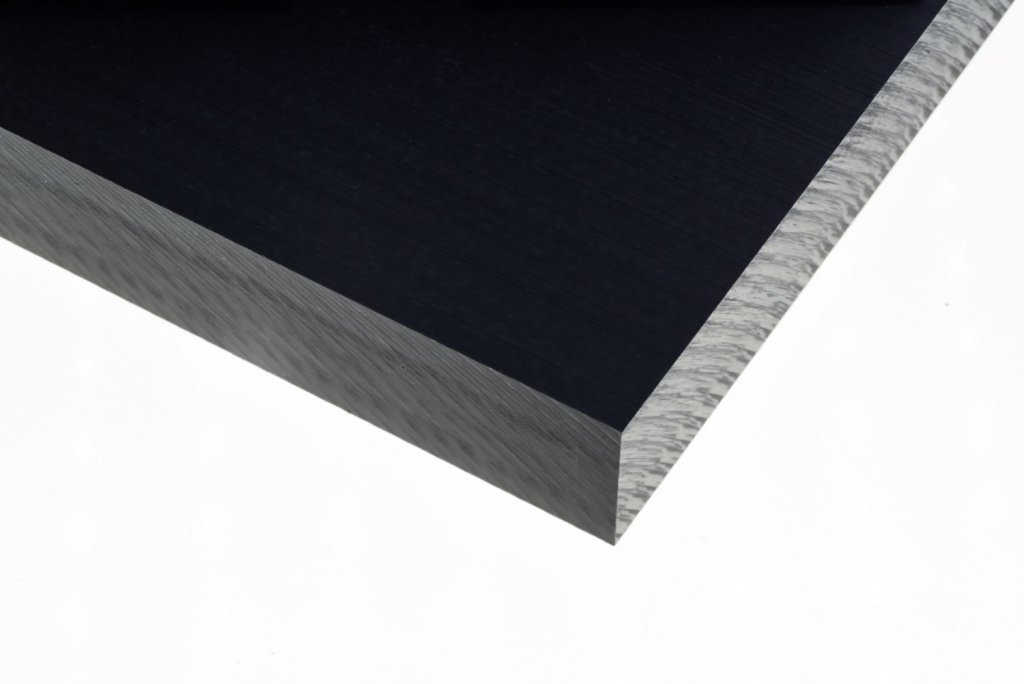

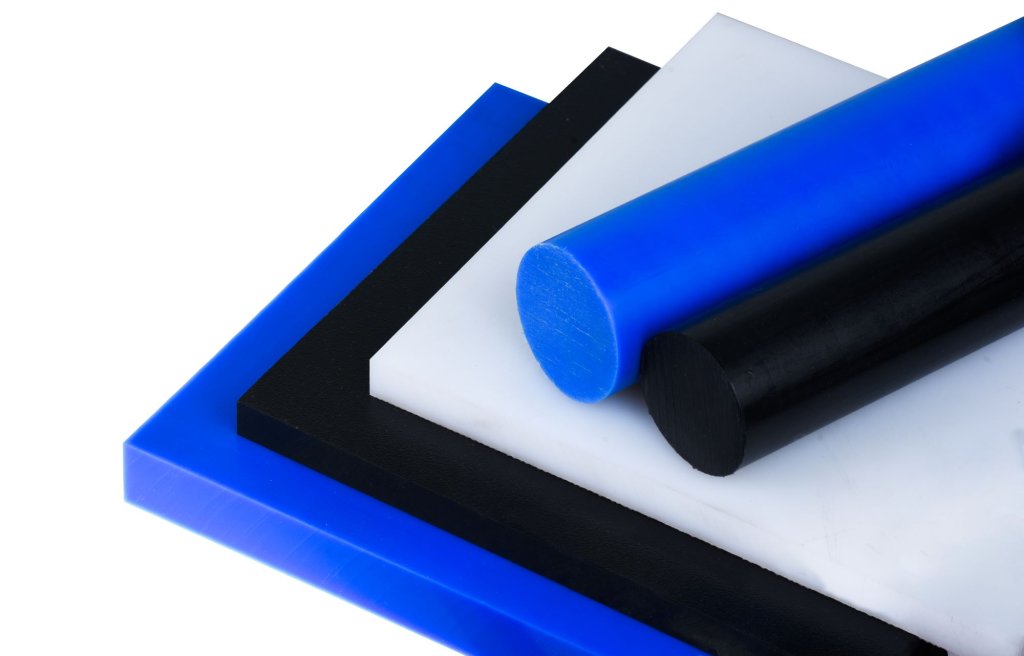

PBT plastic sheet and rod offer strength, stiffness, and electrical insulation for demanding industrial, electrical, and automotive applications.

PBT (Polybutylene Terephthalate)

Durable plastic sheet and rod for industrial and electrical use.

Product Overview

Widely used for:

Performance Characteristics:

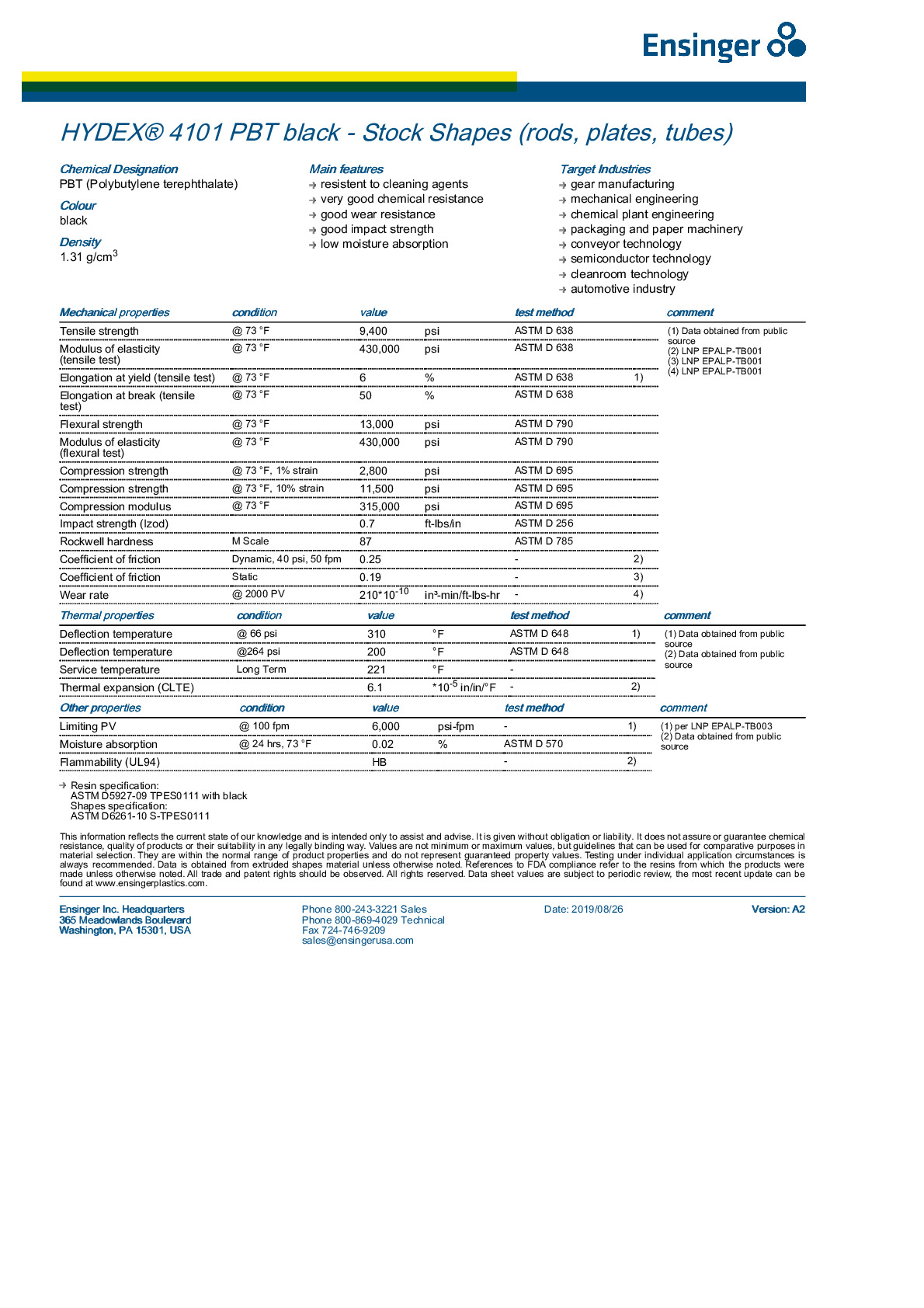

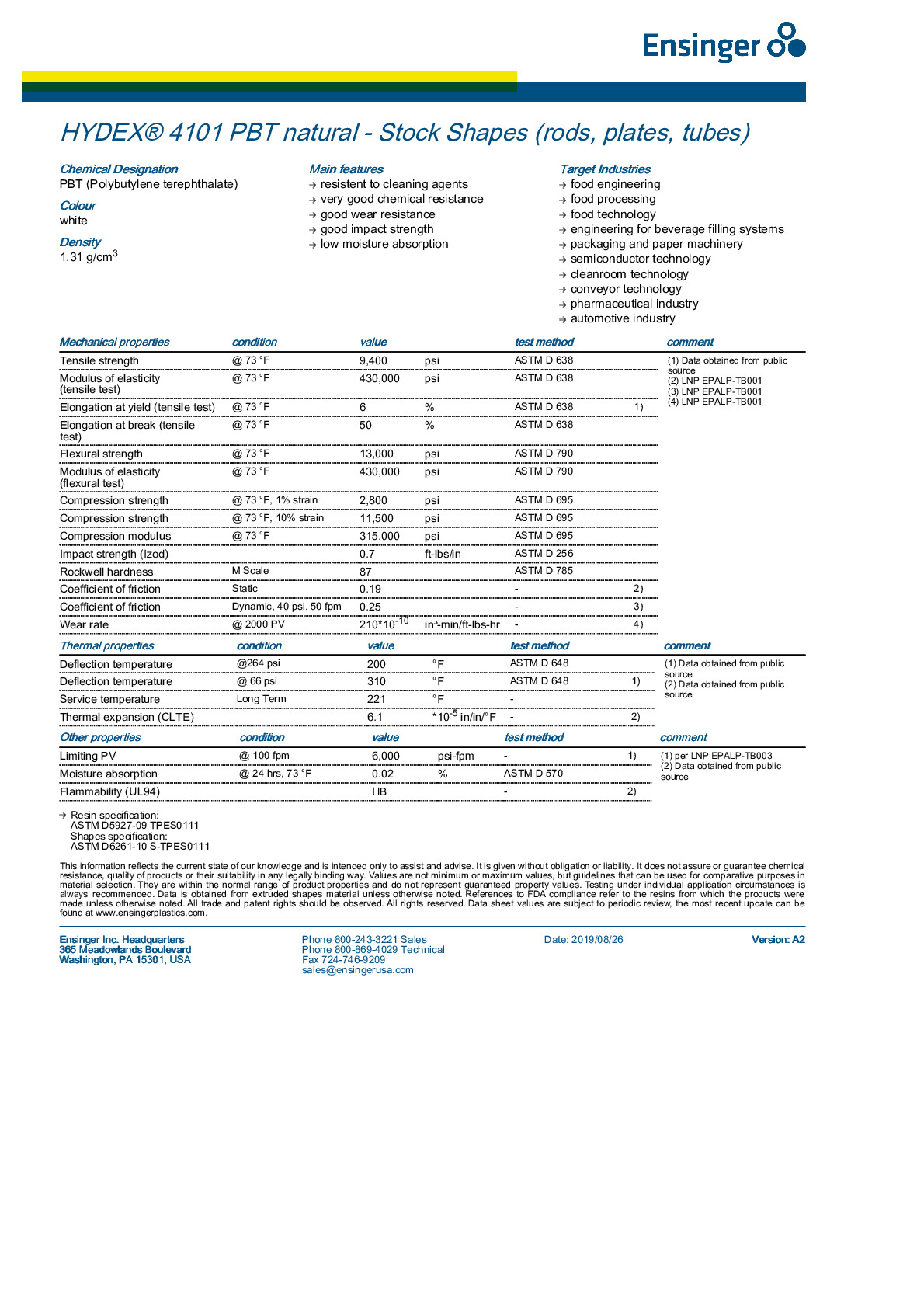

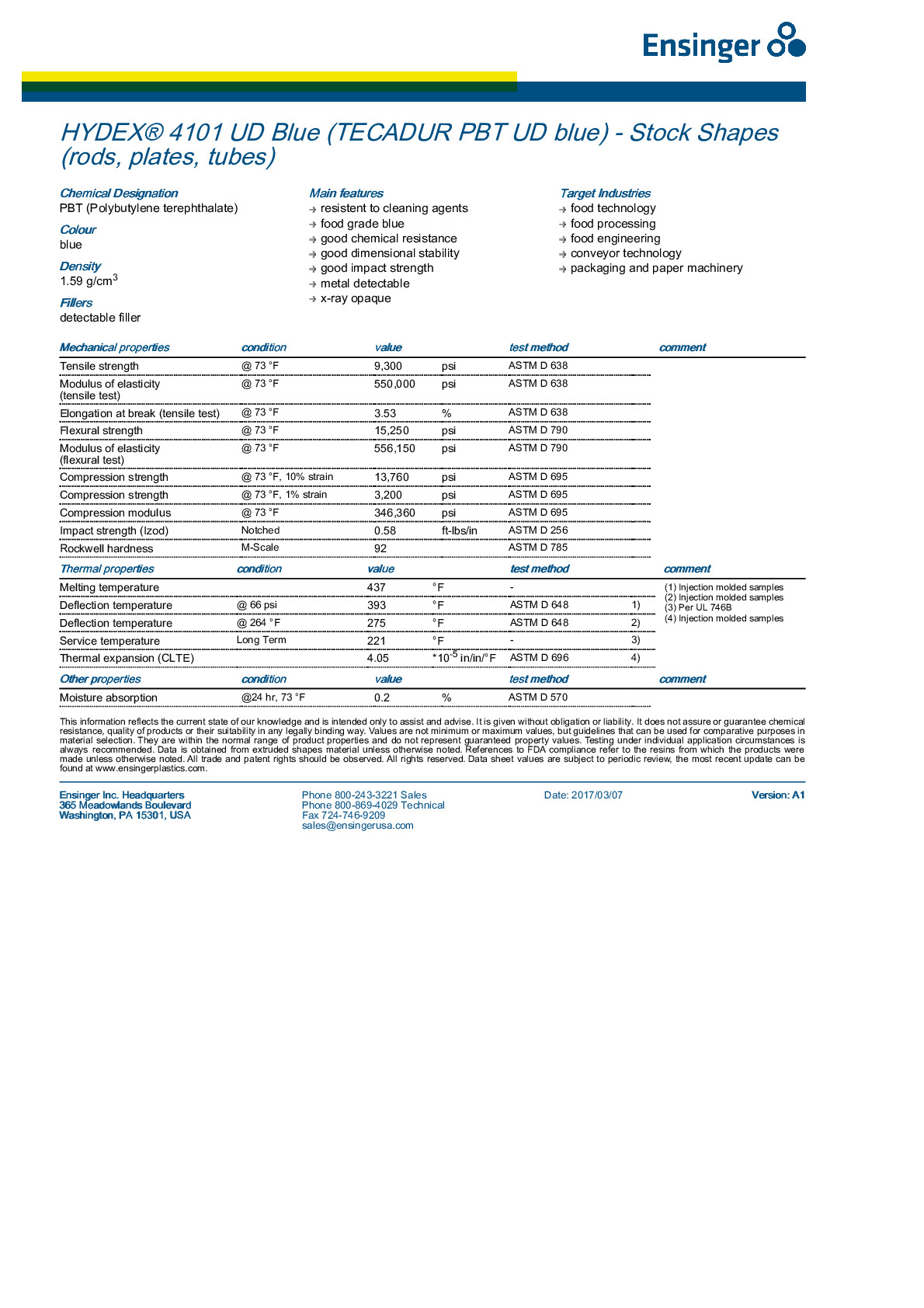

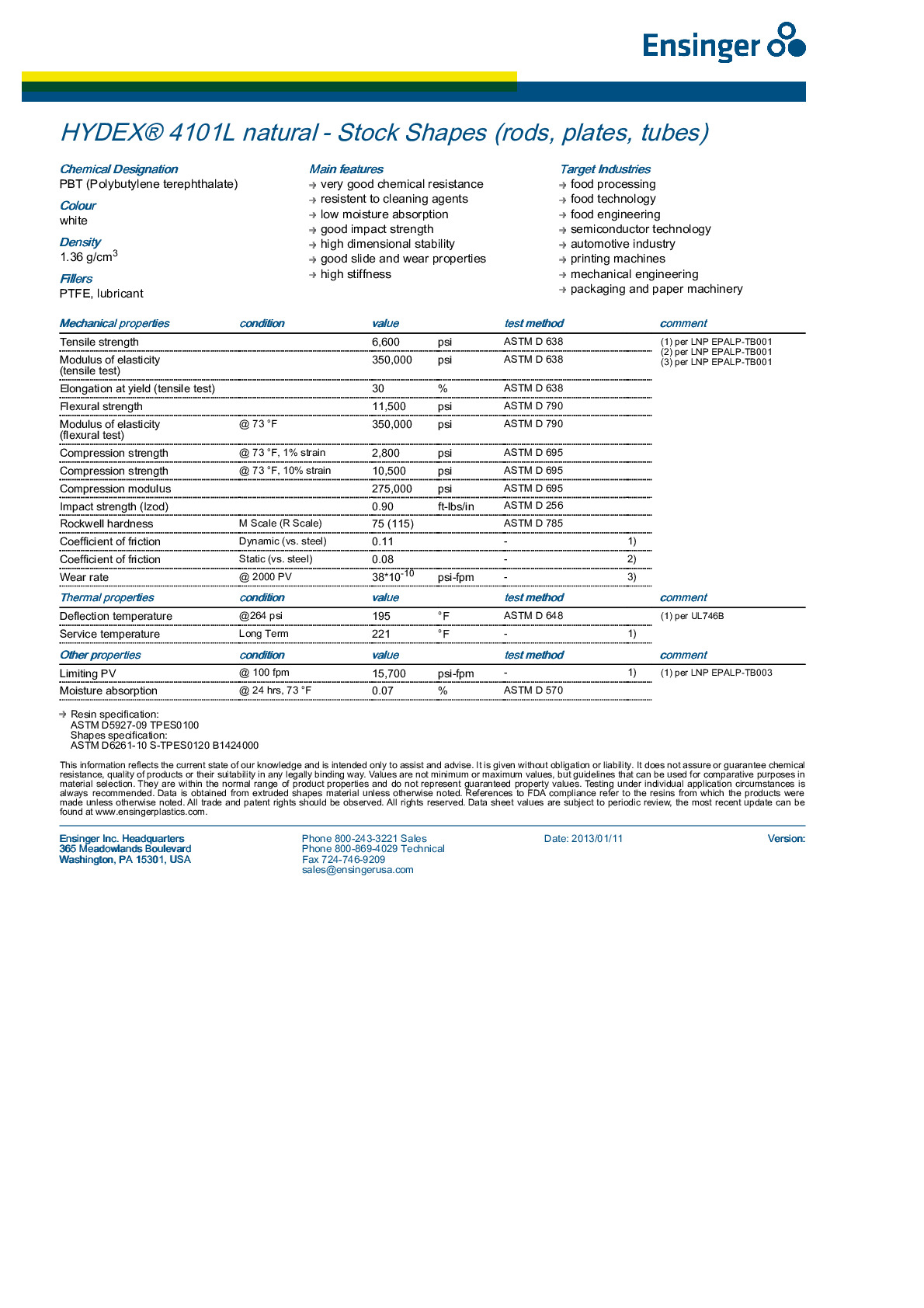

Typical Properties of PBT (Polybutylene Terephthalate)

Common Properties

- Typical Lengths 48, 72, 96 in

- Common Brand Names HYDEX®, Sustadur®

- Typical Widths 24, 36, 48 in

- Typical Rod Diameter 0.25 – 6 in

- Common Profiles Sheet, Rod

- Friendly Names Polybutylene Terephthalate

- Typical Thickness Size 0.25 - 2.5 in

Electrical Properties

- Surface Resistivity 1.0E+14 ohm

- Dielectric Constant 3

- Comparative Tracking Index (CTI) 250 V

- Dissipation Factor 0.02

- Dielectric Strength 18 kV/mm

- Volume Resistivity 1.0E+15 ohm·cm

- Arc Resistance 120 seconds

- Electrostatic Discharge (ESD) Sensitivity Low

- Thermal Coefficient of Dielectric Constant -0.002 1/°C

- Breakdown Voltage 20 kV

Mechanical Properties

- Izod Impact, Notched 0.6 J/cm

- Compressive Yield Strength 70 MPa

- Izod Impact, Unnotched 4.5 J/cm

- Tensile Strength, Ultimate 55 MPa

- Bearing Yield Strength 80 MPa

- Shear Strength 35 MPa

- Flexural Yield Strength 75 MPa

- Falling Dart Impact 25 J

- Gardner Impact 20 J

- Tensile Strength, Yield 50 MPa

- Flexural Modulus 2400 MPa

- Instrumented Impact Total Energy 50 J

- Elongation at Break 3 %

- Modulus of Elasticity 2500 MPa

- Elongation at Yield 2.5 %

- Hardness, Rockwell R 77

Physical Properties

- Water Absorption 0.1 - 0.6 %

- Melt Flow 2 - 30 g/10 min

- Density 0.9 - 1.3 g/cm³

- Moisture Absorption at Equilibrium 0.1 - 0.4 %

- Linear Mold Shrinkage 0.002 - 0.025 mm/mm

Regulation Properties

Thermal Properties

- Flammability HB UL94

- CTE, linear 8 µm/m°C

- Minimum Operating Temperature -40 °F

- Deflection Temperature at 0.46 MPa (66 psi) 210 °C

- Deflection Temperature at 1.8 MPa (264 psi) 180 °C

- Vicat Softening Point 225 °C

- Max Continuous Operating Temperature 150 °F

- Thermal Conductivity 0.3 W/m·K

- CTE, linear, Transverse to Flow 11 µm/m°C

Get a Quote for PBT Plastic at Piedmont Plastics

Polybutylene terephthalate (PBT) is a high-performance engineering thermoplastic known for its toughness, stiffness, and excellent dimensional stability. Offered in sheet and rod form, PBT plastic combines wear resistance, electrical insulation properties, and low moisture absorption, making it a versatile choice across many industries. From automotive components to electrical housings, PBT delivers reliable performance in demanding environments. Contact Piedmont Plastics today to request a quote or learn how PBT plastic can benefit your next project.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of PBT Plastic

PBT offers a balance of mechanical, thermal, and electrical properties that make it ideal for precision applications.

Strong and stiff with excellent dimensional stability

High wear resistance and low-friction surface

Good electrical insulation properties

Low moisture absorption for consistent performance

Resistant to fuels, oils, and many chemicals

Heat-resistant with good thermal stability

Easily machinable into custom parts

Benefits and Advantages

Common Applications

PBT is widely used in industries that require durable, high-precision components with electrical and chemical resistance.

Electrical Components: Insulating housings, connectors, and switches

Automotive Parts: Under-hood components, gears, and fasteners

Industrial Equipment: Wear parts and precision machine components

Consumer Goods: Appliance parts and structural components

Fabricated Parts: Custom machined shapes for high-demand environments

Related Products

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

-

Cast Nylon

Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

-

UHMW PE

UHMW from Piedmont Plastics offers superior durability, low friction, and wear resistance, ideal for conveyors, liners, and food-grade industrial parts.

Frequently Asked Questions

Below are some commonly asked questions about PBT plastic and its performance in various environments.

PBT offers some weatherability but is best suited for indoor or protected environments. UV-stabilized grades are recommended for outdoor use. If you're unsure of what your applicaiton requires, ask your Piedmont Plastics sales rep.

PBT has low moisture absorption, which helps maintain dimensional stability and electrical performance. Always consult the manufacturer’s specifications for detailed information on moisture absorption for your specific grade.

Both are strong and machinable, but PBT provides better electrical insulation and chemical resistance, while acetal offers lower friction.

Why Buy from Piedmont Plastics?

At Piedmont Plastics, we provide high-quality engineering plastics like PBT sheet and rod, backed by expert service and nationwide availability.

Nationwide network of branches: Convenient local access and fast delivery

Custom cutting and fabrication services: Precision CNC cutting tailored to your specs

Deep industry expertise: Guidance from experts across multiple industries

Wide product selection that supports a one-stop-shop experience: A complete range of plastics for every application

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745