How Plastics Improve Battery Safety

As demand for energy storage surges from residential solar installations to grid-scale systems, the need for safe and reliable battery containment has never been greater. While chemistry powers the cells, it’s the materials surrounding them that prevent disaster when things go wrong. High-performance plastics now play a central role in mitigating thermal, electrical, and mechanical risks across modern battery systems.

Energy storage systems, particularly those using lithium-ion technology, store large amounts of energy in compact spaces. Under normal operation, these systems generate heat and can release gases or flammable materials if cell integrity is compromised. A single failure can initiate thermal runaway, damaging adjacent cells or igniting surrounding components. Thus, proper enclosure design is vital in preventing escalation and protecting users, equipment, and property.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Why Plastics Outperform Metals in Battery System Design

Unlike metals, which conduct electricity and add weight, select thermoplastics and composites provide insulation, chemical resistance, and flame performance, while also reducing system mass.

When specified correctly, engineered plastics enhance battery safety by meeting significant technical demands, including:

Electrical Insulation: Plastics like polycarbonate, polypropylene, and PBT prevent arcing and short circuits by isolating conductive components. Many exhibit high dielectric strength, making them ideal for cell spacers, covers, and busbar insulation.

Flame Retardancy: UL 94 V-0-rated plastics, such as flame-retardant PC/ABS or glass-filled nylon, resist ignition and self-extinguish when exposed to flames, which is crucial for containing thermal events inside enclosures.

Thermal Stability: Materials with high heat deflection temperatures maintain dimensional integrity during battery charging, discharging, or fault conditions, even under sustained load. This ensures critical clearances between cells stay intact.

Chemical Resistance: Battery systems may leak or vent electrolyte solvents or gases. Plastics such as polypropylene, acetal, and certain high-grade polyamides withstand exposure without swelling, cracking, or degradation.

Impact and Vibration Resistance: Engineered plastics provide cushioning and energy absorption, protecting sensitive cells from mechanical shock, road vibration, and stress, especially important in mobile and transportation applications.

Design Flexibility and Weight Reduction: Plastics allow complex geometries to be injection molded, integrating mounting features, airflow channels, and sealing surfaces into single components. This reduces part count, simplifies assembly, and minimizes total system weight.

Containment and Fire Mitigation: In battery modules, rigid thermoplastics can form outer housings that help contain gas or fluid release and limit the spread of fire, especially when paired with venting and shielding features.

PC and PC/ABS

In addition, they’re ideal for battery trays, module covers, and busbar guards, providing insulation without weight penalties. They can also be precisely molded to secure battery cells or allow airflow for cooling. With high dimensional stability, they don’t warp or creep, even after thousands of thermal cycles.

Polypropylene

Lead-acid batteries have long used polypropylene for their cases. This is for good reason, as it resists acid, holds up under compression, and doesn’t conduct electricity. Even in lithium systems, PP finds use in spill trays, spacers, and containment barriers.

Along with these qualities, polypropylene is incredibly light and rugged, making it a practical choice for utility-scale storage racks. Copolymer grades offer flexibility, while UV-stabilized versions provide support for outdoor use.

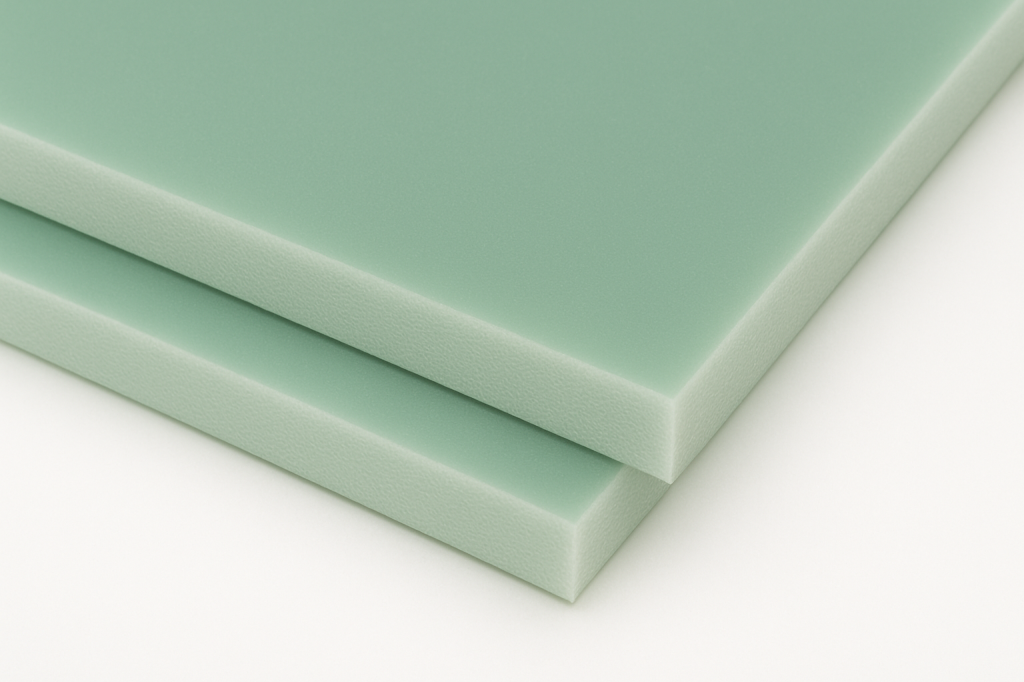

Phenolic Laminates

Beyond their core strength, G-10 and GPO-3 maintain stability under heat and resist moisture absorption. In environments where milliseconds matter, these phenolic boards deliver critical time and protection.

Other Plastics Used

Plastics also support battery systems beyond just containment. Acetal gears in actuators. Nylon grommets around cable pass-throughs. PTFE membranes in pressure relief valves. Each of them contributes to a safer, more durable system.

They also open the door to integrated design. Enclosures can include venting paths, strain reliefs, and mounting points, all of which are molded in. That’s hard to do with metal.

Need Professional Guidance?

Residential solar arrays, commercial UPS systems, and grid-tied mega batteries all share the same need: safe, strong materials that work silently in the background. Piedmont Plastics delivers on that need with flame-rated sheets, acid-resistant liners, and rigid laminates that don’t compromise.

Learn More

Designing your next battery system? We’ll help you select plastics that make it safer, lighter, and better prepared for what comes next. Contact us to get started!

Get A Quote