Reprocessed UHMW (ultra high molecular weight polyethylene) is ideally suited for conveying, handling, packaging, and more.

UHMW Reprocessed

Eco-friendly and durable, UHMW is perfect for friction-intensive non-food applications in industrial and commercial applications.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of UHMW Reprocessed

Common Properties

- Common Brand Names Polystone® M, TIVAR® ECO

- Typical Thickness Size 1/8 - 4 in

- Typical Lengths 24 - 120 in

- Typical Widths 24 - 60 in

- Friendly Names Recycled UHMW

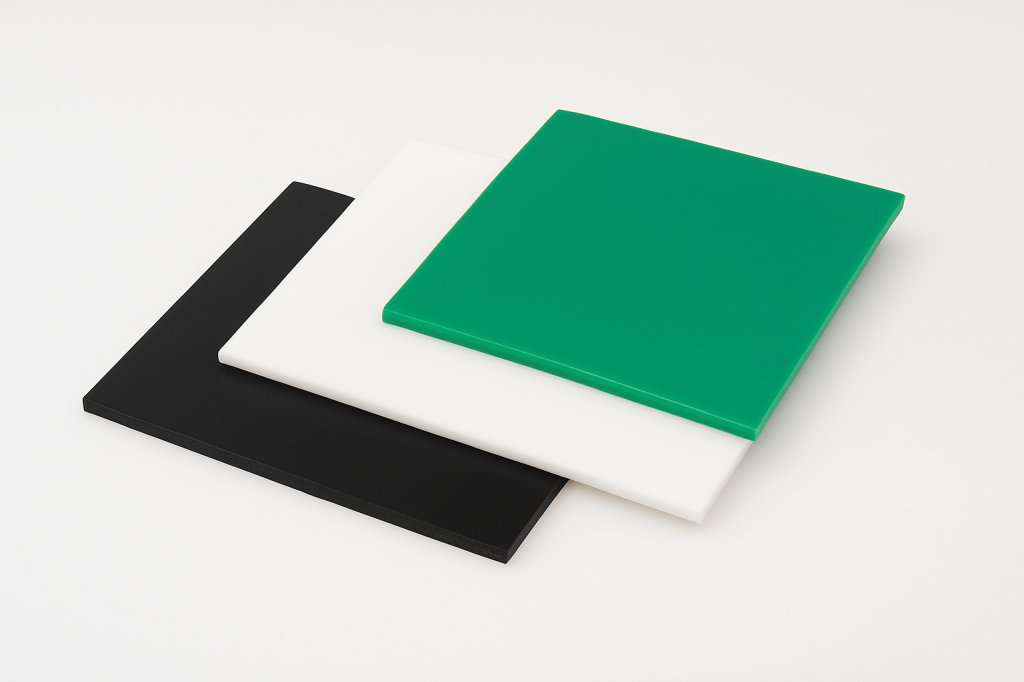

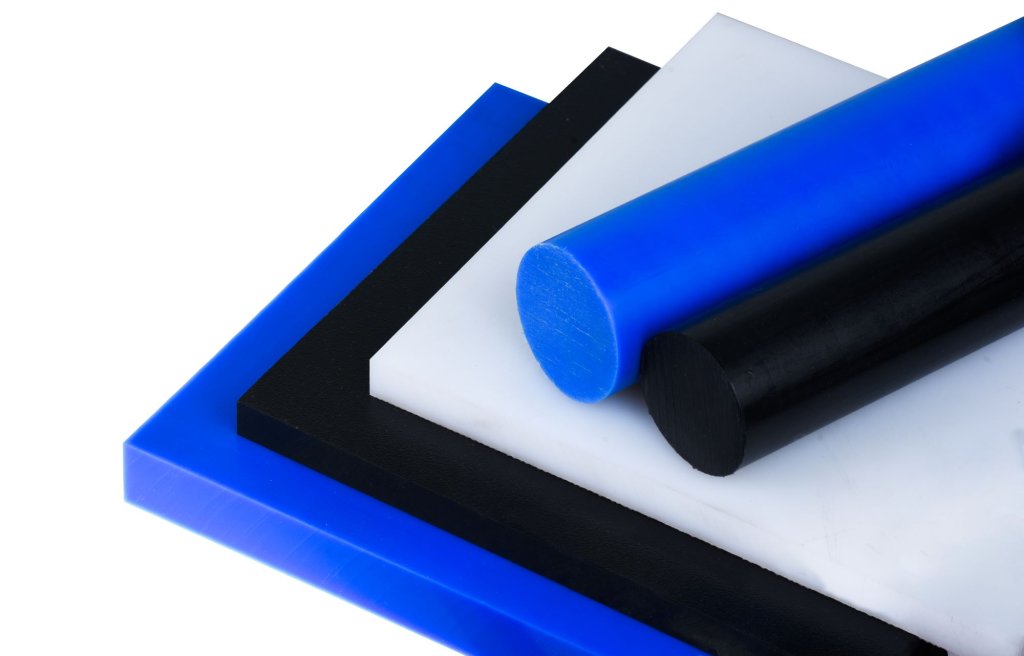

- Common Profiles Sheet, Rod

- Typical Rod Diameter 0.375 - 9 in

- Typical Rod Length 60 - 120 in

Physical Properties

- Density 1.04g/cm³

- Water Absorption 0.3%

- Moisture Absorption at Equilibrium 0.08%

- Linear Mold Shrinkage 0.005mm/mm

- Melt Flow 12g/10 min

Electrical Properties

- Dielectric Strength 50 - 120kV/mm

- Dielectric Constant 2.3 - 2.4none

- Dissipation Factor 0.0002 - 0.0004none

- Volume Resistivity 10^15ohm-cm

- Surface Resistivity 10^13ohms

- Arc Resistance 140 - 160seconds

- Comparative Tracking Index (CTI) 600V

- Thermal Coefficient of Dielectric Constant 0.0021/°C

- Breakdown Voltage 50 - 120kV/mm

Thermal Properties

- CTE, linear 100 - 200µm/m°C

- CTE, linear, Transverse to Flow 100 - 200µm/m°C

- Deflection Temperature at 0.46 MPa (66 psi) 45°C

- Deflection Temperature at 1.8 MPa (264 psi) 36°C

- Vicat Softening Point 88°C

- Flammability, UL94 HBRating

- Max Continuous Operating Temperature in F 180°F

- Minimum Operating Temperature in F - 22°F

- Thermal Conductivity 0.4W/mK

Regulations

- RoHS Compliant

- REACH Compliant

Reprocessed UHMW (Ultra High Molecular Weight Polyethylene) from Piedmont Plastics

Reprocessed UHMW (Ultra High Molecular Weight Polyethylene) is a machinable thermoplastic that serves as an economical and environmentally friendly option for non-food applications. Made from a blend of virgin and recycled UHMW, this thermoplastic’s durability, extremely low coefficient of friction, and inherent lubricity make UHMW ideal for applications where high levels of friction are likely to arise. While it shares many of the same properties as virgin UHMW, such as outstanding impact strength, chemical resistance, and low friction, reprocessed UHMW is better suited for non-food applications.

Thanks to its self-lubricating surface and high wear resistance, reprocessed UHMW is a popular choice in industries like conveying, material handling, and packaging. It holds up well in demanding environments where parts slide, rub, or impact against one another. This makes it ideal for use in wear strips, chute liners, guides, and other components requiring less friction. It’s also easy to machine, giving manufacturers more flexibility in design and performance.

Piedmont Plastics works with many suppliers to offer a wide range of performance plastics that will meet any need. Reprocessed UHMW is available in sheet and rod form in a wide range of sizes and thicknesses. Let the experts at Piedmont help you find the perfect product for your unique application!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Reprocessed UHMW

Reprocessed UHMW is renowned for its impressive performance in demanding environments, making it a go-to material for a wide range of uses. Below are some of the qualities that set UHMW apart:

Versatility and Compliance: A blend of virgin and recycled UHMW, reprocessed UHMW is a highly desired material for a variety of applications.

Machinability and Eco-Friendliness: Reprocessed UHMW’s easy machinability makes it a versatile, eco-friendly, and cost-effective material for countless non-food applications.

Diverse Applications: Reprocessed UHMW is widely used in conveying systems, material handling equipment, and packaging operations where strong wear resistance and long-lasting durability are essential.

Low Coefficient of Friction: Reprocessed UHMW allows materials to glide smoothly over its surface, reducing energy consumption, limiting heat buildup, and minimizing wear on moving parts.

Strength and Durability: Engineered to withstand heavy wear and tear, reprocessed UHMW's exceptional durability ensures long service life in applications such as guides, liners, and wear strips.

Inherent Lubricity: Reprocessed UHMW's built-in lubricity is especially beneficial in conveying and material handling, helping to improve efficiency while reducing maintenance needs.

Impact and Chemical Resistance: These qualities make reprocessed UHMW well-suited for use in harsh environments where mechanical shock or exposure to industrial chemicals might degrade other materials.

Benefits of Reprocessed UHMW

Common Reprocessed UHMW Applications

Reprocessed UHMW is a versatile material that performs well in a wide range of industrial environments. Thanks to its excellent durability and low-friction properties, it’s used across many industries in applications such as:

Conveying and Material Handling: Reprocessed UHMW is a reliable choice for systems that require durability and resistance to wear, making it ideal for conveyor components and material handling equipment.

Packaging: Its cost-efficiency and adaptability make reprocessed UHMW a popular material in various packaging applications.

Transportation and Shipping: This material is commonly used in transportation and shipping industries for components that need to endure impact, friction, and heavy use.

Plastic and Metal Fabrication: Reprocessed UHMW performs well in fabrication processes where toughness and friction resistance are critical, particularly in high-impact environments.

Marine Applications: Frequently used in pile wraps, reprocessed UHMW helps protect docks and pilings from abrasion in harsh marine settings.

Why Buy Reprocessed UHMW from Piedmont Plastics?

At Piedmont Plastics, we’re committed to providing high-quality reprocessed UHMW materials that deliver long-lasting performance and value. Whether you need wear-resistant plastic for conveying, packaging, or fabrication, our team is here to help you find the right solution for your application. Here's why customers trust us as their go-to plastic sheet distributor:

Wide Selection of Products: We offer reprocessed UHMW sheet and rod in a range of sizes and thicknesses to fit a variety of industrial needs.

Custom Cutting and Fabrication: Our advanced CNC cutting and fabrication services ensure your materials are tailored to your exact specifications, helping reduce waste and speed up installation.

Expert Guidance: With decades of experience in performance plastics, our knowledgeable team can help you choose the right UHMW plastic for your specific project and application.

Reliable Nationwide Supply: With locations across North America, we maintain a strong inventory network to ensure fast, reliable access to the materials you need, when and where you need them.

Trusted Quality Standards: We source reprocessed UHMW from top manufacturers and uphold strict quality controls to ensure consistent performance across every order.

Contact Piedmont Plastics today to learn more about our reprocessed UHMW offerings. We're ready to help you find the perfect material for your project!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745