Heavy equipment and agricultural machinery operate in some of the most punishing industrial environments. Constant abrasion, shock loads, vibration, moisture, UV exposure, and temperature swings demand materials that can withstand long service cycles with minimal maintenance. For engineers, OEM manufacturers, and fabricators, material selection is only half the equation. The ability to turn those materials into precision-machined, ready-to-install components is just as critical.

That’s why performance plastics such as nylon and UHMW are widely specified for heavy equipment and agricultural applications, and why working with a supplier that also provides fabrication and machining support can significantly streamline production.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Why Fabrication Matters in Heavy Equipment Design

In heavy equipment manufacturing, components rarely come straight off the shelf. Wear parts, guides, bearings, and structural elements must be machined to exact tolerances to ensure proper fit, function, and longevity.

Sourcing raw plastic material from one vendor and machining from another can introduce longer lead times, inconsistent material performance, higher costs, and supply chain complexity. By contrast, a supplier that provides both material and fabrication services helps OEMs and fabricators reduce risk and improve efficiency.

Nylon: A Go-To Material for Machined Load-Bearing Parts

Nylon is a foundational engineering plastic in heavy equipment and agricultural machinery due to its strength, wear resistance, and machinability.

Why Engineers Choose Nylon:

High tensile and compressive strength

Excellent wear resistance under load

Good fatigue performance

Stable machining characteristics

Available in cast, extruded, oil-filled, and glass-filled grades

Commonly Fabricated Nylon Components

Rather than purchasing nylon only as sheet or rod, many customers rely on fully machined nylon components designed for direct installation. Commonly fabricated nylon parts include sheaves and pulleys, bearings and bushings, wear rings and thrust washers, spacers and guides, and custom structural components. These nylon parts are widely used in harvesters, balers, loaders, conveyors, and material-handling systems, where they help reduce weight, minimize noise, and lower maintenance requirements compared to traditional metal alternatives.

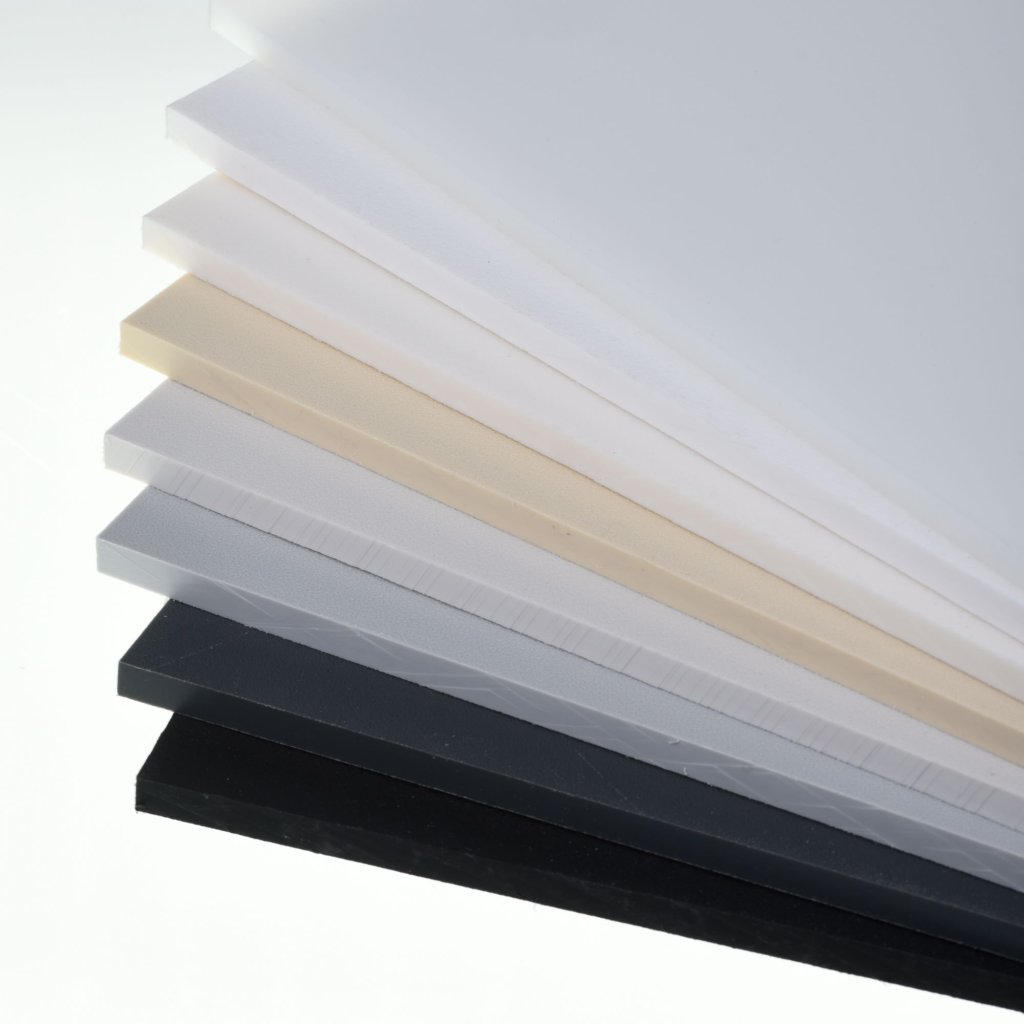

Cast Nylon vs. Extruded Nylon in Heavy and Agricultural Equipment

Both cast nylon and extruded nylon are widely used in heavy equipment and agricultural machinery due to their durability and performance in demanding environments. While they share many core material properties, each form offers advantages that make it better suited for specific applications and fabrication requirements.

Cast Nylon: Designed for Large, High-Load Components

Cast nylon is produced by polymerizing the material directly into molds, allowing for thicker sections, larger part sizes, and reduced internal stress. These characteristics make cast nylon well suited for heavy-duty components exposed to high loads and continuous wear.

Why engineers specify cast nylon:

Excellent load-bearing capability

High wear resistance under compressive stress

Improved vibration and noise dampening

Available in large diameters and thick plates

Typical cast nylon applications include sheaves, pulleys, slide plates, wear plates, chain guides, large wear rings, and structural components. In agricultural and heavy equipment, cast nylon is commonly used in slower-moving, heavily loaded applications where long service life and durability are critical.

Extruded Nylon: Precision and Machinability for Tighter Tolerances

Extruded nylon is manufactured in continuous lengths, resulting in consistent dimensions and predictable machining behavior. This makes it a strong choice for smaller components or parts requiring tighter tolerances.

Why extruded nylon is selected:

Consistent mechanical properties

Easier to machine to precise tolerances

Good wear and fatigue resistance

Cost-effective for smaller, repeatable parts

Common extruded nylon applications include bushings, bearings, spacers, sleeves, structural support components, guides, and wear parts with precise fit requirements. Extruded nylon is often used in rotating or moderate-load applications where dimensional accuracy and repeatability are more important than large cross-section strength.

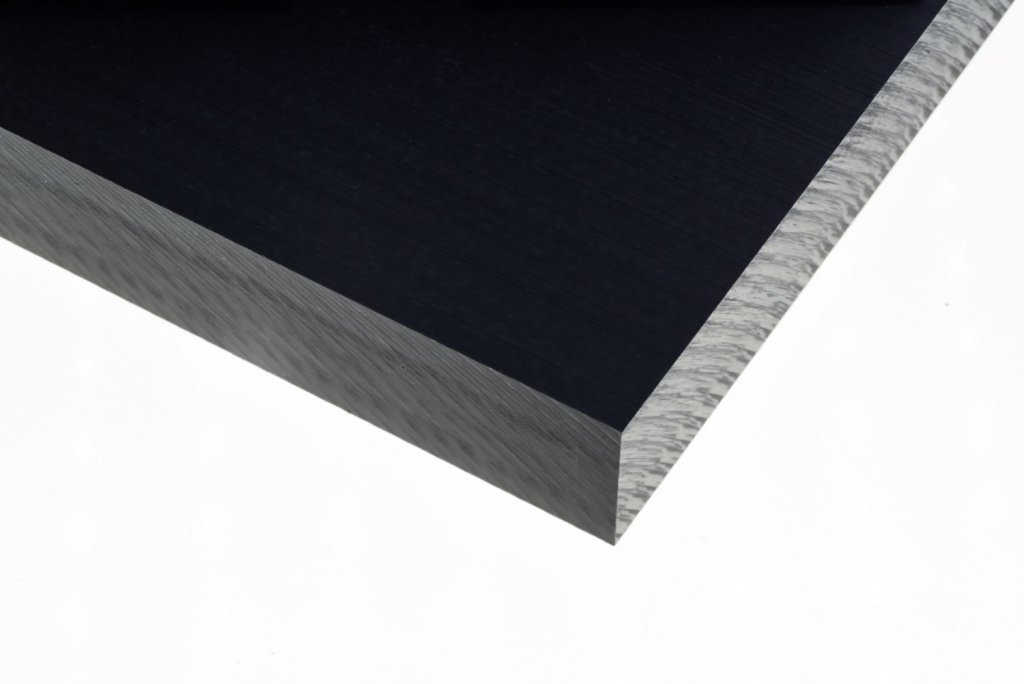

UHMW: Fabricated Wear Parts for Extreme Abrasion

UHMW is best known for its exceptional abrasion resistance and low coefficient of friction, making it ideal for high-wear, sliding, and impact-prone applications.

UHMW Performance Advantages:

Outstanding resistance to abrasion and sliding wear

Extremely low coefficient of friction

Excellent impact resistance, even in cold environments

Moisture, chemical, and corrosion resistance

UHMW Parts That Benefit from Fabrication

UHMW is rarely used as-is. Instead, it is most effective when machined into application-specific components such as wear pads, wear strips, chain guides, slide rails, chute liners, guide blocks, and track components.

Precision machining ensures consistent thickness, mounting features, and repeatability, which are critical for OEM production and replacement parts programs.

Where UHMW Fits Alongside Nylon

While cast and extruded nylon excel in load-bearing and structural applications, UHMW plays an equally important role in heavy equipment and agricultural machinery, particularly where sliding wear and abrasion dominate.

In heavy equipment designs, nylon and UHMW are often used together. While nylon works well for structural or load-bearing parts, UHMW is terrific for sacrificial wear surfaces that protect metal and extend equipment life.

Supporting Plastics and Machined Components

In addition to nylon and UHMW, heavy equipment designs often incorporate other performance plastics that benefit from fabrication services.

Other Plastics Used In Heavy Equipment Applications

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

-

HDPE (High Density Polyethylene)

HDPE offers strength, low weight, and resistance to chemicals and moisture, making it ideal for food and beverage equipment, industrial components, and marine applications.

-

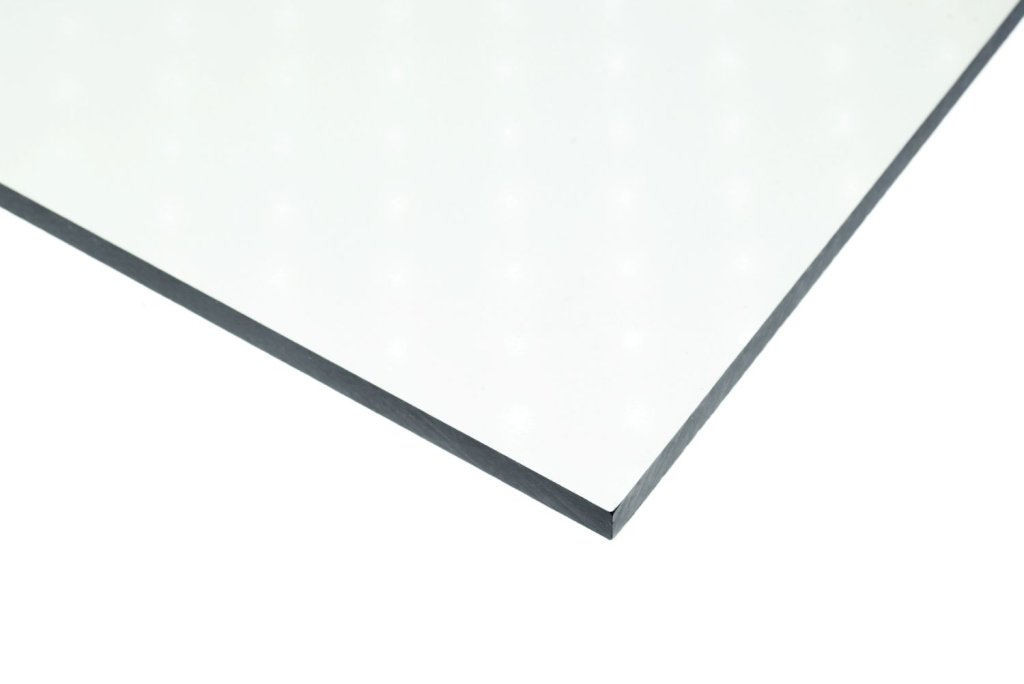

Polycarbonate

Polycarbonate is a high-performance, impact-resistant thermoplastic known for its clarity, strength, and weatherability, making it suitable for applications such as eyewear lenses, bullet-resistant glass, construction materials, and automotive parts.

-

PETG

Strong and versatile, PETG plastic sheet can be used in various applications, including signage, displays, medical implants, and beverage containers.

-

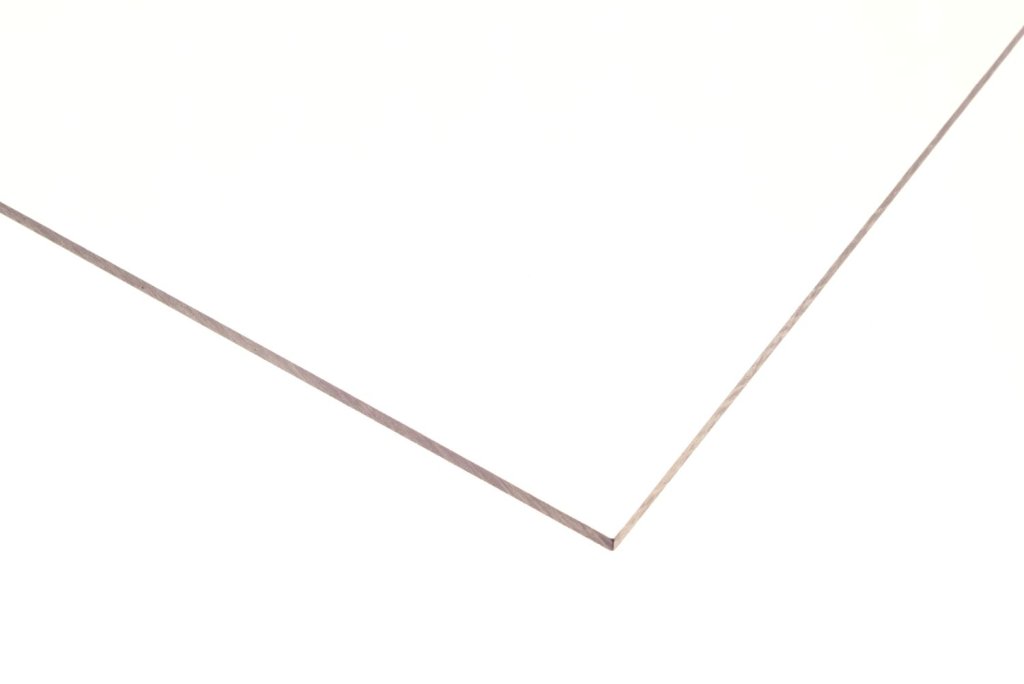

Specialty Acrylic Sheet

Specialty acrylic sheet offers enhanced durability, UV protection, and glare or impact resistance that are ideal for demanding optical, display, and security applications.

Acetal (POM) is commonly specified for applications requiring tight tolerances, low moisture absorption, and excellent bearing performance. In comparison, HDPE is valued for its impact resistance and chemical stability, making it well suited for demanding environments. When transparency and impact strength are required, polycarbonate is frequently used for protective glazing applications. Meanwhile, PETG and acrylic are often selected for lightweight, clear panels and machine guards where visibility and ease of fabrication are important.

These materials are often machined into rings, gaskets, spacers, guards, and enclosures that must meet strict dimensional and performance requirements.

Performance Glazing: Fabricated for Fit and Safety

Operator visibility and safety are critical in agricultural and construction equipment. Performance glazing materials, especially polycarbonate, are commonly cut, machined, and formed to meet specific cab and enclosure designs.

Fabricated Glazing Applications:

Tractor and combine cab windows

Skid steer and loader enclosures

Equipment guards and shields

Inspection windows and access panels

Fabrication allows glazing panels to be delivered cut-to-size, drilled, edge-finished, and ready for installation, saving OEMs time and labor.

Piedmont Plastics: Your One-Stop Shop for Material and Fabrication

What truly sets Piedmont Plastics apart in the heavy equipment and agricultural market is the ability to support customers from material selection through finished part fabrication.

Fabrication Capabilities That Support This Industry

Piedmont Plastics provides value-added services designed specifically for industrial and OEM customers, including:

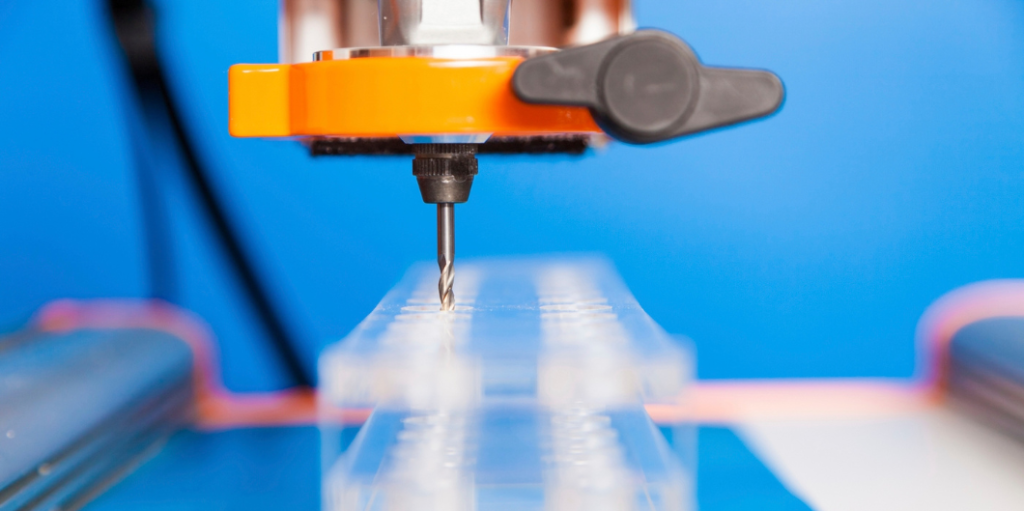

CNC machining

Prototyping and short production runs

Repeatable production support

Whether you need UHMW wear pads machined to print, nylon sheaves produced in volume, or custom plastic components for a new equipment design, Piedmont helps eliminate the gap between raw material and finished part.

Simplifying Procurement for OEMs and Fabricators

By combining material supply and fabrication, Piedmont Plastics helps customers reduce vendor count and shorten lead times, improving consistency and quality. Our team can also help simplify inventory management and accelerate time to market. This one-stop-shop approach is especially valuable for OEMs supporting both new equipment builds and after-market replacement parts.

Engineering Support Beyond the Material

This collaborative approach ensures parts are designed for manufacturability, not just material performance.

Built for the Demands of Heavy Equipment and Agriculture

From construction and mining equipment to tractors, combines, and material-handling systems, performance plastics are integral to modern equipment design. When paired with expert fabrication, materials like nylon and UHMW help improve durability, reduce maintenance, and extend equipment life.

If you’re designing or manufacturing heavy equipment or agricultural machinery and need machined plastic components, not just raw material, Piedmont Plastics is ready to help!

Ready to Dig Deeper?

Contact Piedmont Plastics today to discuss materials, fabrication capabilities, and custom plastic solutions tailored to your application!

Request A Quote