High-Density Polyethylene (HDPE) is a petroleum-based thermoplastic polymer considered one of the most versatile plastic materials available today. It is used to manufacture numerous items, including food and beverage containers, cleaning product bottles, pipes, cutting boards, and some shoe parts. HDPE also appears in more complex items such as wood-plastic composites, 3-D printing filaments, and components used for skeletal and facial reconstruction surgery.

HDPE production started in the UK during the 1930s but began to gain more widespread popularity and use when production in the US took off during the 1950s. Today, it’s the most widely used type of plastic on the market. It’s lightweight, strong, and long-lasting.

Why is it so popular? Among the top reasons are:

An impressive tensile strength

Easy to fabricate

Superior strength-to-density ratio

High-impact resistance factor

High melting point

Available in many textures and sizes

FDA compliant

Good chemical resistance

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Uses for HDPE Plastic

Because one of HDPE plastic’s most attractive features is its durability and weather resistance, it stands to reason that it’s also resistant to mold, mildew, rotting, and insects. Also, it can be easily molded into almost any shape—making it perfect for any number of products that may spend a lot of time outdoors, including:

Outdoor patio furniture

Playground equipment

Storage containers

Trash and recycling bins

Compost bins

Plastic lumber

Plastic automobile parts—including fuel reservoirs

For indoors, it’s a popular material for items found in kitchens. In addition to various food and beverage container items, HDPE plastic is used for cutting boards, shelving, counters, tables, and small appliances.

Industrial-grade, FDA, NSF, and USDA-approved food-quality HDPE plastic is specially made to be low maintenance, safe, and long-lasting. HDPE plastic boards can come with textured surfaces to provide an adequate grip for secure food handling.

Notable Benefits of HDPE Plastic

HDPE plastic is the perfect material for products found in nearly every manufacturing niche imaginable. Here, we break down some of the most notable benefits of using HDPE plastic.

-

High Strength to Density Ratio

Although the density of HDPE is only marginally higher than LDPE (low-density polyethylene), its linear structure demonstrates significantly less branching. This means that it exhibits stronger intermolecular forces and tensile strength than LDPE. This is why a 60-gram HDPE container can safely carry around 8 pounds of weight or over a gallon of liquid.

-

Malleability

One of the main benefits of HDPE plastic is its ability to be molded easily once the optimum temperature is reached. Due to a high melting point, HDPE stays rigid until it reaches very high temperatures. Once it’s reached its melting point, the material can be efficiently molded for various applications, from milk jugs and food storage containers to corrosion-resistant piping and playground equipment.

-

Easily Recycled

Recycling is not only a thoughtful and responsible environmental move, but it’s also an important consideration when marketing and promoting specific products. Fortunately, HDPE plastic is easily recyclable. Businesses and individuals can significantly reduce plastic production costs by sending used or no longer needed HDPE plastic to the recycling plant instead of the landfill. And most HDPE-produced consumer item containers can go straight into any neighborhood’s weekly recycling pickup.

-

Resistance To Environmental Factors

While strength is an essential factor when considering the benefits of HDPE plastic, so is resistance to external factors such as mold, mildew, and rotting. Because it is long-lasting, weather-resistant, and can withstand contact with strong mineral acids and bases that occur naturally in soil, it’s an ideal material for underground piping used to deliver water. Because HDPE can be sterilized by boiling, it’s an excellent material for food and beverage containers. Finally, HDPE plastic is pretty much impervious to most common chemicals, water, solvents, acids, detergents, and cleaning fluids.

A container made of HDPE is built to last.

You’ll find that HDPE plastic often replaces heavier materials, allowing companies and individuals to meet sustainable and affordable manufacturing goals. Thanks to its high malleability, rigid strength, and corrosion resistance, HDPE is the perfect combination of strength, cost-efficiency, and environmental friendliness.

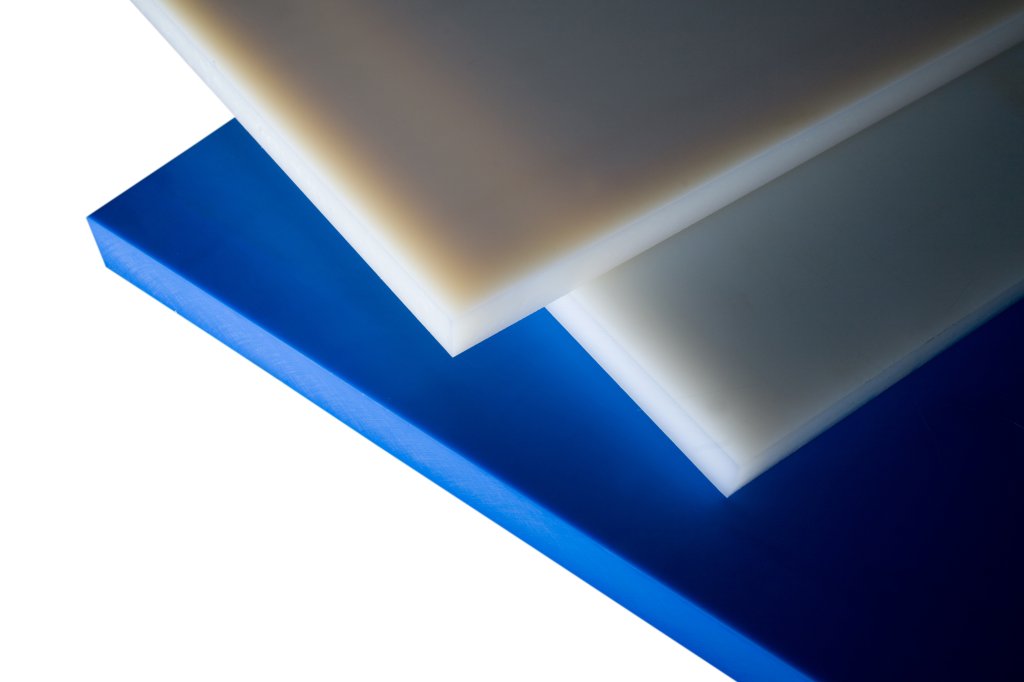

How To Buy HDPE Plastic Sheet

HDPE sheet can be easily cut, machined, fabricated, welded, and or mechanically fastened. Piedmont Plastics offers HDPE in natural, black, or white and in thicknesses ranging from 1/16” to 4”. We offer cutting services in multiple locations across North America to help you get the most for your purchase.

Piedmont Plastics offers an online pricing and ordering system that makes it convenient to acquire precisely what you need for the best price possible.

Learn More

Contact us to find out more about HDPE plastic solutions, or shop our online inventory today!

Contact Us