Ideal for electrical, aerospace, and industrial applications, G10/FR-4 glass epoxy offers superior strength, electrical insulation, and durability.

G10/FR-4

A strong composite material that consists of glass fabric, electrical grade epoxy resin.

Product Overview

Widely used for:

Performance Characteristics:

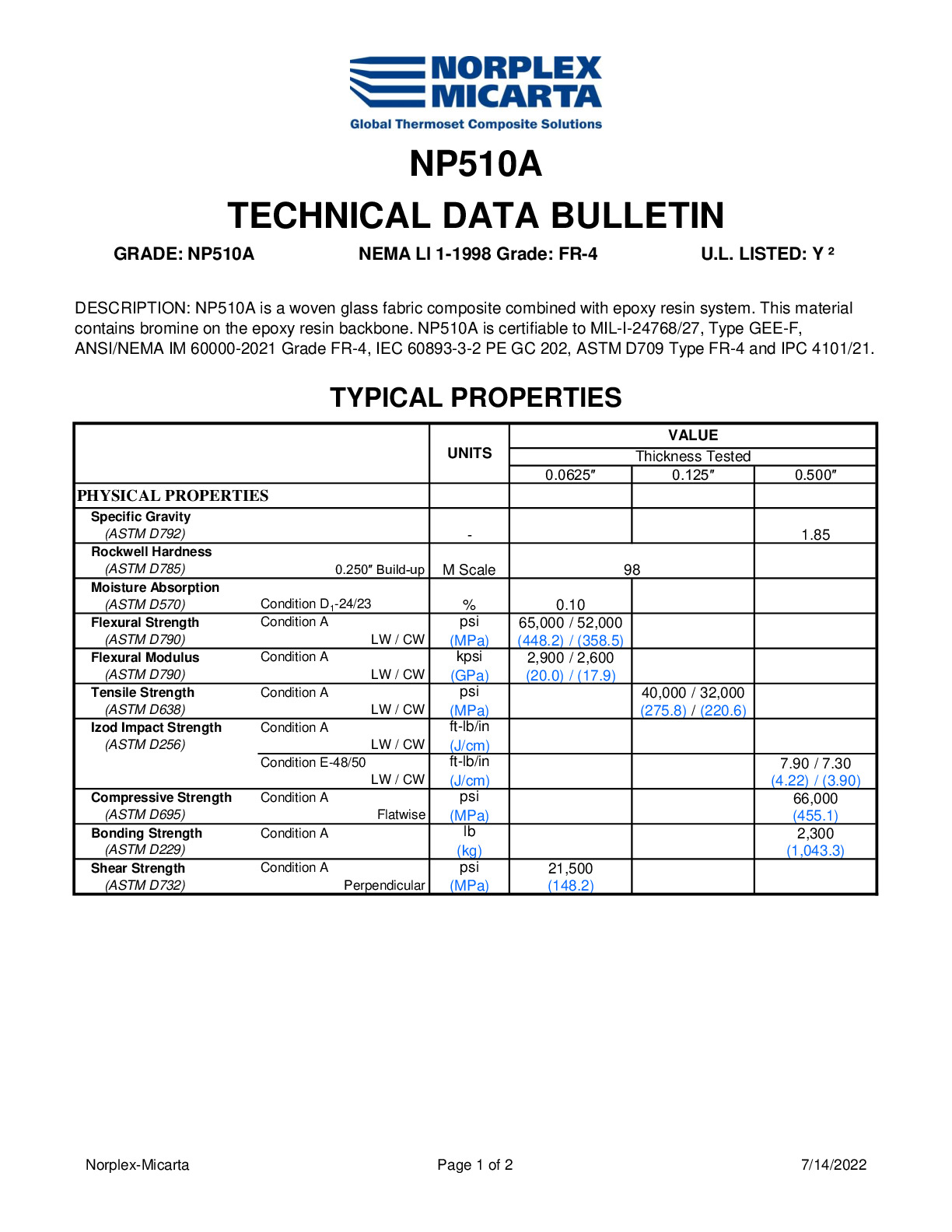

Typical Properties of G10/FR-4

Common Properties

- Typical Thickness Size 0.010 to 2 in

- Friendly Names Glass Epoxy, Epoxy Fiberglass, Industrial Laminate N/A

- Typical Lengths 12 to 48 in

- Typical Rod Diametes 0.062 to 6 in

- Common Brand Names Micarta® N/A

- Common Profiles Sheet, Rod, Tube N/A

- Typical Widths 12 to 48 in

Electrical Properties

- Breakdown Voltage 35 kV

- Electrostatic Discharge (ESD) Sensitivity Low Qualitative

- Dielectric Constant 4.8 Dimensionless

- Thermal Coefficient of Dielectric Constant ±0.02 1/°C

- Arc Resistance 120 sec

- Comparative Tracking Index (CTI) 175 V

- Surface Resistivity 1 x 10^8 ohm/sq

- Volume Resistivity 1 x 10^8 ohm-cm

- Dissipation Factor 0.017 Dimensionless

- Dielectric Strength 450 V/mil

Mechanical Properties

- Tensile Strength, Yield 35 ksi

- Shear Strength 10 ksi

- Izod Impact, Notched 12 ft-lb/in

- Flexural Modulus 2.5 Msi

- Compressive Yield Strength 60 ksi

- Flexural Yield Strength 50 ksi

- Bearing Yield Strength 30 ksi

- Modulus of Elasticity 2.5 Msi

- Tensile Strength, Ultimate 35-45 ksi

- Hardness 110 Rockwell R

- Elongation at Break 1 %

Physical Properties

- Melt Flow 10 g/10 min

- Linear Mold Shrinkage 0.5 %

- Density 1.80 g/cm^3

- Water Absorption 0.1 %

- Moisture Absorption at Equilibrium 0.2 %

Regulation Properties

Thermal Properties

- Max Continuous Operating Temperature 266 °F

- Vicat Softening Point >=347 °F

- CTE, linear, Transverse to Flow 16 µin/in/°F

- Deflection Temperature at 0.46 MPa (66 psi) 284 °F

- Deflection Temperature at 1.8 MPa (264 psi) 244 °F

- Flammability V-0 UL94

- Minimum Operating Temperature -58 °F

- CTE, linear 9 µin/in/°F

- Thermal Conductivity 0.29 W/mK

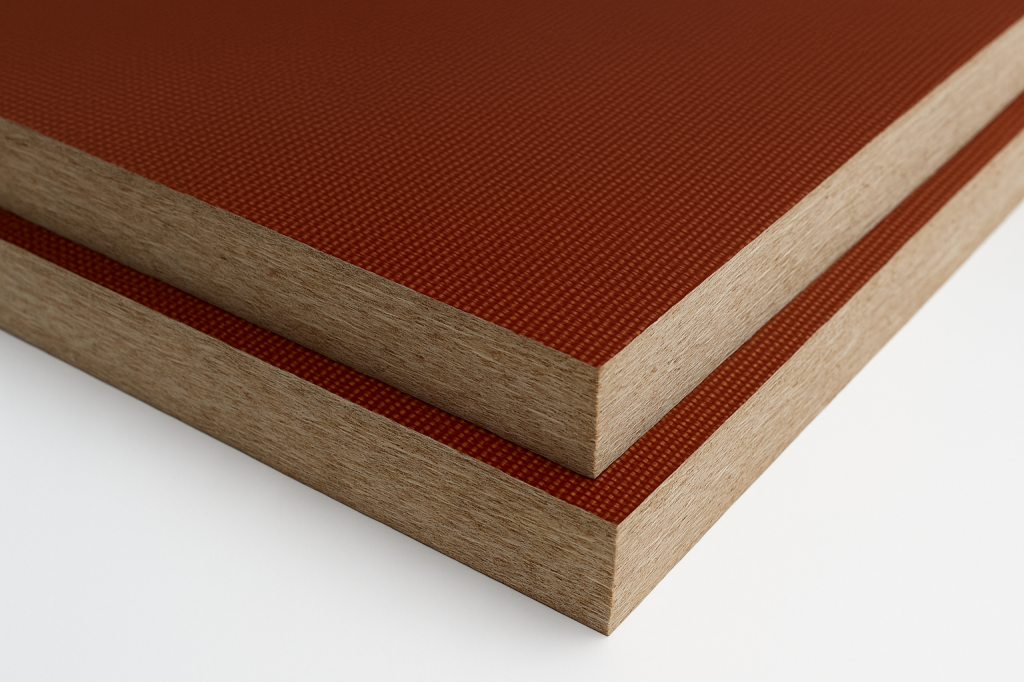

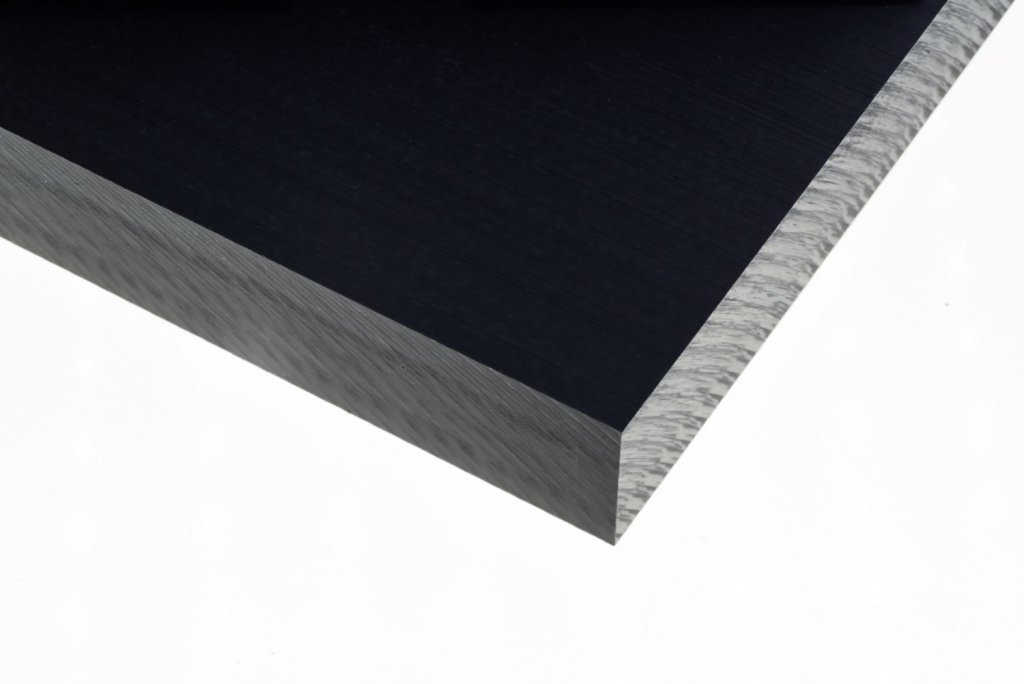

Premium G10 and FR-4 sheet and Rod for Demanding Applications

G10/FR-4 glass epoxy are high-pressure fiberglass laminates made by stacking multiple layers of glass cloth saturated with epoxy resin and compressing them under heat and pressure. Known for their exceptional mechanical strength, low moisture absorption, and excellent electrical insulating properties, G10 and FR4 materials are trusted in a wide range of demanding environments.

While G10 and FR4 are mechanically identical, FR4 is distinguished by its flame-retardant properties, making it ideal for electrical and electronic applications requiring fire safety compliance. These fiberglass laminates maintain stability across a wide temperature range and perform reliably in harsh operating conditions.

Commonly used in printed circuit boards (PCBs), electrical enclosures, mechanical insulation, and aerospace components, G10/FR4 sheets offer unmatched versatility. Whether for structural support, electrical insulation, or chemical resistance, G10 and FR4 fiberglass laminates deliver reliable performance across industries.

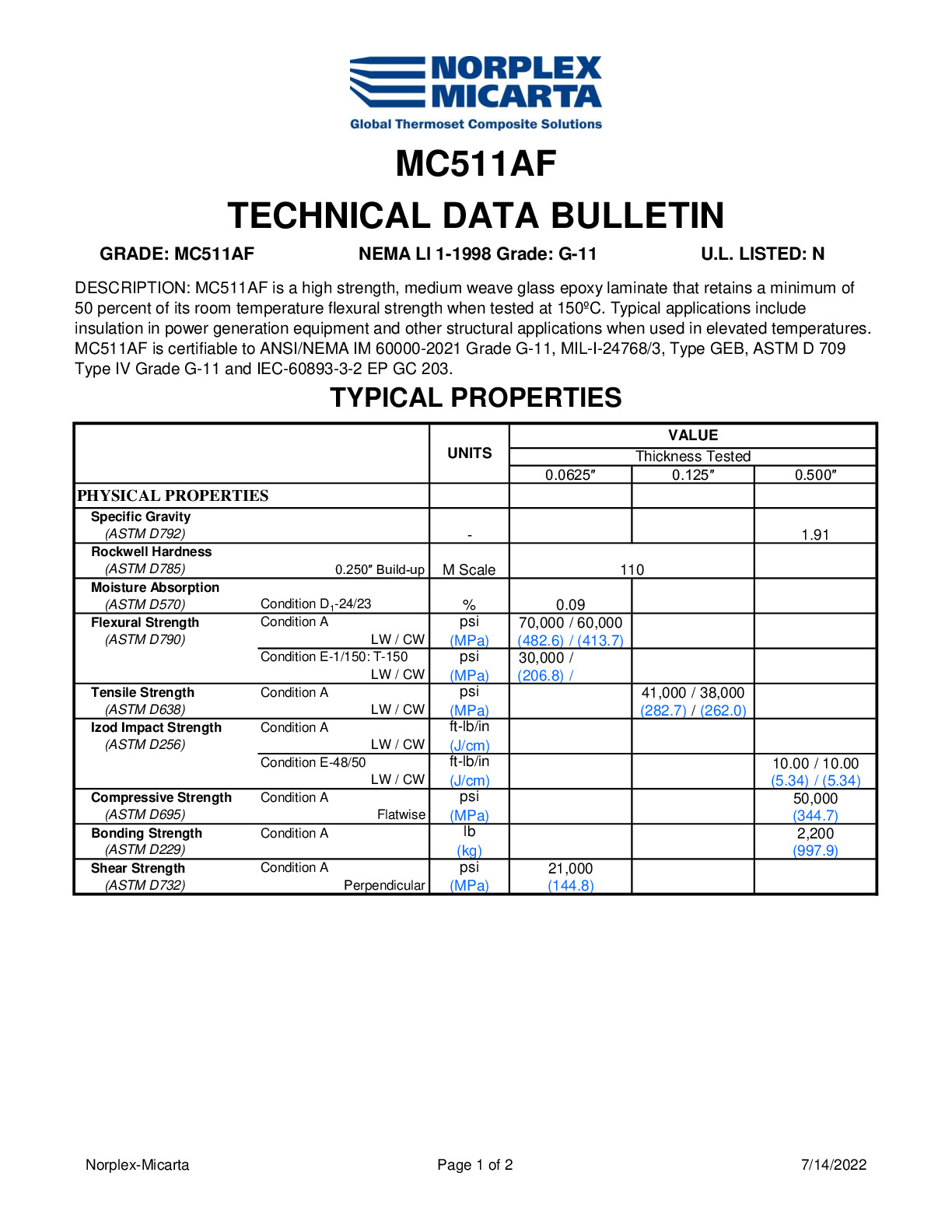

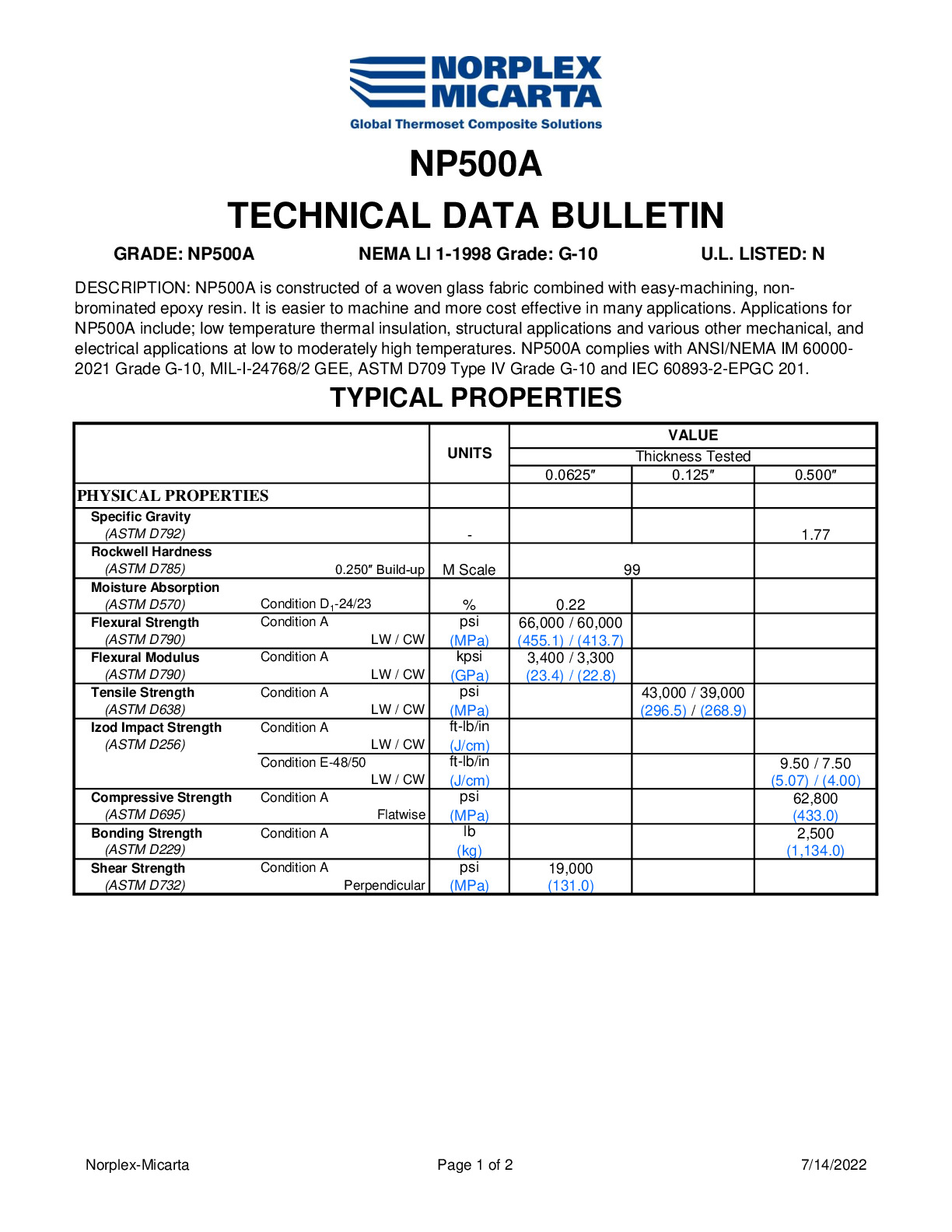

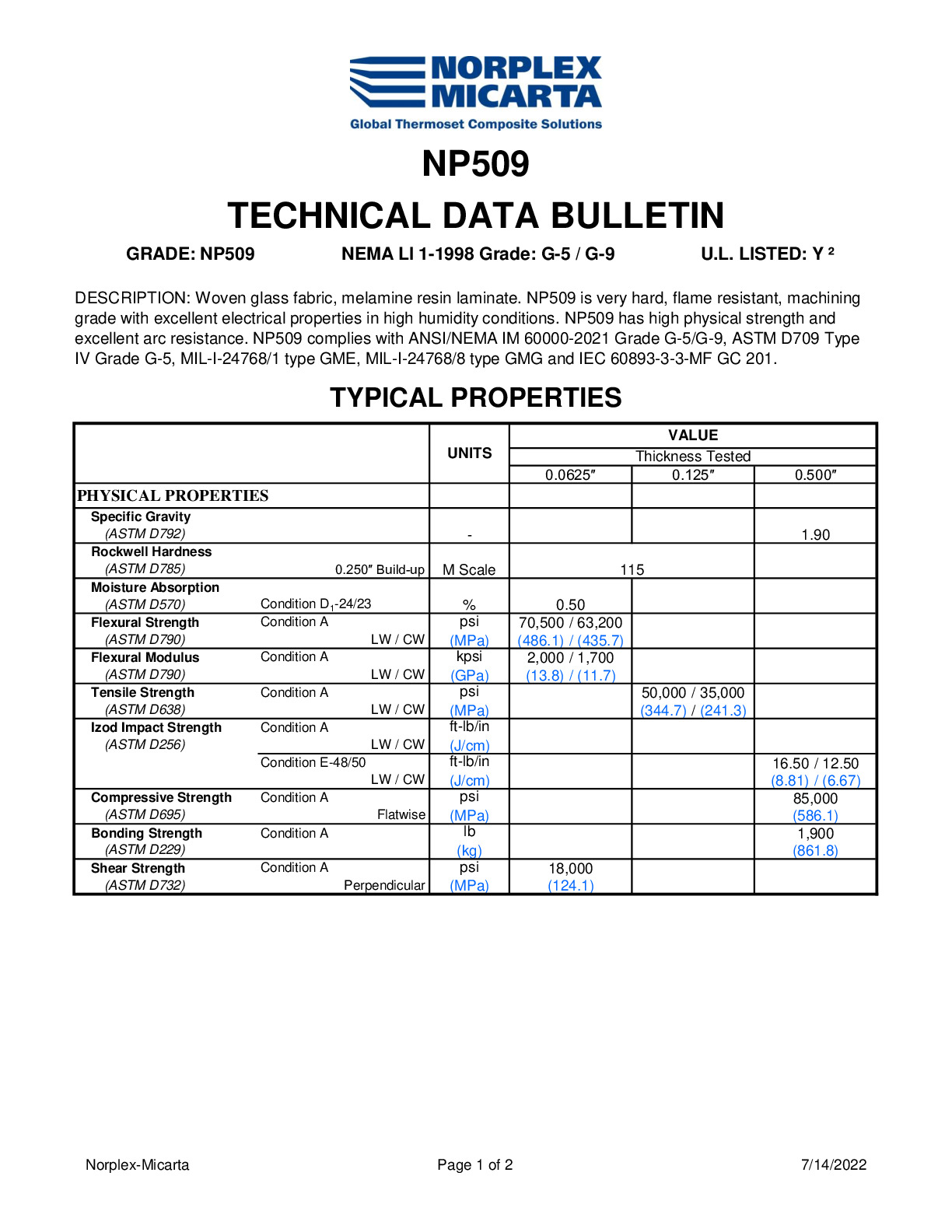

| Grade | Composite Type | Certifies |

|---|---|---|

| G-10 | Glass Epoxy Laminate | MIL-I-24768/2 (GEE) |

| G-11 | Glass Epoxy Laminate | MIL-I-24768/3 (GEB) |

| FR4 | Glass Epoxy Laminate | MIL-I-24768/27 (GEE-F) |

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Our G10/FR4 Sheets

Electrical Insulation: G10/FR4 material is highly valued for its outstanding dielectric strength, making it ideal for insulating electrical components and protecting against current leakage.

Mechanical Strength and Dimensional Stability: These fiberglass laminates maintain their shape and strength under mechanical stress, ensuring reliable performance even under load, impact, or vibration.

Flame Retardant (FR4 Material Complies with UL94 V-0 Standard): FR4 sheet meets stringent fire safety standards, providing critical flame resistance that is essential in electrical, aerospace, and industrial applications.

Low Water Absorption and Chemical Resistance: G10/FR4 maintains its structural and electrical properties even in moist or chemically aggressive environments, offering long-term durability.

Easy to Machine, Cut, and Fabricate: G10/FR4 can be precision machined using conventional tools, allowing for efficient customization without compromising material integrity.

Reliable Performance Across Temperatures: G10/FR4 withstands a wide range of operating temperatures, maintaining its electrical insulation and mechanical properties even under thermal stress.

Lightweight and Corrosion-Resistant: Despite its high strength, G10/FR4 is lightweight and naturally resists corrosion, making it easier to handle and ideal for harsh or outdoor environments.

Benefits of G10 & FR-4 Glass Epoxy Laminates

Applications of G10/FR4

G10 and FR4 are trusted across a wide range of industries where strength, insulation, and reliability are critical. Their unique combination of mechanical and electrical properties makes them ideal for both standard and high-performance applications.

Electrical and electronic components, including PCB boards

High-voltage insulation barriers

Aerospace and aviation structural supports

Marine and offshore applications requiring chemical resistance

Industrial machine parts and insulation panels

Battery and power distribution equipment

Medical device components

No matter the complexity of your project, G10 and FR4 laminate offer the durability and versatility needed to deliver lasting results.

Related Products

-

Phenolic

Phenolic is a durable industrial laminate used for terminal boards, antenna insulators, printed circuit boards, washers, spacers, cams, inserts, bushings, and more.

-

GPO-3

GPO-3 is a flame-retardant fiberglass laminate ideal for electrical insulation, structural support, and high-heat environments

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

Frequently Asked Questions

If you’re considering G10/FR4 for your next project, you may have questions about its properties, uses, and performance. Below, we’ve answered some of the most frequently asked questions to help you better understand how G10/FR4 fiberglass laminate can meet your technical and application needs.

G10 and FR4 are both high-pressure laminate materials made with woven glass fabric and epoxy resin. The key difference is that FR4 is flame retardant, meeting the UL94 V-0 fire safety standard, while G10 is not.

GPO-3 uses polyester resin with chopped glass mat and is flame-retardant (UL 94 V-0), ideal for electrical insulation and structural applications. G10 uses epoxy resin with woven fiberglass cloth, offering higher strength and moisture resistance but no flame rating. GPO-3 is best for switchgear and enclosures; G10 is preferred for PCBs and precision parts.

Yes, G10/FR4 sheets are easily machinable using standard tools such as routers, mills, and saws. The material cuts cleanly and can be drilled or shaped with precision, making it ideal for custom components and complex part geometries. Piedmont Plastics can also assist with cut-to-size services.

Yes, both G10 and FR4 materials exhibit low moisture absorption and excellent resistance to humidity. This makes them ideal for use in environments with high moisture or condensation, such as marine, outdoor, or HVAC applications.

G10/FR4 is used across a wide range of industries, including electronics, aerospace, marine, automotive, industrial equipment, medical devices, and telecommunications. It’s commonly found in applications such as circuit boards, electrical insulators, structural supports, gaskets, terminal boards, and switchgear components—anywhere that requires a high-strength, electrically insulating, and dimensionally stable material.

Piedmont Plastics is a trusted G10 and FR4 supplier with branches nationwide. Find your nearest location to order G10/FR4 laminates for your project.

Why Buy G10/FR-4 from Piedmont Plastics?

At Piedmont Plastics, we offer more than just materials; we deliver complete G10/FR4 solutions tailored to your unique needs. Here’s why we are your trusted source for high-performance G10/FR4 fiberglass laminates:

Extensive Product Selection: Our inventory features a wide range of G10/FR4 sheet and rod sizes and thicknesses, ensuring you have the right material for electrical, aerospace, industrial, and mechanical applications.

Custom Cut and Fabrication Services: Using advanced CNC technology, we provide precision cutting and fabrication services to deliver G10/FR4 components manufactured exactly to your specifications.

Proven Expertise: Backed by decades of industry experience, our knowledgeable team is ready to assist you in selecting the ideal G10 or FR4 material for your project’s specific requirements.

Nationwide Availability: With a vast network of branches across North America, our high-quality G10/FR4 sheet and rods are always within reach, ensuring fast delivery and reliable local support.

Commitment to Quality: We uphold strict quality standards, ensuring that every G10/FR4 product we supply meets or exceeds industry specifications for performance, safety, and durability.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745