G10 fiberglass laminate is a high-performance thermoset material engineered for demanding electrical and mechanical applications. With its unique balance of strength, insulation, and durability, G10 has become a go-to material across multiple industries. Whether you're an engineer specifying materials for electrical enclosures or a purchaser sourcing reliable sheet stock, this guide covers everything you need to know about G10 fiberglass laminate.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Is G10 Fiberglass Laminate?

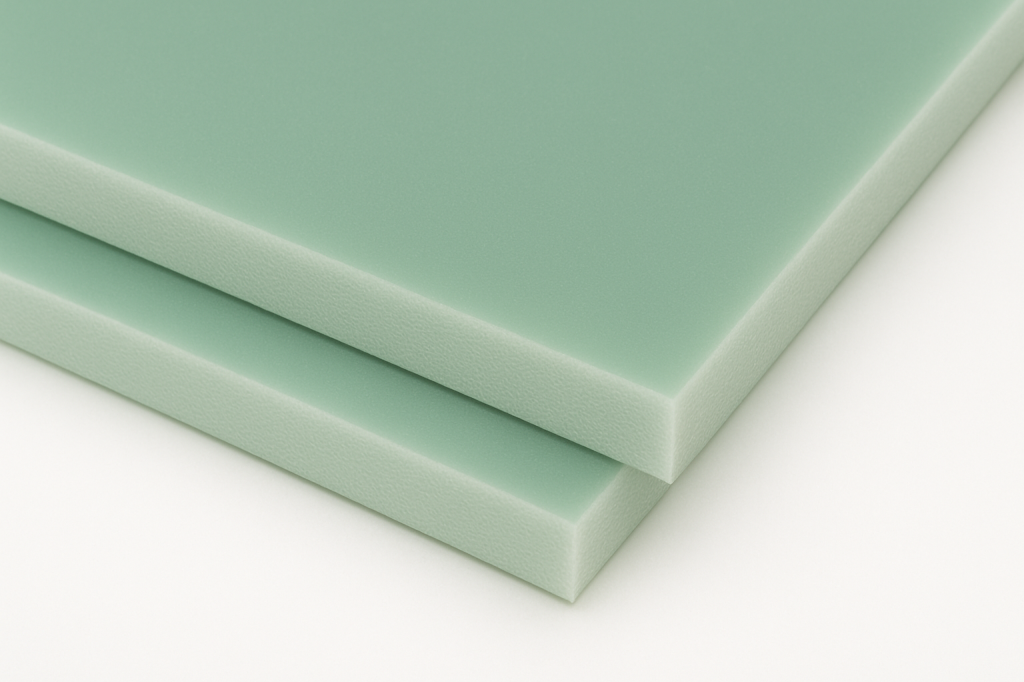

G10 is a fiberglass-reinforced epoxy laminate made by stacking layers of woven glass cloth soaked in epoxy resin, then compressing them under heat and pressure. The result is a rigid, tough material with excellent electrical insulating properties and mechanical strength.

Key Properties of G10:

High dielectric strength

Excellent mechanical durability

Moisture resistance

Chemical resistance

Dimensional stability under heat and pressure

Flame retardant variants (G10/FR4)

This combination makes G10 ideal for applications that require both structural performance and electrical insulation.

Top Applications for G10 Sheet

G10’s unique material properties make it suitable for a wide range of industries and applications:

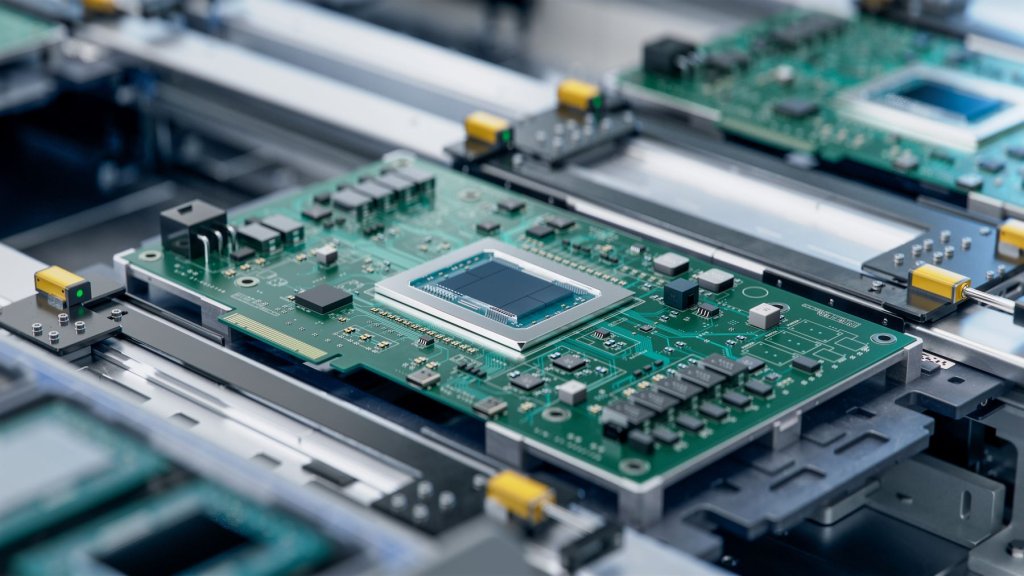

1. Electrical Insualtion

- Circuit board backers

- Switchgear and power equipment

- Bus bar insulation

- Arc shields

2. Aerospace and Defense

- Lightweight structural components

- Thermal and electrical isolation in aircraft systems

3. Industrial Equipment

- Gaskets and washers

- Load-bearing support panels

- Custom-machined parts

4. Oil and Gas

- Downhole insulation

- Tool insulation in high-heat, high-pressure environments

5. Transportation

- Battery enclosures

- High-voltage component protection

- Vibration-resistant structural panels

G10 vs. FR4: A Common Comparison

Choose G10 if:

Choose FR4 if:

G10 vs. Phenolic Materials: What’s the Difference?

While phenolic laminates and G10 are both used in electrical and industrial applications, they differ significantly in performance and composition.

| Feature | G10 Fiberglass Laminate | Phenolic Laminates |

|---|---|---|

| Reinforcement | Woven fiberglass | Paper, cotton, or glass cloth |

| Resin Type | Epoxy | Phenolic |

| Electrical Insulation | Excellent | Moderate to high (depending on type) |

| Moisture Resistance | High | Moderate |

| Mechanical Strength | High | Moderate to high |

| Machinability | Excellent | Good |

| Cost | Higher | Lower |

Bottom Line:

Phenolic materials may be more cost-effective for basic mechanical applications, but G10 offers superior strength, moisture resistance, and electrical insulation, making it the better choice for high-performance environments.

Common Sheet Sizes and Specifications

G10 fiberglass sheets are typically available in:

Thicknesses: From 0.010” up to 2.00”

Sheet Sizes: 36” x 48”, 48” x 96”, and custom-cut sizes

Color: Most commonly green or yellow-green

These sheets can be machined, milled, drilled, and laser cut to fit custom specifications. Piedmont Plastics offers cut-to-size services to ensure fast, precise fabrication.

Why Engineers and Purchasers Choose G10

G10 is more than just a strong plastic. It's a proven solution for engineers who need reliability in the field and for purchasers who demand consistency in quality and supply.

Benefits at a Glance:

Long-term performance in harsh environments

Easy to machine for custom components

Ideal for insulating, supporting, and protecting electrical systems

Readily available in various thicknesses and sheet sizes

G10 Fiberglass Laminate at Piedmont Plastics

At Piedmont Plastics, we carry a wide selection of G10 fiberglass sheet in standard and custom sizes. Our nationwide branch network ensures fast delivery, and our experienced team provides support for applications, material selection, and value-added services, including cut-to-size and fabrication.

We Offer:

A wide range of G10 thicknesses and grades

Precision fabrication and CNC cutting

Technical support for application-specific needs

Alternative materials like FR4 and phenolic sheet, if G10 is over-specified

Let’s Talk G10 Solutions

Need high-performance electrical insulation or custom-machined G10 components? Piedmont Plastics is your trusted source. With expert support and flexible distribution, we make it easy to get the G10 solutions you need, delivered on time and cut to spec.

Get A Quote