The Future of Durability

Plastics play a crucial role in friction and wear applications, offering several advantages over traditional materials. Some commonly used plastics for these applications include PTFE, Nylon, and PEEK.

This article will discuss the importance of friction and wear in plastics, their comparison, and factors to consider when picking the best plastic. But first, it helps to understand the basics of friction and wear.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Introduction to Friction and Wear

Friction and wear directly impact the longevity and performance of components. Below is a quick review of how these concepts can impact components:

Friction is the resistance encountered when two surfaces come into contact and move relative to each other. It opposes the relative motion and is present in all mechanical systems. Different materials exhibit varying frictional properties.

On the other hand, wear is the progressive loss of material from a surface due to the mechanical action of another surface. Examples of this in action include adhesion, abrasion, erosion, and fatigue. The wear rate of a material depends on factors such as the material's mechanical properties, the contact form between the surfaces, the presence of lubrication, and the environmental conditions.

Both friction and wear have significant implications for the performance and longevity of components. Below, you'll learn how both can be better understood.

Understanding the Coefficient of Friction

The coefficient of friction (COF) measures the frictional force between two surfaces in contact and is crucial in determining materials' sliding behavior and performance. The equation for COF is μ = F/N. F equals the frictional force, and N is the normal force.

COF numbers typically range from 0 to 1. Lower numbers imply there is less friction (and therefore less wear). Plastics usually range from 0.2 to 0.6, benefiting from the inherent strength and low friction of good engineering plastics.

In addition to these inherent properties, the friction properties of plastics can be further enhanced by incorporating additives. Additives such as internal lubricants, solid lubricants, or fillers can improve the sliding behavior and reduce frictional losses.

The Importance of Wear Resistance

Wear resistance is incredibly important from an engineering standpoint because it determines the long-term form and integrity of the material while in use. Regarding COF, lower numbers here result in a higher wear resistance of your chosen material.

Signs of good wear resistance include self-lubricating properties and improved reliability during operations. Advancements in engineering plastics have revolutionized industries such as automotive, aerospace, electronics, and manufacturing, offering a range of benefits that contribute to the overall efficiency and reliability of components.

Essential Properties of Plastics

High-performance plastics possess several essential properties to ensure optimal performance and longevity. These properties are crucial for components that experience constant contact, high-stress levels, and exposure to various environments.

We've already gone through two properties: low COF and high wear resistance. Below are some additional properties that plastics can impact:

-

Good Corrosion Resistance

In environments where exposure to moisture, chemicals, or other corrosive substances is common, plastics must exhibit good corrosion resistance. This property protects the components from degradation, maintaining mechanical integrity and preventing premature failures.

-

Stress Resistance

Friction and wear applications often involve high levels of stress and pressure on the components. Plastics should be able to withstand these stresses without deforming or experiencing structural failure.

-

Thermal Stability

Heat and thermal cycling can significantly impact the performance and lifespan of friction and wear components. Plastics should be thermally stable, maintaining their good mechanical properties even when exposed to extreme temperatures.

-

Impact Resistance

Friction and wear components are often subject to shock loading or high-impact forces. In these cases, plastics must possess good impact resistance to avoid premature failure or deformation.

These essential properties allow plastics to provide the necessary reliability, efficiency, and durability for friction and wear applications. Next, you'll learn more about the common plastics that meet these requirements.

5 Common Plastics Used in Friction and Wear

Several commonly used plastics have proven highly effective in friction and wear applications. Below is a quick list of those plastics.

1. PEEK (Polyetheretherketone):

PEEK (also known as Ketron®) has a low friction coefficient, ensuring smooth movement between components and reducing energy losses.

- Suitable for temperatures up to 260°C (480°F)

- Chemically resistant

- Built tough and lightweight for harsh environments

- Used for bearings, bushings, semiconductor components, seals, and food processing.

2. UHMW (Ultra-High Molecular Weight Polyethylene):

UHMW is a versatile plastic with excellent friction properties, making it ideal for friction and wear applications.

- Impact resistant against high stress and force

- Resistant to damage from friction and abrasion

- Food safe and often used in home repairs

- Suitable for temperatures up to 180°F (82°C) and as low as -22°F (-30°C)

- Chemically resistant

3. Acetal (Polyoxymethylene):

Acetal is a high-performance plastic known for its excellent wear resistance and low friction properties.

- FDA-compliant (in its natural form)

- Easy to machine due to its high strength and low moisture absorption

- Temperature resistant up to 180° F (82° C)

- Found in bearings, bushings, can mandrels, manifolds, and many more engineering uses.

4. PTFE (Polytetrafluoroethylene)

PTFE (or Teflon®, a registered trademark of DuPont) is a unique, highly durable plastic often used in friction and wear applications due to its low coefficient of friction and excellent chemical resistance.

- Withstands major temperatures up to 500° F (260° C)

- Comes in both Virgin (no added recycled material) and reprocessed forms

- Can be filled with materials to enhance its resistance to deformation, thermal, and electrical properties

- Used in high-end tech fronts like solar panels and semiconductors

5. PET-P (Polyethylene terephthalate polyester)

PET-P (Polyester) is a biodegradable plastic with excellent wear and corrosion resistance.

- Internally lubricated to improve wear and stability

- Excellent under high pressure and velocity conditions (not as ideal for

- Excellent under temperatures up to 180°F (85°C)

- FDA compliant

Industry-Specific Applications for Plastic

Plastic is incredibly helpful across numerous industry applications. Below, you'll learn about a few examples.

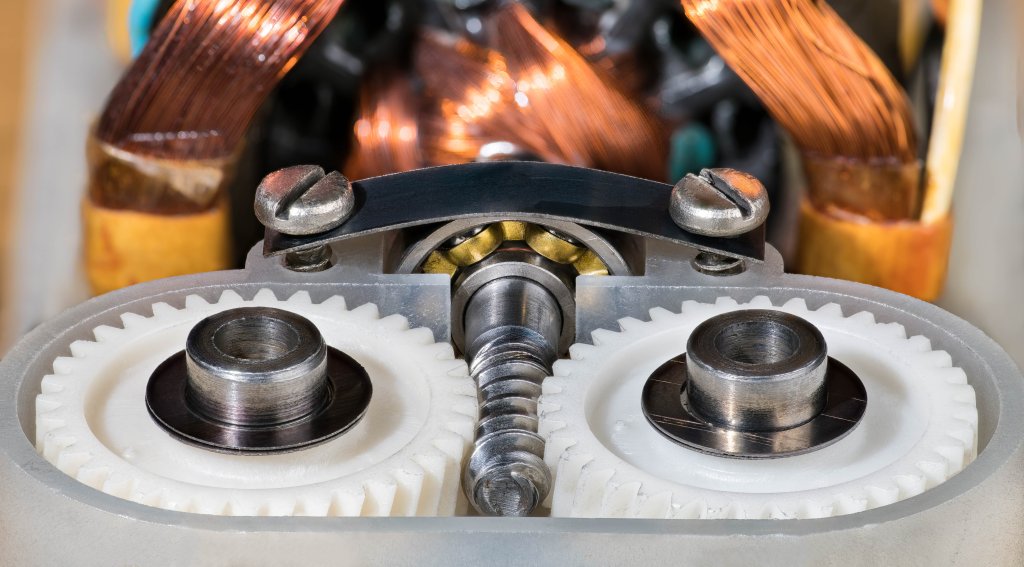

The automotive industry, for example, demands materials that can withstand high-stress environments and provide excellent friction and wear properties. Many plastics offer good mechanical strength and wear resistance, making them suitable for components such as gears, bushings, and bearings.

In the aerospace industry, where reliability and safety are paramount, materials that can withstand extreme conditions and high temperatures are essential. Spartech® Polycast™, for example, provides a wide range of options for helicopters, commercial aircraft, and military vehicles.

The medical industry also has unique requirements for friction and wear. Materials used in medical applications must be biocompatible, have low friction properties, and offer excellent wear resistance. PETG is a thermoplastic known for excellent thermoforming characteristics and impact resistance ideal for medical applications.

Different industries have specific requirements when it comes to friction and wear. Below, you'll find out more about how plastic advancements have helped.

Advancements in Plastic Materials

The continuous advancements in plastic materials have revolutionized many industries by providing exceptional friction and wear properties. These developments have significantly improved the coefficient of friction, wear resistance, and other performance properties of plastics, making them highly sought-after materials for various applications.

One key aspect of these advancements is the incorporation of additives into plastic formulations. These additives can enhance specific properties, such as wear resistance and friction coefficients, to meet the demands of different applications. Lubricants, for example, can improve the tribological properties of plastics, reducing energy losses and enhancing overall efficiency. Additives also play a crucial role in improving plastics' chemical and corrosion resistance, ensuring their suitability for harsh environments.

Selection Criteria in Finding Plastic Materials for Friction and Wear Applications

When it comes to selecting a plastic material for friction and wear applications, several key factors should be taken into consideration. These factors determine the performance and suitability of the material for specific application requirements.

Recall that we've already gone through a few of these considerations above. They include having a low COF number (which reduces wear), corrosion resistance, thermal capacity, and impact resistance. Below, you'll learn a few additional considerations:

Mechanical strength refers to the ability of the material to withstand mechanical stresses, such as load or impact, without deformation or failure. It's essential to assess the tensile strength, flexural strength, and impact resistance of the plastic material to ensure its suitability for the application.

Cost is another important factor when selecting a plastic material for friction and wear applications. For instance, composite materials are increasingly used because they are lightweight and cost-effective.

Environment is important in selecting plastics for friction and wear applications. Certain environmental conditions, such as high temperature and humidity, can affect the performance of plastics. The material should be able to withstand these environmental conditions without getting damaged.

Different industries have unique demands and challenges regarding friction and wear applications. For example, the automotive industry requires materials with low friction coefficients and excellent wear resistance to improve fuel efficiency and reduce maintenance costs. On the other hand, the aerospace industry may require materials that can withstand high temperatures and have superior mechanical strength for critical components.

The product's design is also important when selecting plastics for friction and wear applications. The material needs to be chosen per the complex geometric requirements of the application. For instance, aerospace components often require intricate designs that are difficult to carry out using conventional materials.

Need Additional Information?

Selecting the appropriate plastic material for friction and wear applications requires careful consideration of several key factors. To learn more about how to find the best plastics for your unique industry needs, contact our experts at Piedmont Plastics today.

Get In Touch