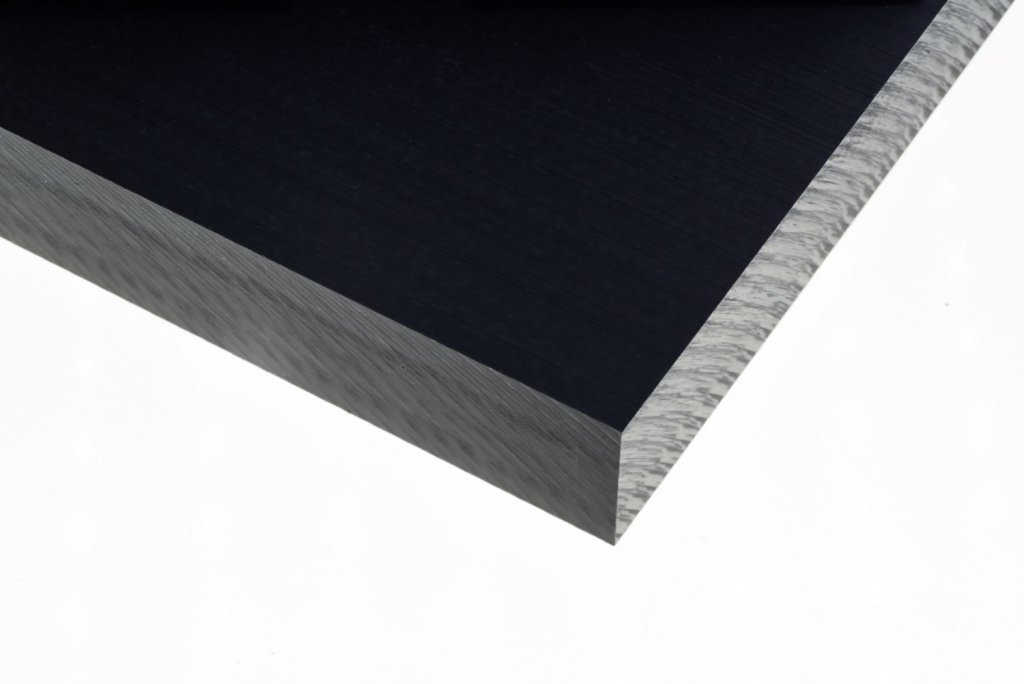

Polyethylene terephthalate sheet and rod offer high strength, stiffness, and dimensional stability. Ideal for precision parts, food equipment, and wear applications.

PET (Polyethylene Terephthalate)

A versatile engineering thermoplastic polymer with excellent wear resistance.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of PET (Polyethylene Terephthalate)

Common Properties

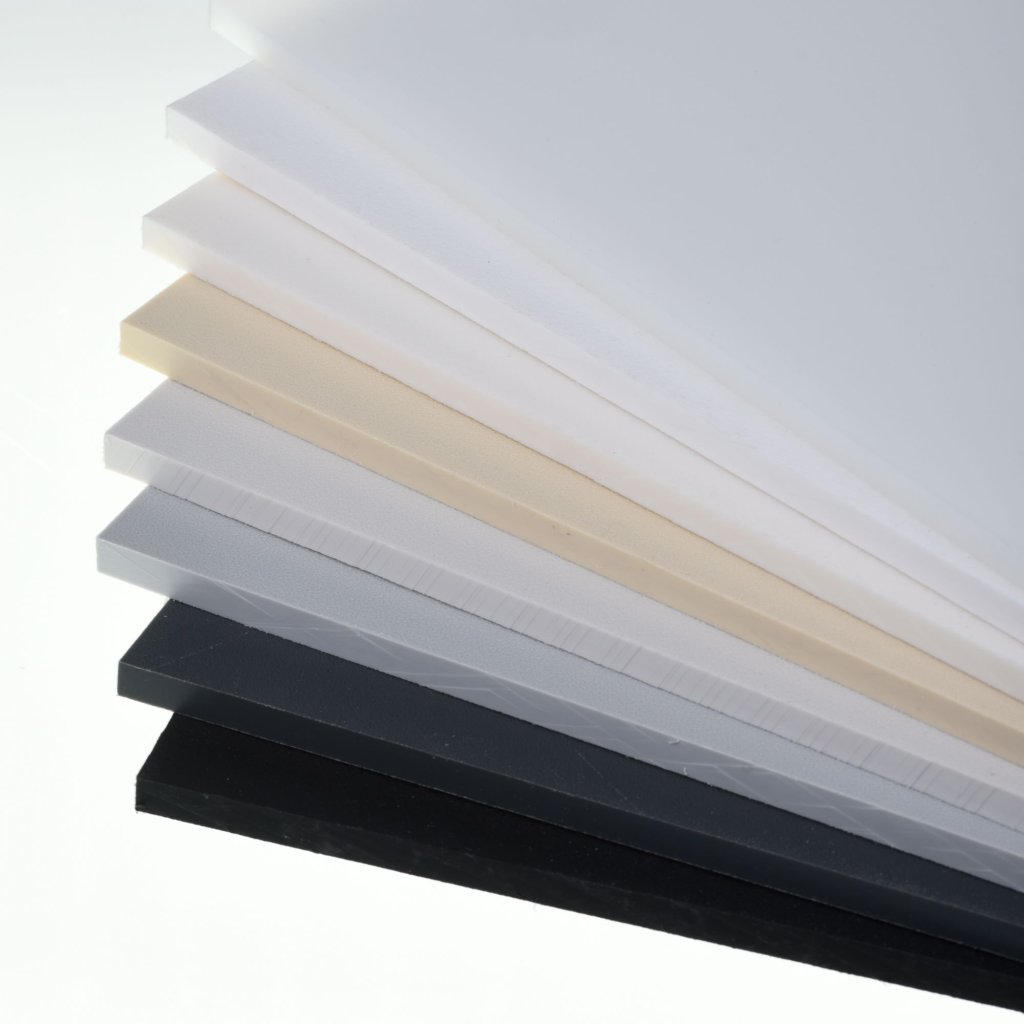

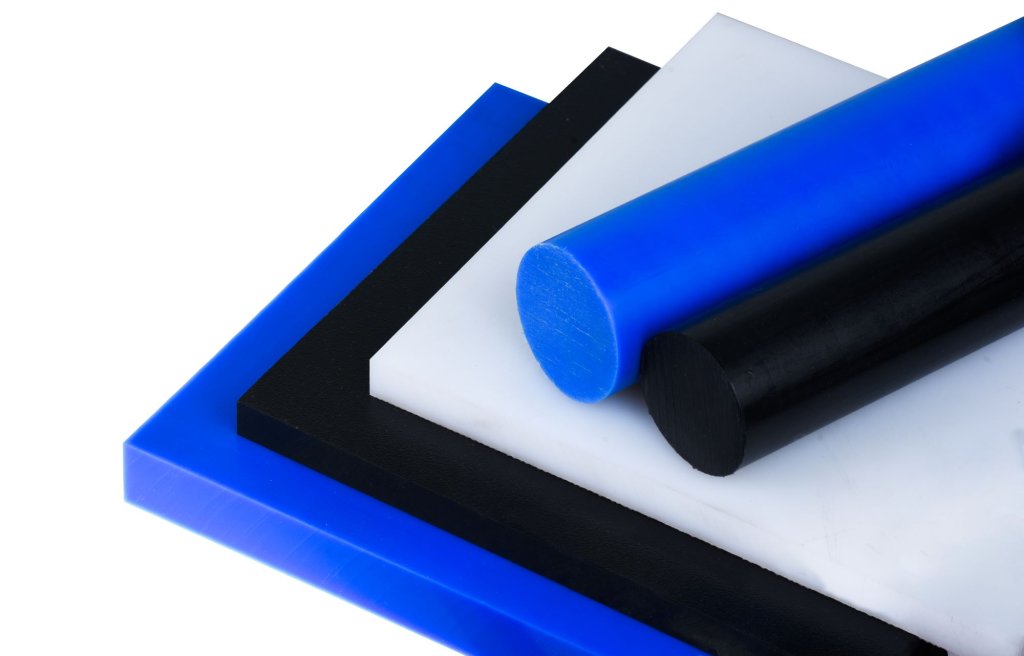

- Common Profiles Sheet, Rod

- Typical Thickness Size (in) 0.08-4 in

- Typical Rod Diameter 0.375-7 in

- Typical Lengths (in) 12-120 in

- Typical Widths (in) 12-40 in

- Typical Rod Length 12-120 in

- Friendly Names PET, PET-P

- Common Brand Names Ertalyte®, Semitron PET-P, Sustadur PET

Electrical Properties

- Dielectric Constant 3.3

- Dissipation Factor 0.007

- Surface Resistivity 1×10¹⁴ ohms/square

- Arc Resistance 130 s

- Dielectric Strength 400 V/mil

- Volume Resistivity 1×10¹⁵ ohm-cm

- Breakdown Voltage 17 kV/mm

Mechanical Properties

- Bearing Yield Strength 15000 psi

- Shear Strength 48 MPa

- Izod Impact, Notched 0.5 ft-lb/in

- Falling Dart Impact 10 ft-lb

- Compressive Yield Strength 13000 psi

- Hardness, Rockwell R 115

- Tensile Strength, Yield 62 MPa

- Tensile Strength, Ultimate 70 MPa

- Flexural Modulus 500000 psi

- Elongation at Break 20 %

- Modulus of Elasticity 400,000 psi

- Instrumented Impact Total Energy 10 ft-lb

- Elongation at Yield 6 %

- Izod Impact, Unnotched 3 ft-lb/in

- Gardner Impact 5 ft-lb

- Flexural Yield Strength 15000 psi

Physical Properties

- Density 1.39 g/cm³

- Melt Flow 9 g/10 min @ 250°C

- Water Absorption 0.07 %

- Moisture Absorption at Equilibrium 0.3 %

- Linear Mold Shrinkage 0.4 %

Regulation Properties

Thermal Properties

- Minimum Operating Temperature –40 °F

- CTE, Linear (Flow Direction) 3.9 × 10⁻⁵ in/in-°F

- Deflection Temperature at 0.46 MPa (66 psi) 160 °F

- Flammability (UL 94) HB

- Thermal Conductivity 0.15 W/m-K

- Vicat Softening Point 190 °F

- Deflection Temperature at 1.8 MPa (264 psi) 120 °F

- Max Continuous Operating Temperature 200 °F

- CTE, Linear (Transverse to Flow) 5.0 × 10⁻⁵ in/in-°F

Literature and Data Sheets

-

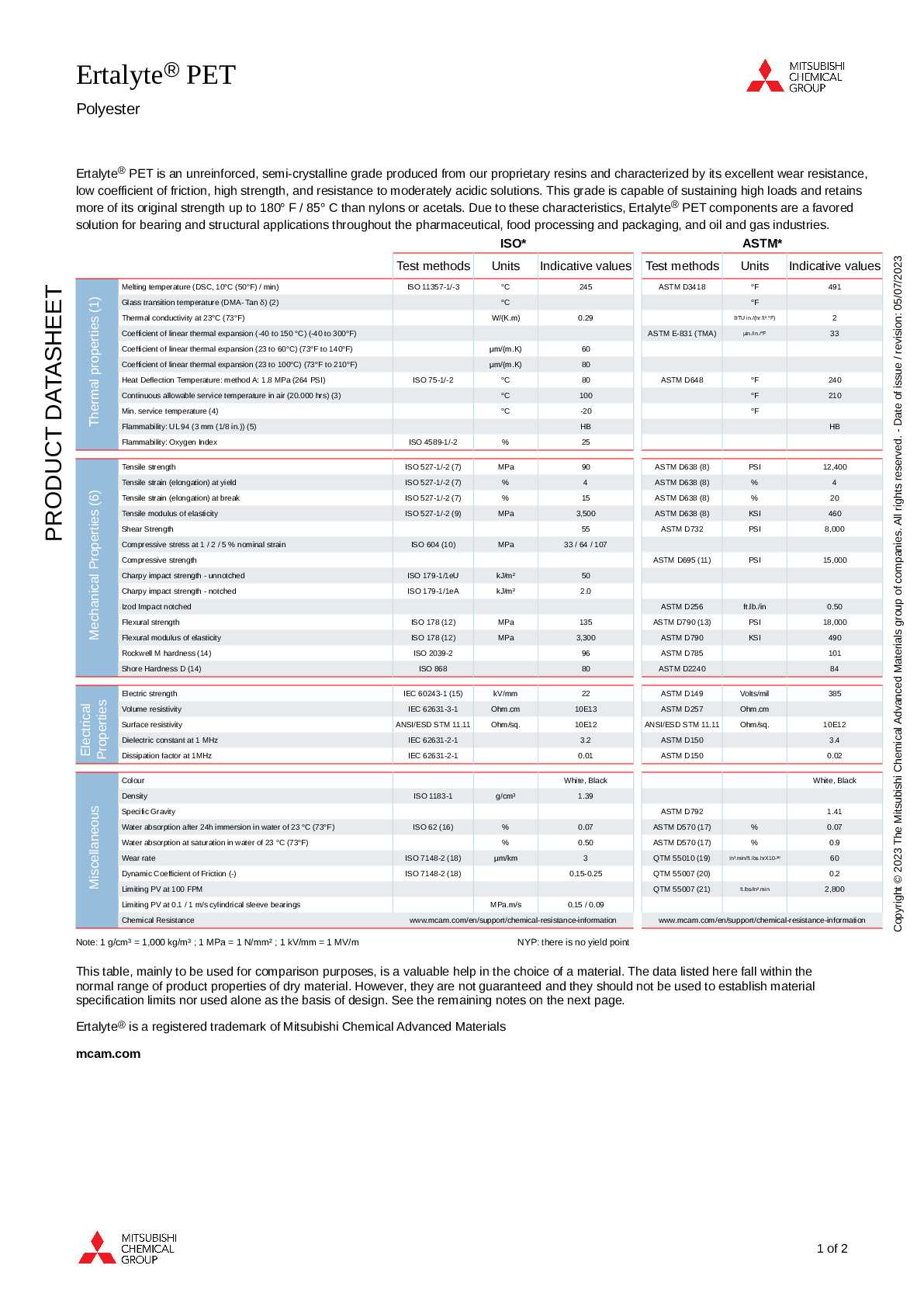

Ertalyte PET Mitsubishi Chemical Group

Ertalyte PET Mitsubishi Chemical Group -

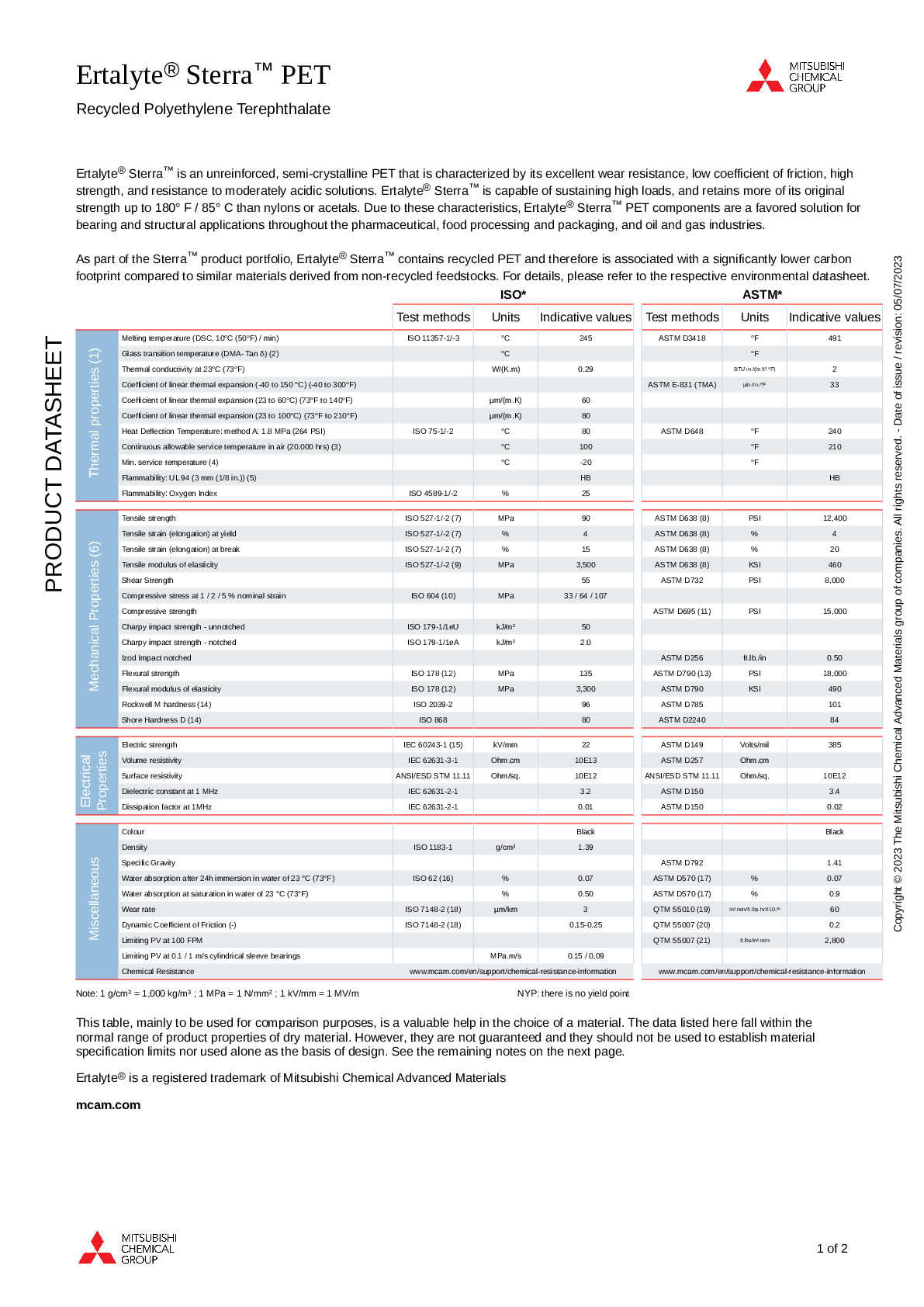

Ertalyte Sterra PET Mitsubishi Chemical Group

Ertalyte Sterra PET Mitsubishi Chemical Group -

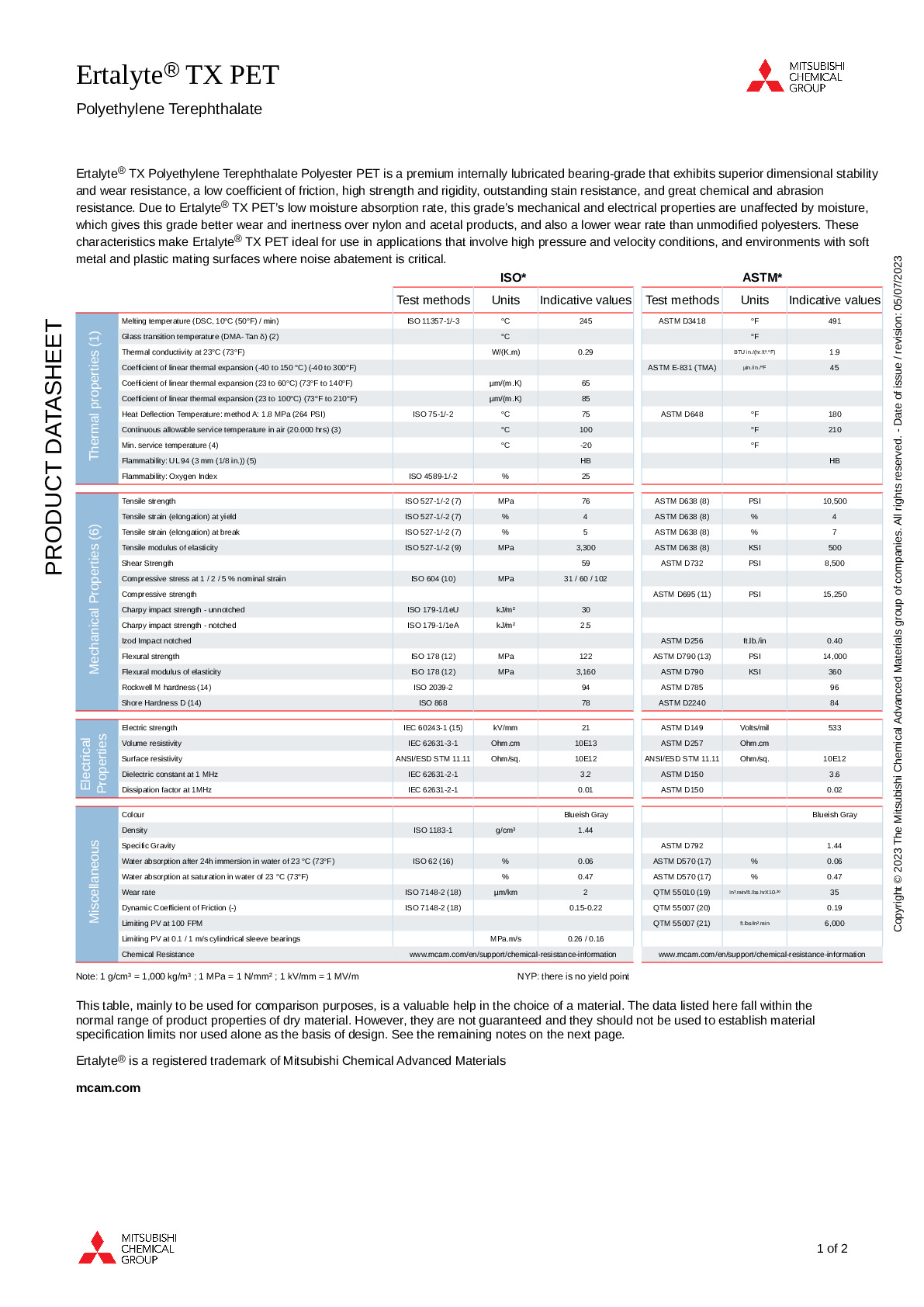

Ertalyte TX PET Mitsubishi Chemical Group

Ertalyte TX PET Mitsubishi Chemical Group -

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics

Piedmont Plastics High-Performance Plastic Solutions Brochure Piedmont Plastics -

MCAM Ertalyte® PET-P Nacelle Yawing Slide Pad Mitsubishi Chemical Group

MCAM Ertalyte® PET-P Nacelle Yawing Slide Pad Mitsubishi Chemical Group -

MCAM Ertalyte® TX PET-P Mitsubishi Chemical Group

MCAM Ertalyte® TX PET-P Mitsubishi Chemical Group -

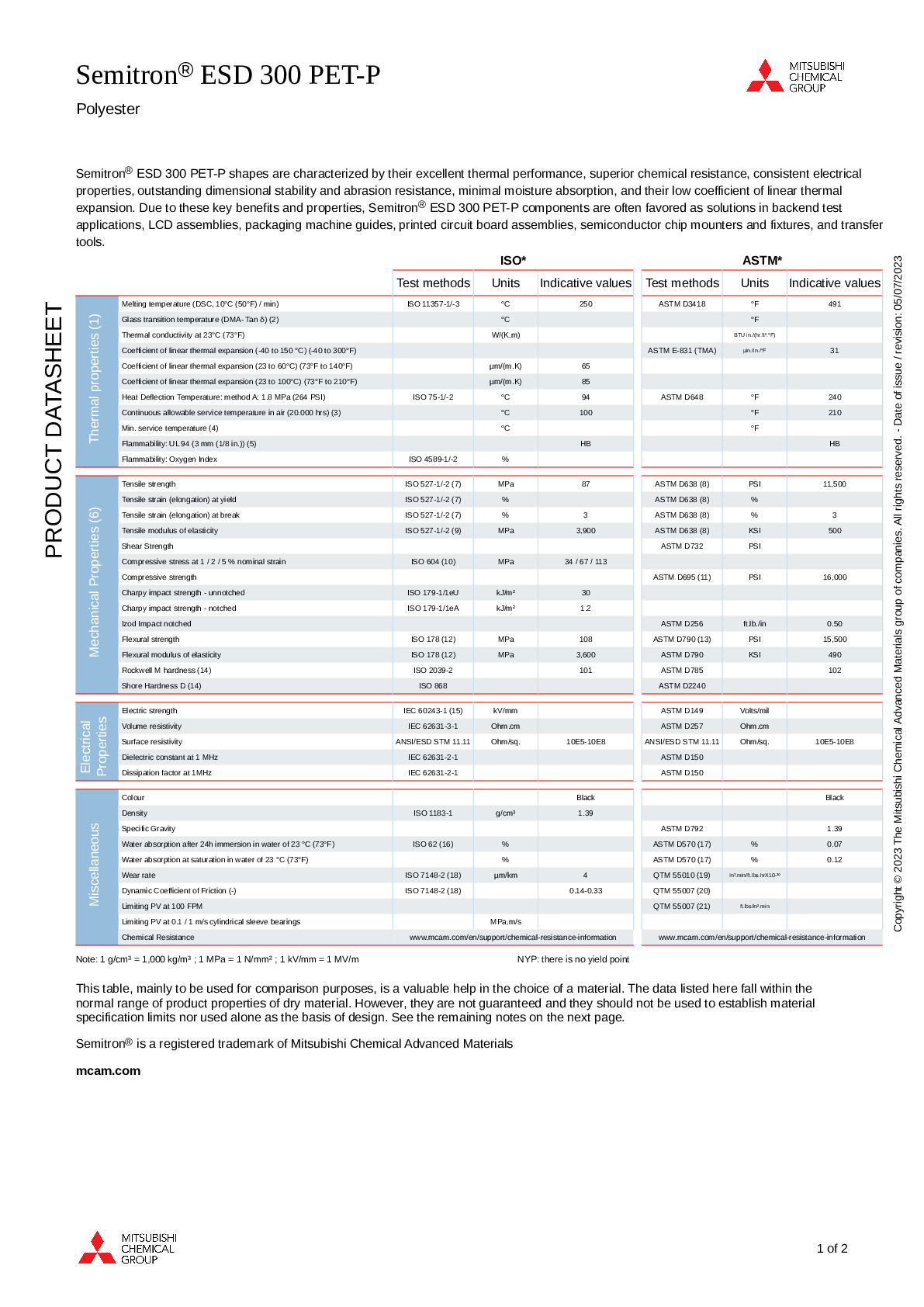

Semitron ESD 300 PET-P Mitsubishi Chemical Group

Semitron ESD 300 PET-P Mitsubishi Chemical Group -

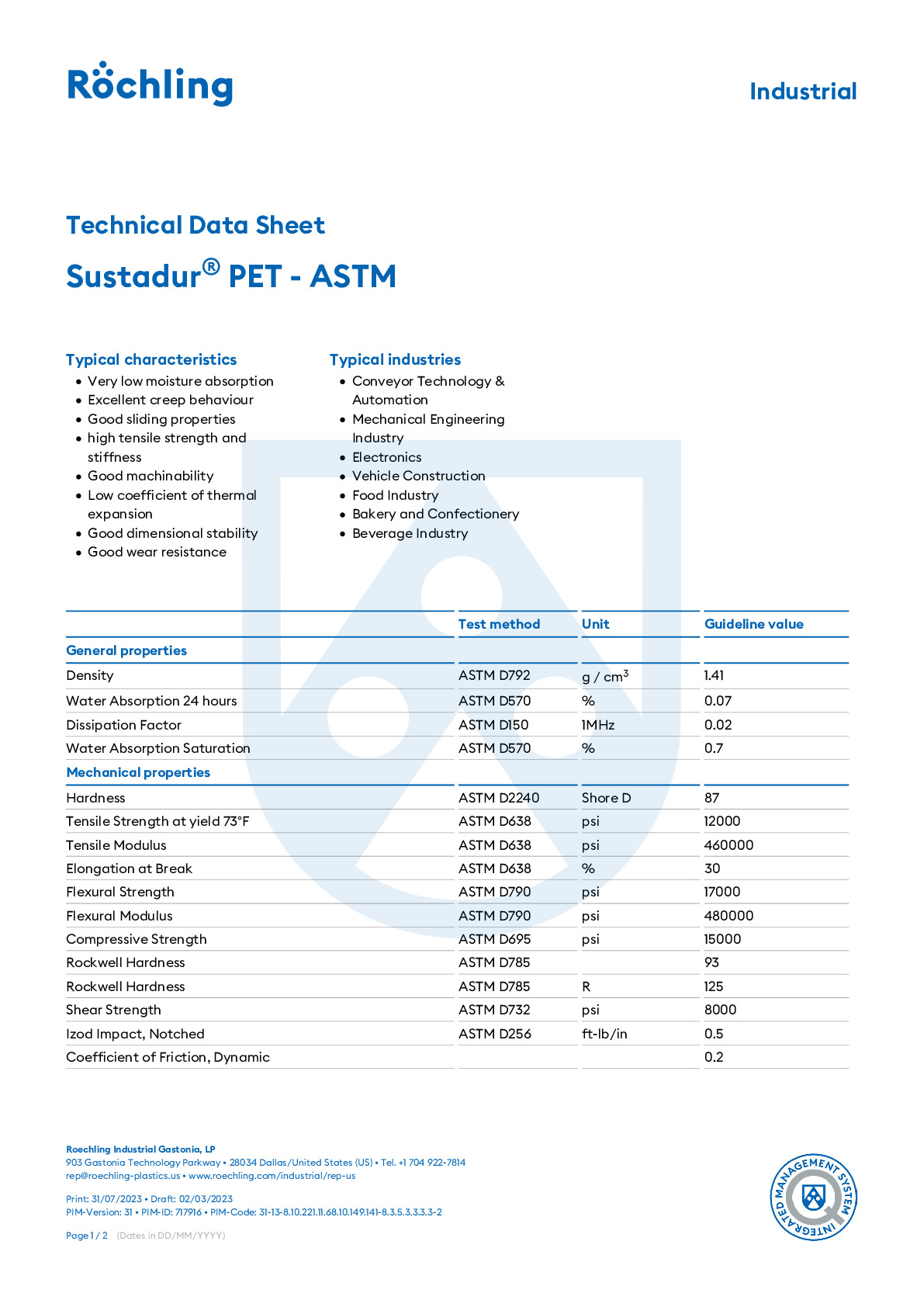

Sustadur PET - ASTM Röchling Engineering Plastics

Sustadur PET - ASTM Röchling Engineering Plastics

Get a Quote for PET at Piedmont Plastics

Polyethylene terephthalate, also known as PET plastic is an engineering thermoplastic known for its excellent dimensional stability, strength, and low moisture absorption. Available in both sheet and rod form, PET delivers exceptional wear resistance and machinability, making it an ideal choice for precision parts in demanding industrial environments.

With its naturally low coefficient of friction and resistance to chemicals and abrasion, PET performs exceptionally well in applications that require tight tolerances and long-term durability. Piedmont Plastics offers PET materials that are easily machined, FDA-compliant for food contact, and well suited for both dry and lubricated environments.

Contact your local Piedmont Plastics branch to request a quote or learn more about how PET can improve the performance and service life of your components.

Key Features of Polyethylene Terephthalate

PET provides a strong combination of mechanical and thermal properties for precision engineering and wear applications. Its excellent dimensional stability and low moisture absorption make it a preferred alternative to materials like acetal or nylon in high-precision parts.

Key performance characteristics include:

High mechanical strength and rigidity

Excellent dimensional stability under load

Low moisture absorption for consistent performance

Good wear resistance and low friction coefficient

FDA-compliant for food contact applications

Easy to machine with tight tolerances

Resistance to oils, greases, and common solvents

Performs well in dry or lubricated operating conditions

Benefits and Advantages

Common Applications

PET sheet and rod are commonly used in industrial, mechanical, and food-processing or packaging environments where stability and wear resistance are critical.

Typical applications include:

Gears and Bearings: Smooth, low-friction operation under heavy load

Precision Mechanical Components: Tight-tolerance parts with minimal expansion

Food Processing Equipment: FDA-approved surfaces for safe contact

Conveyor Components: Reliable, wear-resistant guides and supports

Electrical Insulation Parts: Good dielectric properties with low moisture uptake

Pump and Valve Parts: Chemical resistance for long-term durability

Related Products

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

-

Cast Nylon

Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

-

HDPE (High Density Polyethylene)

HDPE offers strength, low weight, and resistance to chemicals and moisture, making it ideal for food and beverage equipment, industrial components, and marine applications.

-

PBT (Polybutylene Terephthalate)

PBT plastic sheet and rod offer strength, stiffness, and electrical insulation for demanding industrial, electrical, and automotive applications.

-

UHMW PE

UHMW from Piedmont Plastics offers superior durability, low friction, and wear resistance, ideal for conveyors, liners, and food-grade industrial parts.

-

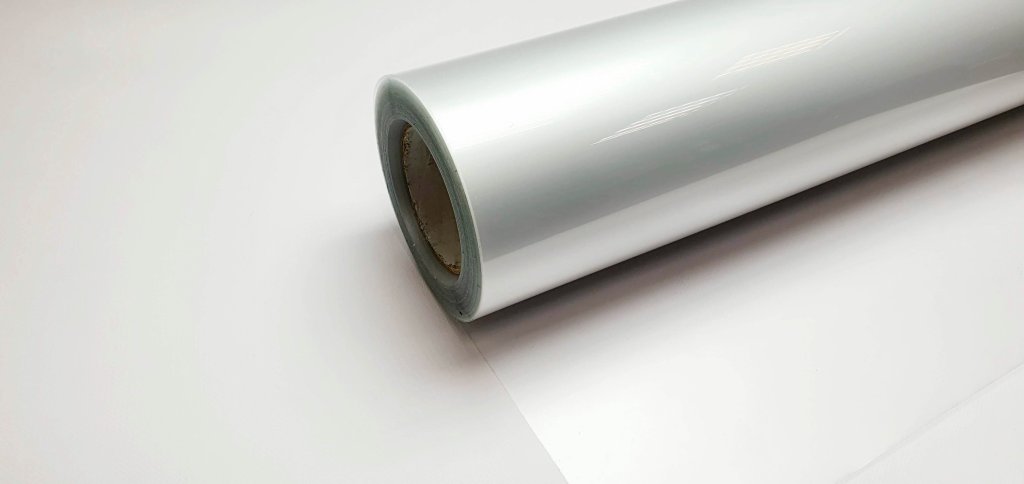

Polyester Film

Polyester (PET) film offers strength, clarity, and dimensional stability for applications in packaging, protection, graphics, and electrical insulation.

Frequently Asked Questions

Below are some of the most commonly asked questions about polyethylene terephthalate sheet and rod, including how the material performs in different environments and how it compares to other engineering plastics. These answers can help you determine whether PET is the right choice for your application.

Many PET grades are formulated to meet food contact standards, making them well suited for use in food processing and handling equipment. However, users should always verify with the manufacturer or supplier that the specific material grade purchased complies with the applicable regulations and requirements for their intended application.

PET offers lower moisture absorption and better dimensional stability than nylon, with higher stiffness and wear performance similar to or better than acetal.

PET typically operates continuously up to approximately 210°F (100°C) and maintains its mechanical properties well under load. However, actual performance can vary by grade and application, so it’s important to confirm the recommended operating temperature with the manufacturer or material supplier.

Why Buy from Piedmont Plastics?

At Piedmont Plastics, we combine technical expertise with local inventory to deliver reliable material solutions tailored to your needs.

Nationwide network of branches: Providing fast local delivery and expert support.

Custom cutting and fabrication services: Ready to machine PET sheet and rod to your specifications.

Deep industry expertise: Trusted by engineers and fabricators across diverse industries.

Wide product selection: Your one-stop shop for performance plastics and complementary materials.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745