Polyester (PET) film offers strength, clarity, and dimensional stability for applications in packaging, protection, graphics, and electrical insulation.

Polyester Film

A durable, versatile film known for its chemical resistance. Ideal for industrial, electronic, and consumer products.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Polyester Film

Common Properties

- Common Brand Names Melinex®, MYLAR®, Skyrol®, PolyEfx®, ARYAPET

- Typical Thickness Size 0.001 – 0.014 in

- Typical Lengths 100 ft

- Typical Widths 24, 36, 48, 60 in

- Friendly Names PET Film

- Common Profiles Film

Physical Properties

- Density 1.35–1.40g/cm³

- Water Absorption 0.1-0.5%

- Moisture Absorption at Equilibrium 0.1-1%

- Linear Mold Shrinkage 0.2–0.6%

- Melt Flow 0.1-50g/10 min

Electrical Properties

- Dielectric Strength 15-25kV/mm

- Dielectric Constant 3.2-3.8

- Dissipation Factor 0.003-0.005

- Volume Resistivity 10^14-10^16ohm·cm

- Surface Resistivity 10^15-10^17ohm/sq

- Arc Resistance 100-120seconds

- Comparative Tracking Index (CTI) 200-600V

- Thermal Coefficient of Dielectric Constant 20-50ppm/°C

- Electrostatic Discharge (ESD) Sensitivity Moderate

- Breakdown Voltage 10-30kV

Mechanical Properties

- Hardness 110Rockwell R

- Tensile Strength, Ultimate 550MPa

- Tensile Strength, Yield 150–300MPa

- Elongation at Break 80-120%

- Elongation at Yield 5–10%

- Modulus of Elasticity 2500MPa

- Flexural Yield Strength 200MPa

- Flexural Modulus 2500MPa

- Compressive Yield Strength 150MPa

- Bearing Yield Strength 100–130MPa

- Shear Strength 50–70MPa

- Izod Impact, Notched 0.35J/cm

- Izod Impact, Unnotched 2.5J/cm

- Gardner Impact 10–15J

- Falling Dart Impact 25J

- Instrumented Impact Total Energy 5J

Thermal Properties

- CTE, linear 70µm/m-°C

- CTE, linear, Transverse to Flow 100µm/m-°C

- Deflection Temperature at 0.46 MPa (66 psi) 80–90°C

- Deflection Temperature at 1.8 MPa (264 psi) 70–80°C

- Vicat Softening Point 100–120°C

- Flammability VTM-2 or HBUL94

- Max Continuous Operating Temperature 150–170°F

- Minimum Operating Temperature -40°F

- Thermal Conductivity 0.15W/m-K

Regulations

- UL-94 Flame Class

- FDA

- ASTM/Mil-Spec

- USDA

- D635 Self Extinguishing

- RoHS Compliant

- REACH Compliant

Literature and Data Sheets

- All Suppliers

- Dupont Teijin Films

- JBF RAK LLC

- Klockner Pentaplast

- Newlife Magnetics

- Piedmont Plastics

- Scitop USA

- SK microworks America

-

Drytac® ReTac® Clear PET No SupplierView

-

DuPont Teijin Films™ Melinex® 454 Dupont Teijin FilmsView

-

DuPont Teijin Films™ 561 PET Film Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® 1311 Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® 329 Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® 339 Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® 377 Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® 516 Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® S Dupont Teijin FilmsView

-

DuPont Teijin Films™ Melinex® ST505 Dupont Teijin FilmsView

Get a Quote for Polyester (PET) Film from Piedmont Plastics

Polyester film, also known as PET film, is a clear, strong, and flexible plastic film that delivers dependable performance in many different industries. It combines high tensile strength with excellent dimensional stability, meaning it keeps its shape and structure even under heat or stress. PET film also resists moisture, chemicals, and wear, making it a durable option for demanding environments.

This versatile material can be printed, laminated, coated, or die-cut to meet specific project needs. It’s often chosen for its smooth, glossy surface and ability to maintain clarity and performance over time. These qualities make polyester film ideal for both functional and decorative applications where appearance and reliability matter.

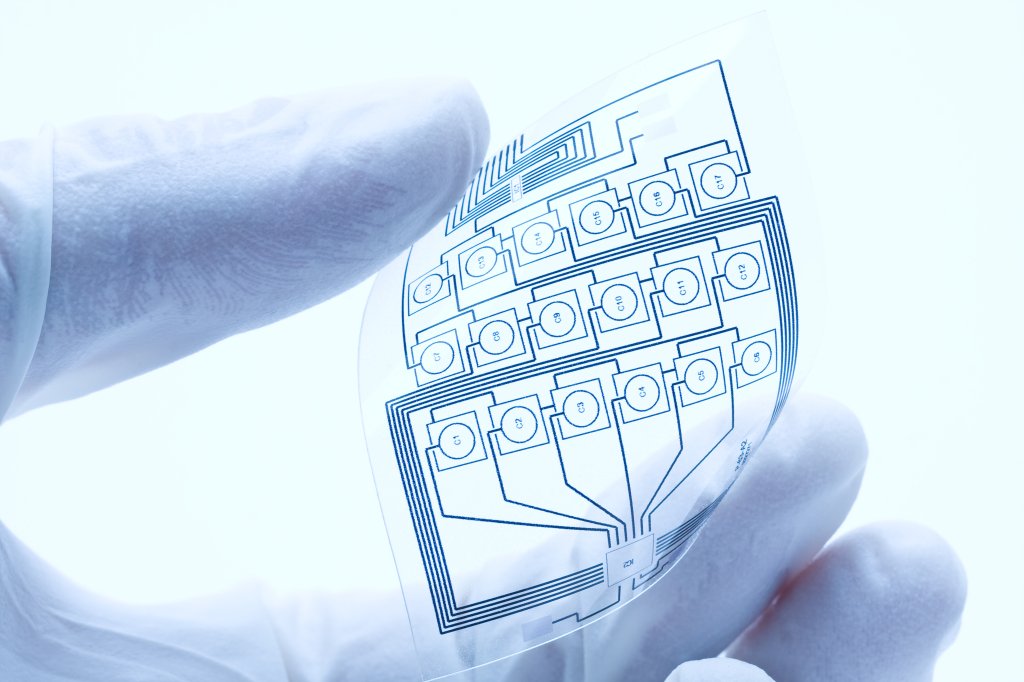

PET film is widely used in packaging, where it serves as a protective and flexible barrier for food and consumer products. It’s also a popular choice for graphic overlays, labels, and decals, offering a printable surface that holds vibrant colors and fine details. In the electrical and electronics industries, PET film provides reliable insulation for transformers, motors, and flexible circuits. Additionally, it’s used in solar and optical applications that require consistent clarity and UV resistance.

Whether you need a clear protective layer, a printable surface, or an electrically insulating material, polyester film offers the strength and versatility to perform. Contact Piedmont Plastics today to find the right PET film for your application. Our team can help you choose from a variety of grades, textures, and transparencies to meet your exact specifications!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of PET Film

Polyester film delivers a combination of clarity, mechanical strength, and heat resistance that makes it ideal for both functional and decorative uses.

Key performance characteristics include:

Chemical Resistance and Durability: Polyester film offers outstanding chemical resistance and long-lasting durability, outperforming many other common plastic films in tough environments.

Dimensional Stability: PET film maintains its shape and size under heat and stress, making it ideal for precise applications such as face shields, laminates, and electronic insulation.

Optical Clarity: Known for its exceptional transparency, PET film delivers excellent optical clarity, perfect for display panels, ID cards, and printed electronic components.

Thermal and Chemical Stability: Even when exposed to temperature fluctuations or harsh chemicals, PET film retains its physical and mechanical properties, ensuring consistent performance over time.

Versatility: This material’s adaptability makes it suitable for hundreds of uses, including packaging, printing, die-cutting, electronics, and protective overlays.

Variety of Finishes: Available in clear, hazy, matte, and white finishes, PET film can also be surface-treated for single- or double-sided printing, providing flexibility for design and production.

FDA Compliance: Certain PET film grades meet FDA standards, making them suitable for sterile or clean applications such as medical face shields and food packaging.

Weather Resistance: With strong resistance to water and environmental exposure, PET film performs reliably in both indoor and outdoor conditions, making it virtually weatherproof.

Together, these features make polyester film a highly adaptable, high-performance material trusted across industrial, commercial, and consumer sectors.

Benefits of Using PET Film

Common Applications for PET Film

Polyester film is valued for its versatility and performance, making it suitable for countless applications across multiple industries.

Packaging: PET film is widely used in food and beverage packaging due to its strength, clarity, and food-safe versatility that protect products while enhancing their appearance.

ID Cards and Displays: With its excellent optical clarity, polyester film allows photos, text, and graphics to appear crisp and vibrant, making it ideal for ID cards, signage, and display materials.

Printed Electronics: In flexible circuits, membrane switches, and electronic displays, PET film offers the stability and flexibility needed for precision manufacturing.

Medical Devices and Face Shields: Certain grades of PET film meet FDA standards, allowing safe use in medical environments for items such as face shields and protective covers.

Electronics and Insulation: Polyester film provides reliable electrical insulation for components like transformers, motors, and capacitors due to its dimensional stability and dielectric strength.

Industrial Applications: PET film is used in die-cut parts, protective overlays, and barrier layers where durability and chemical resistance are necessary.

Graphic Arts: Its smooth surface, easy printability, and ability to hold fine detail make PET film an excellent choice for graphic arts, labels, and decals.

Across every application, polyester film stands out for its durability, clarity, and adaptability, qualities that make it a trusted material for both industrial and consumer use.

Related Products

-

Rigid Vinyl Film

Rigid vinyl film is a type of durable PVC film for printing, packaging, and industrial applications. Piedmont Plastics supplies high-quality rigid vinyl film with excellent dimensional stability and performance.

-

Polyethylene Film

Piedmont Plastics stocks polyethylene (PE) film, commonly used as a protective barrier in exterminating, painting, renovations, and waterproofing.

-

Polycarbonate Film

Polycarbonate film offers exceptional clarity, top-quality printing, high heat resistance, and easy thermoforming and molding capabilities.

Frequently Asked Questions About PET Film

Below are some commonly asked questions about polyester film and how it performs in various environments.

Yes, PET film is BPA-free and considered safe for food and beverage contact by regulatory agencies like the FDA.

Yes, PET film accepts a variety of printing methods, including screen, offset, and digital printing, after appropriate surface treatment.

Polyester film is recyclable under many local recycling programs and can be reprocessed into new polyester materials.

PET film can typically withstand continuous service temperatures up to about 150°C (302°F), depending on the grade. Contact your local Piedmont Plastics sales representative for specific technical information.

Some grades of PET film include UV inhibitors for enhanced outdoor performance.

Why Buy PET Film from Piedmont Plastics?

Our material experts at Piedmont Plastics are ready to help you find the right polyester film for your specific applications. With decades of experience serving industries such as packaging, graphics, and electronics, our team provides the technical knowledge and customer service you can depend on.

Discover the benefits of partnering with Piedmont Plastics for your polyester film needs:

Wide Product Selection: We offer PET film in a variety of thicknesses, finishes, and grades to meet the demands of diverse industries and performance requirements.

Custom Fabrication Services: Our cutting and converting capabilities allow us to deliver polyester film products tailored to your exact size and application specifications.

Trusted Industry Knowledge: Backed by extensive expertise in plastics distribution, our team can guide you in choosing the right PET film for your project.

Nationwide Availability: With multiple branches across North America, Piedmont Plastics provides local inventory and efficient delivery wherever your business operates.

Consistent Quality Assurance: We are committed to supplying polyester film that meets or exceeds industry standards for clarity, strength, and reliability.

Want to learn more? Contact our team today to discover how Piedmont Plastics can support your next project with high-quality polyester film solutions!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745

.jpg)