Wood fiber faced foam sheet combines a dense foam core with wood fiber facers for rigidity, printability, and dimensional stability. Ideal for signs, exhibits, and mounting displays.

Wood Fiber Faced Foam Sheet

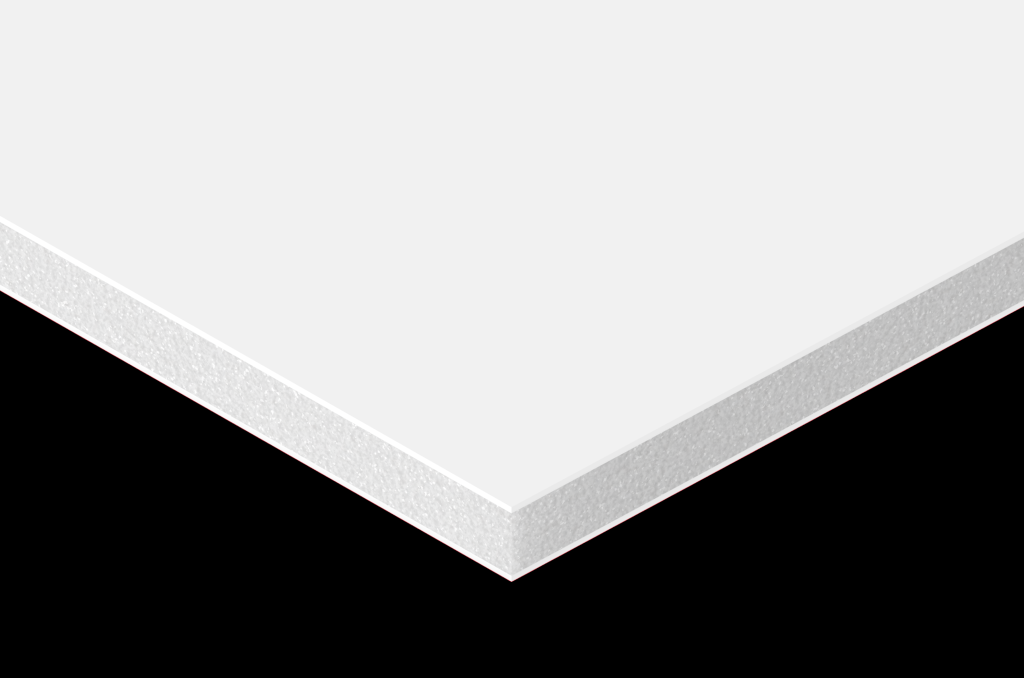

Lightweight, rigid foam board with smooth wood fiber facers.

No store found.

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Wood Fiber Faced Foam Sheet

Common Properties

- Friendly Names Gator Board, Fiber-Faced Foam Board

- Typical Thickness Size 3/16, 3/8, 1/2, 3/4, 1 in

- Common Profiles Sheet

- Typical Lengths 48, 96, 100, 120 in

- Common Brand Names Gatorfoam®

- Typical Widths 24, 48, 50, 60 in

Regulation Properties

Get a Quote for Wood Fiber Faced Foam Sheet at Piedmont Plastics

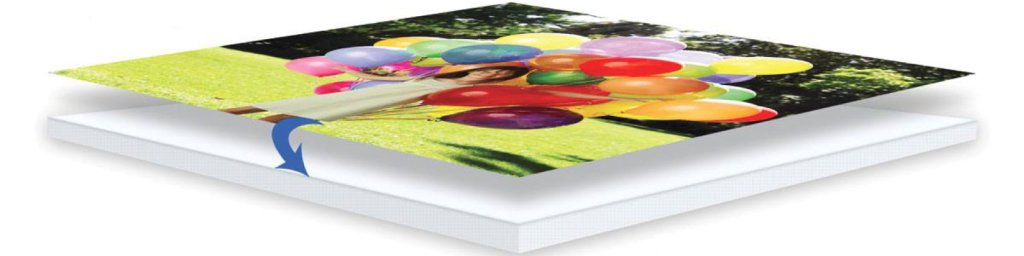

Wood fiber faced foam sheet is a rigid composite material featuring a lightweight polystyrene or polyurethane foam core laminated between two durable wood fiber facers. The result is a sheet that offers an ideal balance of strength, stiffness, and smoothness, making it a go-to solution for high-quality graphic displays, photo mounting, and architectural models.

At Piedmont Plastics, we supply wood fiber faced foam sheet in standard and custom sheet sizes to meet your specific application requirements. Contact us today to discuss your project and request a quote.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Wood Fiber Faced Foam Sheet

Wood fiber faced foam sheet provides a stable surface with excellent dimensional integrity and print performance. Its unique structure makes it stronger and more durable than traditional paper-faced foam boards.

Key performance characteristics include:

Smooth, uniform wood fiber facers for superior surface quality

Lightweight yet rigid construction

Excellent dimensional stability under temperature and humidity changes

Compatible with direct digital printing, mounting, and laminating

Clean cutting and easy fabrication with standard tools

Resistant to warping, denting, and edge crush

Benefits and Advantages

Common Applications

Wood fiber faced foam sheet is widely used across printing, architectural, and display markets where rigidity and visual quality are essential.

Art and Drawing: Wood fiber faced foam sheet provides a smooth, stable surface ideal for drawing, painting, and mounting artwork.

Backdrop and Set Design: In film, photography, and theater production, this material is commonly used to build lightweight backdrops, props, and light modifiers.

Display and Signage: Durable yet lightweight, wood fiber faced foam sheet is a popular choice for exhibition displays, retail signage, and trade show graphics. It can be easily fabricated for printing and mounting.

Model Making: Ideal for architectural models, dioramas, and prototypes, wood fiber faced foam sheet can be cut, carved, or textured to achieve realistic details while maintaining structural integrity.

Craft and DIY Projects: Easy to work with and versatile, this material is perfect for creating custom frames, decorative panels, bulletin boards, and other creative home or hobby projects.

Related Products

-

Expanded Foam PVC

Lightweight, durable, and versatile, Expanded Foam PVC is perfect for signs, exhibits, and displays, offering smooth printing, easy fabrication, and moisture resistance.

-

Foam Sheet

Piedmont Plastics carries all types of foam sheet, including open cell foam sheet for cushions and closed cell foam sheet for signs and prototypes.

-

Paper Faced Foam Board

Known for their strong performance, paper faced foam boards can be used for art canvases, mounting, backing, framing, die cutting and 3-D designs.

-

Styrene-Faced Foam Board

Styrene-faced foam sheets combine a lightweight foam core with durable styrene surfaces, offering smooth printability, rigidity, and easy fabrication for signage, display, and graphic applications.

Frequently Asked Questions

Below are some frequently asked questions about wood fiber faced foam sheet, its performance characteristics, and common uses. These answers can help you choose the right material for your next display, signage, or creative project.

It features a rigid foam core laminated between two wood fiber facers, combining light weight with structural strength.

Yes. It supports direct digital printing, screen printing, and vinyl mounting for high-quality graphic output.

It is primarily designed for indoor applications. Extended outdoor exposure may cause surface degradation over time.

Why Buy from Piedmont Plastics?

Piedmont Plastics is a trusted distributor of performance plastics and composite sheet materials. With decades of experience supporting the graphics and display industry, we offer both product expertise and exceptional service.

Nationwide network of branches: Local inventory and responsive delivery.

Custom cutting and fabrication services: Tailored solutions for every project.

Deep industry expertise: Knowledgeable specialists for signage, print, and display markets.

Wide product selection: One-stop source for rigid and flexible sheet materials.

Talk to An Expert

Near You