LDPE (low density polyethylene) sheet and rod are excellent for drape forming or vacuum forming containers, bottles, bags, and lab equipment.

LDPE (Low Density Polyethylene)

Lightweight, flexible, and impact-resistant, low density polyethylene works well for a variety of applications, including orthotics and prosthetic devices.

Product Overview

Widely used for:

Performance Characteristics:

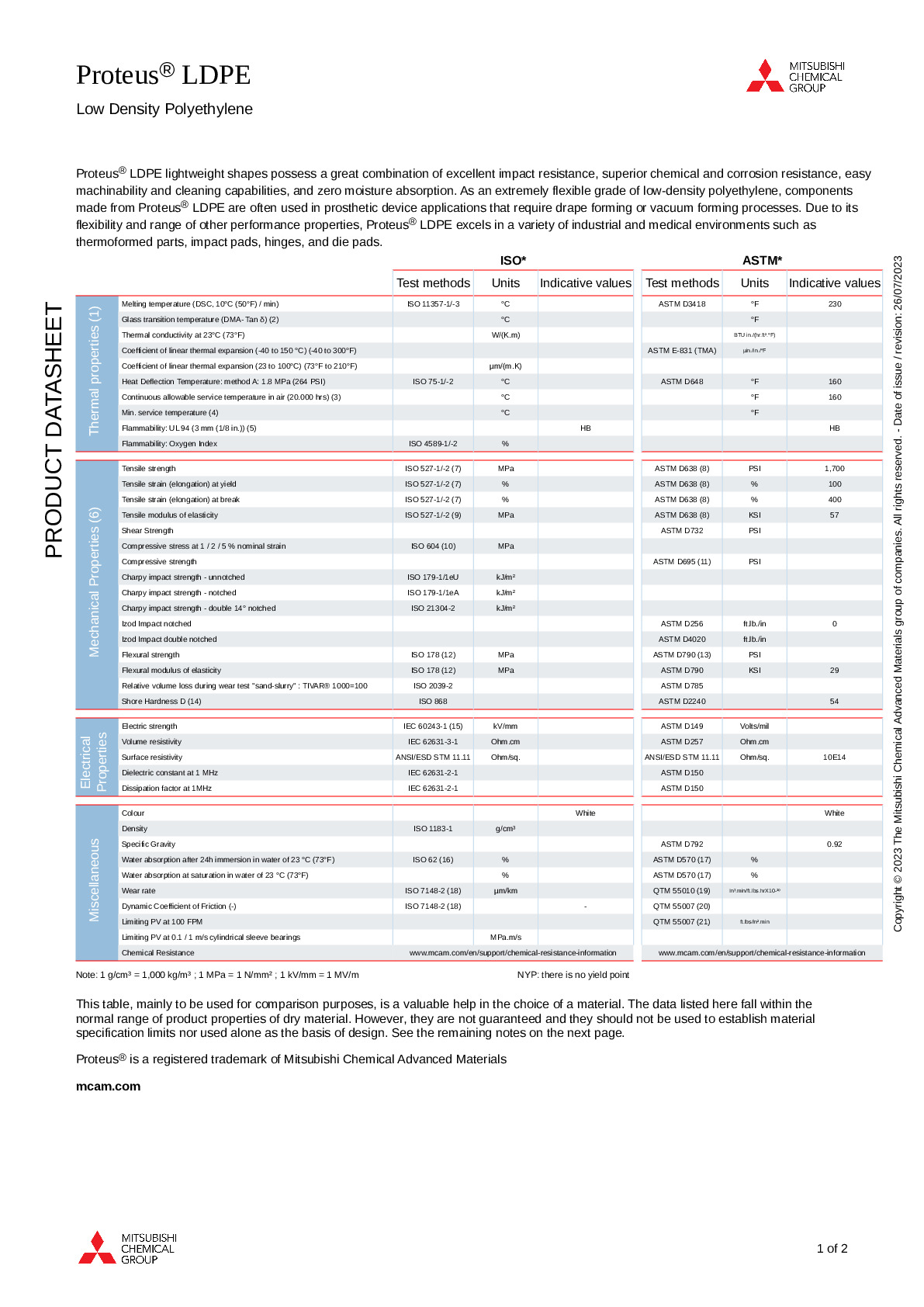

Typical Properties of LDPE (Low Density Polyethylene)

Common Properties

- Typical Lengths 36, 48, 60, 96 in

- Friendly Names Low Density Plastic, Flexible Polyethylene

- Typical Thickness Size 0.030 - 0.500 in

- Typical Rod Diameters 0.250 – 16 in

- Common Profiles Sheet, Rod, Tube, Film

- Typical Widths 36, 48, 60 in

- Common Brand Names KPC® LDPE, Prime® LDPE, Proteus® LDPE

Electrical Properties

- Breakdown Voltage 400 kV

- Arc Resistance 280 seconds

- Thermal Coefficient of Dielectric Constant 0.001 1/°C

- Dielectric Constant 2.3

- Dielectric Strength 400 V/mil

- Dissipation Factor 0.0002

- Electrostatic Discharge (ESD) Sensitivity High

- Volume Resistivity 1.0E+16 ohm-cm

- Comparative Tracking Index (CTI) 600 V

- Surface Resistivity 1.0E+15 ohm/square

Mechanical Properties

- Elongation at Yield 12 %

- Modulus of Elasticity 210 MPa

- Gardner Impact 10 J

- Falling Dart Impact 25 J

- Instrumented Impact Total Energy 30 J

- Tensile Strength, Ultimate 8.3 MPa

- Tensile Strength, Yield 7 MPa

- Izod Impact, Unnotched 0.45 J/cm

- Hardness, Rockwell R 20

- Bearing Yield Strength 7.5 MPa

- Compressive Yield Strength 8.3 MPa

- Elongation at Break 100 %

- Izod Impact, Notched 0.15 J/cm

- Flexural Yield Strength 6.9 MPa

- Shear Strength 4 MPa

- Flexural Modulus 250 MPa

Physical Properties

- Moisture Absorption at Equilibrium 0.2 - 0.8 %

- Water Absorption 0.1 - 0.5 %

- Melt Flow Rate 0.1 - 50 g/10 min

- Linear Mold Shrinkage 0.2 - 1.0 %

- Density 0.9 - 1.6 g/cm³

Regulation Properties

Thermal Properties

- Max Continuous Operating Temperature in F 176 °F

- Flammability, UL94 HB rating

- CTE, linear 100 µm/m°C

- CTE, linear, Transverse to Flow 150 µm/m°C

- Deflection Temperature at 1.8 MPa (264 psi) 30 °C

- Minimum Operating Temperature in F -58 °F

- Vicat Softening Point 85 °C

- Thermal Conductivity 0.33 W/mK

- Deflection Temperature at 0.46 MPa (66 psi) 38 °C

LDPE from Piedmont Plastics

Low density polyethylene (LDPE) is a flexible, lightweight performance plastic material known for its durability and wide range of uses. As a branching form of polyethylene, LDPE has a lower density than linear varieties like HDPE, thanks to its loosely arranged molecular structure. This gives LDPE its unique combination of softness and strength, making it ideal for many everyday applications.

LDPE offers excellent impact resistance, resists stains and moisture, and has strong electrical insulating properties. It’s also transparent, which allows for better light reflection, an added benefit for products that need visibility or clarity.

You’ll find LDPE in many common items, such as plastic wraps, flexible packaging, and food or beverage containers. It’s also widely used in the medical field for making orthotics and prosthetics due to its safe and adaptable nature.

At Piedmont Plastics, we offer LDPE sheet and rod stock to meet your specific project needs. Whether you're in packaging, medical, or manufacturing, LDPE is a reliable material that gets the job done. Contact us to learn more or request a quote today!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of LDPE

LDPE boasts a wide range of features that make it an asset to many different industries. These qualities include:

Flexibility and Toughness: LDPE offers excellent flexibility and durability, making it well-suited for applications in industries such as medicine and food handling.

Chemical Resistance: LDPE resists chemical attacks very well and remains insoluble in most organic solvents at room temperature.

Impact Resistance: This material’s strong impact resistance makes it a great choice for uses such as impact pads and prosthetic devices.

Ease of Processing: With excellent machinability and thermoforming capabilities, LDPE is easy to work with and well-suited for producing fabricated parts.

Moisture Resistance: LDPE has near-zero moisture absorption, making it ideal for food handling and for producing containers, bottles, and bags.

Transparency: LDPE film's transparency and light-reflective properties make it terrific for applications like packaging and film.

Heat Sealing: LDPE’s relatively low heat resistance and melting point make the film material suitable for heat sealing applications.

Benefits of LDPE

Common Applications for LDPE

Due to its strength and robustness, LDPE works well for a variety of purposes, including:

Packaging: LDPE is used for packaging applications such as industrial bags, shrink bundling, produce bags, garment bags, and blow-molded bottles.

Medical: It is utilized in prosthetic appliances, medical equipment, and semi-flexible tubing.

Automotive: LDPE is used for sound deadening and various automotive applications.

Food Storage: Because it meets food handling guidelines, LDPE is ideal for containers, bottles, and bags used in food storage.

Industrial: LDPE is used in large agricultural tanks, chemical shipping containers, and tote boxes.

Orthopedics: LDPE is used in orthopedic and prosthetic appliances.

Laboratory Equipment: It is suitable for manufacturing certain laboratory equipment.

Construction: LDPE is used in applications like root barriers and corrosion-resistant work surfaces.

These applications showcase the versatility of LDPE across various industries, thanks to its qualities such as impact resistance, flexibility, and chemical resistance.

Frequently Asked Questions

Low density polyethylene (LDPE) is a flexible, chemical-resistant plastic used in medical, industrial, and packaging applications. This FAQ covers the most common questions about LDPE’s properties, uses, and more to help you determine if it’s the right fit for your project.

It depends on the application. LDPE is more flexible and impact-resistant at low temperatures, while HDPE (High-Density Polyethylene) is stronger, stiffer, and better suited for structural or high-strength needs.

Yes, many LDPE grades are FDA and USDA compliant and approved for direct food contact, making them suitable for use in food storage containers, films, and liners.

LDPE stands for Low-Density Polyethylene, a thermoplastic known for its flexibility, low density, chemical resistance, and excellent performance at low temperatures. It is commonly used in packaging, containers, liners, and tubing.

LDPE is valued for its flexibility, chemical resistance, and moisture barrier properties. In industrial settings, it’s commonly used for chemical tank liners, protective sheeting, tubing, and wire insulation. In the medical field, LDPE is used in orthotics, prosthetics, IV bags, laboratory tubing, and disposable medical containers or packaging. Additionally, LDPE is widely used in packaging applications such as shrink wraps and squeeze bottles, and in construction as vapor barriers and waterproof films.

Yes, LDPE is recyclable and classified as Resin Identification Code #4. However, its recycling availability depends on local facilities, as not all centers accept soft plastics.

Why Buy LDPE from Piedmont Plastics?

At Piedmont Plastics, we offer only the highest-quality LDPE materials because we understand how essential it is to use top-grade materials in your projects. Regardless of your industry, we provide the ideal mix of product expertise and material options to ensure your success. Here’s why you can rely on us as your trusted supplier:

Wide Product Selection: Our inventory includes a broad range of LDPE sheet and rod in various sizes and thicknesses, catering to diverse needs.

Custom Cutting and Fabrication: Using advanced CNC technology, we provide precision cutting and fabrication services to create custom LDPE sheet and rod that meet your exact specifications.

Trusted Expertise: With decades of experience, our knowledgeable team is dedicated to helping you select the perfect LDPE material for your specific application.

Nationwide Availability: With multiple locations across North America, we ensure that you have convenient access to LDPE and other performance plastic materials, no matter where you are.

Unyielding Quality: We uphold stringent quality standards to guarantee that every LDPE product exceeds industry expectations.

Ready to discover the Piedmont difference? Contact us today!

Talk to An Expert In

San Antonio

5202 Rittiman Rd

210-806-3505