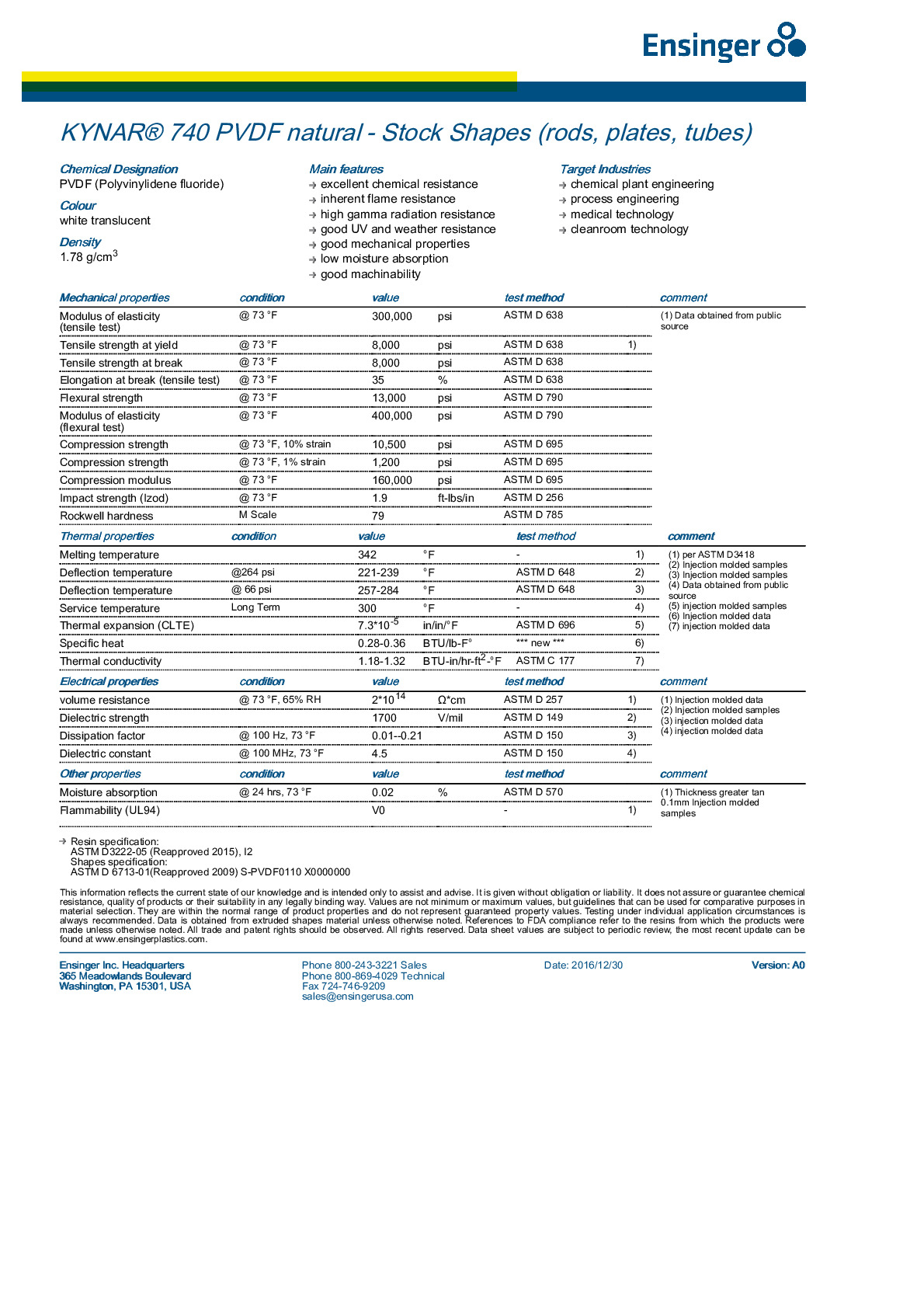

KYNAR 740 PVDF natural Ensinger

KYNAR 740 PVDF natural Ensinger -

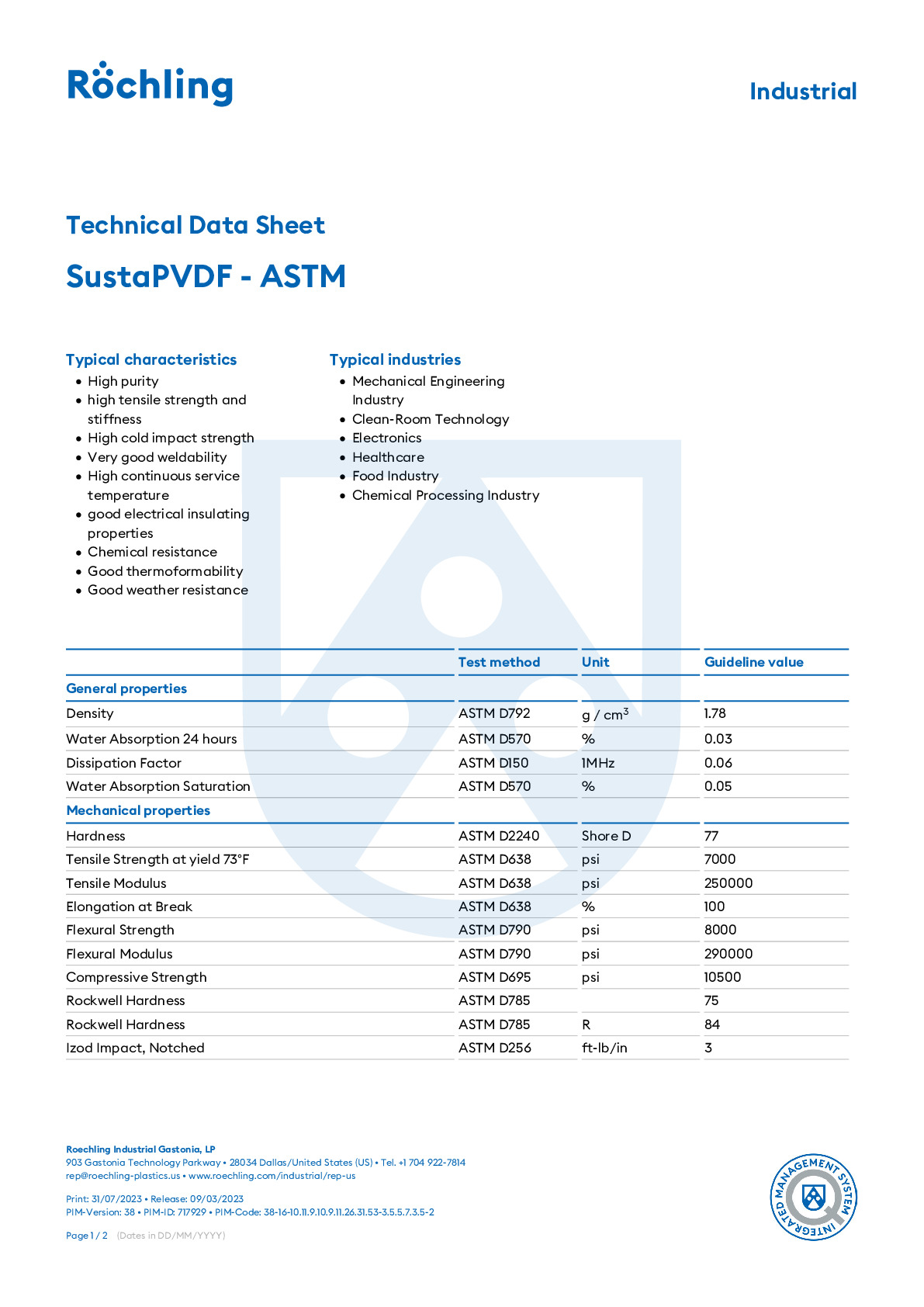

Röchling SUSTAPVDF Röchling Engineering Plastics

Röchling SUSTAPVDF Röchling Engineering Plastics -

SustaPVDF - ASTM Röchling Engineering Plastics

SustaPVDF - ASTM Röchling Engineering Plastics -

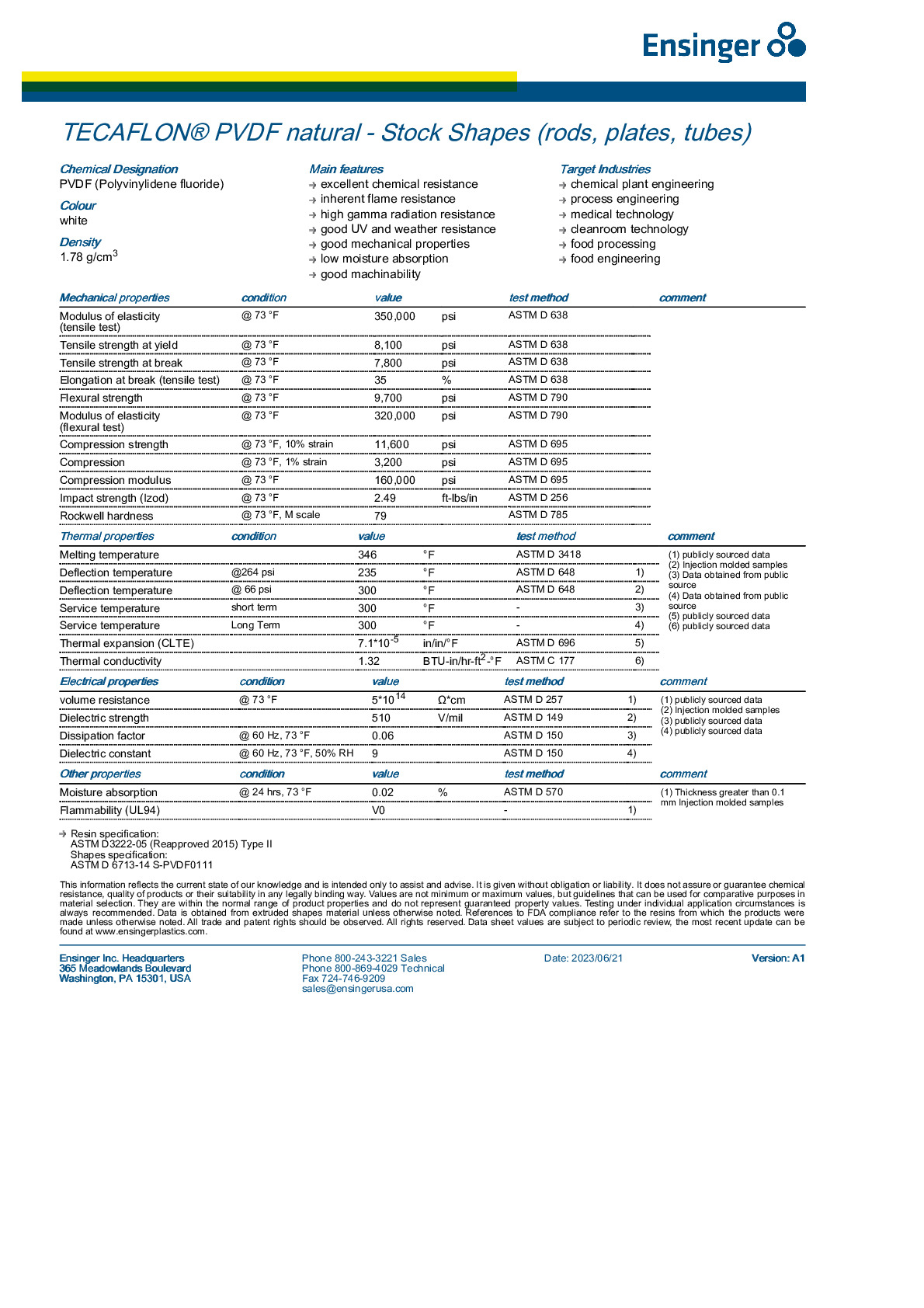

TECAFLON PVDF natural Ensinger

TECAFLON PVDF natural Ensinger -

VYCOM FLAMETEC® KYTEC® PVDF Vycom

VYCOM FLAMETEC® KYTEC® PVDF Vycom

Get a Quote for PVDF Sheet and Rod at Piedmont Plastics

PVDF, or polyvinylidene fluoride, is a high-performance thermoplastic known for its outstanding chemical resistance, mechanical strength, and stability in extreme environments. Often chosen for demanding applications in the chemical, semiconductor, and electrical industries, PVDF provides an ideal balance of purity, toughness, and long-term durability.

At Piedmont Plastics, we offer PVDF in sheet and rod form, supporting both precision machining and fabrication. Our PVDF materials maintain consistent performance across a wide temperature range, resist most acids and solvents, and deliver superior UV and radiation resistance. Contact us today to request a quote or learn more about our PVDF material solutions.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of PVDF Plastic

PVDF is a semi-crystalline fluoropolymer valued for its balance of performance properties and processability. It provides higher mechanical strength and abrasion resistance than other fluoropolymers like PTFE or FEP.

Key performance characteristics include:

Excellent chemical and corrosion resistance

High mechanical strength and impact resistance

Broad operating temperature range (-40°F to 300°F)

Exceptional UV, weather, and radiation resistance

Low moisture absorption and high purity

Good dimensional stability and machinability

Natural flame resistance (UL-94 V-0)

Electrically insulating with low dielectric constant

Benefits and Advantages

Common Applications

PVDF sheet and rod are used across industries where chemical resistance and purity are critical. Typical applications include:

Chemical processing equipment: Tanks, piping, valves, and fittings resistant to acids and solvents.

Semiconductor manufacturing: Components requiring high purity and minimal off-gassing.

Electrical and electronics: Insulators, connectors, and wire coatings with stable dielectric performance.

Industrial equipment: Pump housings, seals, and manifolds exposed to harsh chemicals.

Food and pharmaceutical processing: Surfaces and components that meet stringent cleanliness requirements.

Related Products

-

PTFE (Polytetrafluoroethylene)

PTFE plastic sheet and rod offer unmatched chemical resistance, high temperature performance, and low friction properties for industrial, electrical, and mechanical applications.

-

PEEK (Polyetheretherketone)

PEEK (polyetheretherketone) sheet, rod, and tube deliver superior strength, chemical resistance, and thermal stability for aerospace, medical, and industrial applications.

-

Polypropylene

Polypropylene is a tough, lightweight plastic known for its chemical resistance, low moisture absorption, and versatility in industrial, medical, and food-grade applications.

Frequently Asked Questions

Below are some frequently asked questions about PVDF plastic, its properties, and how it performs in demanding environments. These answers can help you better understand the advantages of PVDF sheet and rod and how they compare to other high-performance materials.

PVDF offers higher mechanical strength and easier processability, while PTFE provides superior chemical inertness and lower friction.

Yes. PVDF exhibits excellent resistance to UV radiation and weathering, making it ideal for outdoor applications.

Certain PVDF grades are available that comply with FDA and NSF regulations for food and water contact.

Why Buy from Piedmont Plastics?

Piedmont Plastics is your trusted source for high-performance thermoplastics, offering extensive material expertise and nationwide support.

Nationwide network of branches: Local inventory and fast delivery from over 50 locations.

Custom cutting and fabrication services: Precise sizing for your application requirements.

Deep industry expertise: Decades of experience supporting chemical, electrical, and semiconductor markets.

Wide product selection: One-stop access to high-performance fluoropolymers and engineering plastics.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745