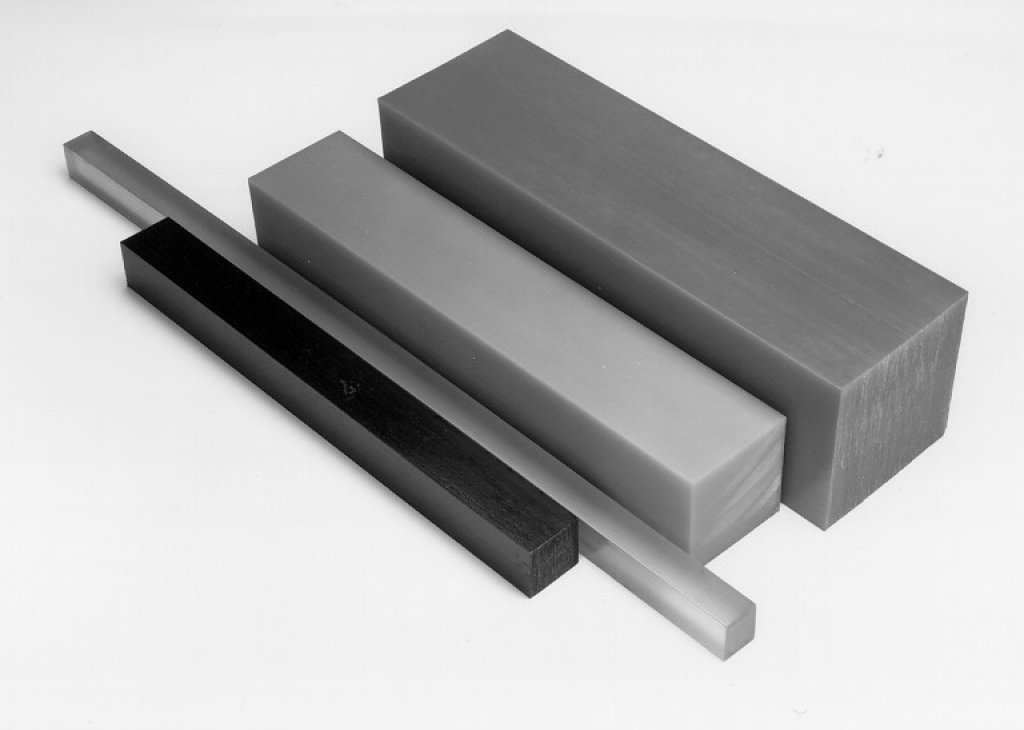

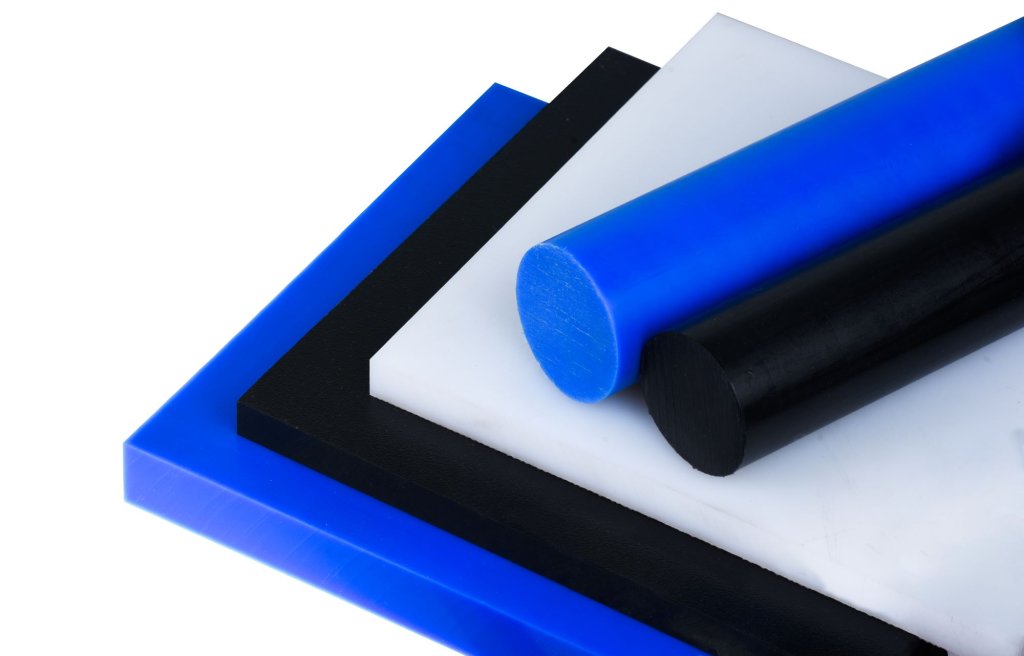

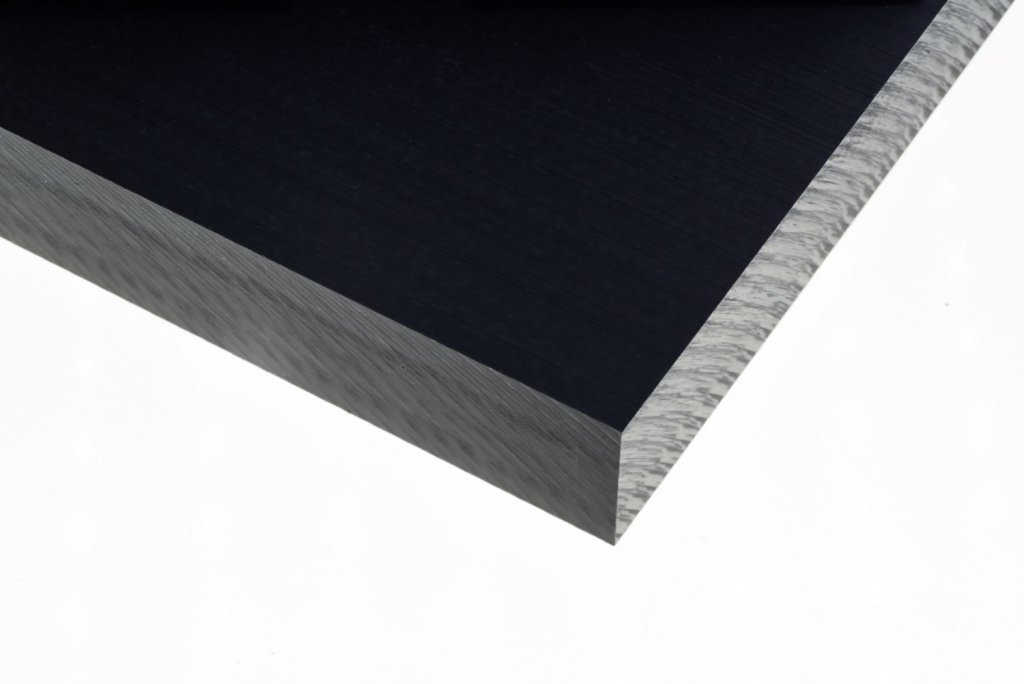

Polyurethane sheet, rod, and tube deliver toughness, impact resistance, and versatility for industrial, manufacturing, and equipment applications.

Polyurethane

Durable polyurethane sheet, rod, and tube for tough, high-wear applications.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Polyurethane

Common Properties

- Common Brand Names HYDEX, Harkness MP

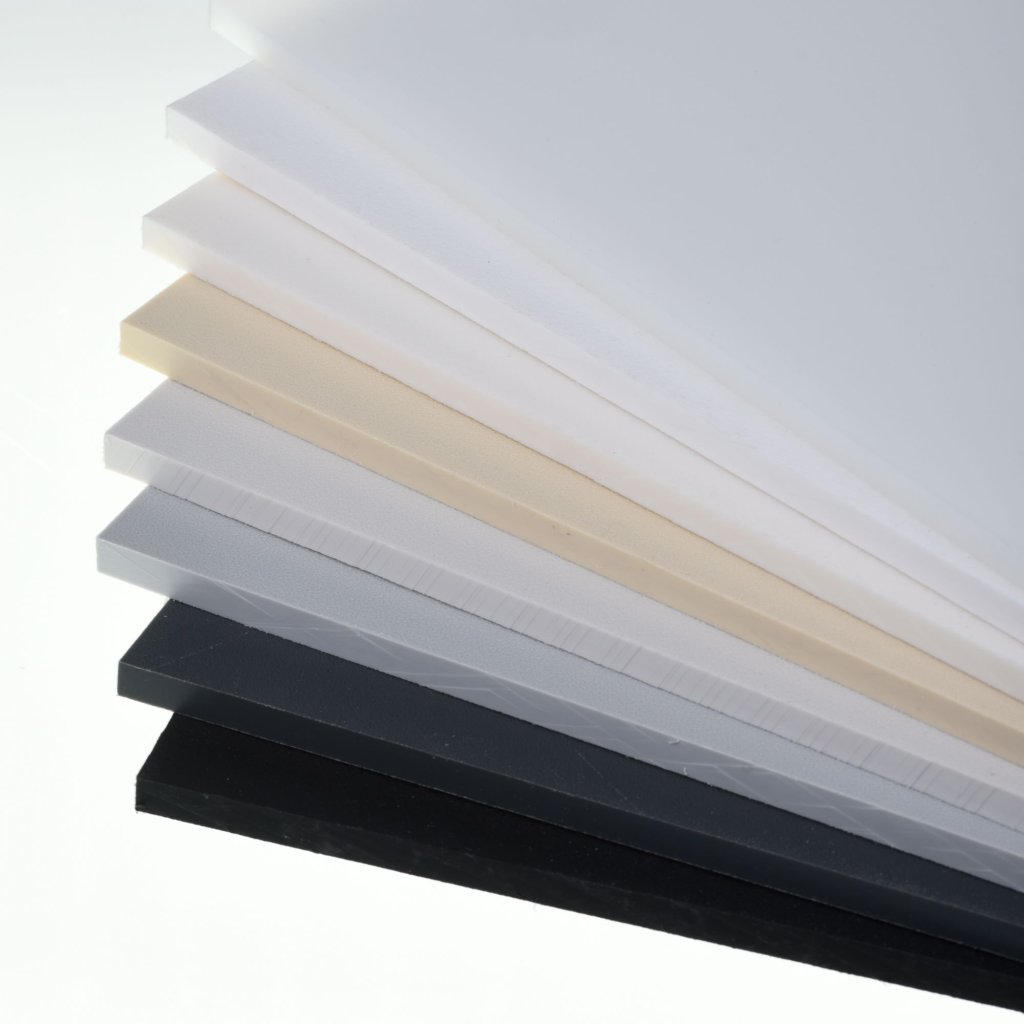

- Typical Thickness Size 0.03 - 8 in

- Typical Lengths 12 - 120 in

- Typical Widths 12 - 60 in

- Friendly Names Urethane, PU

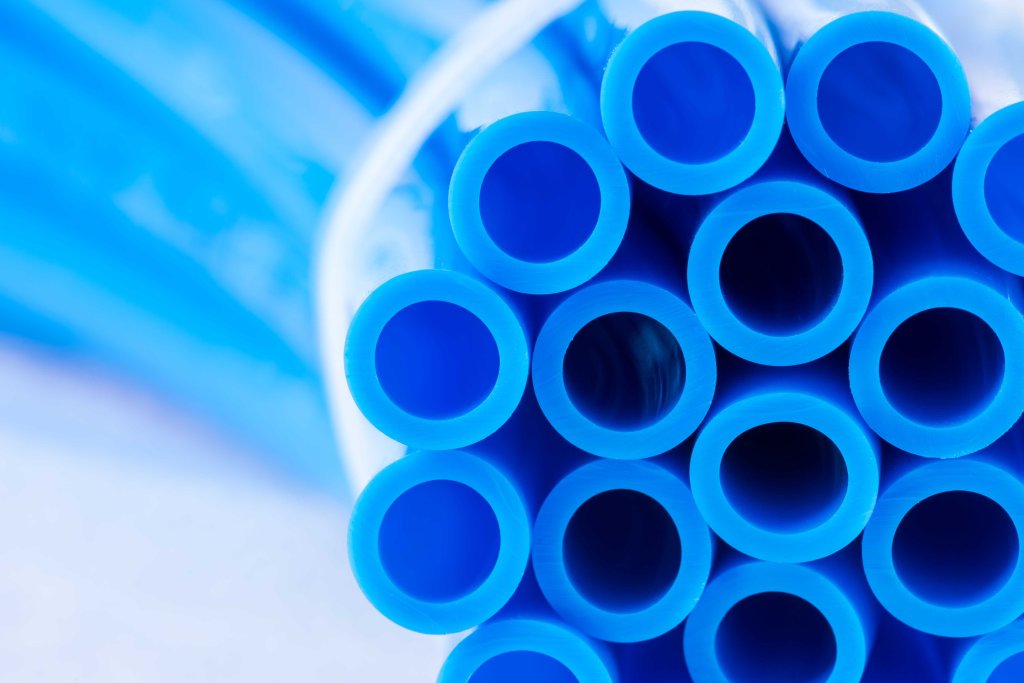

- Common Profiles Sheet, Rod, Tube

- Typical Rod Diameter 0.250 – 16 in

- Typical Rod Length 36 in

- Typical Tube Outside Diameter 0.125 – 7 in

- Typical Tube Length 100 ft

Physical Properties

- Density 0.9g/cm³

- Water Absorption 0.1%

- Moisture Absorption at Equilibrium 0.3%

- Linear Mold Shrinkage 0.002cm/cm

- Melt Flow 10g/10 min

Electrical Properties

- Dielectric Strength 17kV/mm

- Dielectric Constant 3

- Dissipation Factor 0.015

- Volume Resistivity 1.0E+14ohm·cm

- Surface Resistivity 1.0E+14ohm/sq

- Arc Resistance 120seconds

- Comparative Tracking Index (CTI) 600V

- Thermal Coefficient of Dielectric Constant 0.02%%/°C

- Electrostatic Discharge (ESD) Sensitivity Medium

- Breakdown Voltage 25kV

Mechanical Properties

- Hardness 80Rockwell R

- Tensile Strength, Ultimate 5500psi

- Tensile Strength, Yield 3500psi

- Elongation at Break 200%

- Elongation at Yield 10%

- Modulus of Elasticity 300000psi

- Flexural Yield Strength 4500psi

- Flexural Modulus 250000psi

- Compressive Yield Strength 3500psi

- Bearing Yield Strength 4000psi

- Shear Strength 2500psi

- Izod Impact, Notched 12ft-lb/in

- Izod Impact, Unnotched 20ft-lb/in

- Gardner Impact 200in-lb

- Falling Dart Impact 50ft-lb

- Instrumented Impact Total Energy 40ft-lb

Thermal Properties

- CTE, linear 60-150µm/(m·°C)

- CTE, linear, Transverse to Flow 60-100µm/(m·°C)

- Deflection Temperature at 0.46 MPa (66 psi) 146°C

- Deflection Temperature at 1.8 MPa (264 psi) 120-130°C

- Vicat Softening Point 180-200°C

- Flammability, UL94 HB-

- Max Continuous Operating Temperature in F 250°F

- Minimum Operating Temperature in F -40°F

- Thermal Conductivity 0.1-0.25W/(m·K)

Regulations

- UL-94 Flame Class

- FDA

- ASTM/Mil-Spec

- USDA

- NSF

- USP Class VI

- D635 Self Extinguishing

- RoHS Compliant

- REACH Compliant

Literature and Data Sheets

-

Harkness Industries MP 500 Harkness IndustriesView

-

Harkness Industries MP 600 Harkness IndustriesView

-

Harkness Industries MP 700 Harkness IndustriesView

-

Harkness Industries MP 750 Harkness IndustriesView

-

Harkness Industries MP 850 Harkness IndustriesView

-

Harkness Industries MP 900 Harkness IndustriesView

-

Harkness Industries MP 950 Harkness IndustriesView

-

HYDEX 202 natural EnsingerView

-

HYDEX 301 natural EnsingerView

-

HYDEX 4101 PBT black EnsingerView

Get a Quote for Polyurethane at Piedmont Plastics

Polyurethane (PU), also known as urethane, is a versatile, high-performance plastic recognized for its exceptional abrasion resistance, resilience, and ability to withstand repeated impact. Available in sheet, rod, and tube form, polyurethane offers a unique balance of flexibility and strength, making it a preferred choice for demanding industrial environments. Its vibration-damping properties and resistance to tearing, weathering, and many chemicals make it ideal for parts exposed to continuous wear.

Whether you need stock shapes or precision-cut components, Piedmont Plastics can supply polyurethane in the right form for your project. Contact us today for a quote and to discuss your application needs.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Polyurethane

Polyurethane combines the elasticity of rubber with the strength of engineering plastics, delivering a performance profile that excels in challenging conditions.

Outstanding Abrasion Resistance: Ideal for parts exposed to high wear and friction.

High Impact Strength: Absorbs shock and resists cracking or breaking under repeated stress.

Excellent Tear Resistance: Maintains integrity in demanding mechanical applications.

Good Chemical Resistance: Withstands oils, solvents, and some chemicals.

Wide Hardness Range: Available in varying durometers for custom performance.

Noise and Vibration Damping: Reduces operational noise in equipment.

Weather and UV Resistance: Performs reliably in outdoor environments.

Benefits and Advantages

Common Applications

Polyurethane sheet, rod, and tube are widely used across manufacturing, transportation, and heavy equipment industries.

Typical Uses Include:

Bushings and Bearings: Reduce friction while absorbing shock.

Rollers and Wheels: Provide wear resistance and load capacity.

Wear Strips and Guides: Protect machinery from abrasion damage.

Seals and Gaskets: Maintain flexibility and sealing properties over time.

Bumpers and Pads: Cushion impact in industrial equipment.

Vibration Isolators: Minimize noise and mechanical stress.

Related Products

-

UHMW PE

UHMW from Piedmont Plastics offers superior durability, low friction, and wear resistance, ideal for conveyors, liners, and food-grade industrial parts.

-

HDPE (High Density Polyethylene)

HDPE offers strength, low weight, and resistance to chemicals and moisture, making it ideal for food and beverage equipment, industrial components, and marine applications.

-

Cast Nylon

Cast nylon is a highly versatile, strong, and wear-resistant engineering plastic, commonly used for gears, rollers, and bearings.

-

Acetal

Acetal (POM) is an engineering plastic known for its durability, dimensional stability, and wear and abrasion resistance, making it a popular choice for precision parts in automotive, electronics, and food processing applications.

Frequently Asked Questions

Below are some of the most common questions about polyurethane sheet, rod, and tube, including its performance, uses, and material properties.

Why Buy from Piedmont Plastics?

Choosing Piedmont Plastics means partnering with a trusted distributor who understands your application needs and delivers quality materials on time.

Nationwide network of branches: Local inventory and quick delivery across North America.

Custom cutting and fabrication services: Precision cutting and fabrication services to meet your exact requirements.

Deep industry expertise: Technical support for selecting the best material and grade.

Wide product selection: One-stop shop for performance plastics and related materials.

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745