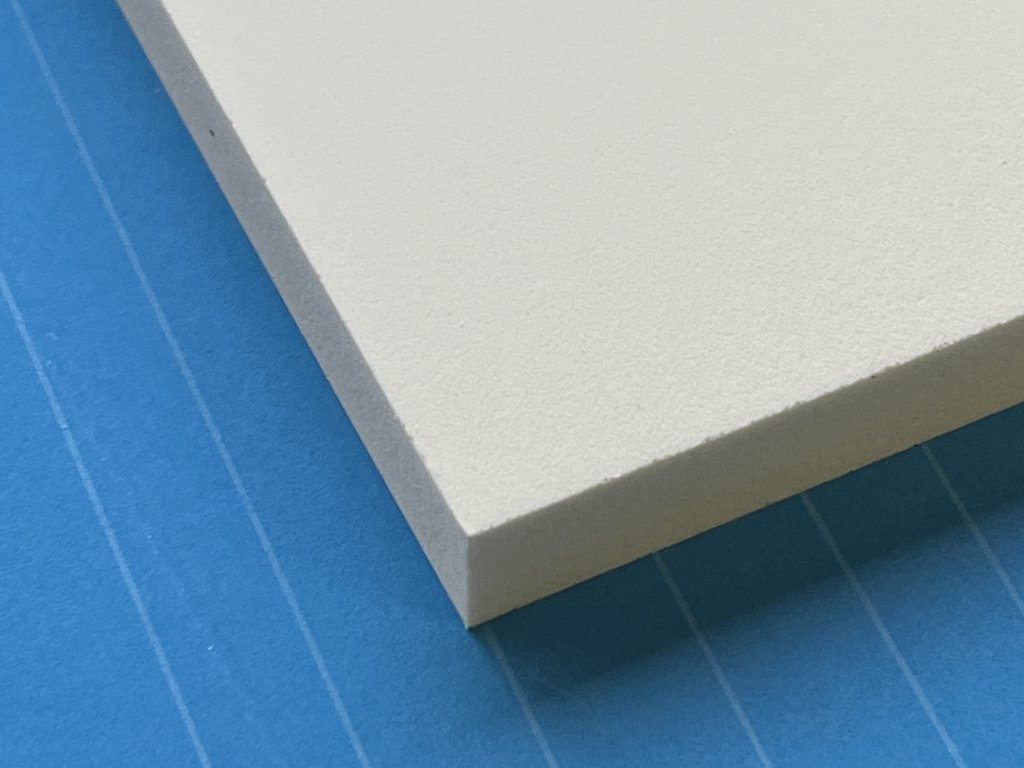

A strong, lightweight, and weatherable plastic sheet ideal for marine, outdoor, and high-humidity applications due to its durability and ease of fabrication.

Marine-Grade PVC Foam Sheet

A durable, lightweight, and moisture-resistant PVC foam material.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Marine-Grade PVC Foam Sheet

Common Properties

- Common Brand Names Aqua Plas 1 Ultra, Aqua Plas 3 Ultra LG, Seaboard Endurabond

- Typical Thickness Size 0.25, 0.5, 0.75, 1 in

- Typical Lengths 48, 96, 120 in

- Typical Widths 24, 48 in

- Friendly Names PVC Foam, Expanded PVC

- Common Profiles Sheet

Physical Properties

- Density 0.95 - 1.2g/cm³

- Water Absorption 0.3 - 0.5%

- Moisture Absorption at Equilibrium 3.0 - 4.0%

- Linear Mold Shrinkage 0.4 - 2.0%

- Melt Flow 5 - 30g/10 min

Electrical Properties

- Dielectric Strength 15.7kV/mm

- Dielectric Constant 2.9

- Dissipation Factor 0.015

- Volume Resistivity 1.0E+15ohm·cm

- Surface Resistivity 10000000000000ohm/sq

- Arc Resistance 120seconds

- Comparative Tracking Index (CTI) 600V

- Thermal Coefficient of Dielectric Constant - 0.02%/°C

- Breakdown Voltage 157kV

Mechanical Properties

- Hardness, Rockwell R 90HRR

- Tensile Strength, Ultimate 60MPa

- Tensile Strength, Yield 45MPa

- Elongation at Break 10%

- Elongation at Yield 4%

- Modulus of Elasticity 3000MPa

- Flexural Yield Strength 55MPa

- Flexural Modulus 3200MPa

- Compressive Yield Strength 50MPa

- Bearing Yield Strength 100MPa

- Shear Strength 40MPa

- Izod Impact, Notched 100J/m

- Izod Impact, Unnotched 900J/m

- Gardner Impact 15J

- Falling Dart Impact 25J

- Instrumented Impact Total Energy 20J

Thermal Properties

- CTE, linear 60µm/m°C

- CTE, linear, Transverse to Flow 40µm/m°C

- Deflection Temperature at 0.46 MPa (66 psi) 70°C

- Deflection Temperature at 1.8 MPa (264 psi) 60°C

- Vicat Softening Point 85°C

- Flammability, UL94 V - 0

- Max Continuous Operating Temperature in F 140°F

- Minimum Operating Temperature in F - 40°F

- Thermal Conductivity 0.035W/mK

Regulations

- UL-94 Flame Class

- ASTM/Mil-Spec

- D635 Self Extinguishing

- RoHS Compliant

- REACH Compliant

Marine-Grade PVC Foam Sheet for Demanding, Moisture-Rich Environments

Marine-grade PVC foam sheet, a type of expanded PVC, is a lightweight, closed-cell plastic material engineered for superior moisture resistance and durability. Specifically designed to perform in wet and humid conditions, this versatile sheet is ideal for a variety of marine and outdoor applications.

Manufactured with enhanced weatherability and UV protection, marine-grade PVC foam sheet maintains dimensional stability and resists warping, rotting, and corrosion. It is easy to cut, route, and thermoform, making it a popular choice for fabricators, designers, and OEMs seeking long-lasting performance without sacrificing aesthetics.

Available in a range of thicknesses and colors, this material is frequently used for boat interiors, dashboard panels, cabinetry, signage, and other structural and decorative applications in moisture-prone environments. Whether you are retrofitting a watercraft or designing high-end marine displays, marine-grade PVC foam sheet offers the durability and fabrication ease needed for demanding projects.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Marine-Grade PVC Foam Sheets

Our marine-grade PVC foam sheets offer several performance and fabrication advantages that make them a standout material across various industries.

Moisture Resistant: Closed-cell construction prevents water absorption, making it ideal for marine and high-humidity environments.

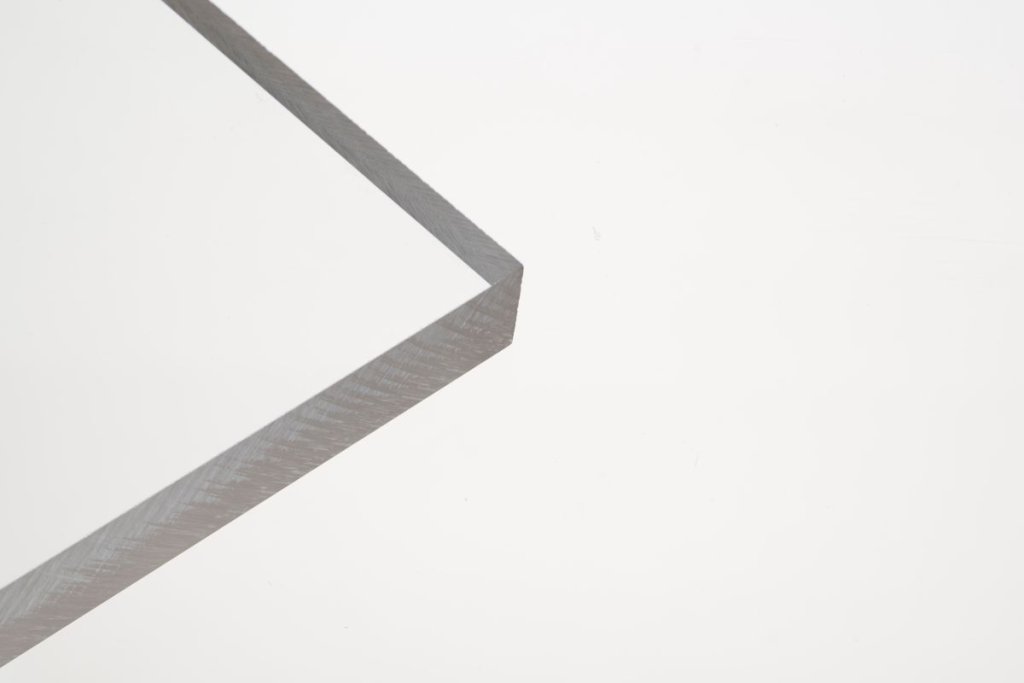

Lightweight Yet Rigid: Offers excellent strength-to-weight ratio, reducing overall load without compromising stability.

UV and Weather Resistant: Engineered to withstand prolonged sun exposure and outdoor conditions without degrading or fading.

Easy to Fabricate: Can be easily cut, routed, drilled, or thermoformed using standard tools and techniques.

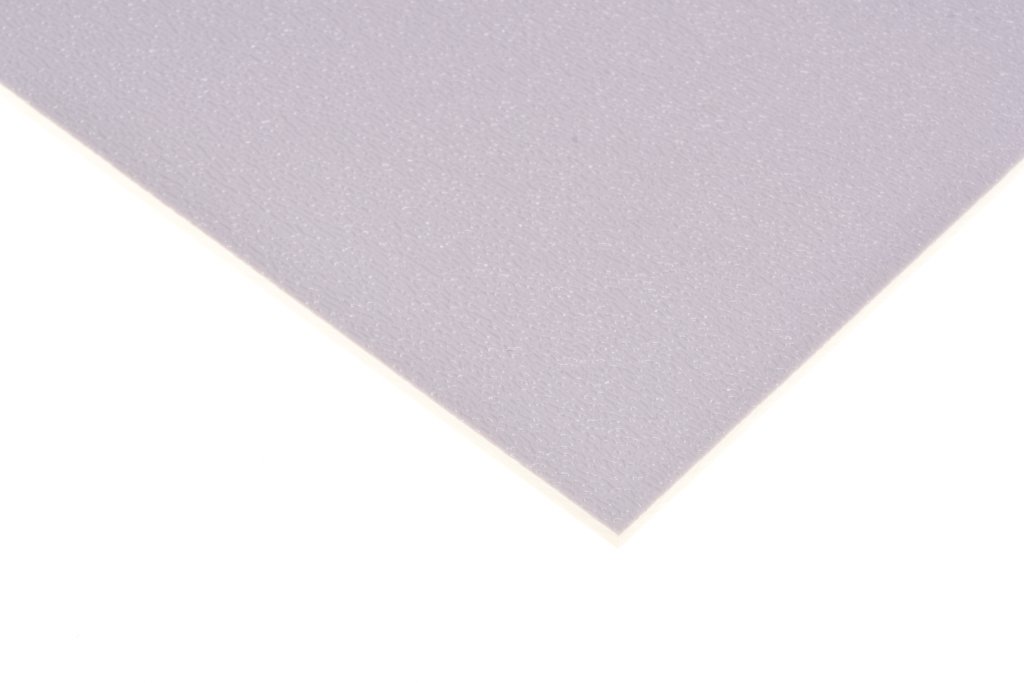

Smooth Surface Finish: Features a uniform surface that readily accepts adhesives, paints, and vinyl graphics for a clean, professional appearance.

These features make marine-grade PVC foam sheet a practical and cost-effective solution for customers seeking reliable performance in wet or outdoor environments.

Benefits of PVC Foam Sheet For Marine Applications

Applications of Marine Grade PVC Foam Sheet

Marine-grade PVC foam is used across several industries for both structural and decorative purposes. Its unique blend of properties makes it ideal for environments where moisture, salt, and UV exposure are concerns.

In the marine industry, it's commonly used for upholstery backing, cabinetry, bulkheads, hatch covers, and wall liners. Its lightweight nature makes it easy to work with during boat construction or retrofitting.

In architectural and construction applications, the material is used for outdoor enclosures, bathroom partitions, and wall panels where resistance to humidity and corrosion is critical.

From boat manufacturers to builders, marine-grade PVC foam sheet continues to be a trusted material for moisture-resistant projects of all kinds.

Related Products

-

Marine Grade ABS

Piedmont Plastics carries Marine Grade ABS, Aqua-Plas V. AP V is available in neutral colors to match most surfaces and is easily machined and fabricated.

-

Marine Grade Polyolefin

Marine grade polyolefins offer superior flexibility and toughness to the marine market, and often last longer than teak and other common marine materials.

-

Marine Grade Acrylic Sheet

Known for its superior performance, high customizability, and excellent impact resistance, marine grade acrylic sheet is ideal for various boat applications, such as windows, hatches, and custom enclosures.

Available Marine Grade Foam Sheet Product Options

Aqua-Plas I Ultra: Specifically engineered for use in marine upholstery applications, renowned for its ability to hold staples and screws securely. This product distinguishes itself by offering superior impact strength, outperforming many other PVC foam sheets available on the market. Not only is it lightweight, but it is also environmentally friendly, making it a conscientious choice for your marine projects.

Aqua-Plas III Ultra LG: Designed specifically for fiberglass boat builders, our lamination-grade PVC foam sheet is an environmentally friendly option that does not sacrifice performance. This lightweight sheet boasts superior impact strength, excellent screw retention, and a modified finish that is optimized for lamination, allowing for strong adhesion to fiberglass surfaces without the need for prior surface preparation.

Endurabond: An exceptional alternative to wood coring materials, Endurabond boasts features that are tailored for high-performance applications. It adheres seamlessly to fiberglass without any prior surface preparation and is crafted to resist corrosion, delamination, rot, and splintering.

Frequently Asked Questions About Marine Grade Foam PVC

Have questions about marine-grade PVC foam? Below are some commonly asked questions to help guide your decision.

Why Buy Marine Grade PVC Foam from Piedmont Plastics?

At Piedmont Plastics, we go beyond supplying material. We deliver complete solutions designed to meet your project needs. Here's what makes us your trusted source for marine-grade PVC foam sheet:

Extensive Inventory: We offer a wide selection of marine-grade PVC foam sheets in various thicknesses and sizes to suit both standard and custom applications.

Custom Fabrication Capabilities: Our advanced equipment allows us to provide precision cutting and fabrication services, delivering material tailored to your exact requirements.

Industry Knowledge: With decades of experience, our team is ready to help you identify the right marine-grade PVC solution for your specific environment and performance needs.

Nationwide Reach: With locations across North America, we ensure quick and convenient access to the materials you need, wherever your project is located.

Reliable Quality: Our marine-grade PVC foam products are selected for their consistency, durability, and proven performance in demanding marine and outdoor conditions.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745