Polyester is a type of plastic polymer with various uses and a substantial array of positive characteristics. Made from polyethylene terephthalate (PET), polyester plastic can be manipulated under certain heating conditions to form sheets, rods, films, and other shapes.

Characteristics of Polyester Film

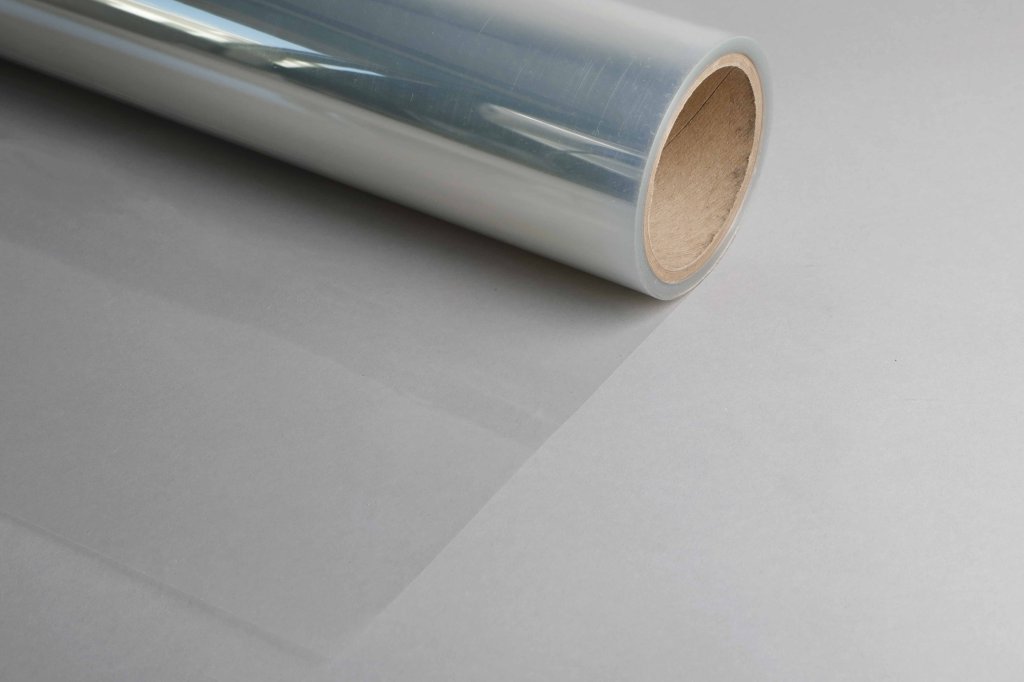

Polyester film is typically available with a clear coat and a glossy finish. It can, however, be created with alternative visual finishes such as matte, hazy, or no masking. In addition, the surface can be altered to meet specified textures, whether you want a very smooth or rough finish.

Polyester film is noted for its optical clarity, physical and mechanical strength, and thermal and chemical stability. It can be built to the exact specifications of each user. It can also maintain its shape in almost any environment—even when subjected to high temperature changes or chemical exposure.

A variety of leading industry suppliers offer polyester film. As a result, it is sometimes referred to by brand names like MYLAR®, MELINEX®, reflexTM, Autoflex®, and Sarafil.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Benefits of Polyester Film

PET is exceptionally well known for providing superb optical clarity, which is especially beneficial for making display products. In addition to a choice of available textures and finishes, PET features anti-glare and anti-fog properties in nearly all of these forms.

Additionally, polyester sheet enjoys a high level of stability. It can be exposed to various temperatures with very low shrinkage. PET is also resistant to water and chemical exposure. It’s essentially weatherproof and can withstand nearly any environmental condition.

Polyester film is also valued for its:

Chemical Resistance

The chemically-resistant properties of PET allow it to work with any number of chemical treatments depending on the end user’s needs. In addition, its chemical resistance helps improve adhesions to various coatings, inks, and adhesives—all of which make it ideal for printed displays, packaging, and signage.

Trustworthiness

Polyester film is a mainstay of the packaging industry. Not only is it safe for contact with food and beverages, but the material also doesn’t contaminate products with chemicals or other harmful materials.

Eco-friendliness

Because it is a thermoplastic engineered material, its form can be altered with various heat levels. This makes it simple to recycle and reuse, thus reducing the need for new raw materials and high energy output for manufacturing.

Versatility

In addition to its ability to be reshaped and reformed under heat, polyester plastic sheets can be die-cut, or laser cut relatively easily. This makes custom manufacturing more efficient and less wasteful.

Uses For Polyester Film

Because of its physical properties, polyester film material is an excellent choice for many applications. It’s commonly used in packaging, ID cards, and printed electronics, to name a few.

Polyester film, in particular, can be employed in various packaging applications due to its ability to take on both rigid and flexible shapes. Because it is a food-safe polymer, it is prevalent in the food and beverage industries. Various grades of PET are designed to meet specific food and beverage industry regulations, such as FDA, USDA, 3A-Dairy, and Canada AG.

PET is also used in printed electronics. Because it is so adaptable, polyester sheet is found in various components, such as flexible circuits, membrane touch switches, and printed electronics displays.

Polyester film provides optical clarity when it comes to ID cards and displays, allowing photos, text, and graphics to stand out. Users can choose from various finishing options to give their cards or signage the look they want. In addition, the material produces a durable surface that can withstand many environmental or usage conditions.

PET is also commonly used to make:

Capacitors

Motor films

Wires and cables

Imaging media

Polyester Plastic Film at Piedmont Plastics

Piedmont Plastics carries a large selection of PET products in varying grades, textures, and transparencies in over 55 locations across North America. In most locations, we can help with custom sizes, finishes, colors, and other attributes you need for your project.

Find What You Need

Please contact us today to discuss your polyester film needs, and our dedicated film specialists will help you select the right solution for your application!

Get In Touch