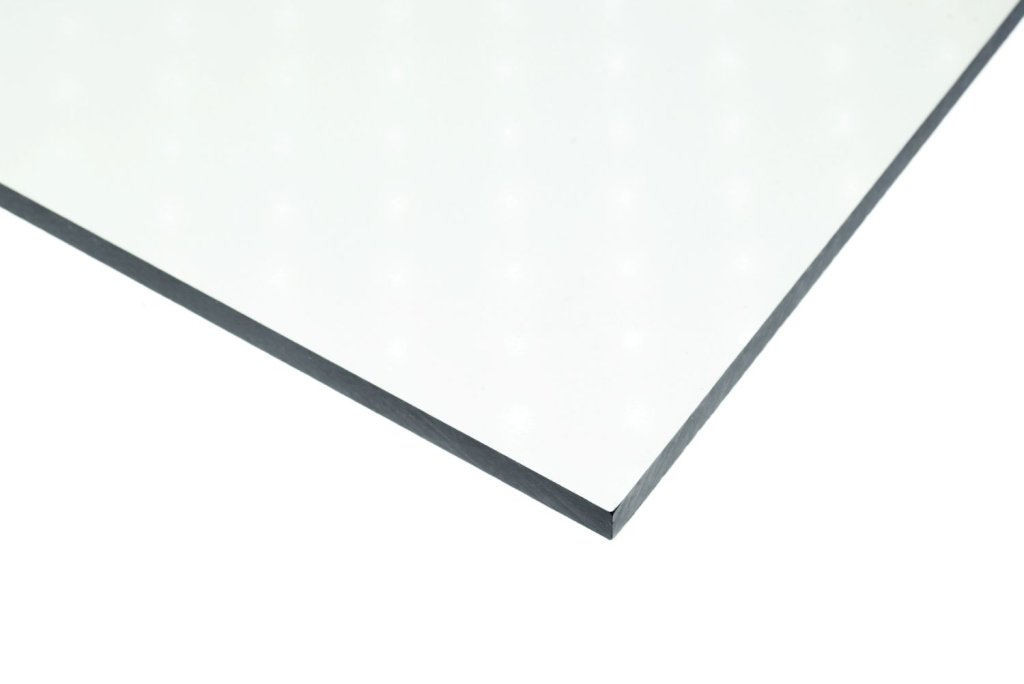

A corrugated plastic material designed with exceptional durability and strength, twinwall polycarbonate is lightweight and strong, which is perfect for outdoor applications like roofing panels and glazing.

Twinwall Polycarbonate

Durable and lightweight, twinwall polycarbonate is perfect for outdoor construction and glazing.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Twinwall Polycarbonate

Common Properties

- Common Brand Names Polygal®, SUNLITE®

- Typical Widths 48, 72, 96, 120, 144 in

- Typical Thickness Size 0.125, 0.25, 0.375, 0.5 in

- Friendly Names Multiwall Polycarbonate, Fluted Polycarbonate

- Typical Lengths 48, 96, 120, 144, 192 in

- Common Profiles Sheet

Electrical Properties

- Electrostatic Discharge (ESD) Sensitivity Sensitive qualitative

- Comparative Tracking Index (CTI) 600 volts

- Thermal Coefficient of Dielectric Constant 30-50 ppm/°C

- Surface Resistivity 10^15-10^16 ohms/square

- Dissipation Factor 0.006-0.009 unitless

- Arc Resistance 120-150 seconds

- Dielectric Constant 2.8-3.5 unitless

- Volume Resistivity 10^16 ohm-cm

- Breakdown Voltage 15-25 kV

- Dielectric Strength 15-25 kV/mm

Mechanical Properties

- Bearing Yield Strength 6000 psi

- Elongation at Yield 6 %

- Shear Strength 7000 psi

- Modulus of Elasticity 330000 psi

- Flexural Yield Strength 13500 psi

- Gardner Impact 320 in-lb

- Instrumented Impact Total Energy 50 ft-lb

- Falling Dart Impact 20 ft-lb

- Flexural Modulus 345000 psi

- Tensile Strength, Ultimate 9500 psi

- Izod Impact, Notched 12 ft-lb/in

- Hardness, Rockwell R N/A M scale

- Elongation at Break 100 %

- Izod Impact, Unnotched 60 ft-lb/in

- Compressive Yield Strength 11300 psi

- Tensile Strength, Yield 9000 psi

Physical Properties

- Density 0.9 g/cm³

- Moisture Absorption at Equilibrium 0.1 %

- Water Absorption 0.2 %

- Linear Mold Shrinkage 1.5 %

- Melt Flow 10 g/10 min

Regulation Properties

Thermal Properties

- Minimum Operating Temperature in F -40 °F

- Max Continuous Operating Temperature in F 240 °F

- Deflection Temperature at 0.46 MPa (66 psi) 280 °F

- Flammability, UL94 V-2

- Thermal Conductivity 0.20 W/m·K

- Vicat Softening Point 304 °F

- Deflection Temperature at 1.8 MPa (264 psi) 270 °F

- CTE, linear, Transverse to Flow 6.5 x10^-5/°C

- CTE, linear 6.5 x10^-5/°C

Literature and Data Sheets

-

Polygal® Mega-Lock Polygal

Polygal® Mega-Lock Polygal -

Polygal® Polycoolite® Polygal

Polygal® Polycoolite® Polygal -

Polygal® Polymatte™ Polygal

Polygal® Polymatte™ Polygal -

Polygal® Protected Pools Polygal

Polygal® Protected Pools Polygal -

Polygal® Selectogal (RFX) Polygal

Polygal® Selectogal (RFX) Polygal -

Polygal® Standard Grade Multiwall Sheet Polygal

Polygal® Standard Grade Multiwall Sheet Polygal -

Polygal® Sungal™ Polygal

Polygal® Sungal™ Polygal -

Polygal® Thermogal Polygal

Polygal® Thermogal Polygal -

Polygal® Titan Polygal

Polygal® Titan Polygal -

Polygal® Triple-Clip Polygal

Polygal® Triple-Clip Polygal

Twinwall Polycarbonate from Piedmont Plastics

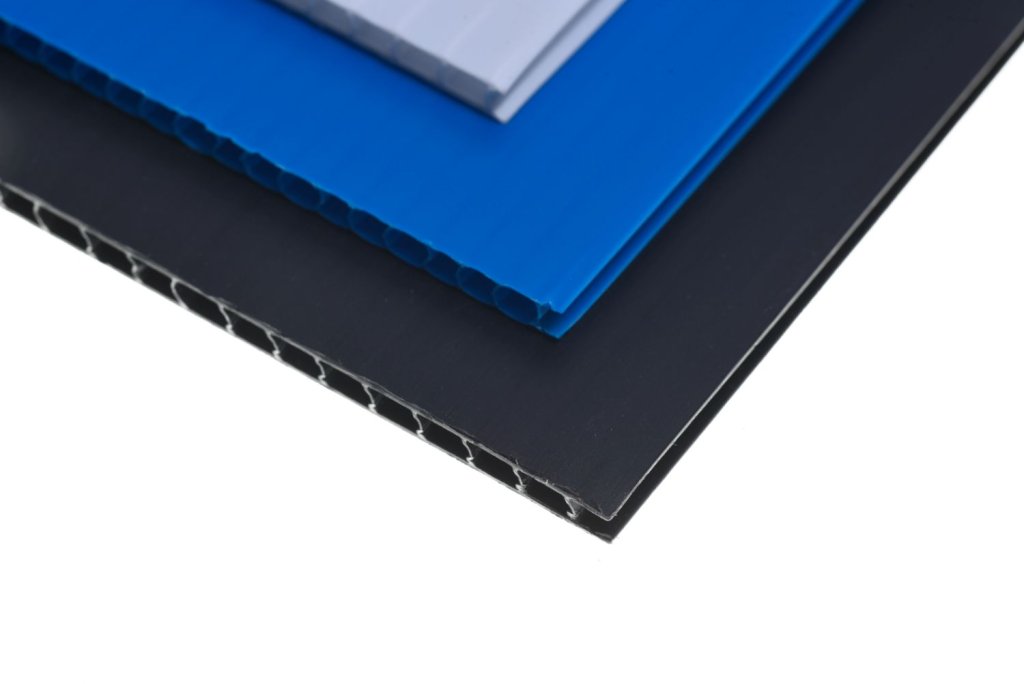

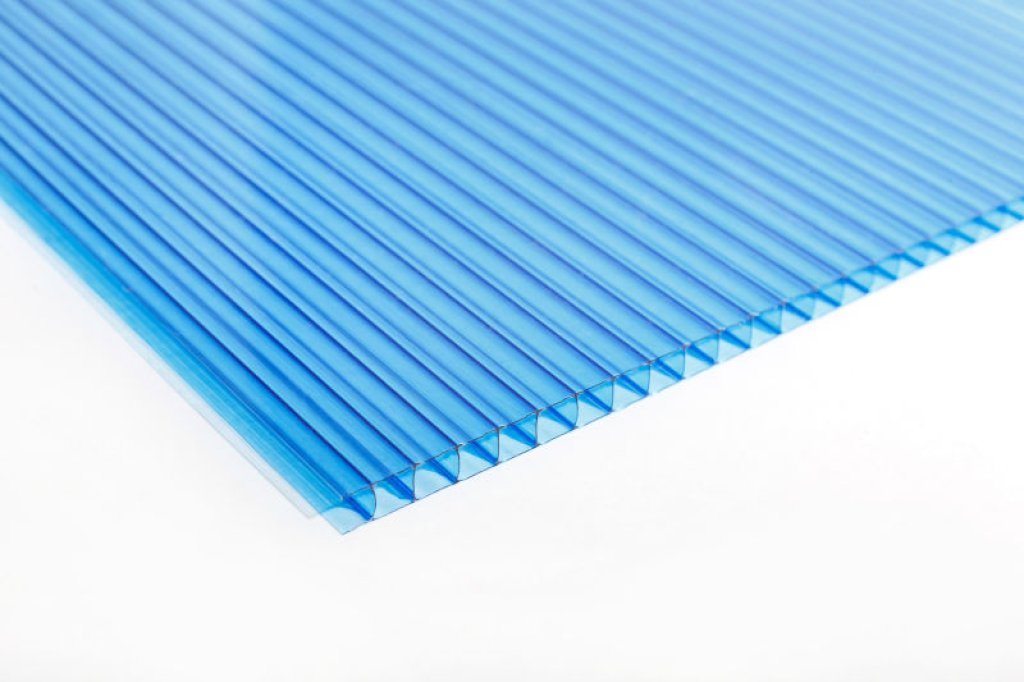

Twinwall polycarbonate is a corrugated plastic material with a unique structure made up of two walls, or layers, with air in between. This multi-walled design gives it added strength and insulation compared to glass. Known for its durability and impact resistance, twinwall polycarbonate is a popular choice for outdoor and indoor building projects. It’s often used for greenhouse coverings, skylights, patio and pergola roofing, signs, and glazing panels. Thanks to its lightweight nature, it’s easy to handle and install, making it a favorite among architects, commercial contractors, and DIYers.

One of the biggest advantages of twinwall polycarbonate is that it provides excellent light transmission while blocking harmful UV rays. It also holds up well in extreme weather conditions, resisting hail, wind, and temperature changes better than many other materials. Unlike glass, it won’t shatter, making it a safer option in areas where breakage could be a concern.

At Piedmont Plastics, we are a leading twinwall polycarbonate supplier and trusted plastic sheet distributor with locations across North America. Our team is here to help you choose the right material for your project and provide custom cutting options to meet your exact needs. Contact us today to learn more or request a quote for your next building or glazing project!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Twinwall Polycarbonate

Twinwall polycarbonate offers many benefits for architectural and glazing applications. Key features include:

Light Weight: Twelve times lighter than glass, twinwall polycarbonate is easier to install and support in applications like greenhouses and roofing panels.

Durability and Strength: Twinwall polycarbonate is virtually unbreakable, resisting cracking or denting even under extreme conditions such as hailstorms.

Energy Efficiency: This material traps heat inside, offering excellent thermal insulation and reducing energy costs.

UV Resistance: With a UV-resistant outer layer that prevents yellowing and hardening, twinwall polycarbonate brings long-term durability and protection from the elements.

Light Transmission: Twinwall polycarbonate allows a significant amount of natural light to pass through, which is helpful for applications like greenhouses.

Versatility and Flexibility: Easily cut to size using standard tools, this material works well for applications such as greenhouses, skylights, and safety barriers.

Water Resistance: Twinwall polycarbonate withstands condensation and keeps water out, providing additional protection for applications such as greenhouses.

These features make twinwall polycarbonate a preferred choice for both commercial and residential projects, especially in construction and agriculture.

Benefits of Twinwall Polycarbonate

Common Applications for Twinwall Polycarbonate

Due to its versatility, durability, and light weight, twinwall polycarbonate is used in a variety of applications, including:

Greenhouses: Lightweight and durable, twinwall polycarbonate is ideal for greenhouse construction, providing excellent thermal insulation and keeping heat inside.

Skylights and Roofing: Its ability to allow natural light to pass through makes it suitable for skylights and roofing.

Safety Barriers and Partitions: Twinwall polycarbonate is used for safety barriers and partitions due to its strength and impact resistance.

Awnings: It is also used in awnings, providing much-needed protection and light transmission.

Specialty Vehicle Roofing: Due to its lightweight and durable nature, twinwall polycarbonate is useful for specialty vehicle roofing applications.

Data Center Aisle Containment: Twinwall polycarbonate is commonly used to separate hot and cold aisles in data centers, improving airflow management and energy efficiency while maintaining lightweight, structural integrity.

These applications benefit from the material’s impact resistance, weather durability, and thermal insulation properties.

Related Products

-

Polycarbonate

Polycarbonate is a high-performance, impact-resistant thermoplastic known for its clarity, strength, and weatherability, making it suitable for applications such as eyewear lenses, bullet-resistant glass, construction materials, and automotive parts.

-

Specialty Polycarbonate Sheet

Specialty polycarbonate sheet offers superior impact, scratch, and chemical resistance, plus options for flame retardance, FDA compliance, and bullet resistance. Ideal for safety, industrial, and containment uses.

-

Fluted Polypropylene

Piedmont Plastics supplies durable fluted polypropylene sheets that are ideal for signage, packaging materials, and more.

-

Specialty Acrylic Sheet

Specialty acrylic sheet offers enhanced durability, UV protection, and glare or impact resistance that are ideal for demanding optical, display, and security applications.

Twinwall Polycarbonate FAQs

Twinwall polycarbonate is a popular choice for builders thanks to its strength, insulation, and versatility. Below are answers to some of the most frequently asked questions about this durable, lightweight material.

Absolutely. Twinwall polycarbonate is inherently waterproof and highly resistant to UV rays, wind, rain, snow, and hail. Its durable construction makes it suitable for outdoor use in a wide range of climates.

Twinwall polycarbonate is commonly used in applications that require lightweight, durable, and insulating materials. Typical uses include greenhouse glazing, skylights, patio covers, carports, pergolas, and interior partitions. Its hollow core structure provides excellent thermal insulation, making it ideal for energy-efficient building projects.

Depending on the application, twinwall polycarbonate offers many advantages over glass. It is significantly lighter, up to 200 times more impact-resistant, and provides better insulation. It’s also easier to cut, install, and shape than glass, making it a preferred option for DIY projects and commercial construction alike.

Why Buy Twinwall Polycarbonate from Piedmont Plastics?

At Piedmont Plastics, we take pride in offering only the best twinwall polycarbonate materials because we know how important reliable performance is to your project’s success. We combine expert guidance with a wide selection of materials to help you find the right solution every time.

Here’s why Piedmont Plastics is your trusted twinwall polycarbonate sheet supplier:

Wide Product Selection: We stock an extensive range of twinwall polycarbonate sheets in different sizes, shapes, thicknesses, and colors to suit nearly any application.

Custom Cutting Services: Our advanced CNC cutting and fabrication capabilities allow us to deliver twinwall polycarbonate sheets precisely tailored to your specifications.

Trusted Expertise: With decades of industry experience, our knowledgeable team can help you choose the best material for your specific needs.

Nationwide Availability: With locations across North America, we make it easy to access the materials you need, wherever you’re located.

Consistent Quality: Every sheet we supply meets strict quality standards to ensure top performance and durability.

Let us help you find the right material for your application. Contact Piedmont Plastics today to speak with a trusted plastic sheet distributor near you!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745