In modern construction, balancing strength, insulation, and light transmission is key to creating energy-efficient and visually appealing structures. Twinwall polycarbonate panels offer all three benefits in one durable, lightweight material.

With their unique dual-wall design, these panels provide superior thermal insulation compared to glass or acrylic while maintaining excellent clarity and UV protection. This combination makes twinwall polycarbonate a leading choice for architects, builders, and engineers focused on sustainability and performance.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Is Twinwall Polycarbonate?

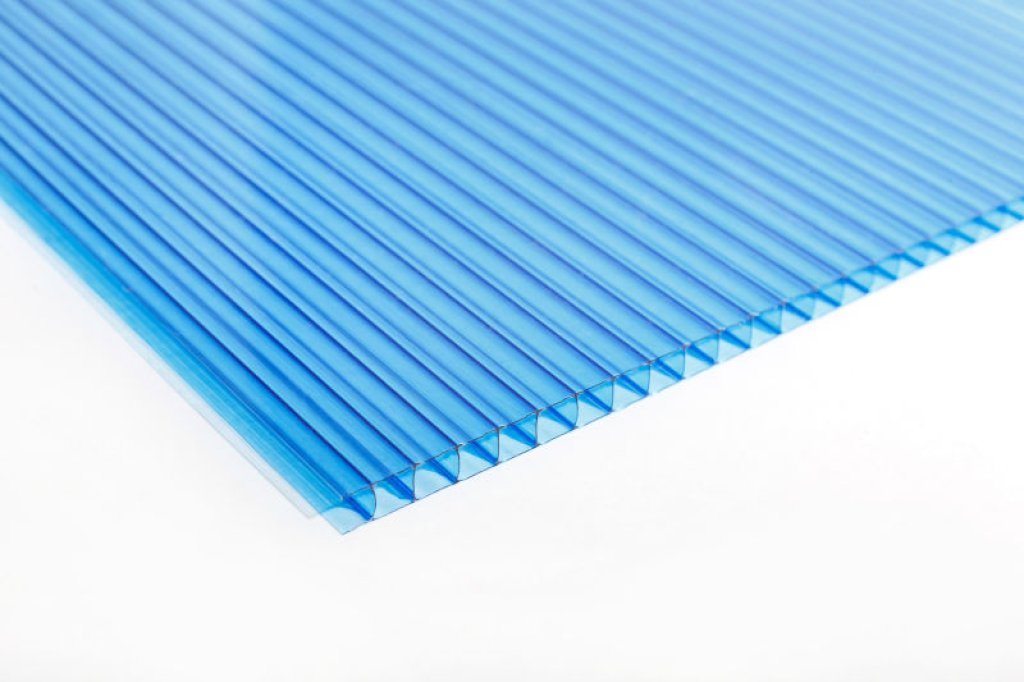

Twinwall polycarbonate is a type of structured plastic sheet made from two layers (or “walls”) of polycarbonate separated by internal ribs. The air pocket between the layers acts as an insulation chamber, improving thermal efficiency and strength without adding weight.

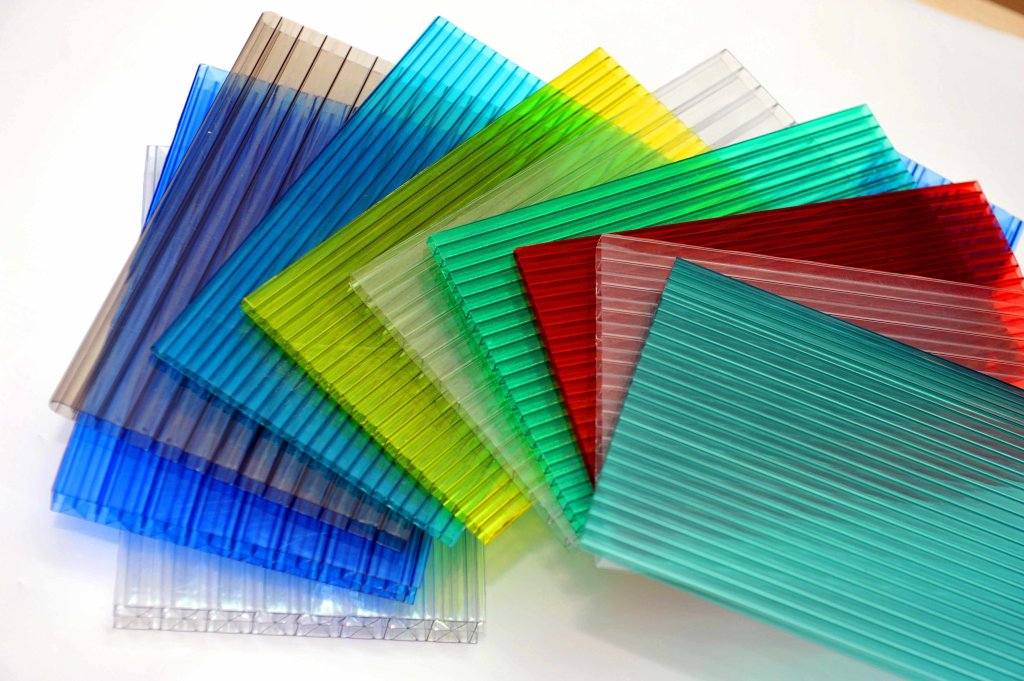

Available in a range of thicknesses and colors, twinwall sheets are used in applications that require both light transmission and impact resistance.

Key characteristics include:

Lightweight Structure: Twinwall polycarbonate is up to 12 times lighter than glass for easier handling and installation.

High Impact Resistance: This material is virtually unbreakable, even under extreme weather or impact.

UV Protection: Its co-extruded UV layer blocks harmful rays, preventing yellowing or degradation.

Thermal Insulation: The air chamber helps maintain indoor temperatures, reducing energy costs.

Design Flexibility: Twinwall polycarbonate can be cold-bent or fabricated for curved and custom applications.

Top Applications for Twinwall Polycarbonate Panels

Common uses for twinwall polycarbonate include:

-

Greenhouses and Horticultural Structures

Twinwall polycarbonate is widely used for greenhouses and nurseries because it provides diffused natural light while reducing heat loss. Its UV-resistant coating protects plants from harmful rays, and its durability ensures years of performance, even under heavy snow, wind, or hail.

-

Skylights and Roofing Systems

For skylights, patio covers, and roofing, twinwall polycarbonate panels offer a lightweight, weather-resistant alternative to glass. Their ability to transmit up to 80% of visible light brightens interiors naturally, reducing the need for artificial lighting and helping meet daylighting goals in LEED-certified projects.

-

Architectural Glazing

Used in architectural facades, wall cladding, and curtain walls, twinwall polycarbonate panels combine impact resistance and aesthetic appeal. The panels can be produced in various colors and finishes, offering modern design versatility for commercial and industrial projects.

-

Interior Partitions and Safety Barriers

Because twinwall polycarbonate is non-brittle and shatter-resistant, it is also used for office partitions, machine guards, and protective barriers where light transmission and impact protection are both important.

Energy Efficiency and Thermal Insulation Benefits

A defining advantage of twinwall polycarbonate is its superior thermal insulation compared to single-layer glazing materials. The air pocket within each panel acts as a natural thermal barrier, minimizing heat transfer.

This property provides measurable energy savings in both heated and cooled environments:

In cold climates: Reduces heat loss, helping maintain consistent indoor temperatures

In hot climates: Limits solar heat gain while allowing natural light

Because of its low U-value (a measure of heat transfer), twinwall polycarbonate contributes to reduced energy costs and improved building performance. When paired with UV protection and optional coatings, it also maintains long-term optical clarity and color stability, ensuring that structures look as good as they perform.

* For projects that require even higher insulation, multiwall polycarbonate sheets (with three or more internal layers) provide enhanced thermal performance while maintaining similar strength and light transmission benefits.

Twinwall Polycarbonate vs. Acrylic and Glass

Learn more about how twinwall polycarbonate compares to acrylic and glass:

| Property | Twinwall Polycarbonate | Acrylic | Glass |

|---|---|---|---|

| Weight | Up to 12 times lighter | Moderate | Heavy |

| Impact Strength | Virtually unbreakable | Moderate | Brittle |

| Thermal Insulation | Excellent | Fair | Low |

| UV Resistance | Built-in protection | Fair | Requires coatings |

| Fabrication | Easy to cut, drill, and install | Easy | Requires specialized tools |

| Cost Efficiency | Lower installation and energy costs | Moderate | Higher long-term costs |

Compared to glass or acrylic, twinwall polycarbonate offers the best balance of strength, insulation, and versatility. It eliminates the risk of breakage, simplifies installation, and lowers both transportation and labor costs without compromising visual appeal.

Ease of Fabrication and Installation

Additional installation benefits include:

These properties make twinwall polycarbonate a preferred material for retrofit projects, temporary structures, and new construction alike.

Frequently Asked Questions About Twinwall Polycarbonate

Twinwall polycarbonate has two walls with one air chamber, while multiwall polycarbonate can have three or more layers for added insulation and strength. Both share the same core benefits, including impact resistance, UV protection, and lightweight performance, but twinwall is the most common and versatile option for everyday construction projects.

In most cases, yes. Twinwall polycarbonate is 12 times lighter and 200 times stronger than glass, making it easier to install and virtually unbreakable. It also provides better thermal insulation and UV resistance, helping to reduce energy costs while maintaining outstanding light transmission.

When properly installed, twinwall polycarbonate panels can last 10–20 years or more. Most panels feature a UV-resistant co-extruded layer that prevents yellowing, cracking, and brittleness over time. Regular cleaning and proper installation further extend their lifespan.

Absolutely. Polycarbonate roofing panels are a top choice for skylights, patio covers, pergolas, and canopies. They allow natural light to enter while protecting against weather and UV rays. In addition, their light weight and flexibility make them suitable for curved or arched roof structures.

Yes. The air space between the two layers acts as an insulating chamber, helping to reduce heat transfer. This makes twinwall polycarbonate an ideal material for energy-efficient construction, particularly in greenhouses, atriums, and commercial buildings where maintaining stable indoor temperatures is critical.

Polycarbonate greenhouse panels offer the perfect balance of light diffusion, durability, and insulation. The twinwall design allows sunlight to pass through evenly, promoting healthy plant growth while maintaining a stable interior temperature.

Unlike glass, polycarbonate won’t shatter in hail or high winds, and its UV-resistant surface helps prevent plant damage from excessive radiation. This makes it the preferred material for commercial and residential greenhouse construction.

Why Choose Piedmont Plastics for Polycarbonate Panels

Piedmont Plastics supplies a full range of twinwall polycarbonate sheets in various thicknesses, colors, and configurations. With local inventory across North America and quick-turn cutting and routing services, we make it easy to source material for your next greenhouse, skylight, or architectural project.

Our experienced team can help you:

Select the right sheet configuration for your application.

Optimize panel sizing to reduce waste.

Ensure compatibility with framing and glazing systems.

Whether you need clear twinwall panels for a greenhouse or tinted sheets for an energy-efficient roof system, Piedmont Plastics has you covered!

Connect With The Experts

Ready to improve efficiency and performance in your next construction project? Contact your local Piedmont Plastics branch to learn more about our twinwall polycarbonate panel options!

Request A Quote