Power generation systems operate in demanding environments, with high voltage, heat, vibration, moisture, and chemicals all placing stress on equipment. To keep systems running safely and reliably, engineers and maintenance teams rely on performance plastics that deliver electrical insulation, durability, and long service life.

At Piedmont Plastics, we supply a wide range of plastic materials used across power generation and electrical infrastructure. This article highlights the best plastics for power generation, with a focus on red GPO-3 and other commonly specified materials such as G10 and FR4, phenolic, HDPE, PVC, polypropylene, polycarbonate, nylon, and PEEK.

Why Performance Plastics Are Used in Power Generation

Performance plastics play a critical role in electrical systems where metal alone cannot meet safety and performance needs. These materials help protect equipment from environmental exposure, improve safety, and extend service life in stationary power facilities.

In power generation systems, plastics are valued because they can:

Electrically insulate high-voltage components

Resist heat, flame, and electrical arcing

Reduce weight compared to metal parts

Withstand moisture, chemicals, and corrosion

The right plastic material helps improve safety, reliability, and long-term system performance.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

GPO-3: A Standard for Electrical Insulation

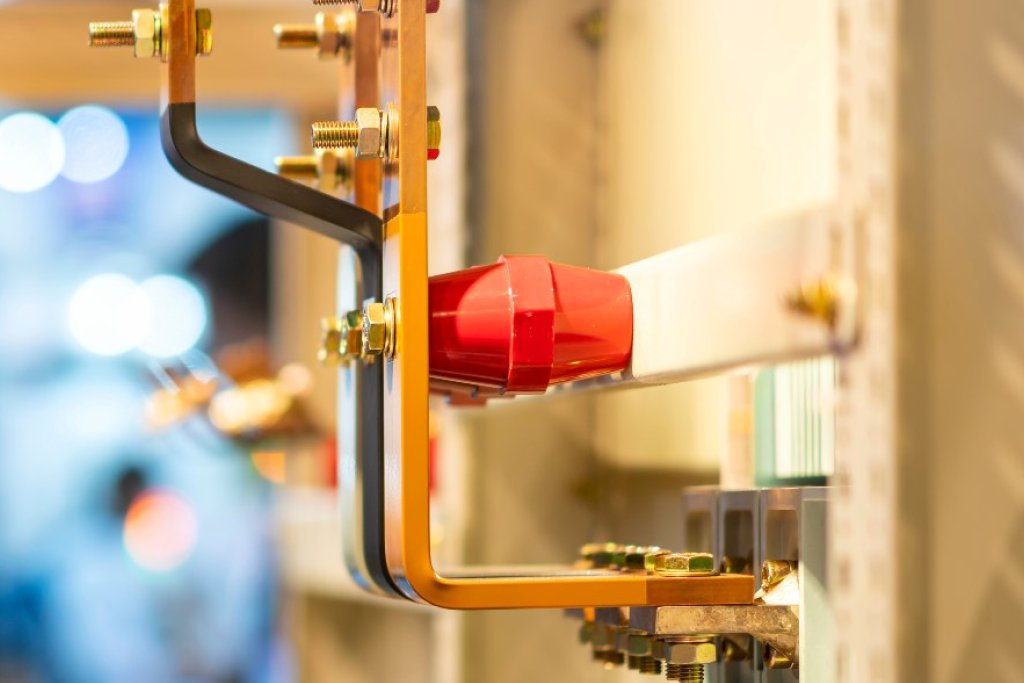

GPO-3 fiberglass laminate is a trusted choice for electrical insulation in power generation applications. Often referred to by the brand name Glastic®, it delivers reliable dielectric protection while maintaining strength and stability under demanding mechanical and high-temperature conditions.

GPO-3 is valued for its flame resistance and arc-resistant properties, making it ideal for high-voltage applications. Its red color also improves visibility, allowing maintenance teams to quickly identify insulated components.

Common GPO-3 applications include:

Busbar supports and spacers

Switchgear insulation panels

Transformer components

Electrical barriers and standoff parts

Various channels and profiles

These applications rely on GPO-3 for dependable electrical insulation, mechanical strength, and long-term reliability in demanding environments.

G10 and FR4: High-Strength Glass Epoxy Laminates

G10 and FR4 are glass epoxy laminates widely used in power generation systems where strength, electrical insulation, and flame resistance are critical. Both materials offer excellent dielectric strength, making them ideal for insulating high-voltage components. They also maintain strong mechanical properties under load, which allows them to serve as both structural and insulating components.

In power generation facilities, G10 and FR4 are commonly used for:

Switchgear insulation panels

Busbar supports and spacers

Transformer components

Terminal boards

Structural insulating supports

G10 vs. FR4: What’s the Difference?

G10 and FR4 are both glass epoxy laminates made from woven fiberglass cloth and epoxy resin. In many power generation applications, they can perform the same structural and insulating roles.

The key difference is flame resistance.

-

G10 provides strong mechanical strength and excellent electrical insulation. It performs well in high-voltage environments but does not have a built-in flame-retardant rating.

-

FR4 is a flame-retardant version of G10. It is engineered to meet specific fire safety standards, making it better suited for applications where flame resistance is required.

FR4 is often selected for switchgear and control panels where fire safety compliance is critical. G10 may be used in structural insulating components where flame rating is not a primary concern.

Both materials are trusted for their strength, insulation performance, and long-term reliability in demanding electrical environments.

Phenolic: Proven Electrical Insulation for Power Systems

Phenolic laminates have been used in electrical systems for decades. They are known for strong dielectric properties, mechanical stability, and dependable performance in high-load applications.

In power generation environments, phenolic materials are commonly used for:

Switchgear panels

Busbar supports

Terminal boards

Electrical backer panels

Phenolic offers a cost-effective alternative to higher-end laminates while still delivering reliable insulation and heat resistance. For many substations and control systems, it remains a trusted material choice.

More Material Options for Power Generation Applications

In addition to the materials listed above, a wide range of other plastics can be found in power generation applications. From electrical enclosures to barriers and wear pads, Piedmont Plastics is your one-stop shop for the materials you need to fabricate these versatile components.

-

HDPE

A tough, lightweight plastic known for its excellent resistance to moisture, chemicals, and corrosion. It is commonly used to make electrical enclosures, protective covers, and cable management components.

-

PVC

Delivers dependable electrical insulation and is available in flame-retardant grades. It is commonly used for electrical enclosures, raceway systems, fabricated panels, and structural profiles.

-

Polypropylene

Valued for its excellent chemical resistance and lightweight performance, this material holds up well in areas exposed to moisture, cleaning solutions, oils, and other corrosive environments. It is primarily used for electrical enclosures, protective covers, fabricated panels, and corrosion-resistant components.

-

Nylon

Valued for its mechanical strength, wear resistance, and ability to handle repeated movement. Best used for insulating components, wear pads, bushings, and structural parts.

-

PEEK

For applications that demand exceptional strength and heat resistance. Often specified for generator components, high-temperature electrical insulation, and critical parts.

-

Polycarbonate

A material with high impact strength and clarity. Commonly used for clear switchgear covers, safety guards, and protective panels

Selecting the Right Plastic Material

No single plastic works for every power generation application. The best choice depends on operating temperature, voltage, mechanical stress, environmental exposure, and safety requirements.

Power generation systems require materials that perform reliably over time. Working with an experienced plastics supplier helps ensure the selected material meets both performance expectations and industry standards. Piedmont Plastics offers a broad selection of performance plastics, local inventory, and technical expertise to support your application.

Whether you need GPO-3 for switchgear, HDPE for enclosures, PEEK for high-temperature components, or polycarbonate for safety panels, our team is ready to help!

Work with Piedmont Plastics

Contact Piedmont Plastics today to discuss your application, request material recommendations, or receive a quote from your local branch.

Get In Touch