HIPS is a tough, versatile plastic material that's easy to fabricate and print on, commonly used in signage, displays, packaging, and thermoformed products.

High Impact Polystyrene (HIPS)

A durable and low-cost thermoplastic known for its excellent impact resistance, easy fabrication, and printable surface.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of High Impact Polystyrene (HIPS)

Common Properties

- Common Brand Names Prime DIGI - HIPS

- Typical Thickness Size 0.020 – 0.250 inches

- Typical Lengths 48, 96 inches

- Typical Widths 24, 48 inches

- Friendly Names HIPS, High Impact Polystyrene

- Common Profiles Sheet

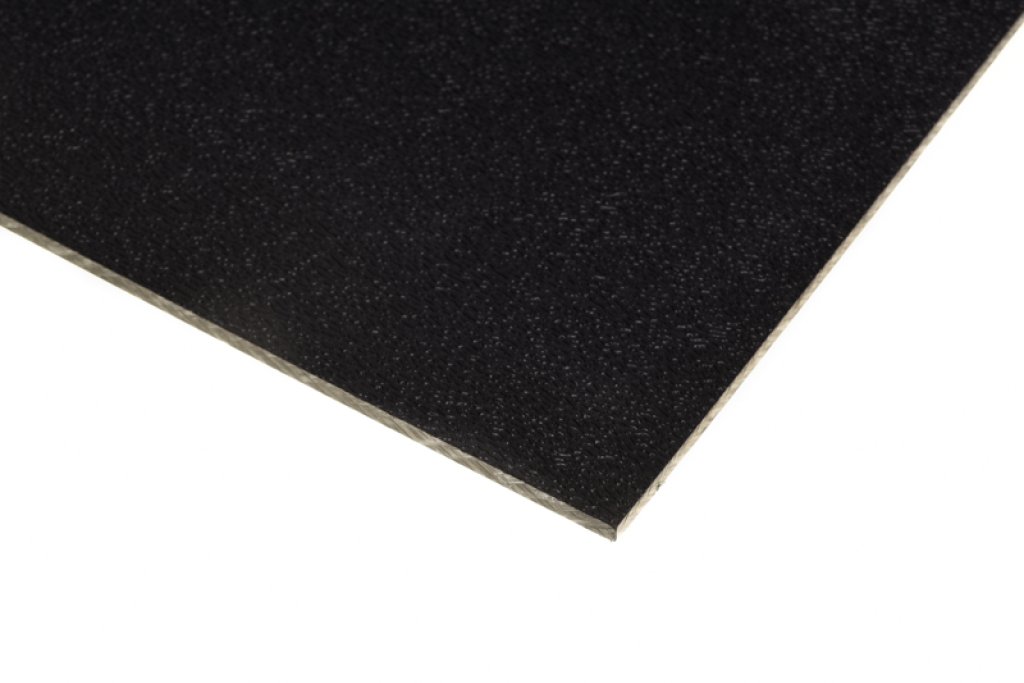

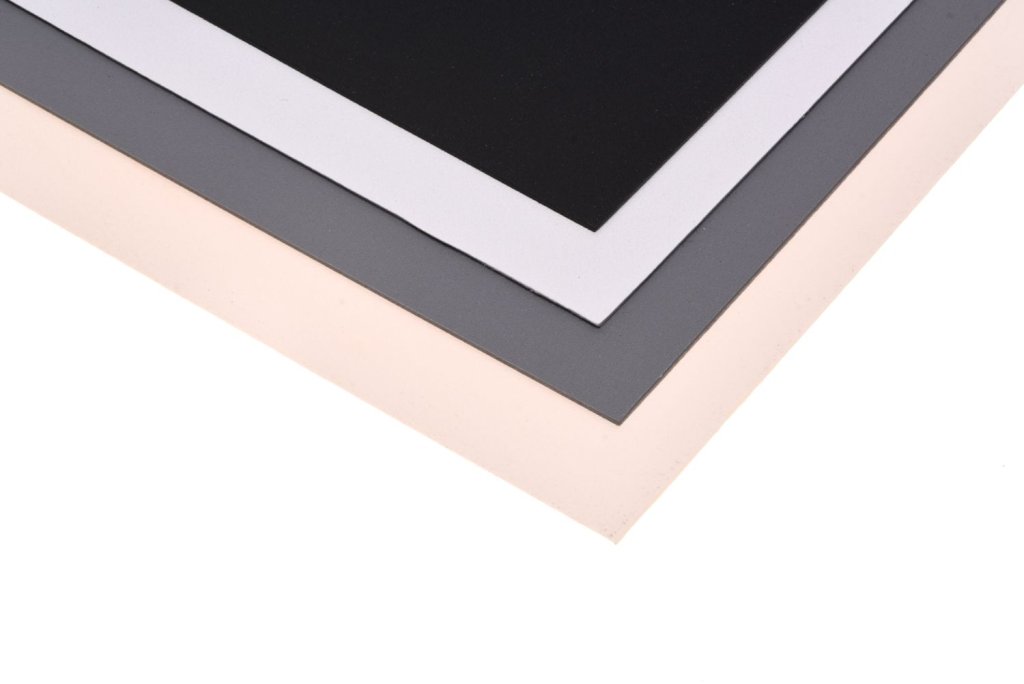

- Common Color Options White and Black

Physical Properties

- Density 0.9g/cm³

- Water Absorption 0.3%

- Moisture Absorption at Equilibrium 0.2%

- Linear Mold Shrinkage 0.02in/in

- Melt Flow 10g/10 min

Regulations

- UL-94 Flame Class

- FDA

- ASTM/Mil-Spec

- USDA

- NSF

- D635 Self Extinguishing

- RoHS Compliant

- REACH Compliant

Premium High Impact Polystyrene Sheets for Versatile Applications

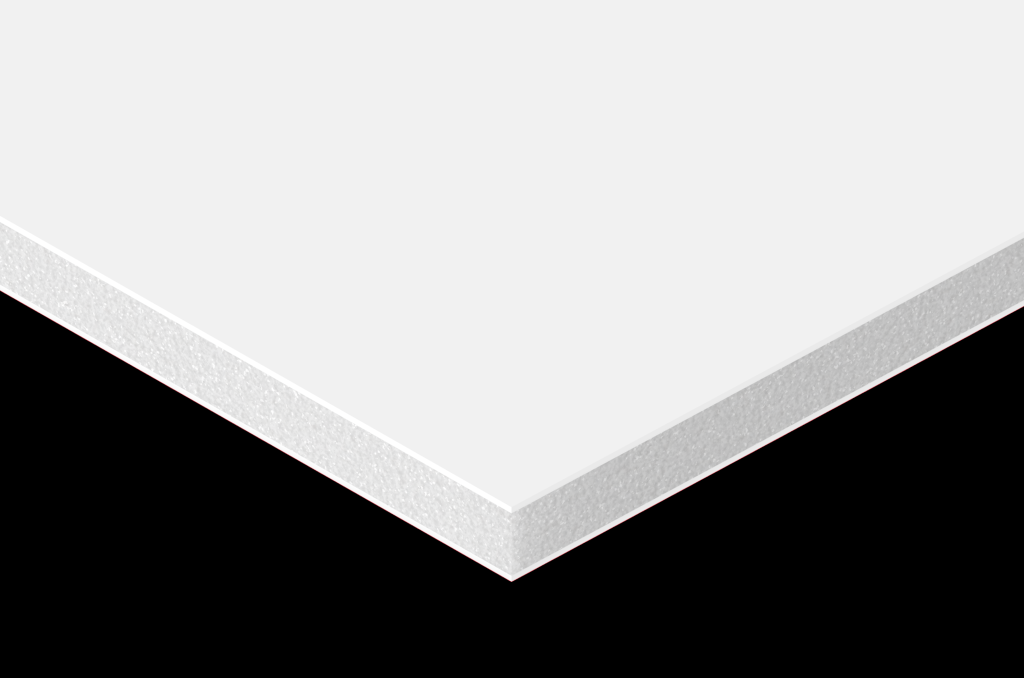

High impact polystyrene (HIPS) sheet is a lightweight, rigid plastic material known for its outstanding impact resistance and easy fabrication. As one of the more cost-effective and adaptable thermoplastics on the market, HIPS plastic materials are ideal for a wide variety of applications that require durability and visual appeal.

HIPS plastic offers a smooth matte surface that readily accepts printing, making it an excellent choice for graphics, signage, displays, and packaging. It can be thermoformed, machined, and cut with minimal effort, which helps reduce processing time and costs.

With its impressive impact resistance and good aesthetic qualities, high impact styrene plastic is widely used across industries such as retail, medical, and food service. Whether you’re looking for a reliable substrate for vacuum forming or a printable plastic sheet for indoor signage, HIPS sheet delivers the versatility you need.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Our High Impact Polystyrene Sheet

HIPS comes with a range of qualities that make it suitable for both functional and aesthetic applications. Here’s what makes HIPS material a go-to choice:

Impact Resistance: HIPS plastic offers excellent resistance to impact and cracking, making it ideal for high-traffic and high-stress environments.

Easy Fabrication: This material is easy to cut, drill, thermoform, and bond, enabling quick and efficient production.

Printable Surface: The matte surface of high impact polystyrene plastic ensures excellent ink adhesion for screen printing and digital printing applications.

Lightweight: HIPS material is significantly lighter than many other plastic alternatives, making it easier to handle and install.

Cost-Effective: One of the most affordable thermoplastics available, HIPS plastic helps reduce overall project costs.

These features make high impact styrene sheet a flexible and reliable material for a wide range of industries and applications.

Benefits of Choosing HIPS Sheet

Applications of High Impact Polystyrene Sheets

High impact polystyrene sheet is widely used across multiple sectors due to its versatility and ease of use. Common applications include:

Retail and Point-of-Purchase Displays: HIPS is ideal for custom signage, kiosks, and display units due to its printable surface and clean appearance.

Thermoformed Parts: The material's excellent thermoforming properties make it a top choice for trays, housings, and enclosures.

Medical Devices and Orthotics: HIPS plastic is used in temporary prosthetics and orthotic devices, especially in formulations like Orfitrans Stiff.

Packaging Solutions: High impact styrene is frequently used for food packaging, clamshell containers, and protective inserts.

From commercial graphics to industrial parts, HIPS plastic provides a dependable and professional finish that meets demanding performance standards.

Related Products

-

ABS

Acrylonitrile butadiene styrene is a durable, impact-resistant material commonly used in automotive components, consumer goods, and protective housings.

-

KYDEX

KYDEX® is a durable, versatile thermoplastic sheet ideal for industries like aerospace, medical, and retail.

-

Styrene-Faced Foam Sheet

Piedmont carries styrene-faced foam sheets for signage, dimensional lettering, packaging, and preservation, including Infinity, Gatorplast, and Ultra Board.

Frequently Asked Questions About High Impact Polystyrene Sheets

Here are some of the most frequently asked questions about high impact polystyrene sheet to help you better understand the material, its uses, and its advantages.

HIPS plastic is commonly used for signage, displays, packaging, and thermoformed parts in various industries including retail, healthcare, and the automotive sector.

Yes, HIPS sheet is ideal for thermoforming and produces detailed, durable molded components.

Many grades of HIPS are suitable for food contact applications. Please check with your Piedmont Plastics representative for specific compliance requirements.

Yes, HIPS offers a matte surface that allows excellent ink adhesion for both screen and digital printing.

Why Buy HIPS Plastic at Piedmont Plastics?

At Piedmont Plastics, we provide more than just materials. We deliver complete HIPS plastic solutions designed to support your application needs. Here's why we're your trusted source for high impact polystyrene sheet:

Extensive Product Variety: We stock a wide range of HIPS sheets in various sizes, thicknesses, and finishes to suit everything from printing to thermoforming applications.

Custom Cutting and Fabrication: Our advanced cutting and fabrication services ensure your HIPS plastic is tailored to precise specifications, saving you time and effort.

Expert Support: With decades of plastics industry knowledge, our team can guide you to the right HIPS material for your project requirements.

Nationwide Availability: With branches across North America, we make it easy to get the HIPS plastic you need—fast and reliably.

Consistent Quality: We source high impact polystyrene from trusted brands and guarantee materials that meet high performance and quality standards every time.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745