Guide to Selection and Testing

Most people associate plastics with melting under heat: think of overheating food in a plastic container in the microwave or leaving a plastic spatula too close to a hot burner. However, many thermoplastics and other engineered materials are designed to withstand extremely high temperatures. These materials are known as heat-resistant plastics.

Heat-resistant plastics can handle high working temperatures without softening, breaking down, losing stability, or melting. Often, traditional plastic materials are made more heat-resistant by adding something to them to increase their resistance to high temperatures. Here is a closer look at some of the more popular heat-resistant plastics, their properties, and the common applications where they work well.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Popular High-Temperature Plastics

Temperature ratings for these plastics can range from 50 degrees Celsius (122 degrees Fahrenheit) to 240 degrees Celsius (464 degrees Fahrenheit), depending on the material. High-temperature labels are typically reserved for plastics with a maximum operating temperature of 300 degrees Fahrenheit or higher. Some popular plastic products that fit this range include:

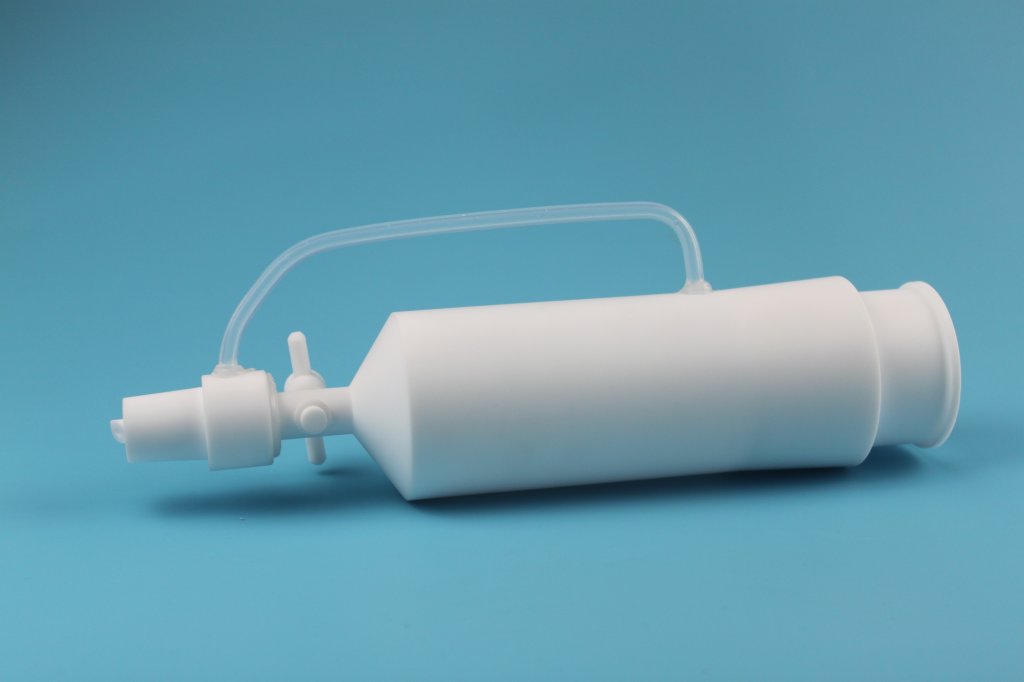

Polytetrafluoroethylene (PTFE) – Better known as Teflon, this plastic has a working temperature of 280 degrees Celsius (500 degrees Fahrenheit). Because of this high-temperature rating, it is often added to other plastics to improve their heat stability.

Polyetheretherketone (PEEK) – PEEK can handle temperatures of up to 250 degrees Celsius (482 degrees Fahrenheit) and sometimes higher, and it also resists radiation and chemical abrasion.

Polyphenylene Sulfide (PPS) – With a working temperature of 220 degrees Celsius (428 degrees Fahrenheit), this thermoplastic has excellent mechanical strength and works well in injection fabrication applications.

Polyetherimide (PEI) – PEI has a rating of 171 degrees Celsius (340 degrees Fahrenheit), and it is a great choice for applications that need rigid strength from a heat-resistant material.

Key Factors That Affect the Performance in High-Temperature Environments

Four main factors affect plastic materials’ performance when exposed to high temperatures:

Top Variables Affecting High-Temperature Performance

-

Chemical makeup of the plastic

-

Material thickness of the plastic

-

Expansion rate at high temperatures

-

Thermal conductivity

These factors work together to determine how well the material will withstand heat exposure for a long period.

Common Applications That Require High-Temperature Plastic Materials

In the manufacturing world, numerous applications require the benefit of high-temperature plastic. The repetitive movement of many factory machines can generate significant heat via friction, and the fabrication of items requires high temperatures to melt or mold the material into a desired shape.

The medical industry also requires high-temperature plastics. These materials can withstand the strenuous sanitation methods necessary for medical equipment. Similarly, the food packaging industry benefits from these materials due to their ability to withstand cooking temperatures and handle sanitation processes.

In aerospace engineering, high temperatures are common, not only from engines and exhaust systems, but also from atmospheric conditions. These environments require plastic materials that can reliably perform at elevated temperatures. Likewise, transportation technologies and engine components in land-based vehicles must also withstand sustained high-heat exposure.

The technology and telecommunications sectors also operate in high-temperature environments, making high-temperature plastics essential for electronics and semiconductor components. Because plastics have low electrical conductivity, they are commonly used to insulate electronic components within computers and other technology systems.

Tips for Testing Plastic Materials in High-Temperature Environments

While the team at Piedmont Plastics will help guide you toward plastics that fit your temperature requirements, it is always a good idea to test the stability of the plastic before using it in a high-cost situation. The main factors to test include:

| Vicat Softening Temperature | The temperature at which an indentation tool can penetrate 1 mm into the surface of the plastic |

|---|---|

| Heat Distortion Temperature | The temperature at which the plastic will deform under pressure |

| Ball Pressure Test | Determines what temperature will cause deformation when the plastic is under a specific, constant load |

Each of these tests provides a clear understanding of a plastic material’s temperature limits. Instead of testing materials on your own, contact the team at Piedmont Plastics to review the performance data for products suited to your specific high-heat application. With the right plastic, you can achieve reliable parts and products that withstand elevated temperatures without softening or losing their shape.

Learn More

Contact your local Piedmont Plastics branch for help with selecting a plastic material that can stand the heat of your application!

Find Your Nearest Location