Equipment used in the oil and gas exploration and production industry must be able to withstand the harsh conditions found in oilfields, offshore drilling rigs, and petrochemical processing plants. When high pressures, high temperatures, abrasive fluids, and saltwater combine, plastics are ideally suited for the challenge. With the proper material selection, performance plastics provide longer lifespans under conditions that would significantly deteriorate most metals over time.

Advantages of Plastics

When cost, downtime, and rig personnel safety are critical, plastics are often the best choice for oil and gas drilling applications. These high-performance plastic materials result in equipment component solutions that provide benefits such as long life, low maintenance, and significant cost savings.

These materials are perhaps the most efficient products to use because they were specifically designed to be versatile and durable in a variety of harsh environments. Piedmont Plastics supplies a wide range of engineering thermoplastics used in petrochemical refining, oil and gas exploration, oil refining, fracking, pumping and sub-sea systems, LNG and LPG gas transfer.

Common Plastics for Oil and Gas Applications

-

PEEK (Polyetheretherketone)

PEEK is a high-performance material with chemical resistance and performs well in high temperatures.

-

PTFE (Polytetrafluoroethylene)

Piedmont Plastics carries virgin and mechanical PTFE, also known as Teflon®, available in sheets, rods and tubes for mechanical and electrical applications.

-

Phenolic

Phenolic is a durable industrial laminate used for terminal boards, antenna insulators, printed circuit boards, washers, spacers, cams, inserts, bushings, and more.

-

Cast Nylon

Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

-

Polycarbonate

Polycarbonate is a high-performance, impact-resistant thermoplastic known for its clarity, strength, and weatherability, making it suitable for applications such as eyewear lenses, bullet-resistant glass, construction materials, and automotive parts.

PEEK

PEEK is a high-performance material that exhibits exceptional strength, dimensional stability, and abrasion resistance. PEEK is also resistant to moisture like steam and salt water, and it can operate in a variety of high temperature ranges.

Despite the high pressures and extreme temperatures of oil and gas environments, PEEK can still retain its physical properties Some common applications for PEEK include downhole drilling tools and valve seats.

PTFE

PTFE has a low coefficient of friction, excellent electrical properties, high chemical resistance, and stability in wide temperature ranges. PTFE can be used for applications such as:

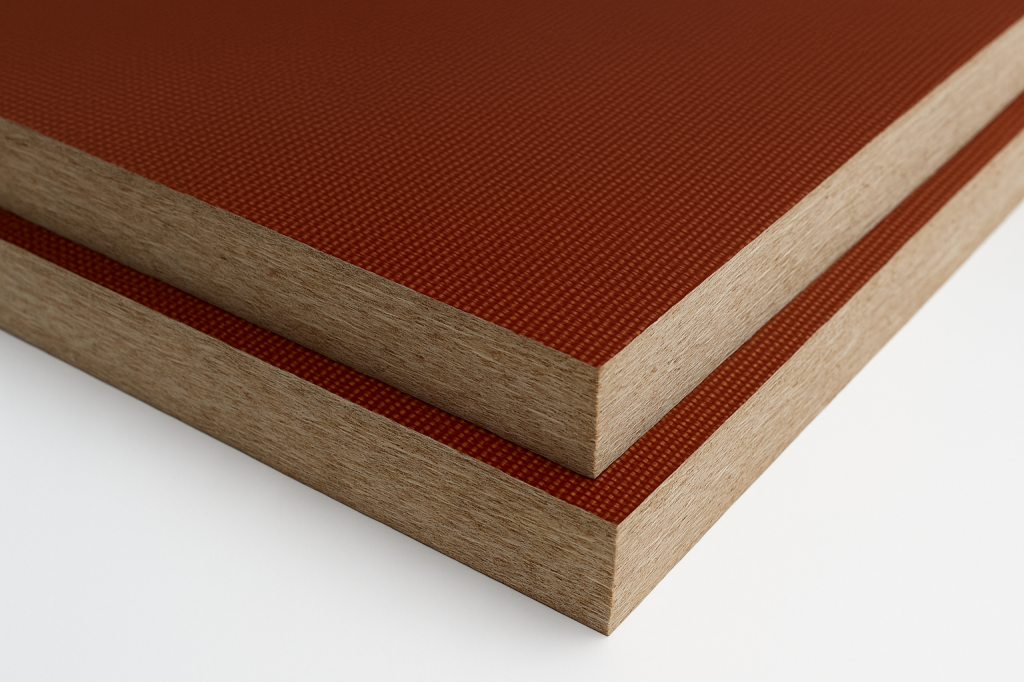

Phenolic

Phenolic materials are hard, dense materials made by applying heat and pressure to varying weighted layers of paper, cotton, or a glass fabric mix that is infused with a synthetic resin. Phenolics are approximately half the weight of aluminum and their physical toughness resists abrasion, friction, impact, and material fatigue.

In addition, phenolics have low water absorption and dissipation factors, corrosion resistance to several chemicals, and superior electrical characteristics over a wide range of temperatures and humidity. Some common phenolic applications include:

Spacers

Rings

Collars

Violent storm or ballistic protection

Cast Nylon

Cast nylon has exceptional toughness, resistance to wear, and great tensile strength. It is lightweight, exhibits a low coefficient of friction, and is chemically and thermally resistant. Cast nylon has almost limitless production possibilities and is easy to machine and fabricate. It also is very cost efficient!

Nylon can be used in:

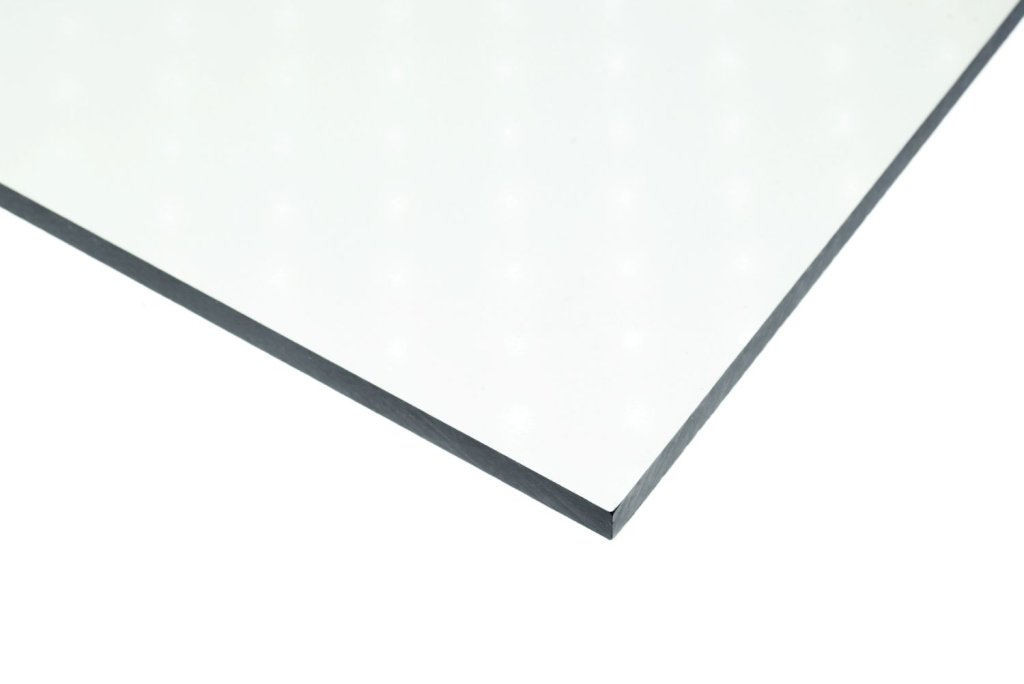

Polycarbonate

Polycarbonate is a transparent plastic material with exceptional impact resistance, toughness, low moisture absorption, dielectric properties, and flame retardance. Polycarbonate is 30 times stronger than acrylic and over 200 times stronger than glass. It is also lightweight, weighing six times less than glass. Polycarbonate is useful for applications such as safety partitions and heavy equipment glazing.

Contact us today for more information!

.jpg)