Engineers, purchasers, and buyers in electrical, mechanical, and industrial markets often rely on high-performance fiberglass laminates for insulation, structural support, and precision-machined components. Among the most widely used materials are G10 and FR4, two glass-reinforced epoxy laminates known for their durability, electrical insulation strength, and reliable performance in demanding environments.

While these materials share a similar manufacturing process and many overlapping properties, their differences (particularly flame retardancy, compliance requirements, and thermal behavior) make each one better suited to certain applications. Understanding those differences helps ensure that your project meets performance, safety, and regulatory needs. This article compares G10 and FR4 in detail and provides guidance on how to choose the right laminate for your electrical or industrial application.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Are G10 and FR4?

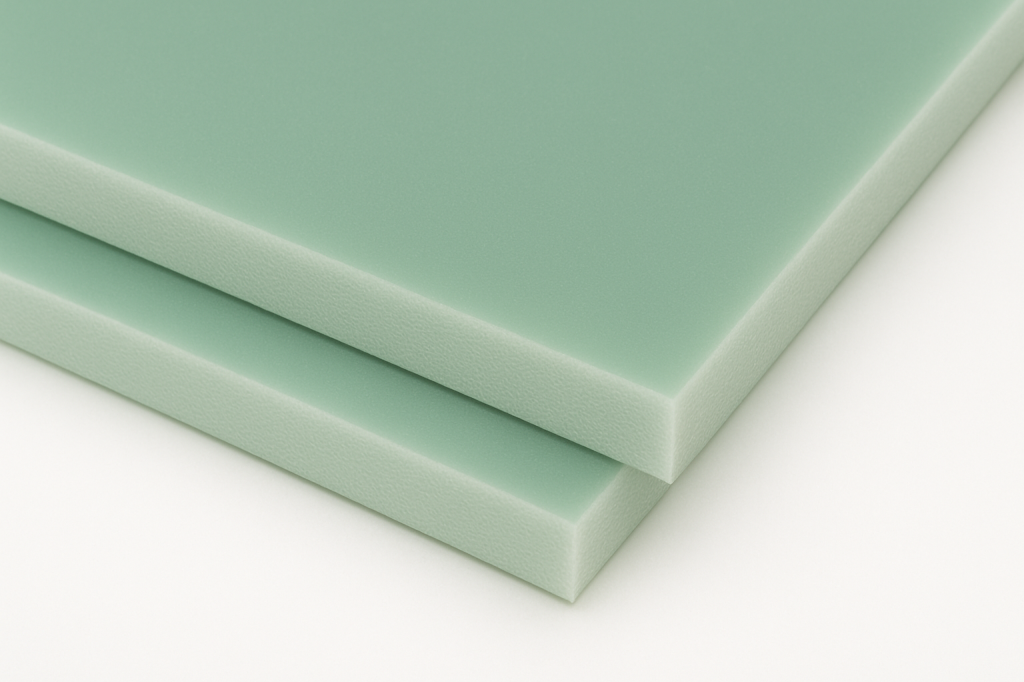

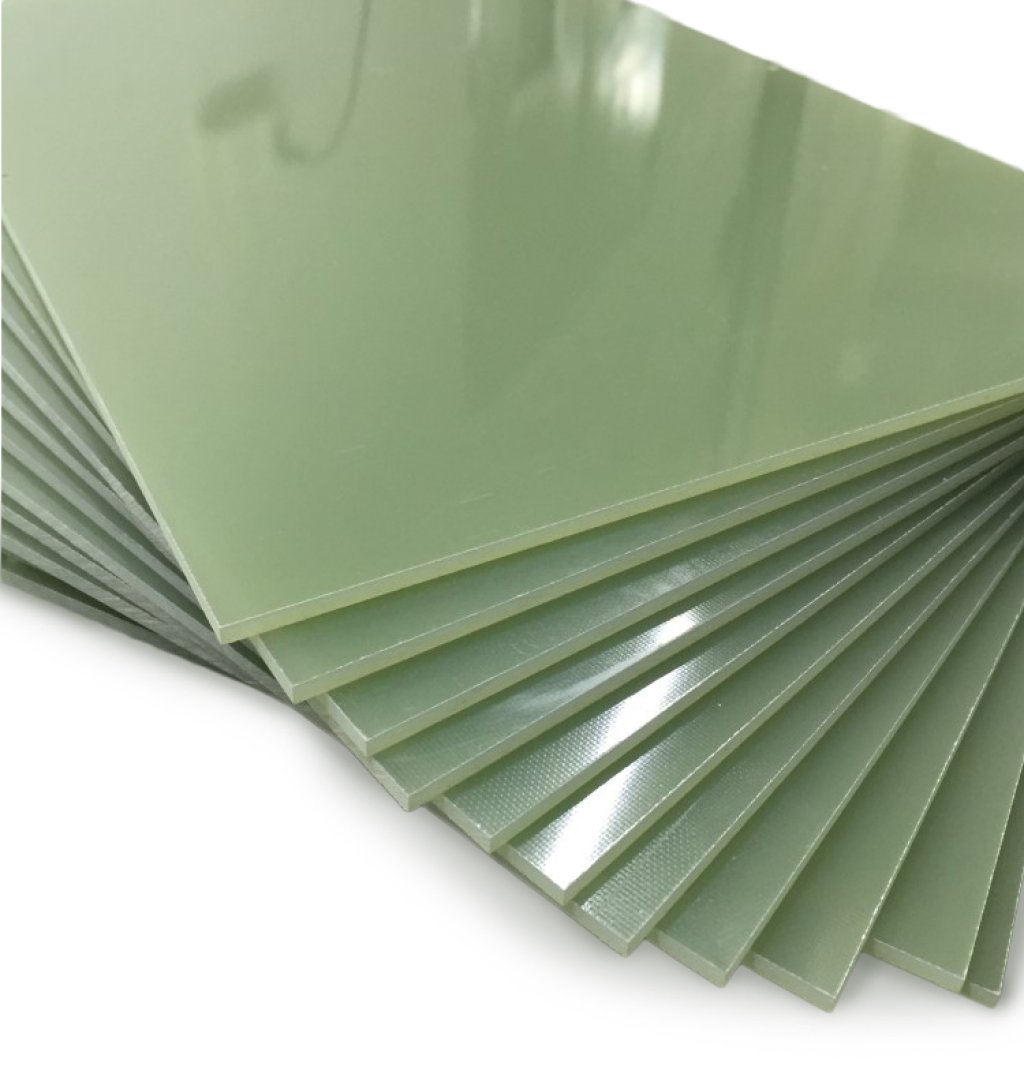

Both G10 and FR4 are produced by impregnating woven fiberglass cloth with epoxy resin, stacking multiple layers, and applying heat and pressure to form a dense, rigid laminate. This construction gives the materials high mechanical strength, excellent dimensional stability, and strong electrical insulation across a wide range of operating conditions.

The fundamental distinction is simple: FR4 contains a flame-retardant additive, whereas G10 does not. This single difference influences flammability ratings, safety certifications, and suitability for specific regulated environments. While their mechanical and electrical performance is similar, their compliance profiles are not.

G10 is generally considered the “non-flame-retardant” version of the material. Meanwhile, FR4 is the flame-retardant grade commonly used in circuit boards, switchgear, and components exposed to heat, arcing, or spark potential.

Key Differences Between G10 and FR4

Flame Retardancy

Flame performance is the most important difference between these materials. FR4 typically meets UL94 V-0 or V-1 ratings depending on grade and manufacturer. This makes it suitable for environments where materials must self-extinguish or resist flame propagation, including electrical enclosures, public spaces, and high-voltage equipment.

In contrast, standard G10 typically carries a UL94 HB rating, meaning it is not required to self-extinguish under the same conditions. While G10 still performs extremely well mechanically and electrically, it is not appropriate where electrical codes or end-user specifications require V-rated plastics.

Electrical Properties

From an electrical perspective, both materials offer high dielectric strength and insulation resistance. Their epoxy-fiberglass construction provides stable performance across a range of voltages and frequencies.

Because FR4 includes a flame-retardant additive and carries more widely recognized certifications, it is often specified for applications requiring formal documentation or compliance audits, even though G10 and FR4 perform similarly in many low- to medium-voltage environments.

Mechanical Strength

Mechanically, G10 and FR4 are nearly identical. Tensile, flexural, and compressive strengths fall within similar ranges, providing excellent rigidity and resistance to mechanical fatigue. This is why both materials are widely used for spacers, plates, insulators, precision-machined components, and structural parts in electrical and industrial systems.

Moisture Absorption and Environmental Resistance

Both materials offer low moisture absorption, typically near or below 0.10%. This ensures dimensional stability, consistent dielectric strength, and reliable long-term performance even in humid environments.

While G10 can occasionally test slightly lower in moisture absorption, the difference is minimal, and both materials perform well in wet or variable climates.

Temperature Resistance

Both G10 and FR4 offer similar thermal performance, with typical maximum service temperatures ranging from 266–284°F (130–140°C). High-temperature FR4 variants can exceed these limits due to enhanced resin systems. In applications involving elevated heat, spark exposure, or potential arcing, FR4’s flame-retardant chemistry makes it the safer and more code-compliant choice.

When G10 Is the Best Choice

Although G10 lacks a flame-retardant additive, it is still an exceptionally strong, stable, and reliable laminate. It is typically chosen when flame-retardant certification is not required and when cost-effectiveness is important.

G10 also performs extremely well in machined parts. Its consistent resin content and fiberglass reinforcement allow tight tolerances, crisp edges, and clean machined features when using properly equipped tooling. Many industrial customers choose G10 for jigs, fixtures, electrical barriers, and structural supports because of its sturdy mechanical behavior and competitive pricing.

Common Applications for G10

Terminal boards

Insulating plates and barriers

Structural supports and mounting components

Spacers, washers, and precision-machined parts

Industrial machinery fixtures

Data center insulation components

Pump, motor, and equipment housings

Industries that do not require flame-tested materials often choose G10 for its reliability and value.

When FR4 Is the Preferred Choice

Because it includes a flame-retardant additive, FR4 is ideal for environments where fire performance and regulatory compliance are essential. It is widely specified in electrical and electronic components where ignition risks or heat sources may be present.

FR4 also offers excellent electrical insulation under elevated temperatures, making it suitable for high-voltage or high-heat systems that must meet stringent safety requirements.

Common Applications for FR4

Printed circuit boards (PCBs)

Busbar supports

Transformer and switchgear insulation

Arc shields and electrical barriers

Components in HVAC units, appliances, and industrial controls

Aviation and transit electrical systems

High-voltage electrical panels and enclosures

With its UL94 V-0 or V-1 rating, FR4 can be confidently used anywhere flame spread must be limited or where regulatory bodies require flame-tested plastic materials.

How Do G10 and FR4 Compare?

| Property | G10 | FR4 |

|---|---|---|

| Flame Rating (UL94) | HB | V-0 or V-1 |

| Dielectric Strength | Excellent | Excellent |

| Mechanical Strength | High | High |

| Moisture Absorption | Low | Low |

| Temperature Resistance | 266-284°F (130–140°C) | 266-302°F (130–150°C), with higher grades available |

| Chemical Resistance | Good | Good |

| Machinability | Excellent | Excellent |

| Cost | Slightly lower | Slightly higher |

| Available Forms | Sheet, rod, tube | Sheet, rod, tube |

Machining Considerations for Both Materials

G10 and FR4 are known for their machinability, but their fiberglass reinforcement makes them abrasive on tooling. For best results, refer to the manufacture specific guidelines or ask how Piedmont Plastics can help fabricate your material.

Compliance and Industry Standards

Engineers often choose FR4 not because it performs better electrically or mechanically, but because its flame rating satisfies the requirements of UL, IEC, and various OEM specifications. Components inside electrical cabinets, appliances, or public infrastructure often require V-rated materials to comply with local safety codes.

G10, on the other hand, is appropriate only where HB-rated plastics are allowed. Its lack of flame retardancy disqualifies it from some electrical enclosures, transportation systems, and aerospace applications. However, many industrial environments do not require V-rating certification, and G10’s balanced performance profile makes it a dependable and cost-effective choice.

Moisture, Heat, and Environmental Performance

In humid environments, both G10 and FR4 maintain stable electrical insulation due to their controlled resin content and dense fiberglass structure. This is why they are frequently used in marine, industrial, and outdoor enclosures where condensation or variable humidity is expected.

When temperature is the primary concern, FR4 may provide an advantage, particularly in applications near transformers, heating elements, or high-voltage components. Flame-retardant formulations help limit combustion risk and ensure the material behaves predictably under heat stress.

Cost Factors

G10 is typically more economical than FR4. For many industrial applications where HB materials are acceptable, the cost savings can be significant, especially in large machined parts or high-volume production runs.

FR4 costs slightly more due to its flame-retardant chemistry and certification requirements. However, in environments where safety or regulatory compliance is a priority, the additional cost is easily justified.

Choosing Between G10 and FR4

Selecting the right laminate comes down to three key considerations. By evaluating these factors alongside your operating environment, you can confidently choose the laminate that best aligns with your performance requirements and budget.

If yes, choose FR4. If not, G10 may be appropriate and more cost-effective.

FR4 offers safer performance and predictable flame resistance under elevated temperatures.

G10 provides nearly identical structural performance at a lower cost.

Why Partner With Piedmont Plastics for G10 and FR4?

Piedmont Plastics stocks G10 and FR4 sheets, rods, and tubes in a wide variety of thicknesses and dimensions. With local branches across North America, customers benefit from:

📦 Convenient local inventory/delivery

✂️ Cut-to-size services

🗜️ CNC routing and fabrication support

🧠 Knowledgeable technical assistance

📋 High-quality materials from trusted suppliers

Whether you are building electrical insulation systems, fabricating structural parts, or designing industrial components, our team can help you identify the right laminate for your needs.

Learn More

If you’re deciding between G10 and FR4 for your next project, we’re here to help. Contact Piedmont Plastics to speak with a materials specialist and find the fiberglass laminate that best fits your electrical or industrial application!

Request A Quote