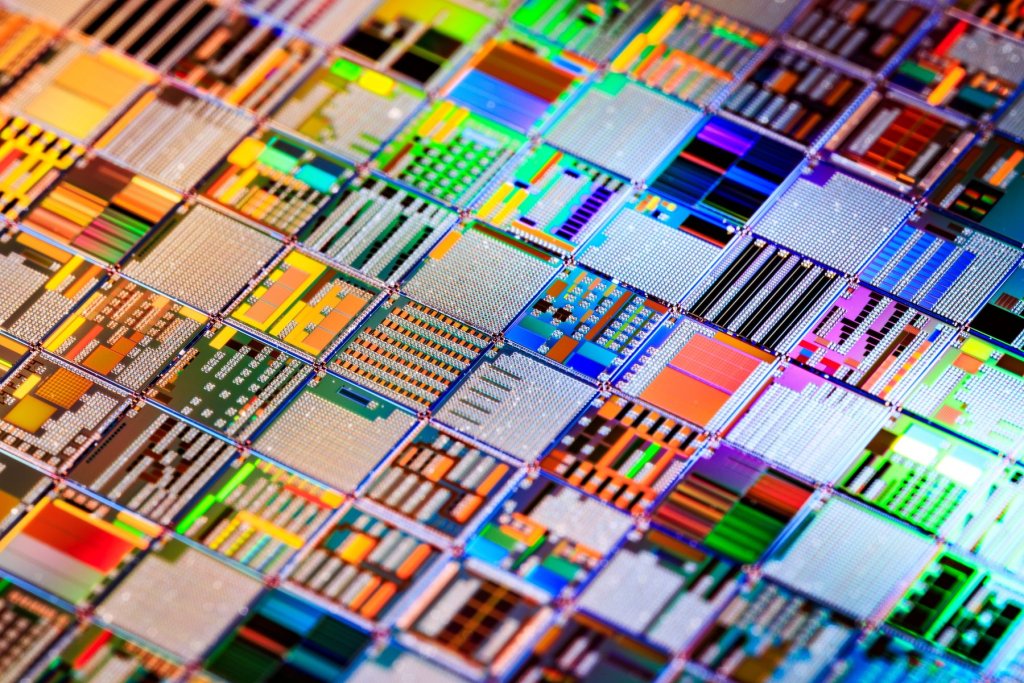

The semiconductor industry relies on precision, purity, and contamination-free environments to produce high-quality wafers. One of the most decisive factors in this process is the use of advanced plastics that guarantee clean, stable, and damage-free wafer handling and manufacturing. Unlike traditional materials such as metals and ceramics, plastics provide superior chemical resistance, thermal stability, and reduced outgassing, making them indispensable in semiconductor fabrication.

With multiple locations across North America, we offer a wide range of specialized plastic materials designed to meet the high demands of wafer manufacturing. These materials play an essential role in handling, processing, and protecting silicon wafers while improving efficiency, reducing contamination risks, and safeguarding long-term durability in semiconductor fabrication environments.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Why Plastic Materials Are Important

The production of semiconductor wafers involves a complex series of steps, including deposition, etching, doping, and layering. Throughout this process, materials must withstand exposure to extreme temperatures, harsh chemicals, and high-precision movement. Plastics have become a preferred choice in the industry because they offer exceptional chemical resistance, maintain dimensional stability, and reduce the risk of contamination.

Unlike metal or ceramic components, plastics do not corrode when exposed to acids and other semiconductor processing chemicals. Their lightweight nature allows for easier handling and integration into automated systems, reducing strain on mechanical components. Plastics also have low outgassing properties, which help maintain the ultra-clean environment needed for semiconductor fabrication. These qualities make them essential for components used in wafer handling, chemical transport, and cleanroom environments.

Most Common Materials Used in Wafer Manufacturing

Several high-performance plastics play a crucial role in semiconductor fabrication due to their chemical resistance, thermal stability, and mechanical strength. These materials are used in wafer handling, chemical transport, and precision manufacturing processes.

Popular types of plastic used when manufacturing and handling wafers include:

1. Polyether Ether Ketone (PEEK): Known for its strength, stability, and high-temperature resistance, PEEK is commonly used in wafer carriers, handling tools, and chemical-resistant components.

2. Polytetrafluoroethylene (PTFE): Offering low friction and extreme chemical resistance, PTFE is suitable for wafer handling systems, chemical transport equipment, and sealing components.

3. Polyvinylidene Fluoride (PVDF): Providing excellent acid and chemical resistance, PVDF allows for safe transport of corrosive chemicals in semiconductor fluid handling systems.

4. Fluorinated Ethylene Propylene (FEP): Highly resistant to aggressive chemicals, FEP is ideal for chemical handling equipment and fluid transport applications in semiconductor processing.

Advantages of High-Performance Plastics

Using the right plastic materials in wafer manufacturing provides numerous benefits. High-purity plastics reduce the risk of contamination, ensuring that semiconductor wafers stay clean and defect-free. Their chemical resistance allows them to withstand harsh processing conditions without degrading, while their excellent thermal stability helps them keep their shape and integrity even under extreme temperatures.

Plastics also help extend the lifespan of wafer handling equipment by providing wear-resistant components that reduce friction and mechanical stress. Their lightweight nature enhances energy efficiency in automated handling systems, minimizing strain on robotic arms and moving parts. Additionally, high-performance plastics offer electrical insulation properties, reducing the risk of interference in semiconductor applications.

Applications of Plastics in Wafer Manufacturing

Plastics are integral to nearly every stage of semiconductor wafer manufacturing, ensuring precision handling, contamination control, and chemical resistance. From wafer transport to cleanroom environments, high-performance plastics play a necessary role in upholding efficiency and quality.

Key Applications

Wafer Handling & Sorting Systems

Plastics are used in wafer carriers, Front Opening Unified Pods (FOUPs), robotic end effectors, and vacuum pick-up tools to safely transport wafers while preventing damage.

Chemical Processing Equipment

High-performance plastics like PTFE, PEEK, and PVDF are used in tanks, tubing, and fittings to resist corrosion from strong acids, solvents, and etchants used in wafer etching and cleaning.

Cleanroom Environments

Antistatic and contamination-resistant plastics are utilized in cleanroom walls, flooring, and fixtures to prevent dust and particle buildup, keeping wafers free from contamination.

Wafer Processing Components

Plastics with dimensional stability and wear resistance are used in wafer guides, wafer boats, and vacuum pick-up tools, ensuring precise and consistent wafer handling throughout manufacturing.

Finding the Right Plastic Material

Selecting the ideal plastic for semiconductor applications depends on several factors. The operating temperature must be considered to guarantee that the material can withstand heat without losing its structural integrity. Chemical resistance is another grave factor, as many semiconductor processes involve exposure to acids and solvents.

Depending on the application, antistatic or conductive properties may also be necessary. Materials used in wafer handling and sorting must meet precise tolerances for proper alignment and handling of wafers. Contemplating these factors ensures that the selected plastic material meets the demands of the semiconductor manufacturing environment while improving efficiency and consistency.

Trends in Wafer Manufacturing

As semiconductor manufacturing continues to evolve, the demand for high-performance plastics is expected to grow. Innovations in electrostatic-dissipative (ESD) plastics are helping to reduce the risks associated with static buildup, which can damage sensitive semiconductor components. The industry is also exploring using ultra-pure and recyclable polymers to enhance sustainability while supporting the strict quality standards required for wafer production.

Additionally, advancements in automation and robotic wafer handling systems drive the need for even more precise and wear-resistant plastic materials. As a result, manufacturers are continually developing new formulations that offer improved dimensional stability and longer lifespans, solidifying the status of plastics as a cornerstone of semiconductor fabrication.

Let’s Work Together

Plastics are important in wafer manufacturing, providing durability, chemical resistance, and precision handling for semiconductor production. From wafer carriers and chemical processing systems to cleanroom environments and wafer handling tools, high-performance plastics contribute to efficiency and contamination control throughout the manufacturing process.

Piedmont Plastics offers a wide selection of advanced plastic materials designed for semiconductor applications. Our materials safeguard precision, reliability, and long-term wafer handling and processing performance, making us your trusted partner for semiconductor solutions.

Consult With The Experts

Need further information? Contact us to learn more about how our high-performance plastics can support your semiconductor manufacturing needs!

Learn More