What is Delrin®?

Delrin® is a DuPont resin brand name for polyoxymethylene (POM), also commonly referred to as an acetal homopolymer, and is a popular material for machining. It’s a semi-crystalline engineering-grade thermoplastic that offers superior dimensional stability, high strength, wide operating temperature range, and low friction. Delrin’s many valuable properties make it a perfect material for creating highly durable and precision-based components.

Get a Quote for Delrin at Piedmont Plastics

Piedmont Plastics offers extruded Delrin plastic and acetal sheet, rod, and tubes. We can also offer compression molded sheets upon request.

Our standard Delrin rods are available in diameters from 0.187 inches up to 9 inches, with standard lengths of 1, 5, and 10 feet. Delrin sheet is stocked in thicknesses ranging from 1/16 inch to 4 inches, with standard widths of 12, 24, and 48 inches and lengths of 24, 48, and 120 inches.

Need a custom-cut size? Just let us know. We also offer value-added services to help ensure you receive material that meets your exact specifications.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Characteristics and Benefits of Delrin

Delrin serves as an excellent alternative for metal due to its high wear resistance, high-tensile strength, low friction, and superior resistance to warping. It also offers overall durability and toughness, perfect for demanding use.

In addition to its benefits as a replacement for metal, Delrin’s material properties include superior density, low moisture absorption, and chemical resistance to hydrocarbons, solvents, and neutral chemicals. Here is a breakdown of Delrin's various properties.

Properties of Delrin Plastic

Mechanical

Since Delrin is produced as an extruded acetal material, it is typically offered in a single, standardized molecular weight. It maintains excellent strength and stiffness at room temperature, delivers a tensile strength of approximately 11,100 psi, and features a high flexural modulus of about 420,000 psi. These characteristics provide outstanding rigidity in load-bearing applications.

In addition, Delrin performs exceptionally well in sliding and wear applications. The coefficient of friction is very low (typically between 0.1 and 0.3) and remains relatively stable across a wide range of temperatures, loads, and surface speeds, making it a reliable choice for precision components and moving parts.

Chemical

Delrin is exceptionally resistant to organic solvents. That said, Delrin® would not be ideal for environments involving strong acids, bases, or oxidizing agents.

Because Delrin is not subject to damage from fungi, insects, or other pests, it is an excellent choice for many underground uses. It also features superior staining and discoloration resistance at temperatures below 160° F.

Thermal

Because Delrin does not use plasticizing to attain its toughness, it does not suffer from brittleness at low temperatures. Its impact resistance at temperatures as low as -40° F is only 20% less than its resistance at room temperature.

For elevated temperatures, Delrin retains excellent strength at temperatures as high as 200° F with a tensile strength of 2,000 psi and flexural modulus at 180,000. Delrin’s upper service temperatures are 180° F in open air and 150° F in water and can withstand brief temperature peaks of 250° F.

Electrical

Delrin makes an excellent dielectric choice for materials as it has notably low dissipation factors and dielectric constants over a broad range of temperatures and frequencies. In addition, it maintains favorable dielectric properties in high-humidity environments while completely submerged in water.

Uses For Delrin Plastic

The above-listed properties of Delrin make it an excellent choice for a variety of applications in industrial, mechanical, automotive, aerospace, energy, food services, healthcare, and consumer industries. Overall, it’s a highly flexible material that can meet a surprising number of needs.

Because Delrin-made parts work well in moist or wet environments, it’s an excellent choice for products such as pump and valve components. In addition, it can be used for water management controls, faucets, and many kitchen appliances for similar reasons.

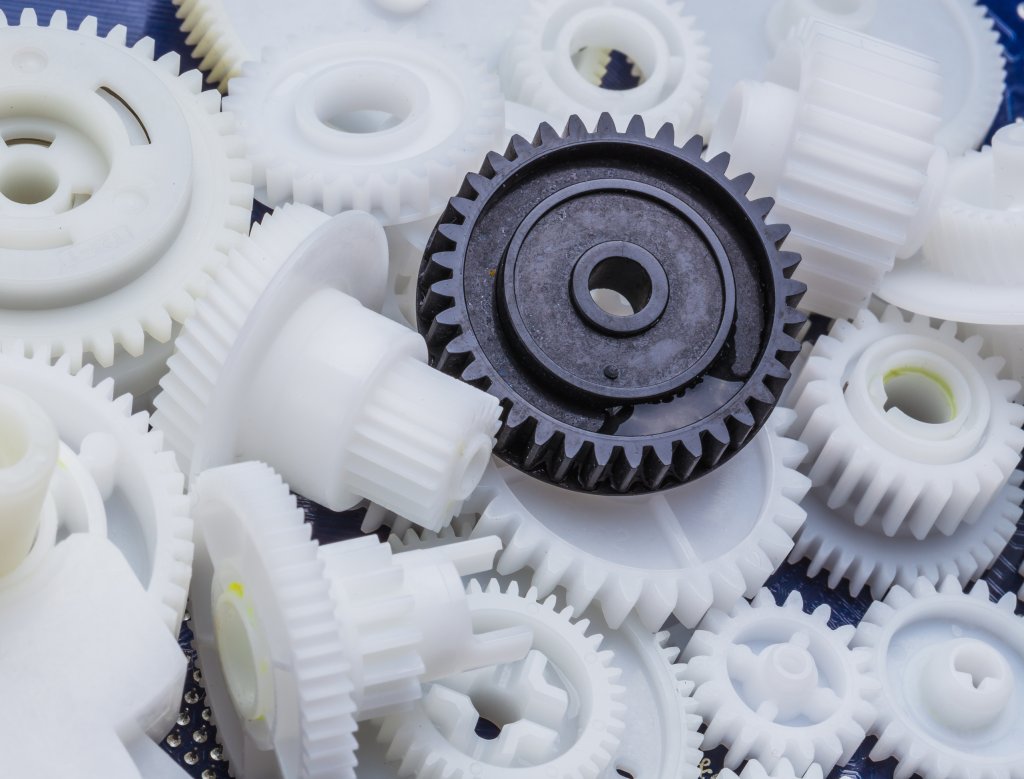

For automotive, mechanical, and industrial purposes, Delrin can be used to make bearings, bushings, gears, fittings, sliding and guiding parts, rollers, conveyor systems, scraper blades, and various electrical insulator parts. Its high impact resistance is suitable for many aerospace-related pieces, including safety restraint components, door systems, and zip fasteners.

In medically-related fields, Delrin is a superbly suitable choice for valves, pumps, inhalers, syringes, pen injectors, diagnostics equipment, wound care, medically-related gas and fluid handling, medical instruments, prosthetics, and implants.

Delrin’s various properties make it an excellent material for various consumer goods that require strength and durability, such as sports equipment, eyeglasses appliances, and food containers.

Common Applications for Delrin®

- Bearings and Bushings

- Conveyor Systems

- Valves, Seals, and Fittings

- Medical Equipment

-

Gears and Screws

-

Rollers

-

Pump Components

-

And more!

Delrin Acetal Homopolymer vs. Acetal Copolymer

Acetal plastics are available in two primary formulations: acetal copolymer and acetal homopolymer (Delrin). While both offer excellent strength, stiffness, and machinability, there are important performance differences that can influence material selection.

Delrin is known for its higher mechanical strength and rigidity. Compared to the copolymer, Delrin typically provides greater tensile strength, stiffness, and fatigue resistance, making it well suited for precision parts, gears, bearings, and other load-bearing or dynamic applications. Its low coefficient of friction and excellent wear performance also make it ideal for moving components that require tight tolerances and consistent performance.

Acetal copolymer, on the other hand, offers superior chemical resistance and improved performance in wet or chemically aggressive environments. It is less prone to centerline porosity and voids, which can occur in thicker sections of homopolymer, making copolymer a strong choice for large-diameter rods, thick plates, or components exposed to hot water, steam, or chemicals. Acetal copolymer also delivers better dimensional stability in applications with frequent moisture exposure.

In summary, Delrin is typically selected when maximum mechanical strength, stiffness, and fatigue resistance are required, while acetal copolymer is often preferred for applications involving moisture, chemicals, or thicker cross-sections where uniform internal structure and chemical durability are critical.

Buy Delrin From Piedmont Plastics Today!

We can customize your order to accommodate the sizes and lengths that fit your manufacturing needs. Contact us, and we’ll put you in touch with our plastics experts, who can help you locate high-quality project materials like Delrin from our North American network of Piedmont Plastics branches.

Contact Us