GPO-3 is a flame-retardant fiberglass laminate ideal for electrical insulation, structural support, and high-heat environments

GPO-3

A fiberglass material that delivers reliable insulation, flame resistance, and mechanical strength for industrial environments.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of GPO-3

Common Properties

- Typical Lengths 36 to 144 in

- Typical Widths 12 to 48 in

- Friendly Names Polyester Glass Laminate, Glass-Mat Reinforced Thermoset

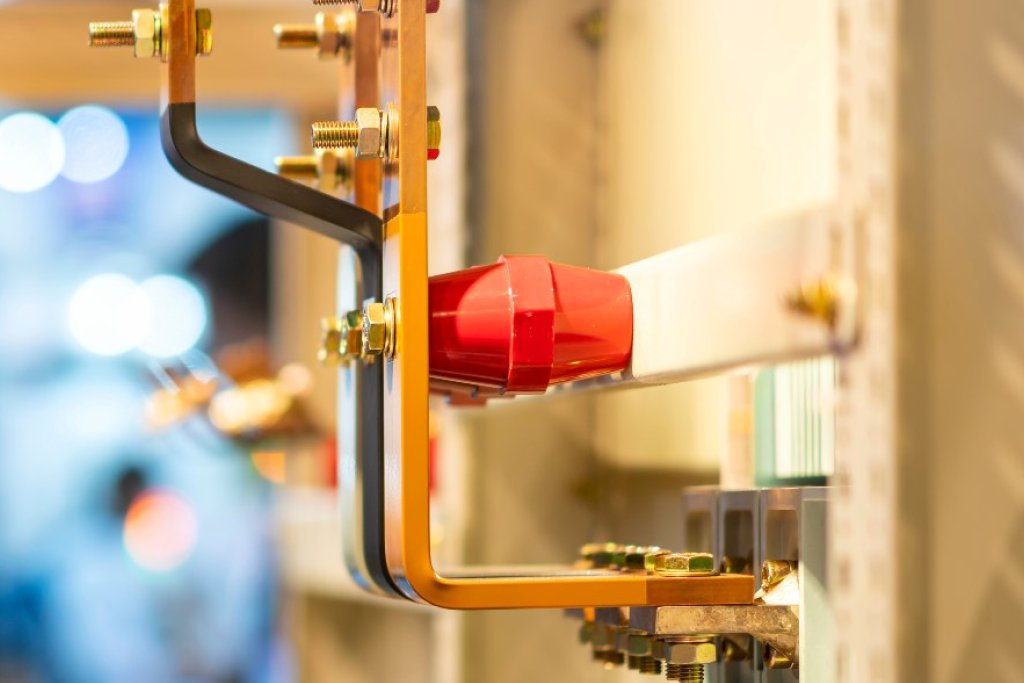

- Common Colors Red

- Common Profiles Sheet, Rod

- Common Brand Names Glastic®

- Typical Thickness Size 0.031 to 2.0 in

Electrical Properties

- Arc Resistance 180 seconds

- Dissipation Factor 0.02 unitless

- Comparative Tracking Index (CTI) 300 Volts

- Volume Resistivity 1.0E+14 ohm-cm

- Surface Resistivity 10000000000000 ohm

- Dielectric Strength 400 V/mil

- Dielectric Constant 4.5 unitless

- Thermal Coefficient of Dielectric Constant 25 ppm/°C

- Breakdown Voltage 35 kV

Mechanical Properties

- Tensile Strength, Yield 110 MPa

- Elongation at Break 2 %

- Izod Impact, Notched 10 kJ/m²

- Flexural Yield Strength 200 MPa

- Flexural Modulus 10300 MPa

- Compressive Yield Strength 150 MPa

- Modulus of Elasticity 10300 MPa

- Izod Impact, Unnotched 20 kJ/m²

- Bearing Yield Strength 140 MPa

- Hardness, Rockwell R 100 R Scale

- Falling Dart Impact 25 J

- Gardner Impact 15 J

- Shear Strength 90 MPa

- Instrumented Impact Total Energy 50 J

- Elongation at Yield 1.5 %

- Tensile Strength, Ultimate 140 MPa

Physical Properties

- Percentage shrinkage during cooling 0.4 - 2.0 %

- Rate of flow of a molten polymer 0.1 - 50 g/10 min

- Percentage of moisture absorbed when equilibrium is reached 0.20 - 1.00 %

- Mass per unit volume 0.90 - 2.20 g/cm³

- Percentage increase in weight due to water absorption 0.01 - 1.20 %

Regulation Properties

Thermal Properties

- CTE, linear 2.2 10^-5/F

- Minimum Operating Temperature in F -60 F

- Thermal Conductivity 0.15 W/mK

- Deflection Temperature at 1.8 MPa (264 psi) 210 F

- CTE, linear, Transverse to Flow 1.8 10^-5/F

- Deflection Temperature at 0.46 MPa (66 psi) 225 F

- Flammability, UL94 V-0 UL94

- Vicat Softening Point 340 F

- Max Continuous Operating Temperature in F 265 F

High-Performance GPO-3 Fiberglass Sheet & Rod for Electrical and Industrial Applications

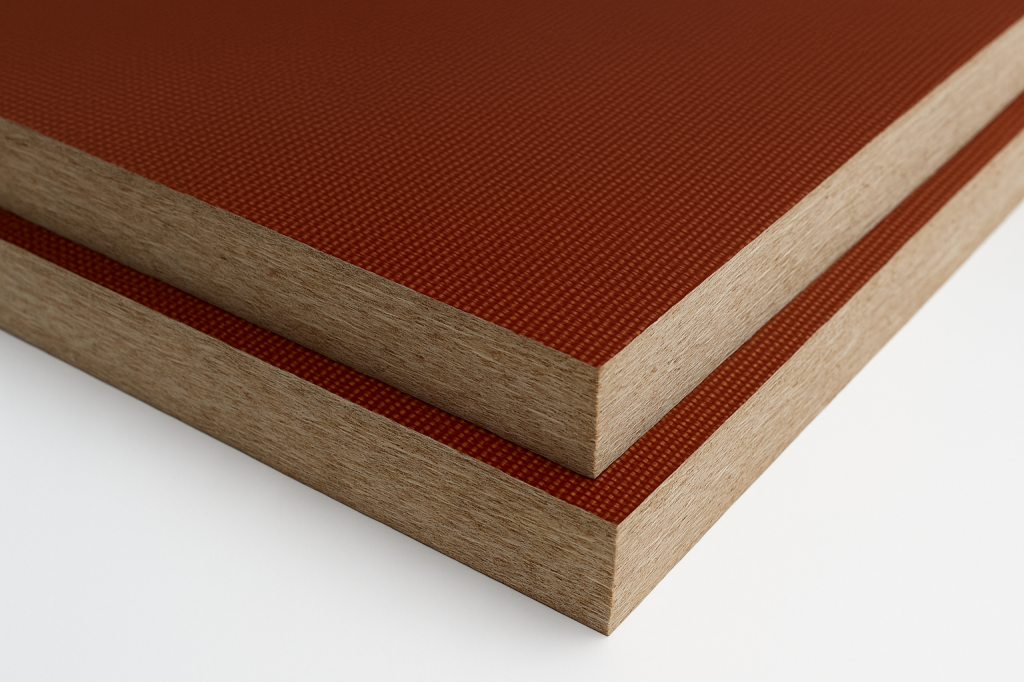

GPO-3 fiberglass sheet and rod are engineered thermoset polyester laminates reinforced with glass mat, designed to meet the rigorous demands of electrical insulation and structural applications. Known for their superior arc and track resistance, flame retardancy, and mechanical strength, GPO-3 materials are a reliable choice for various industries.

Manufactured under high-pressure and high-temperature conditions, these sheets and rods exhibit excellent dimensional stability and maintain their properties under thermal and electrical stress. Their low smoke generation and toxicity levels make them suitable for use in environments where safety and compliance are paramount.

Commonly utilized in electrical equipment, transportation systems, and industrial machinery, GPO-3 sheet and rod provide dependable performance in challenging conditions.

| Grade | Composite Type | Certifies |

|---|---|---|

| GPO-3 | Glass Polyester Laminate | Mil-I-24768/6 (GPO3) |

| GPO-2 | Glass Polyester Laminate | Mil-I-24768/5 (GPO2) |

| GPO-1 | Glass Polyester Laminate | Mil-I-24768/4 (GPO1) |

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of GPO-3 Fiberglass Sheets & Rods

GPO-3 fiberglass sheet and rod offer a combination of properties that make them ideal for demanding applications:

Electrical Insulation: High dielectric strength suitable for high-voltage applications.

Flame Retardant: Meets UL 94 V-0 standards for flame resistance.

Arc and Track Resistance: Excellent resistance to electrical arcing and tracking.

Mechanical Strength: High tensile and flexural strength for structural applications.

Thermal Stability: Operates effectively in temperatures up to 155°C.

Low Smoke Emission: Minimal smoke generation and toxicity in fire conditions.

Moisture Resistance: Low water absorption ensures performance in humid environments.

Benefits of GPO-3

Applications of GPO-3 Fiberglass Sheet & Rod

GPO-3 sheet and rod are versatile materials used across multiple industries:

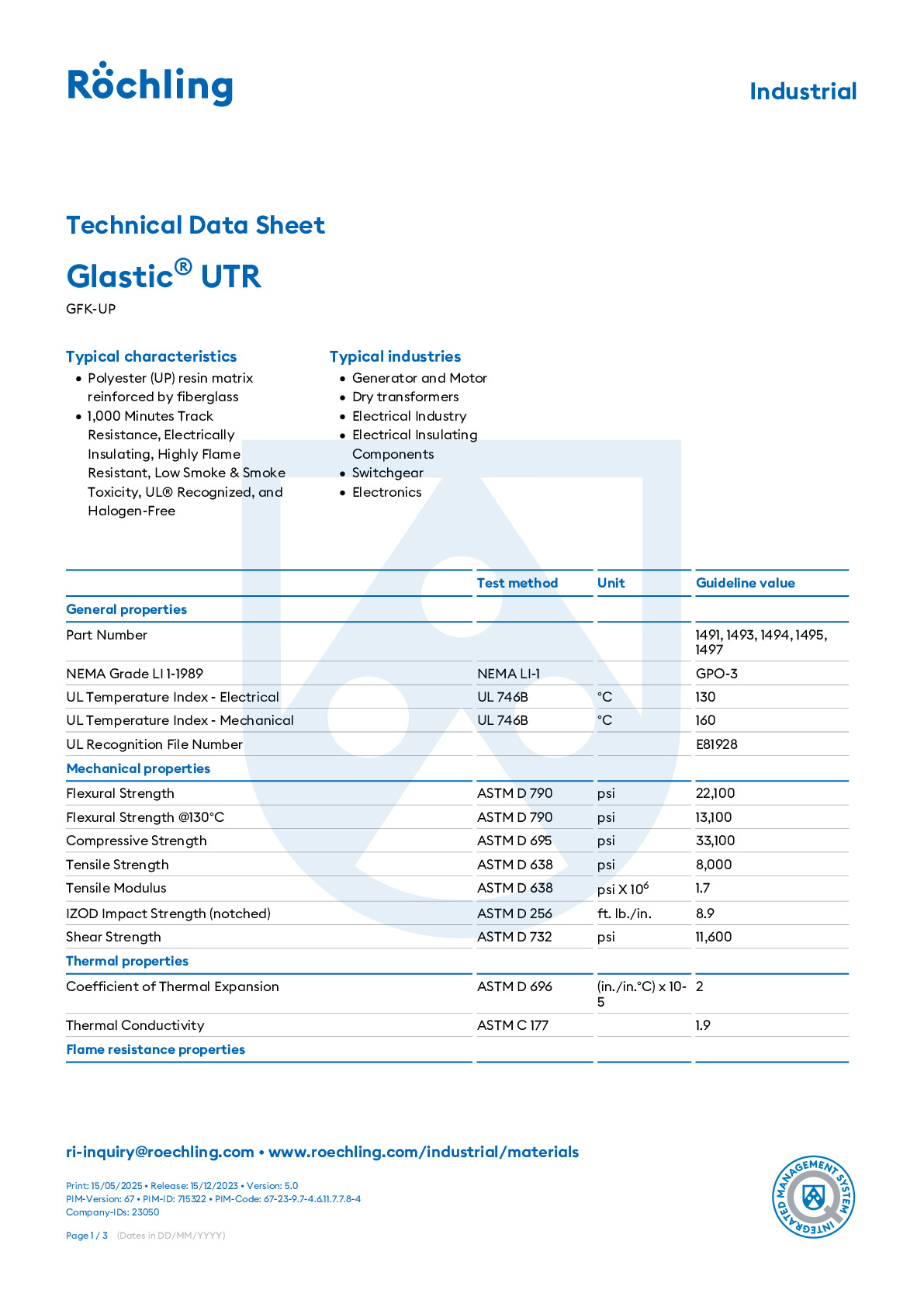

Electrical Industry: Insulating barriers, standoff insulators, bus bar supports, switchgear components, and transformer parts.

Transportation: Components in rail systems and electric vehicles requiring flame retardancy and low smoke emission.

Industrial Machinery: Structural supports and insulating parts in heavy-duty equipment.

Renewable Energy: Insulation in wind turbines and solar power systems.

Construction: Fire-resistant panels and insulating materials in buildings.

These applications, and many others, benefit from GPO-3’s unique combination of electrical insulation, flame resistance, and mechanical strength, making it a trusted material across multiple industries. Whether used to enhance safety in electrical systems or provide structural support in industrial environments, GPO-3 delivers reliable, high-performance solutions.

Related Materials

-

Phenolic

Phenolic is a durable industrial laminate used for terminal boards, antenna insulators, printed circuit boards, washers, spacers, cams, inserts, bushings, and more.

-

G10/FR-4

Ideal for electrical, aerospace, and industrial applications, G10/FR-4 glass epoxy offers superior strength, electrical insulation, and durability.

Frequently Asked Questions About GPO-3

Have questions about GPO-3? You’re not alone. In this section, we’ve compiled answers to some of the most common questions about GPO-3 sheet and rod. Whether you’re specifying materials for electrical equipment or planning a custom fabrication project, this FAQ will help guide your decision-making.

GPO-3 is a glass mat-reinforced thermoset polyester laminate known for its excellent electrical insulation, flame resistance, and mechanical strength. It's commonly used in electrical and industrial applications.

GPO-1 is a general-purpose fiberglass-reinforced thermoset laminate with basic electrical insulation and mechanical strength, suitable for non-critical applications. GPO-2 offers improved dielectric strength and arc resistance compared to GPO-1, making it ideal for electrical insulation in low- to medium-voltage systems. GPO-3 is the highest-performing grade, featuring flame retardancy (UL 94 V-0), superior arc and track resistance, and excellent mechanical and electrical properties, making it the preferred choice for high-demand applications like switchgear, transformers, and transportation components.

GPO-3 uses polyester resin with chopped glass mat and is flame-retardant (UL 94 V-0), ideal for electrical insulation and structural applications. G10 uses epoxy resin with woven fiberglass cloth, offering higher strength and moisture resistance but no flame rating. GPO-3 is best for switchgear and enclosures; G10 is preferred for PCBs and precision parts.

Yes, their resistance to moisture and environmental factors makes them suitable for certain outdoor applications.

Yes, GPO-3 can be machined using standard tools. However, due to its fiberglass content, it can be abrasive on cutting tools, so appropriate tooling and precautions are recommended. Piedmont Plastics can cut your material to size or help with fabrication upon request.

Yes, GPO-3 meets several industry standards, including NEMA GPO-3, UL 94 V-0 for flame resistance, and MIL-I-24768/6.

Why Buy GPO-3 from Piedmont Plastics?

At Piedmont Plastics, we offer more than just material. We deliver complete GPO-3 solutions designed to meet the demands of electrical, industrial, and structural applications. Here’s what sets us apart:

Extensive Inventory: We carry a wide selection of GPO-3 sheets and rods in various sizes and thicknesses to suit diverse insulation and support needs.

Custom Fabrication Capabilities: Our advanced fabrication services, including precision cutting, ensure your GPO-3 components are made to your exact specifications.

Industry Expertise: With decades of experience in high-performance materials, our team helps you choose the right GPO-3 solution for your project’s requirements.

Nationwide Reach: With branch locations across North America, we provide fast, reliable access to GPO-3 wherever your operations are based.

Reliable Quality: Our GPO-3 products meet or exceed industry standards for flame resistance, electrical insulation, and mechanical strength, ensuring safety and performance you can trust.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745