Known for their strong performance, paper faced foam boards can be used for art canvases, mounting, backing, framing, die cutting and 3-D designs.

Paper Faced Foam Board

Lightweight and versatile, foam boards are perfect for artistic and display applications.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Paper Faced Foam Board

Common Properties

- Common Brand Names UltraBoard™, FOME-CORE®, InSite®, Ryno Board®

- Typical Thickness Size 0.125, 0.1875, 0.25, 0.5 inches

- Typical Lengths 24, 48, 96 inches

- Typical Widths 18, 24, 32, 48 inches

- Friendly Names Foam Board, Sandwich Board, Foamcore, Paper-Faced Foam

- Common Profiles Sheet

Literature and Data Sheets

-

3A Fome-Cor® 3A CompositesView

-

3A Fome-Cor® Fabrication Manual 3A CompositesView

-

Gilman Brothers InSite® Acid-Free Paper-Faced Foamboard Gilman BrothersView

-

Gilman Brothers InSite® Reveal® Clay-Coated Paper-Faced Foamboard Gilman BrothersView

-

Gilman Brothers Ryno Board® High-Density Clay-Coated Paper-Faced Foamboard Gilman BrothersView

-

United Industries Ultraboard Core United IndustriesView

-

United Industries Ultraboard Mount United IndustriesView

-

United Industries Ultraboard White DP United IndustriesView

Paper Faced Foam Board from Piedmont Plastics

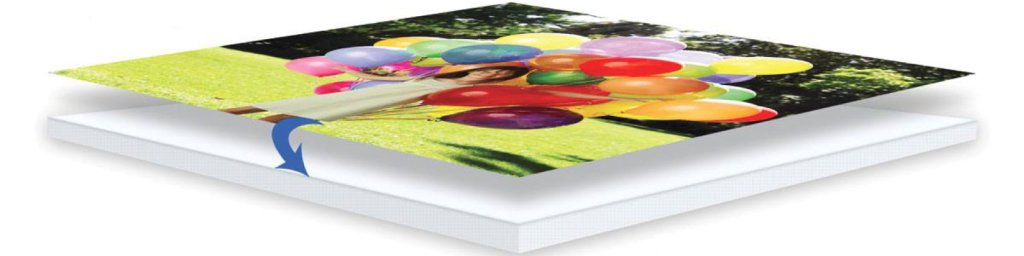

Paper faced foam board is a lightweight, rigid sheet material made with a polystyrene foam core sandwiched between paper liners. Known for its smooth surface and ease of cutting, foam board is a popular choice for displays, mounting, presentations, and short-term signage. Its strength-to-weight ratio allows for creative applications that require durability without unnecessary bulk.

Whether you’re a photographer, artist, designer, or display fabricator, paper faced foam board offers the strength, quality, and versatility you need. Contact Piedmont Plastics today to learn how we can support your paper faced foam board needs!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Paper Faced Foam Board

Paper faced foam board offers consistent performance across graphics, display, and presentation applications. Key features include:

Lightweight Yet Rigid: Paper faced foam board is easy to transport and handle while maintaining flatness.

Smooth, Printable Surface: This material accepts inks, paints, and adhesives for direct printing and mounting.

Easy to Cut and Fabricate: Paper faced foam board can be die cut, hand cut, or machine cut into custom shapes.

Multiple Finish Options: Paper faced foam board is available with white clay-coated paper, natural kraft liners, or black paper/foam combinations.

Memory-Retaining Core: Certain grades resist warping and maintain structure in humid environments.

American-Made: Trusted domestic manufacturing ensures consistent quality.

Benefits of Paper Faced Foam Board

Learn more by contacting our expert sales team today!

Common Applications For Paper Faced Foam Board

Paper faced foam boards are commonly used for a variety of applications due to their light weight and durability. Here are a few main applications:

Framing and Mounting: They provide sturdy yet lightweight backing for photographs, artwork, and presentations.

Artistic Canvases: Certain grades can be embossed or die cut, making them a favorite for creative and artistic projects.

3-D Designs: Easily cut into shape, these boards are a lightweight option for three-dimensional displays, prototypes, and architectural models.

Signage and Displays: The smooth surface of the foam board makes it suitable for direct printing, making it an excellent choice for retail signage, point-of-purchase displays, and promotional graphics.

Graphic Arts and Printing: The smooth surface allows for high-quality graphic printing, producing optimal results for posters, presentations, and advertising materials.

Trade Show Displays: Their lightweight nature makes set-up, transport, and teardown fast and efficient, which is ideal for trade show displays and exhibition spaces.

These applications demonstrate the versatility and practicality of paper faced foam board for design, graphics, and display projects.

Related Products

-

Foam Sheet

Piedmont Plastics carries all types of foam sheet, including open cell foam sheet for cushions and closed cell foam sheet for signs and prototypes.

-

Styrene-Faced Foam Sheet

Piedmont carries styrene-faced foam sheets for signage, dimensional lettering, packaging, and preservation, including Infinity, Gatorplast, and Ultra Board.

-

Wood Fiber Faced Foam Sheet

Piedmont Plastics carries wood fiber faced foam sheets and panels for framing, signs, exhibits, and displays, such as white, black, or wood Gatorfoam.

Frequently Asked Questions

Below are some commonly asked questions about paper faced foam board and its performance in various applications.

Yes, its smooth clay-coated liners provide an excellent surface for direct printing. The boards consist of three layers of material, a polystyrene foam core and two outer layers with your choice of color. These color options include a white clay-coated paper or natural brown craft paper liners over a white foam core, or black paper liners with a black foam core.

Standard foam board is intended for indoor use. For outdoor projects, consider more weatherable plastics like PVC or corrugated polypropylene.

Foam board sheets are available in a variety of sizes, including large sheets up to 8’ x 10’ and thickness ranges from 1/8”- 1/2”. Contact your local Piedmont Plastics branch for exact specifications!

Yes, certain grades can be embossed or precision die cut, making them excellent for creative and display applications.

Foam-X® features a memory-retaining core that resists warping but cannot be embossed, while Fome-Cor® allows for embossing and precise die cutting.

Why Buy Paper Faced Foam Board from Piedmont Plastics?

Piedmont Plastics is a trusted supplier of performance plastics and graphic display materials across North America. When you choose us for foam board, you gain:

Nationwide Branch Network: We provide local inventory and support from our many branches throughout the U.S. and Canada.

Custom Cutting and Fabrication: Using advanced CNC technology, our team can cut and fabricate foam board sheets to your exact specifications.

Deep Industry Expertise: Backed by extensive industry experience, our specialists are ready to help you choose the best material for your application.

Wide Product Selection: As your one-stop source for sign, graphic, and display materials, we stock a comprehensive selection to support diverse applications.

Uncompromised Quality: With a focus on excellence, we deliver paper faced foam board products that consistently exceed industry expectations.

Ready to experience the Piedmont difference? Get in touch with us today!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745