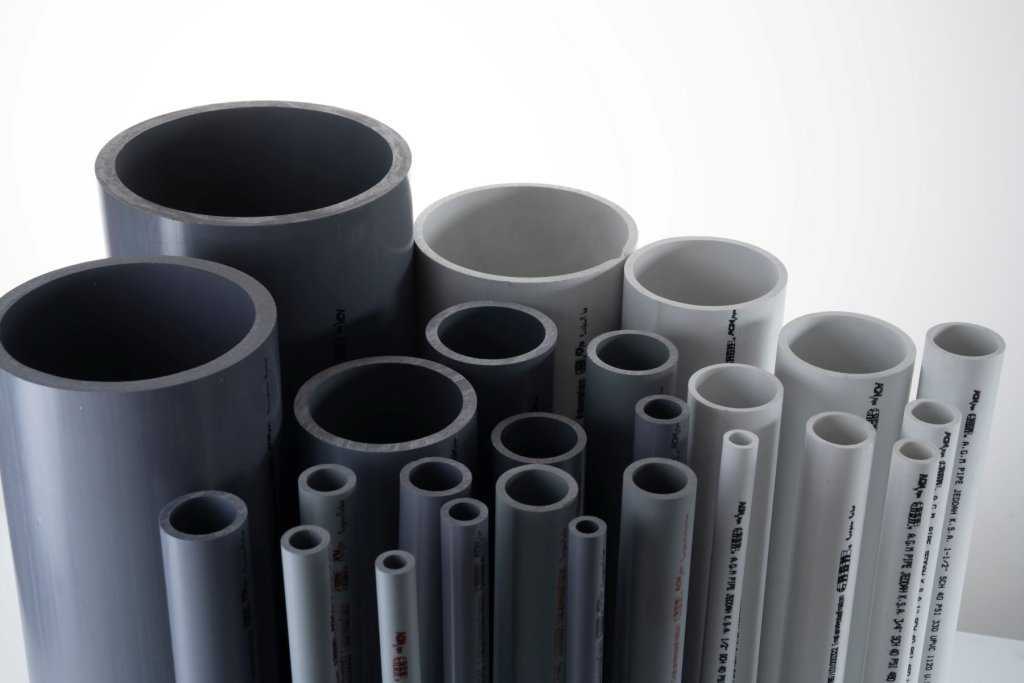

CPVC is a durable, high-performance thermoplastic designed to resist corrosion and handle higher temperatures than standard PVC. It’s widely used in chemical processing, water treatment, and industrial piping systems where strength and reliability are essential.

CPVC

A high-performance thermoplastic known for its excellent chemical resistance and ability to withstand elevated temperatures in industrial applications.

Product Overview

Widely used for:

Performance Characteristics:

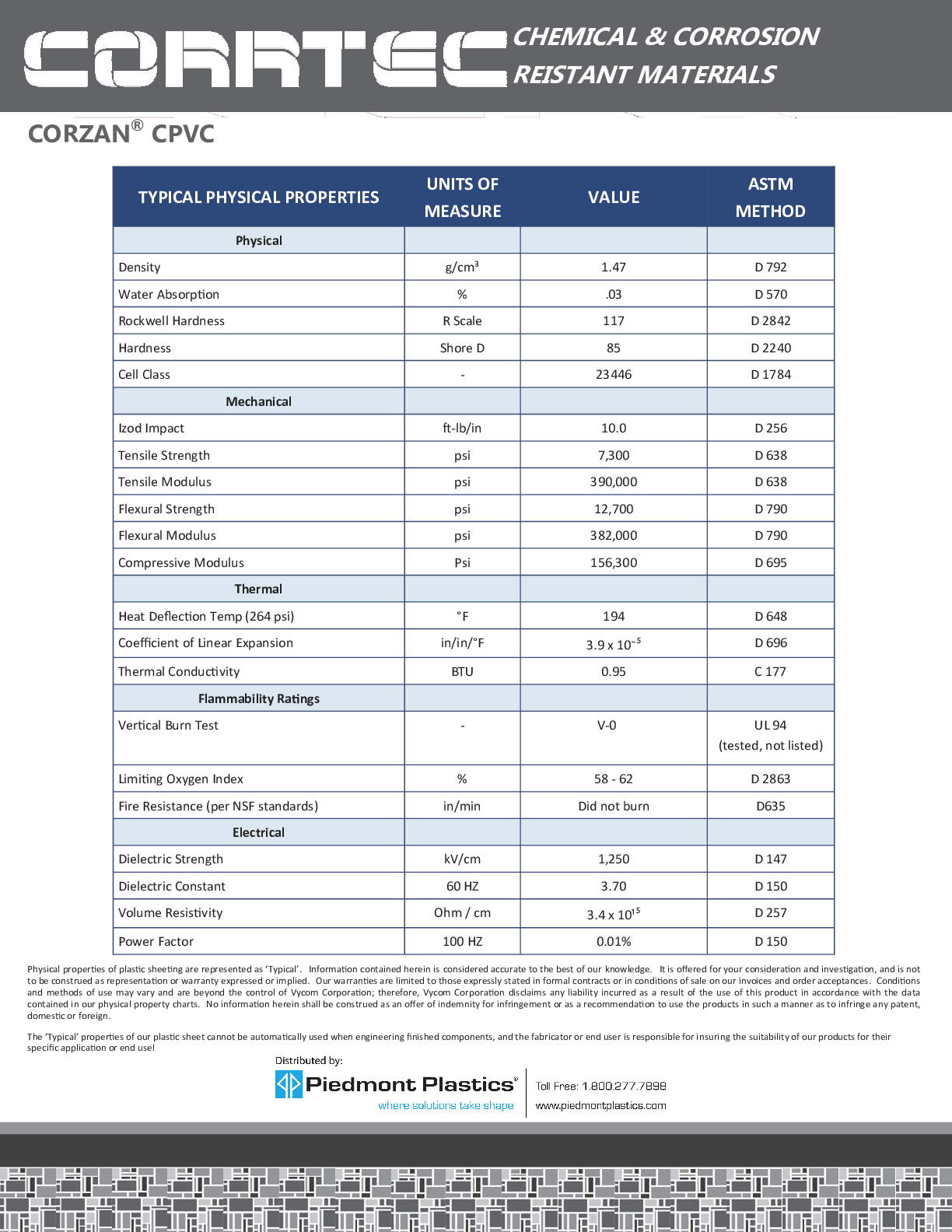

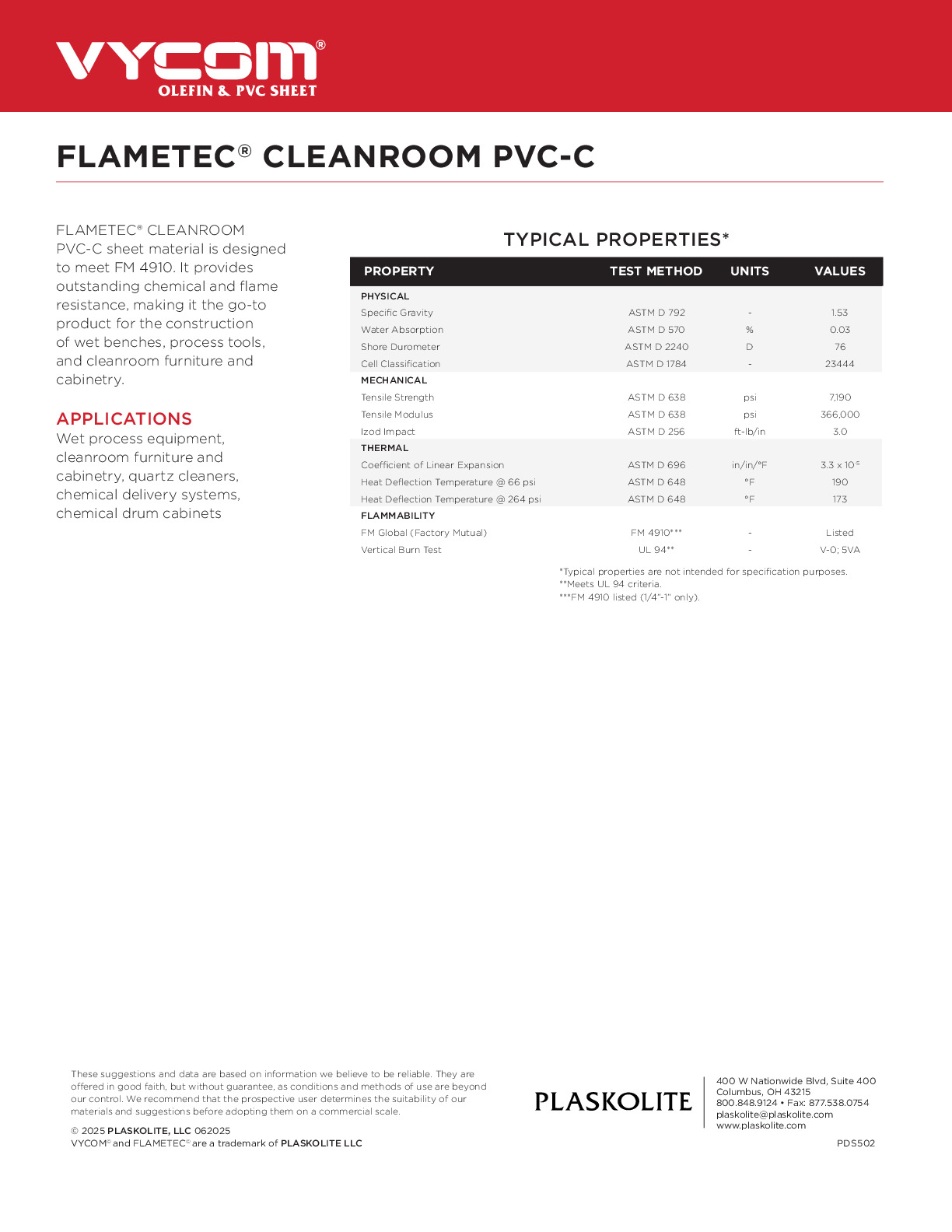

Typical Properties of CPVC

Common Properties

- Common Brand Names Corzan®, FLAMETEC® N/A

- Typical Rod Diameters 0.25 - 4 in

- Friendly Names Chlorinated Polyvinyl Chloride, Industrial CPVC, C-PVC N/A

- Typical Lengths 48, 96 in

- Typical Thickness Size 0.062 – 4 in

- Typical Pipe Diameters 0.5 - 12 in

- Common Profiles Sheet, Rod, Pipe, Tube N/A

- Typical Widths 48 in

Electrical Properties

- Electrostatic Discharge (ESD) Sensitivity Low

- Surface Resistivity 10^12-10^14 ohms

- Comparative Tracking Index (CTI) 600-650 V

- Arc Resistance 120-180 seconds

- Volume Resistivity 10^15-10^16 ohm·cm

- Dielectric Constant 3.6-4.2

- Dielectric Strength 40-150 kV/mm

- Thermal Coefficient of Dielectric Constant 0.008-0.02 1/°C

- Dissipation Factor 0.008-0.02

- Breakdown Voltage 400-600 V

Mechanical Properties

- Compressive Yield Strength 70 MPa

- Gardner Impact 25 Nm

- Flexural Yield Strength 96 MPa

- Shear Strength 34 MPa

- Falling Dart Impact 236 J

- Izod Impact, Unnotched 320 J/m

- Elongation at Yield 3 %

- Tensile Strength, Ultimate 51 MPa

- Tensile Strength, Yield 48 MPa

- Bearing Yield Strength 90 MPa

- Elongation at Break 50 %

- Instrumented Impact Total Energy 12 J

- Izod Impact, Notched 32 J/m

- Modulus of Elasticity 2400 MPa

- Hardness 115 Rockwell R

- Flexural Modulus 2200 MPa

Physical Properties

- Moisture Absorption at Equilibrium 0.2-2.5 %

- Density 0.90-2.20 g/cm³

- Linear Mold Shrinkage 0.1-2.5 %

- Water Absorption 0.01-3.5 %

- Melt Flow 0.1-50 g/10 min

Regulation Properties

Thermal Properties

- Vicat Softening Point 115 °C

- Deflection Temperature at 0.46 MPa (66 psi) 113 °C

- Thermal Conductivity 0.14 W/m·K

- Flammability, UL94 V-0

- Max Continuous Operating Temperature 200 °F

- CTE, linear, Transverse to Flow 80 µm/m/°C

- Deflection Temperature at 1.8 MPa (264 psi) 100 °C

- Minimum Operating Temperature 32 °F

- CTE, linear 72 µm/m/°C

High-Performance CPVC for Demanding Industrial Applications

CPVC plastic, also known as chlorinated polyvinyl chloride, is a high-performance thermoplastic engineered for use in high-temperature and corrosive environments. At Piedmont Plastics, we offer CPVC in sheet, rod, and tube form to meet the exacting demands of industrial, electrical, and fluid handling applications.

Known for its excellent thermal stability and chemical resistance, CPVC maintains its structural integrity in operating temperatures up to 200°F and resists degradation from acids, alkalis, and many corrosive substances. Its machinability and dimensional stability make it a top choice for fabrication and precision components.

Industries ranging from semiconductor manufacturing and chemical processing to wastewater treatment and electrical systems rely on CPVC for its long service life and performance under stress. Common applications include pump components, valve seats, insulation panels, electrical enclosures, and wire harness fixtures.

Whether you’re designing for heat resistance, chemical exposure, or electrical insulation, CPVC offers a reliable and cost-effective material solution. With extensive stock and custom fabrication capabilities, Piedmont Plastics is your trusted partner for CPVC solutions.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Our CPVC Sheet, Rod, and Tube

CPVC offers a unique combination of properties that make it a reliable choice for demanding industrial applications. Below are some key advantages that set CPVC apart from PVC and other materials:

Chemical Resistance: Withstands exposure to a wide range of corrosive chemicals, acids, and bases.

High Temperature Tolerance: Performs continuously at temperatures up to 200°F (93°C), making it suitable for hot water systems and high-heat processes.

Flame Retardant: Carries a UL 94 V-0 rating, meaning it is self-extinguishing and won’t support combustion, enhancing fire safety in enclosed systems.

Good Electrical Insulation: Naturally non-conductive, CPVC is often used in applications requiring safe electrical performance and insulation.

Dimensional Stability: Maintains its shape and structural integrity across a range of temperatures and environmental conditions.

Machinability: Easy to cut, drill, and mill using standard tools.

Solvent Bondable and Weldable: Compatible with solvent cement and hot gas welding techniques for secure, reliable joint construction.

Moisture and Hydrolysis Resistant: Resists swelling, degradation, or performance loss in high-moisture or steam-prone environments.

Whether you're building chemical processing equipment, designing high-temperature piping systems, or sourcing materials for corrosive environments, CPVC offers the performance and reliability you need. With its excellent balance of strength, thermal resistance, and chemical durability, CPVC is a trusted solution across a wide range of demanding industries.

Benefits of CPVC

Applications of Chlorinated Polyvinyl Chloride

CPVC plastic is widely used across industries that demand chemical resistance and thermal stability. Common applications include:

Chemical processing: Industrial pipe and fittings, plumbing systems, and chemical drainage.

Water and wastewater treatment: Flow control components, valve bodies, fittings, tanks, and tubing

Electrical and electronics: Insulating panels, electrical enclosures, and wire routing fixtures

Semiconductor manufacturing: Cleanroom-compatible parts, wet benches, chemical delivery systems

Medical and laboratory: Instrument enclosures (non-implantable), autoclave-resistant fixtures

Related Products

-

PVC Type 1

PVC Type 1 sheet and rod offer enhanced chemical resistance compared to standard PVC. They also offer excellent strength and versatility, making them ideal for industrial, chemical, and engineering applications.

-

PVC Type 2

PVC Type 2 sheet and rod are modified for superior impact resistance compared to Type 1, offering excellent strength and versatility for industrial, chemical, and engineering applications.

-

PVC Tubing

Piedmont Plastics supplies flexible PVC tubing with excellent clarity, flexibility, and chemical resistance, making it ideal for fluid transfer, food-grade, and industrial applications.

Frequently Asked Questions

Below are some commonly asked questions about CPVC and its performance:

Chlorinated Polyvinyl Chloride (CPVC) is a thermoplastic made by chlorinating PVC resin. This gives it higher temperature tolerance and better chemical resistance, making it suitable for more demanding applications than standard PVC.

CPVC has moderate UV resistance, but prolonged exposure to sunlight may cause surface degradation. For outdoor use, it is often recommended to use a UV-protective coating or choose a material with higher weatherability.

Yes, CPVC has a UL 94 V-0 flame rating, meaning it is self-extinguishing and produces low smoke, which is beneficial in enclosed or sensitive environments.

Yes, CPVC is widely used and approved for plumbing applications, especially for hot and cold water distribution in both residential and commercial settings. Many CPVC grades are also NSF 61 certified for use in potable water systems. Be sure to verify certification requirements for your specific application.

You can purchase CPVC from Piedmont Plastics. With a nationwide network of branches, we make it easy to find local inventory and get the material you need quickly.

Why Buy CPVC from Piedmont Plastics?

At Piedmont Plastics, we're more than just a plastic distributor. We provide reliable solutions tailored to your toughest application demands. Here’s why CPVC from Piedmont is the right choice for your project:

Extensive Product Availability: We stock CPVC sheets, rods, and tubes in a variety of sizes and dimensions to support a wide range of industrial and commercial applications.

Custom Cutting and Fabrication: Our advanced CNC and fabrication capabilities allow us to deliver precision-cut CPVC components built to your exact specifications.

Industry Expertise: With decades of experience, our knowledgeable team is ready to help you identify the right CPVC material for high-heat, chemical-resistant, or electrically insulative needs.

Nationwide Access: With locations across North America, we offer fast, reliable access to CPVC and other performance plastics—wherever your operations are.

Reliable Performance: Our CPVC materials meet or exceed industry standards for quality, ensuring consistent performance in even the most demanding environments.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745