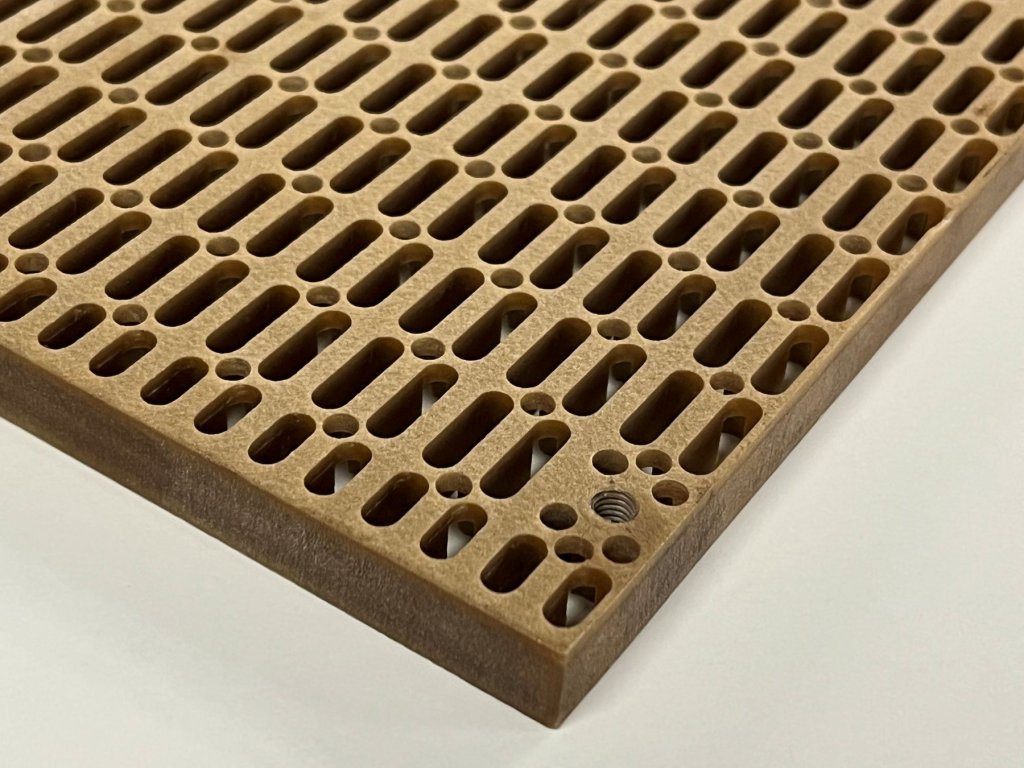

Polyetherimide (PEI) sheet and rod deliver high strength, heat resistance, and dimensional stability, making them ideal for aerospace, automotive, medical, and electronic applications.

PEI (Polyetherimide)

A durable, heat resistant, and strong high-performance sheet and rod for demanding applications.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of PEI (Polyetherimide)

Common Properties

- Typical Thickness Size 0.060 - 3 in

- Friendly Names PEI Material, PEI Plastic

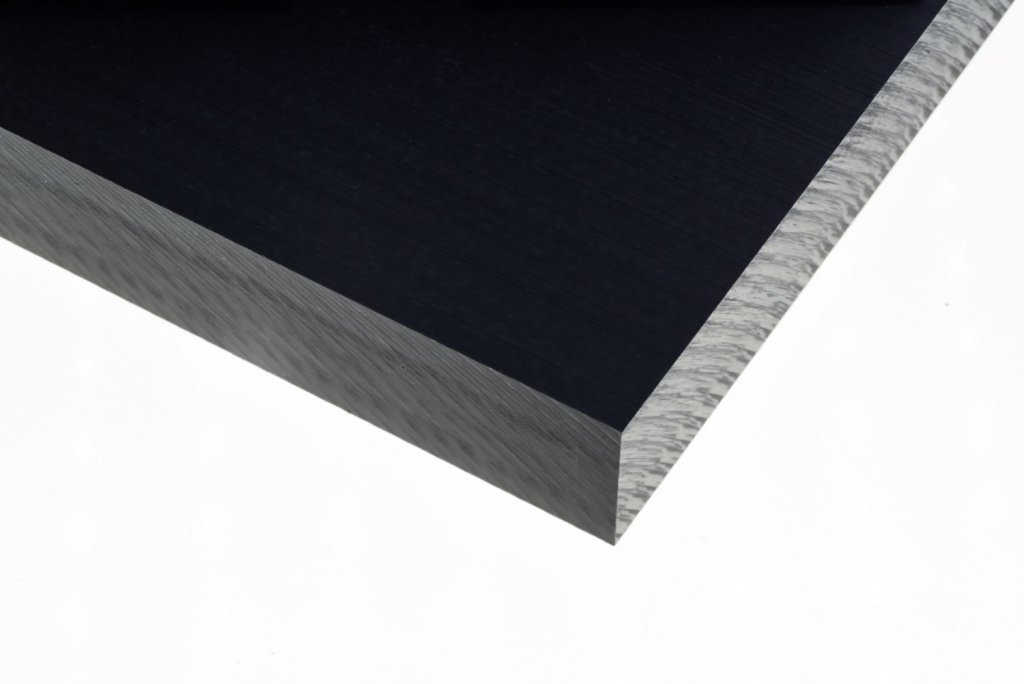

- Common Profiles Sheet, Rod

- Common Brand Names ULTEM®, TECAPEI™, SUSTAPEI, Duratron™ PEI

- Typical Widths 12 - 24 in

- Typical Lengths 12 - 48 in

- Typical Rod Diameter 0.250 – 6 in

- Grades Unfilled, Glass-Filled

Electrical Properties

- Dissipation Factor 0.0025 at 1 MHz

- Dielectric Constant 3.15 at 1 MHz

- Surface Resistivity 1.0E+16 Ohm/sq

- Electrostatic Discharge (ESD) Sensitivity Low

- Breakdown Voltage 16 kV/mm

- Volume Resistivity 1.0E+17 Ohm-cm

- Arc Resistance 120 s

- Comparative Tracking Index (CTI) 150 V

- Dielectric Strength 830 V/mil

- Thermal Coefficient of Dielectric Constant 0.012 %/°C

Mechanical Properties

- Tensile Strength, Ultimate 104 MPa

- Izod Impact, Unnotched 5 J/cm

- Elongation at Yield 6 %

- Elongation at Break 30 %

- Hardness, Rockwell R 125 R

- Izod Impact, Notched 0.6 J/cm

- Flexural Yield Strength 152 MPa

- Gardner Impact 40 J

- Instrumented Impact Total Energy 12 J

- Compressive Yield Strength 110 MPa

- Flexural Modulus 3500 MPa

- Modulus of Elasticity 3400 MPa

- Tensile Strength, Yield 94 MPa

- Falling Dart Impact 25 J

- Bearing Yield Strength 95 MPa

- Shear Strength 69 MPa

Physical Properties

- Rate at which a thermoplastic polymer flows through a specific die when extruded under standardized conditions. 0.1-50 g/10 min

- Percentage of water absorbed by a plastic material after immersion. 0.01-1.5 %

- Mass per unit volume of a plastic material. 0.9-2.2 g/cm³

- Dimensional reduction of a plastic part after it cools down post-molding. 0.1-2.5 %

- Percentage of moisture absorbed by a plastic material when exposed to humid conditions at equilibrium. 0.1-3.5 %

Regulation Properties

Thermal Properties

- Deflection Temperature at 1.8 MPa (264 psi) 170 °C

- CTE, linear, Transverse to Flow 80 µm/m-°C

- Minimum Operating Temperature in F -40 °F

- CTE, linear 54 µm/m-°C

- Deflection Temperature at 0.46 MPa (66 psi) 198 °C

- Vicat Softening Point 215 °C

- Thermal Conductivity 0.22 W/m-K

- Flammability, UL94 V-0

- Max Continuous Operating Temperature in F 340 °F

Literature and Data Sheets

-

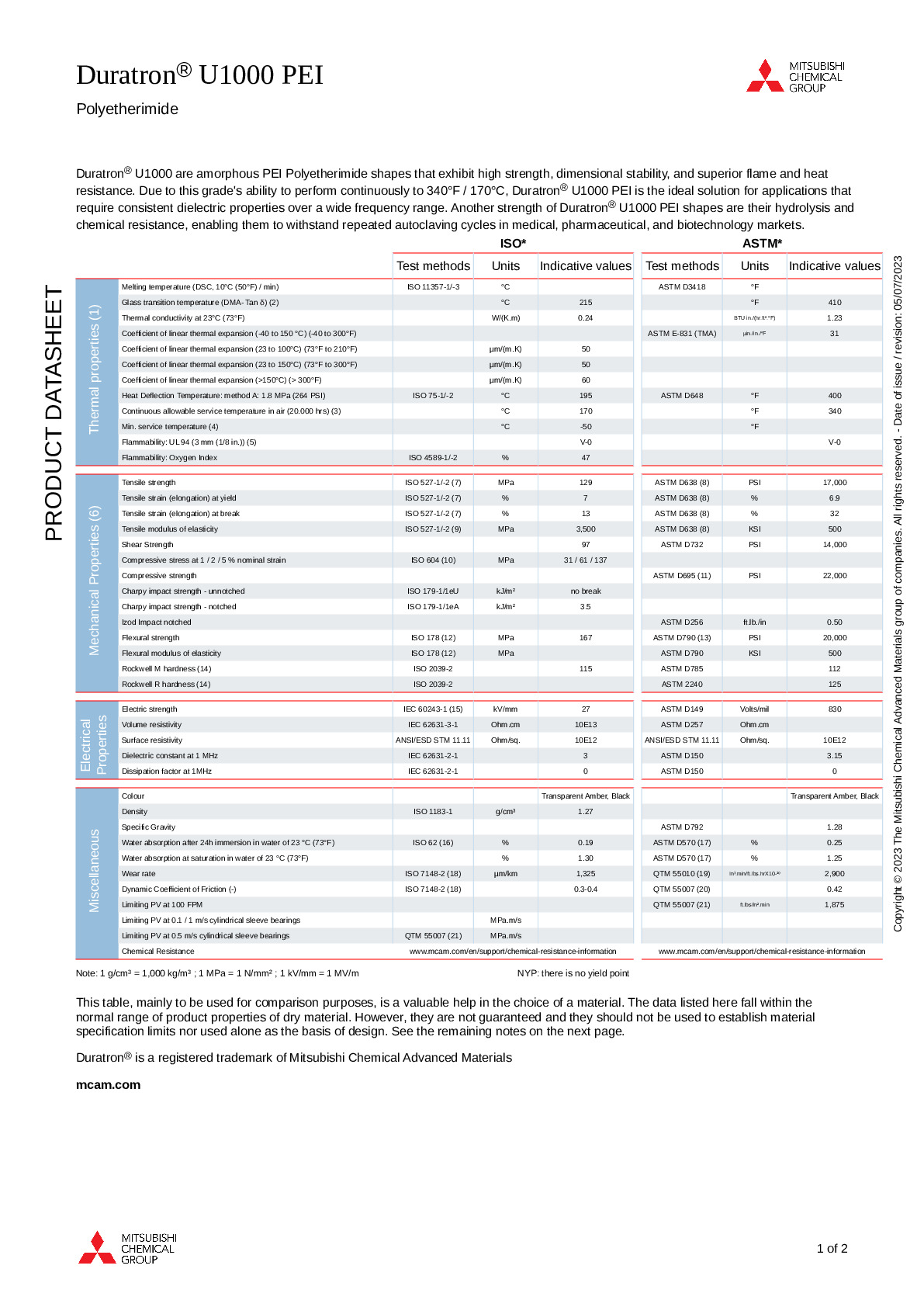

Duratron U1000 PEI Mitsubishi Chemical Group

Duratron U1000 PEI Mitsubishi Chemical Group -

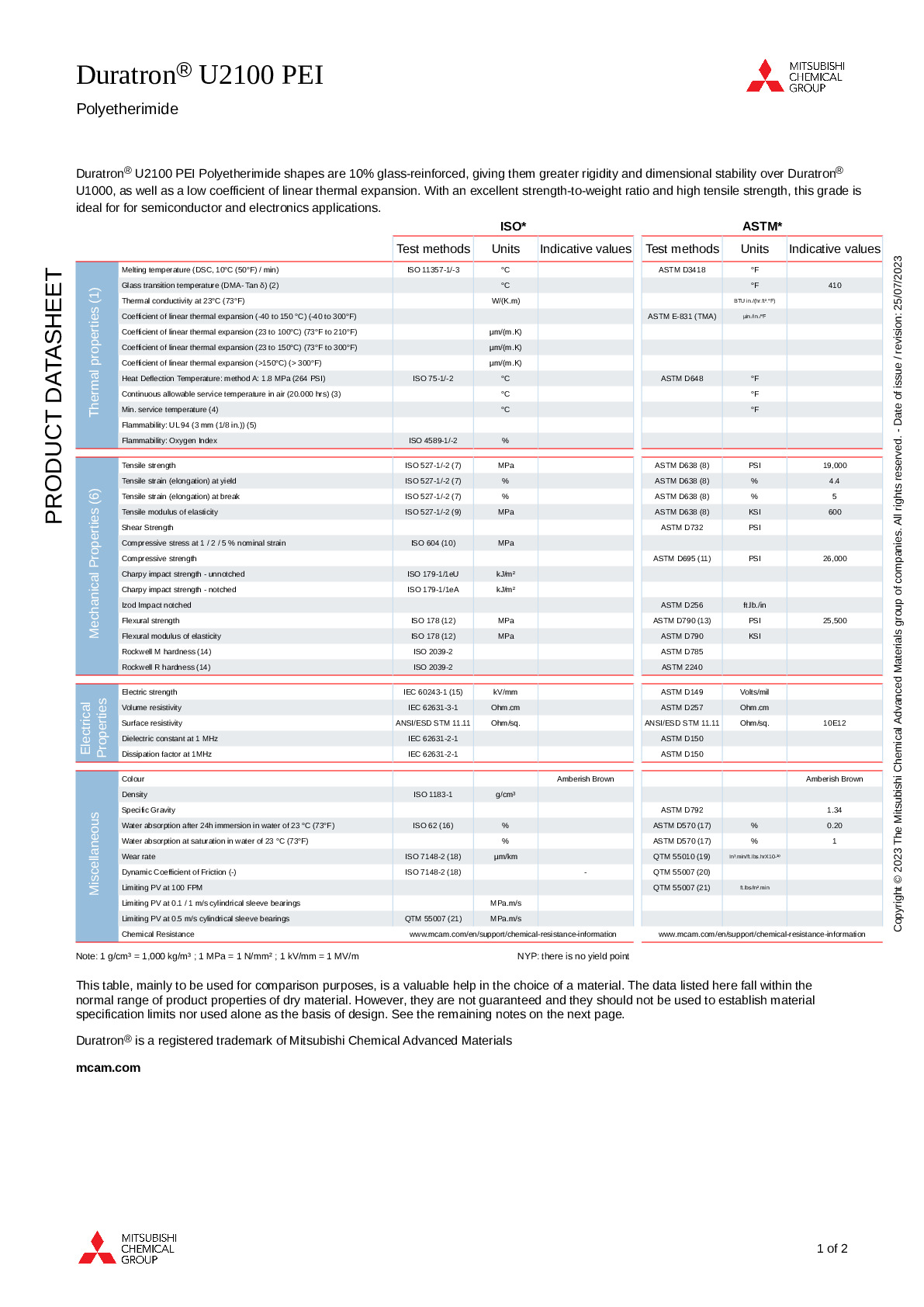

Duratron U2100 PEI Mitsubishi Chemical Group

Duratron U2100 PEI Mitsubishi Chemical Group -

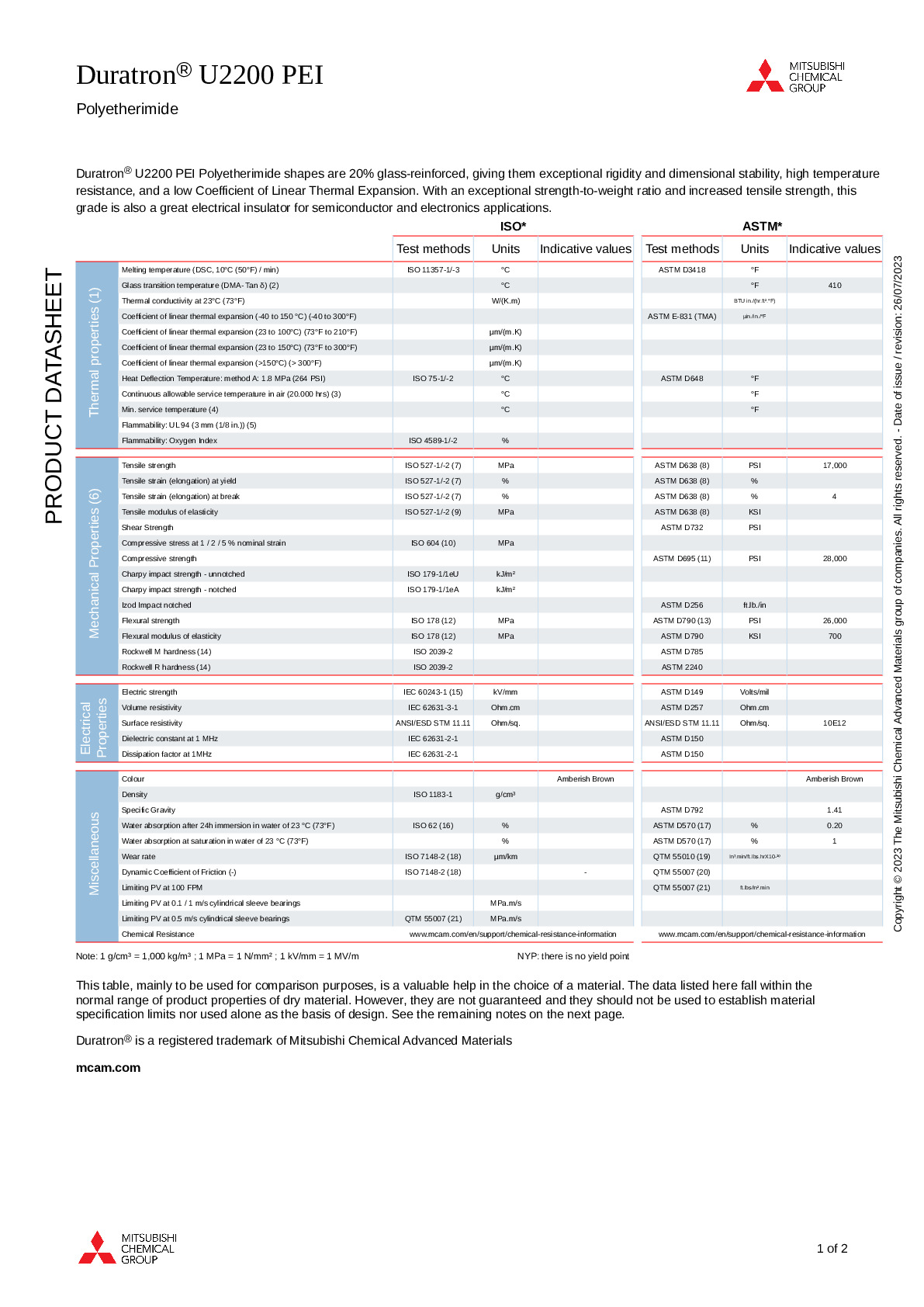

Duratron U2200 PEI Mitsubishi Chemical Group

Duratron U2200 PEI Mitsubishi Chemical Group -

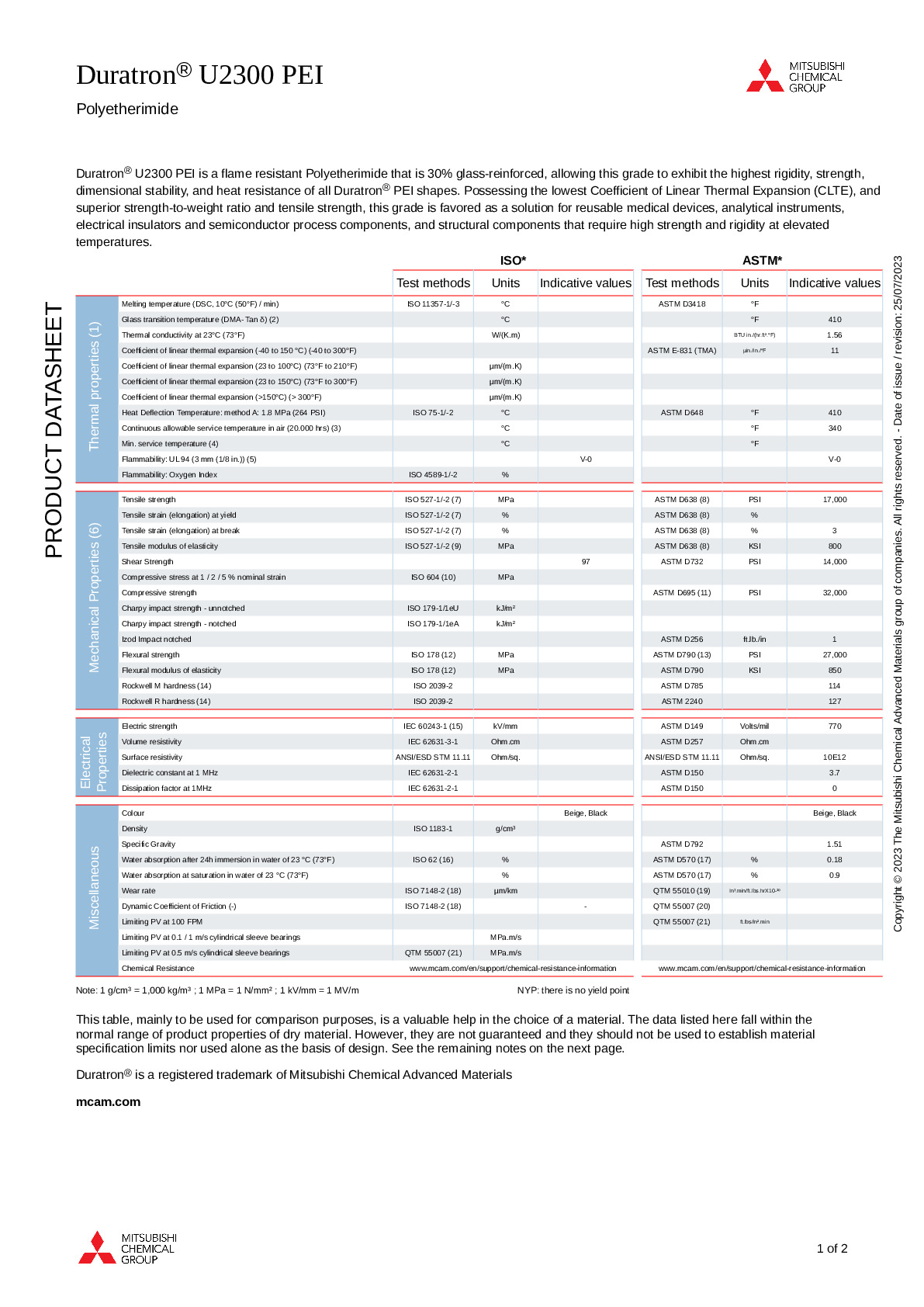

Duratron U2300 PEI Mitsubishi Chemical Group

Duratron U2300 PEI Mitsubishi Chemical Group -

MCAM Duratron® U1000 PEI & U2300 PEI Aircraft Electrical Interconnector Applications Mitsubishi Chemical Group

MCAM Duratron® U1000 PEI & U2300 PEI Aircraft Electrical Interconnector Applications Mitsubishi Chemical Group -

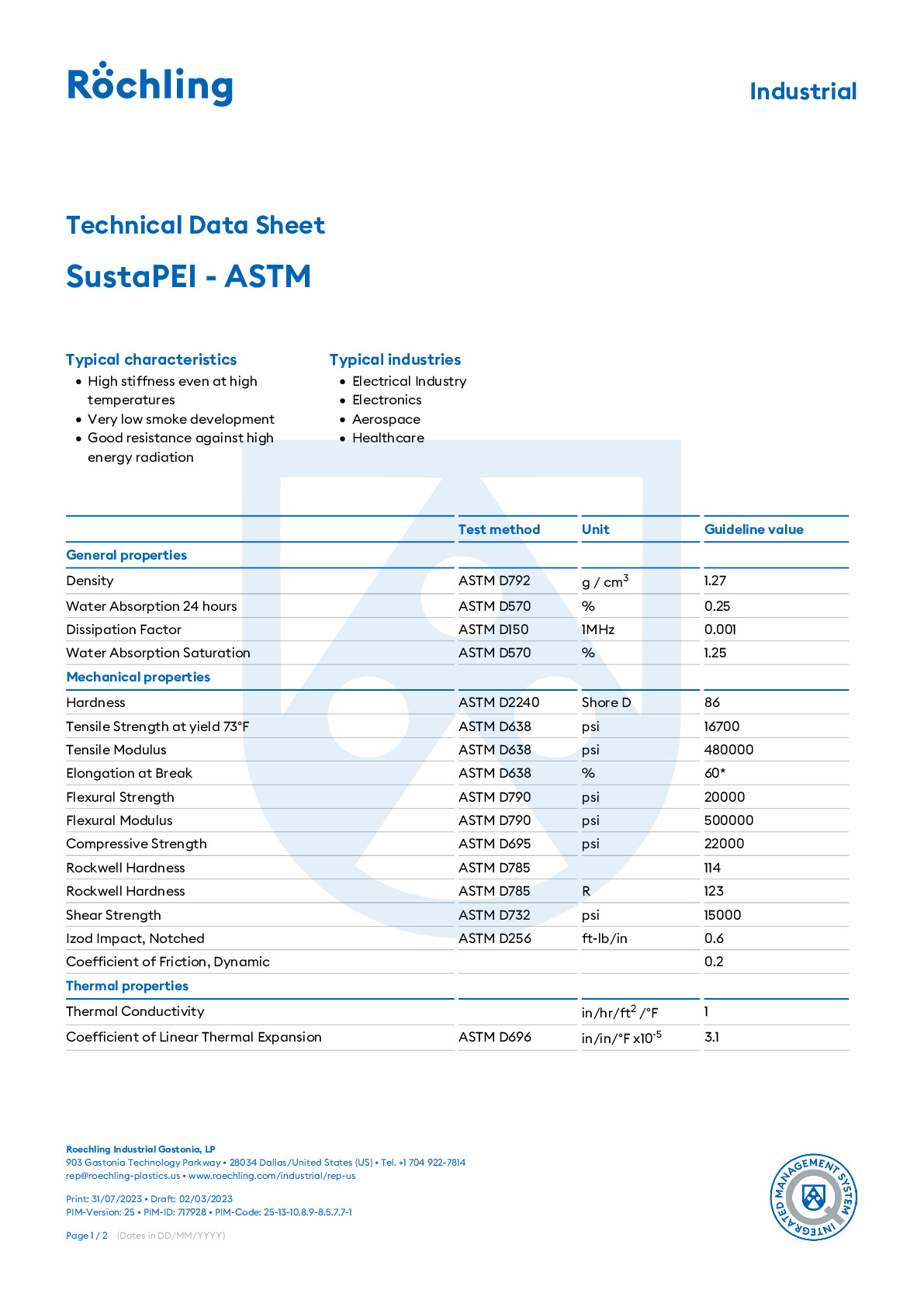

SustaPEI - ASTM Röchling Engineering Plastics

SustaPEI - ASTM Röchling Engineering Plastics -

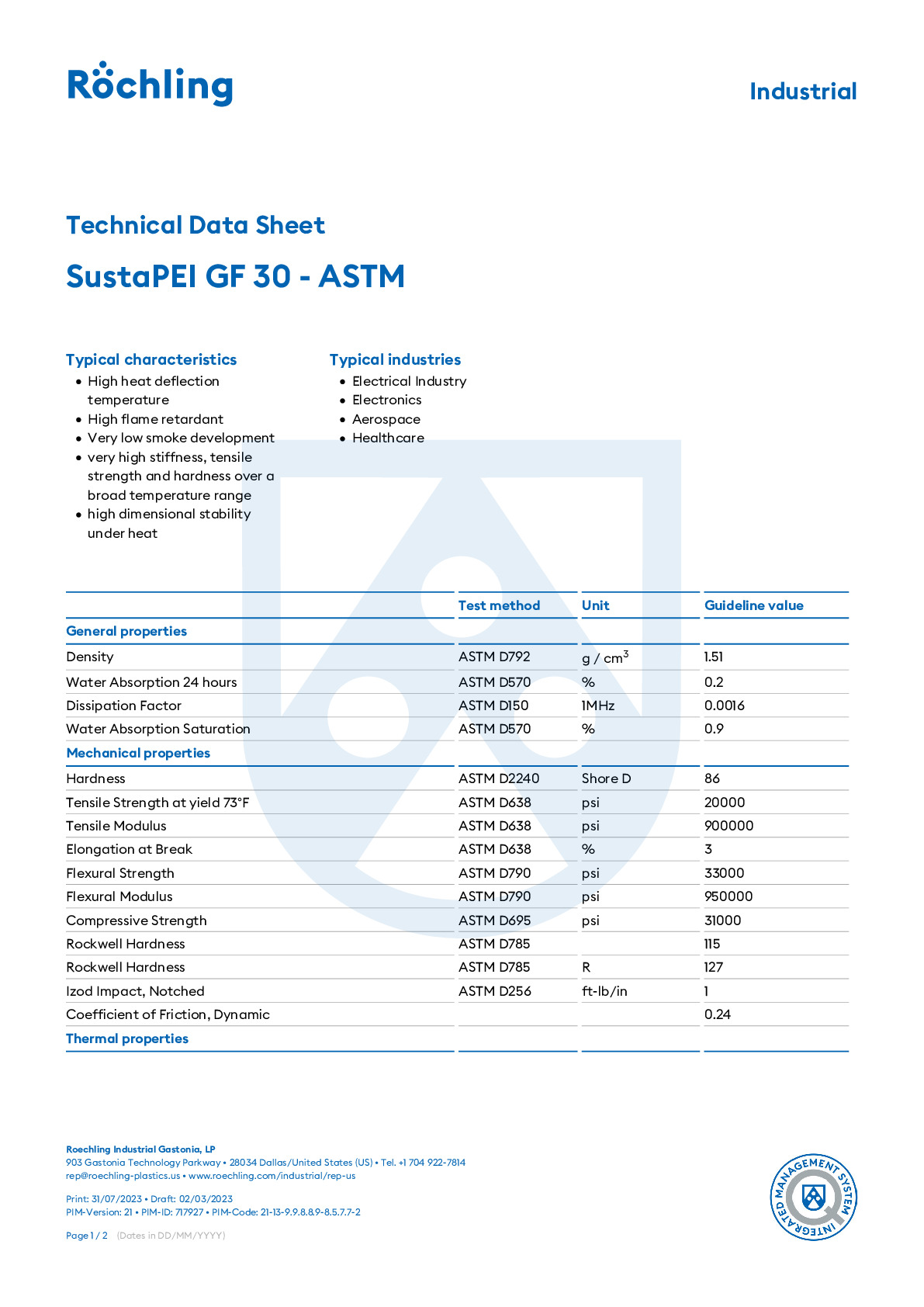

SustaPEI GF 30 - ASTM Röchling Engineering Plastics

SustaPEI GF 30 - ASTM Röchling Engineering Plastics -

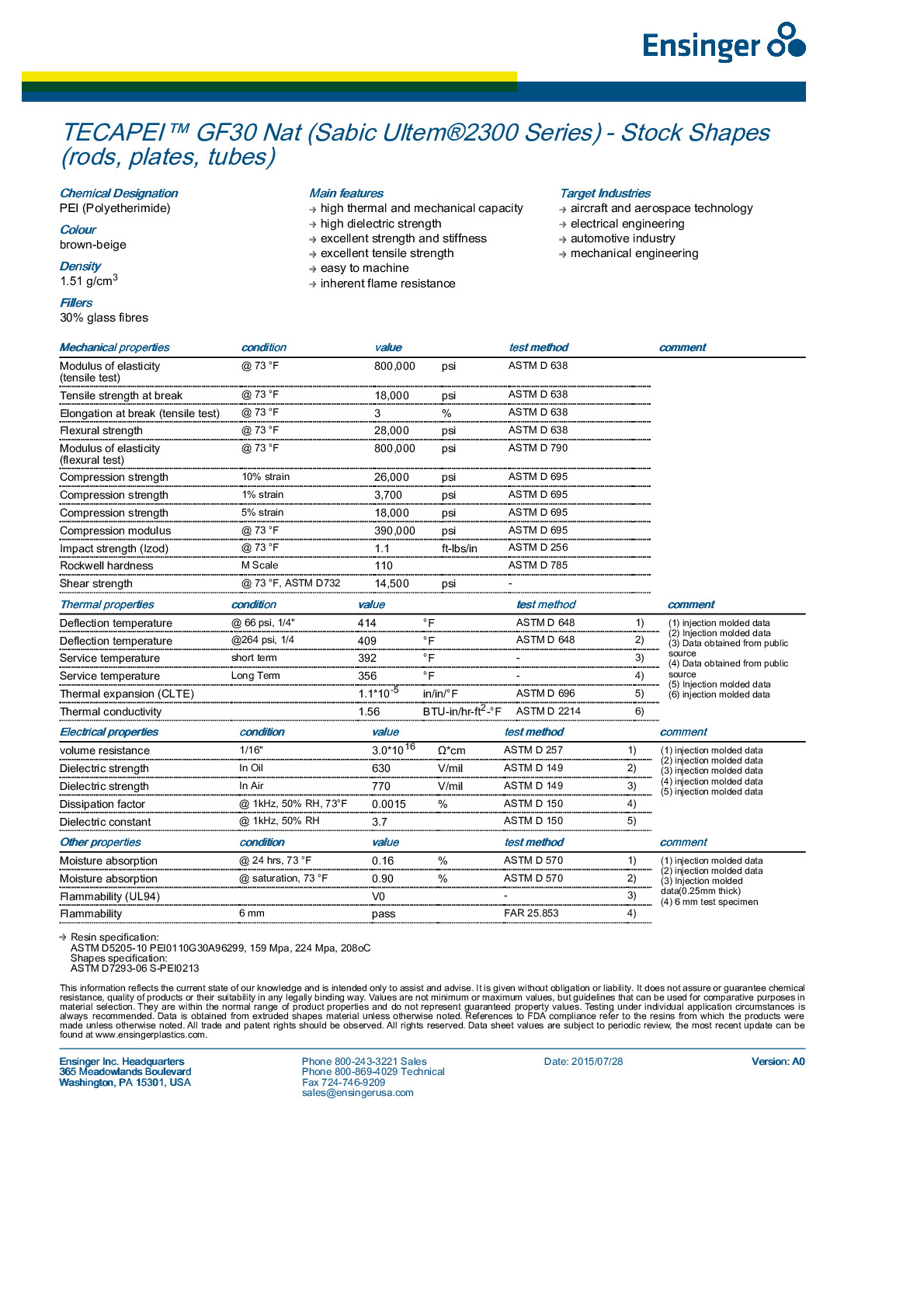

TECAPEI GF30 glass filled Ultem Ensinger

TECAPEI GF30 glass filled Ultem Ensinger -

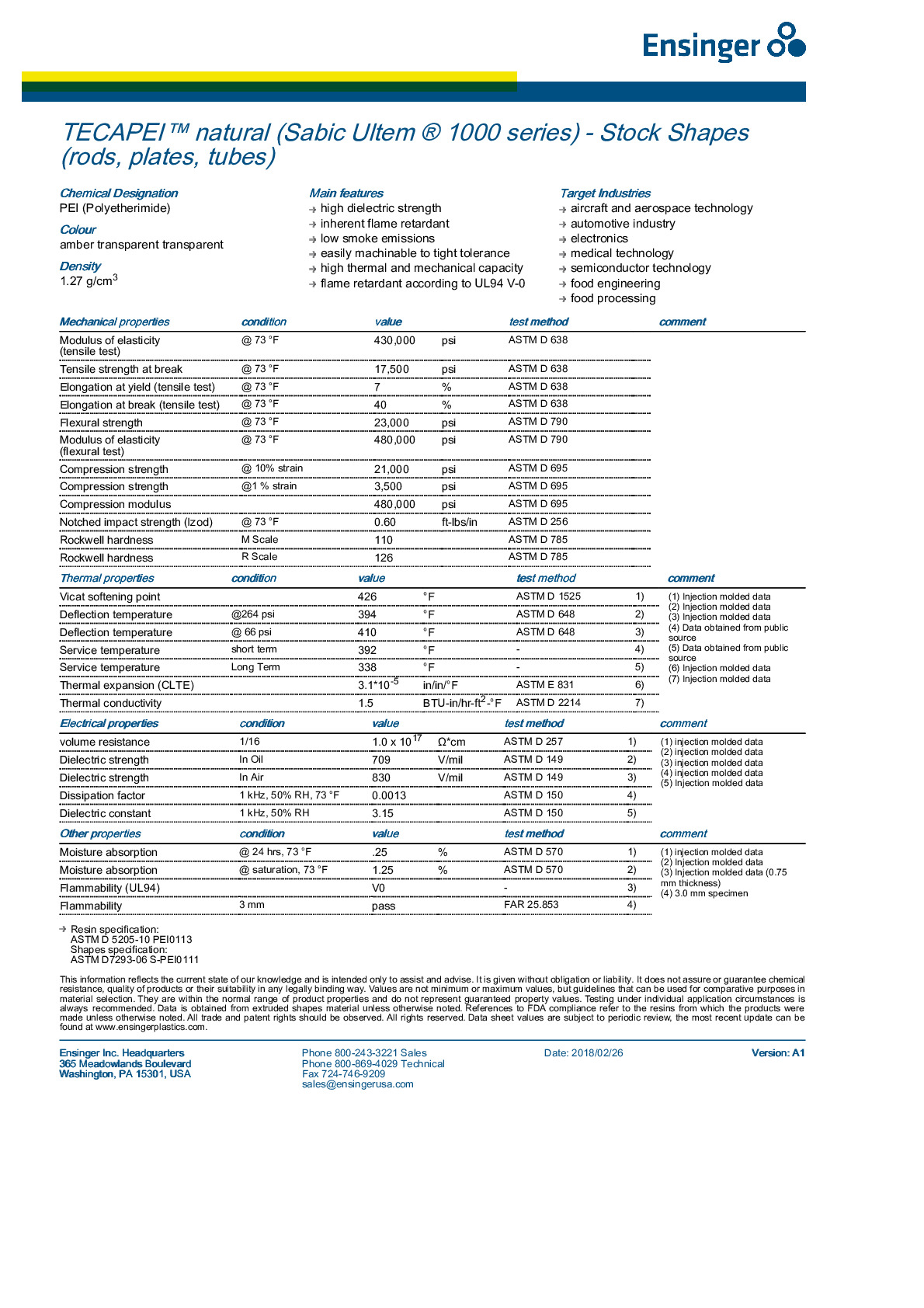

TECAPEI natural Ultem Ensinger

TECAPEI natural Ultem Ensinger

Get a Quote for Polyetherimide (PEI) at Piedmont Plastics

Polyetherimide (PEI) is a high performance thermoplastic engineered for extreme durability and stability under demanding conditions. Available in sheet and rod form, PEI plastic is recognized for its excellent strength-to-weight ratio, superior heat resistance, and outstanding electrical insulation properties. With its ability to maintain physical integrity at elevated temperatures, PEI is trusted across industries such as aerospace, automotive, medical, and electrical engineering.

Contact Piedmont Plastics today to request a quote or speak with an expert about your PEI needs.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Polyetherimide (PEI)

Polyetherimide combines mechanical strength with exceptional thermal and electrical properties. Its unique structure makes it an ideal material for critical applications where reliability is non-negotiable.

High strength and stiffness

Excellent dimensional stability

Heat resistance up to 340°F (170°C) continuous use temperature

Outstanding electrical insulation

Good chemical resistance

Flame resistant with UL-94 V-0 rating

Easy to machine, fabricate, and thermoform

Benefits and Advantages

Common Applications

Polyetherimide is relied upon in industries that demand strength, heat resistance, and electrical performance.

Aerospace components: lightweight, flame-resistant parts for interior and structural use

Automotive parts: high temperature under-the-hood components

Medical devices: sterilizable surgical instruments and housings

Electrical insulation: connectors, circuit boards, and insulating components

Industrial equipment: durable parts that withstand heat and wear

Related Products

-

PEEK (Polyetheretherketone)

PEEK (polyetheretherketone) sheet, rod, and tube deliver superior strength, chemical resistance, and thermal stability for aerospace, medical, and industrial applications.

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

-

Polycarbonate

Polycarbonate is a high-performance, impact-resistant thermoplastic known for its clarity, strength, and weatherability, making it suitable for applications such as eyewear lenses, bullet-resistant glass, construction materials, and automotive parts.

-

High Performance Materials

Piedmont Plastics supplies high performance materials and engineering plastics for engineers, designers, machine shops, and fabricators.

Frequently Asked Questions

Below are some commonly asked questions about Polyetherimide (PEI) and how it performs in different environments.

PEI offers higher heat resistance and better electrical properties than many standard engineering plastics, making it ideal for demanding environments.

Yes. In many applications, PEI provides comparable strength at a fraction of the weight, making it a preferred choice in aerospace and automotive industries.

Piedmont Plastics offers PEI in both sheet and rod form, with custom sizes available upon request.

Why Buy from Piedmont Plastics?

Piedmont Plastics is a trusted supplier of Polyetherimide (PEI) sheet and rod, with decades of experience serving high performance markets.

Nationwide network of branches: Local inventory and fast delivery across North America

Custom cutting and fabrication services: Precision machining and cut-to-size options for PEI

Deep industry expertise: Technical knowledge to guide material selection and applications

Wide product selection that supports a one-stop-shop experience: Access to a full range of performance plastics for your projects

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745