Data centers are the backbone of today’s digital world. From cloud computing and AI to streaming services and financial transactions, these facilities must operate 24/7 with minimal downtime. As data center designs continue to evolve, material selection plays a critical role in safety, efficiency, and long-term performance.

One material continues to stand out across new builds and retrofits alike: twinwall polycarbonate. Known for its lightweight strength, thermal performance, and versatility, twinwall polycarbonate has become a preferred solution for aisle containment systems, panels, doors, and protective barriers inside modern data centers.

In this article, we’ll explain why twinwall polycarbonate is best for data centers, how it supports cooling efficiency and operational safety, and why engineers, designers, and facility managers rely on it for mission-critical environments.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Is Twinwall Polycarbonate?

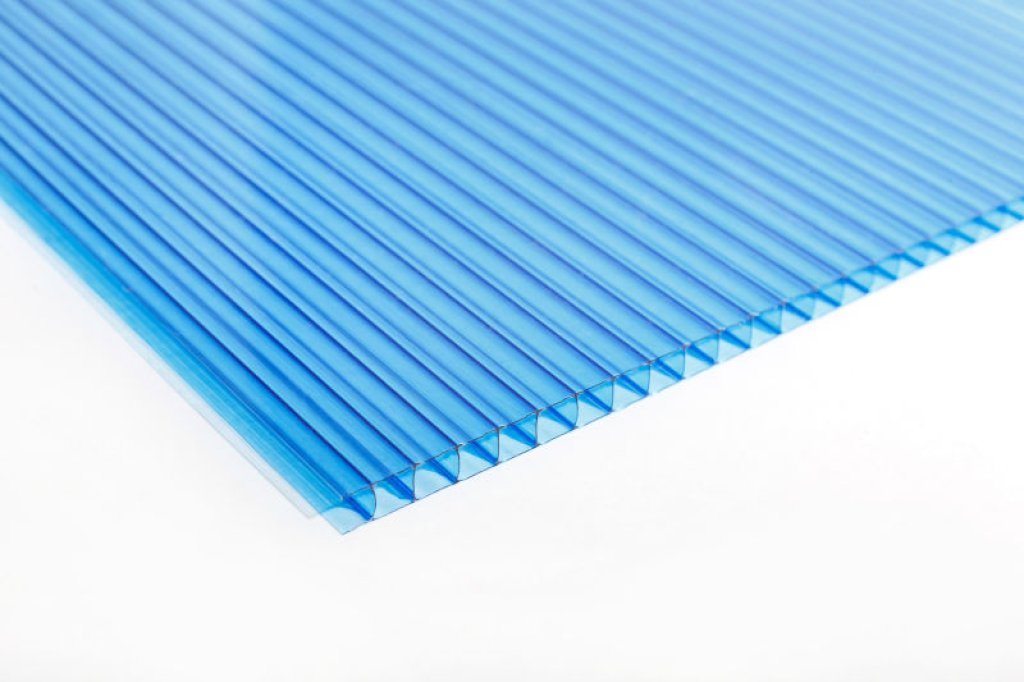

Twinwall polycarbonate is a multiwall thermoplastic sheet made from polycarbonate resin. Unlike solid polycarbonate, twinwall sheets feature an internal rib structure that creates hollow air pockets between layers. This design delivers a unique balance of properties.

Key Qualities of Twinwall Polycarbonate

-

High impact resistance

-

Reduced weight compared to solid sheet

-

Improved thermal insulation

-

Excellent rigidity and dimensional stability

Twinwall polycarbonate is commonly used in architectural glazing, greenhouse panels, and industrial enclosures, but its performance characteristics make it especially valuable in data center infrastructure.

Why Material Choice Matters in Data Centers

Data centers present a demanding operating environment. Materials must perform reliably while supporting:

Temperature control and airflow management

Fire and smoke safety compliance

Equipment protection

Frequent access and maintenance

Long service life with minimal maintenance

Poor material selection can lead to airflow leaks, higher energy costs, safety risks, and premature replacement. That’s why twinwall polycarbonate has become a go-to solution for interior data center applications.

Twinwall Polycarbonate and Aisle Containment Systems

One of the most common uses of twinwall polycarbonate in data centers is hot and cold aisle containment.

Supporting Efficient Cooling

Aisle containment systems separate hot exhaust air from cold supply air, allowing cooling systems to run more efficiently. Twinwall polycarbonate panels are ideal for this role because they help support consistent airflow paths, reduce air leakage between aisles, support higher rack densities, and improve overall cooling efficiency.

The internal air pockets within twinwall polycarbonate also contribute to better thermal performance, helping stabilize temperatures within the containment system.

Lightweight Panels for Large-Scale Installations

Compared to glass or solid plastic sheets, twinwall polycarbonate is significantly lighter. This makes it easier to install overhead ceiling panels, fabricate large wall sections, and reduce structural load on framing systems.

For data centers with expansive aisle containment layouts, reduced weight translates to faster installation and lower labor costs.

Impact Resistance and Safety Benefits

Data centers are busy environments with frequent movement of carts, equipment, and personnel. Materials used for panels and doors must withstand accidental impacts without cracking or shattering.

Twinwall polycarbonate offers exceptional impact resistance, even in thinner gauges. Unlike glass, it does not shatter, helping reduce the risk of injury or debris near sensitive equipment.

This durability makes twinwall polycarbonate well-suited for:

Aisle containment walls

Swing and sliding doors

Equipment enclosures

Protective barriers and guards

Fire Performance and Code Considerations

Fire safety is a top priority in data center design. Many twinwall polycarbonate sheets are available in fire-rated grades designed to meet building and electrical code requirements.

Key advantages include:

Low smoke generation compared to traditional plastics

Self-extinguishing behavior in certain formulations

Availability of tested and certified products for commercial interiors

When paired with proper framing and system design, twinwall polycarbonate can help support compliance with data center fire and life safety standards.

Tip: Always confirm local code requirements and material certifications for your specific application.

Transparency for Visibility and Monitoring

Clear visibility is critical in modern data centers. Operators need to monitor equipment status, indicator lights, and aisle conditions without opening containment systems.

Twinwall polycarbonate can be specified in clear or translucent grades, providing visual access to racks and equipment, improved safety and situational awareness, and a cleaner, more organized appearance. This transparency supports both operational efficiency and facility aesthetics, especially in customer-facing or colocation data centers.

Durability in 24/7 Operating Environments

Data centers never sleep. Materials must hold up under continuous operation, temperature fluctuations, and regular cleaning and maintenance.

Twinwall polycarbonate is known for its long service life, resistance to cracking and fatigue, and dimensional stability over time. Unlike materials that can warp, yellow, or become brittle, twinwall polycarbonate maintains performance even in demanding conditions.

Fabrication Flexibility for Custom Designs

No two data centers are exactly alike. That’s why material flexibility matters.

Twinwall polycarbonate can be:

Cut to size

Routed and drilled

Thermoformed into gentle curves

Integrated into aluminum or steel framing systems

This makes it easy to design custom aisle containment layouts, doors, and partitions tailored to specific rack configurations and cooling strategies.

Acoustic Benefits in Data Centers

While often overlooked, noise control is becoming increasingly important, especially in colocation facilities or hybrid workspaces.

The internal structure of twinwall polycarbonate can help dampen sound transmission, reducing noise from fans and cooling equipment. This creates a more comfortable environment for technicians working inside the facility.

Sustainability and Energy Efficiency Advantages

Other sustainability benefits include:

For operators focused on ESG goals and operating costs, these advantages matter.

Common Data Center Applications for Twinwall Polycarbonate

Twinwall polycarbonate is used throughout modern data centers, including:

Hot and cold aisle containment walls

Ceiling panels for containment systems

Swing and sliding aisle doors

Equipment enclosures and guards

Monitoring and observation panels

Protective barriers around sensitive equipment

Its versatility makes it a smart choice for both new construction and retrofit projects.

Why Source Twinwall Polycarbonate from Piedmont Plastics?

Selecting the right material is only part of the equation. Reliable sourcing, fabrication support, and local availability are just as important.

Piedmont Plastics offers twinwall polycarbonate solutions backed by:

📍 Local inventory across a nationwide branch network

✂️ Cut-to-size and fabrication-ready materials

📞 Support for custom data center applications

🧠 Knowledgeable performance plastics experts

Whether you’re designing a new data center or upgrading an existing facility, working with a trusted plastics distributor helps ensure material performance and project success.

Twinwall Polycarbonate: A Smart Material for Data Centers

Data centers demand materials that deliver strength, efficiency, safety, and long-term reliability. Twinwall polycarbonate checks all of those boxes and more. From improving cooling efficiency and airflow management to enhancing safety and visibility, twinwall polycarbonate has proven itself as one of the best materials for data center environments.

If you’re planning a data center project or evaluating materials for aisle containment systems, twinwall polycarbonate deserves serious consideration. Learn more by getting in touch with us today!

Ready to Get Started?

Contact your local Piedmont Plastics team to discuss material options, availability, and fabrication support, or request a quote to get your project moving!

Consult The Experts