Marine grade polyolefin sheet offers UV stability, moisture resistance, and impact strength for boats, docks, and marine construction.

Marine Grade Polyolefin

Moisture-resistant polyolefin sheets engineered for marine performance.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Marine Grade Polyolefin

Common Properties

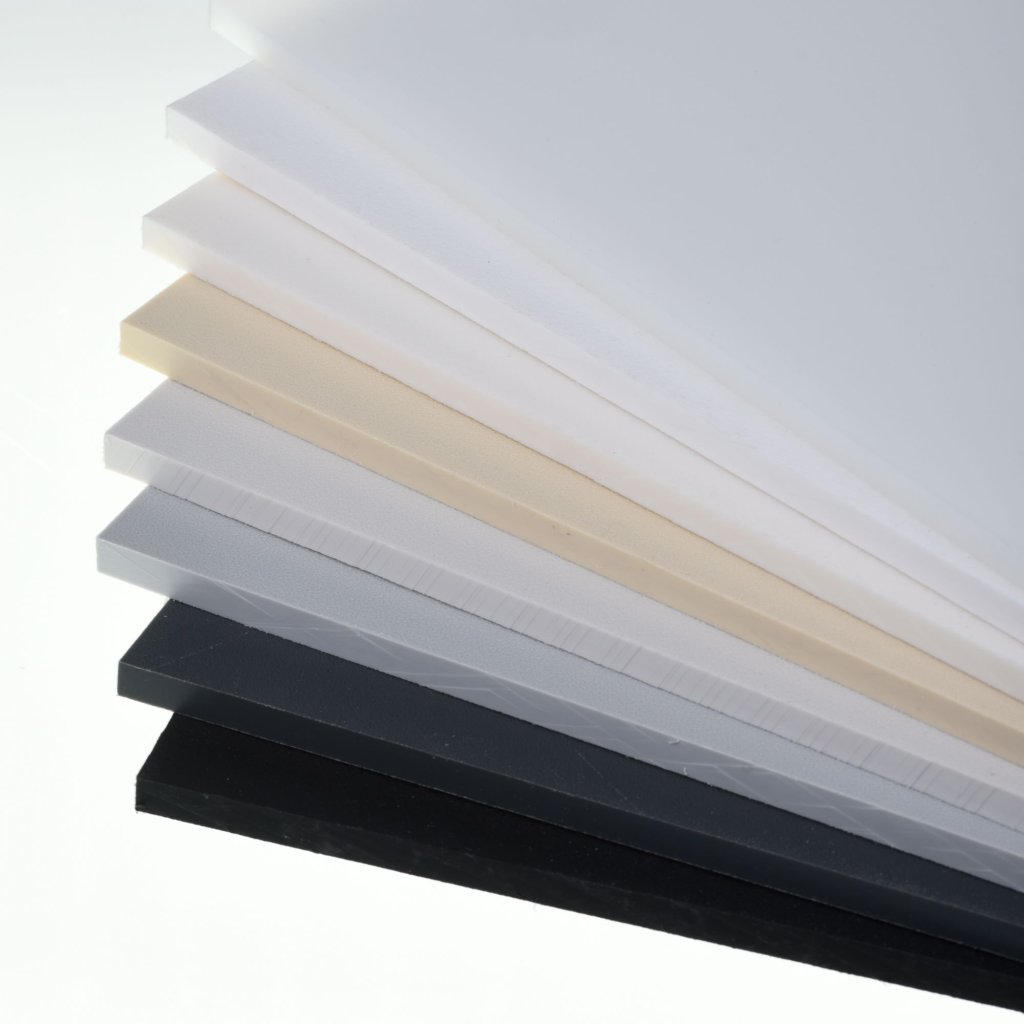

- Common Brand Names AquaPlas® II, King StarBoard®

- Friendly Names HDPE Marine Sheet, Marine Board

- Typical Lengths 96 in

- Typical Width 48, 54 in

- Friendly Names Marine Board

- Typical Thickness Size 0.25, 0.375, 0.50, 0.75, 1, 1.50 in

- Common Profiles Sheet

Literature and Data Sheets

-

King StarBoard® AS King Plastic

King StarBoard® AS King Plastic -

King StarBoard® ST King Plastic

King StarBoard® ST King Plastic -

King StarBoard® XL King Plastic

King StarBoard® XL King Plastic -

King StarBoard® King Plastic

King StarBoard® King Plastic -

King StarLite® XL King Plastic

King StarLite® XL King Plastic -

Piedmont Marine Grade® Aqua-Plas® II Foamed Piedmont Plastics

Piedmont Marine Grade® Aqua-Plas® II Foamed Piedmont Plastics -

Piedmont Marine Grade® Aqua-Plas II LT Foamed Piedmont Plastics

Piedmont Marine Grade® Aqua-Plas II LT Foamed Piedmont Plastics -

Piedmont Marine Grade® Aqua-Plas® Flex Piedmont Plastics

Piedmont Marine Grade® Aqua-Plas® Flex Piedmont Plastics -

Piedmont Marine Grade® Aqua-Plas® II Piedmont Plastics

Piedmont Marine Grade® Aqua-Plas® II Piedmont Plastics

Get a Quote for Marine Grade Polyolefin Sheet at Piedmont Plastics

Marine grade polyolefin sheet is a high-performance thermoplastic engineered for the demanding conditions of marine environments. Often referred to as marine board, this material resists moisture, UV rays, and impact, making it an excellent choice for boats, docks, and outdoor marine structures. Piedmont Plastics supplies marine grade polyolefin sheet in multiple sizes and thicknesses to meet your project requirements. Contact us today to discuss your application and request a quote.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Marine Grade Polyolefin Sheet

Marine grade polyolefin is designed with properties that outperform traditional wood alternatives in wet and sun-exposed conditions.

Moisture resistant: will not swell, rot, or delaminate in water

UV stabilized: resists fading, chalking, and degradation from sunlight

Impact resistant: stands up to heavy use and harsh conditions

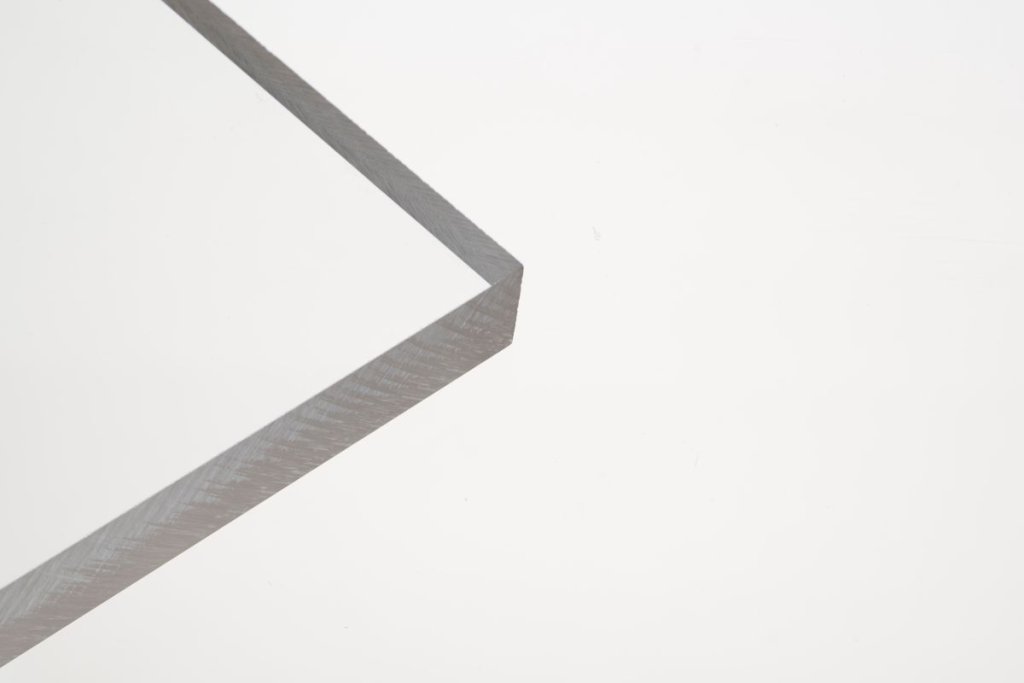

Excellent machinability: easy to cut, route, and fabricate with standard tools

Low maintenance: no painting, sealing, or refinishing required

Slip resistant surface options: improves safety in marine environments

Lightweight yet strong: ideal balance of performance and handling

Benefits and Advantages

Common Applications

Marine grade polyolefin sheet is widely used in boatbuilding, marina construction, and outdoor recreational structures where moisture and UV exposure are constant challenges.

Boat cabinetry and storage: lightweight, rot-resistant compartments

Dock boards and decking: slip-resistant, long-lasting surfaces

Hatch covers and doors: durable closures with excellent weatherability

Seating and consoles: impact-resistant, low-maintenance seating components

Trim and decorative elements: easy to machine and finish for clean aesthetics

Outdoor signage and panels: UV stable for long-term outdoor use

Related Products

-

Marine Grade ABS

Marine grade ABS sheet offers impact resistance, UV stability, and moisture resistance, ideal for boat building, marine interiors, and outdoor applications.

-

Marine Grade Acrylic Sheet

Known for its superior performance, high customizability, and excellent impact resistance, marine grade acrylic sheet is ideal for various boat applications, such as windows, hatches, and custom enclosures.

-

SEABOARD® Endurabond®

SEABOARD® Endurabond® foam PVC sheet offers superior bonding, screw retention, and durability. Ideal for marine, industrial, and structural applications.

-

HDPE (High Density Polyethylene)

HDPE offers strength, low weight, and resistance to chemicals and moisture, making it ideal for food and beverage equipment, industrial components, and marine applications.

Frequently Asked Questions

Below are some commonly asked questions about marine grade polyolefin sheet and its performance in marine environments.

Marine grade polyolefin sheet is engineered to resist corrosion, saltwater exposure, and UV degradation.

Marine grade polyolefin sheet offers several advantages over traditional marine plywood. Unlike plywood, it will not absorb water, swell, or rot. It is also UV stabilized, so it resists fading and degradation. In terms of fabrication, polyolefin machines easily with standard woodworking tools, but it cannot be glued or painted like wood (mechanical fastening is required).

No. Unlike wood products, polyolefin sheet never needs painting, sealing, or refinishing.

Why Buy from Piedmont Plastics?

Piedmont Plastics is a trusted distributor of marine grade plastics and other high-performance materials. We provide unmatched expertise and a wide product selection to support your project needs.

Nationwide network of branches: Local inventory and fast delivery across North America.

Custom cutting and fabrication services: Sheets cut to your specifications for reduced waste and labor.

Deep industry expertise: Decades of experience serving marine, industrial, and commercial markets.

Wide product selection: A one-stop source for plastics used in marine, signage, construction, and more.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745