Piedmont Plastics stocks polyethylene (PE) film, commonly used as a protective barrier in exterminating, painting, renovations, and waterproofing.

Polyethylene Film

Durable, versatile polyethylene (PE) film provides protection for applications in construction, agriculture, and other industries.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of Polyethylene Film

Common Properties

- Common Brand Names kp® Mono, Pentadur®, 561 PE Film

- Typical Thickness Size 0.015, 0.040 in

- Typical Lengths 100 ft

- Typical Widths 12 - 47 in

- Friendly Names PE Film, HDPE Film, LDPE Film, Poly Film,

- Common Profiles Film

Physical Properties

- Density 0.9g/cm^3

- Water Absorption 0.01%

- Moisture Absorption at Equilibrium <0.01%

- Linear Mold Shrinkage 0.005mm/mm

- Melt Flow 10g/10 min

Electrical Properties

- Dielectric Strength 20MV/m

- Dielectric Constant 2.3unitless

- Dissipation Factor 0.0003unitless

- Volume Resistivity 1.0E+16ohm·cm

- Surface Resistivity 1.0E+15ohm/square

- Arc Resistance 150seconds

- Comparative Tracking Index (CTI) 600V

- Thermal Coefficient of Dielectric Constant -0.00041/°C

- Electrostatic Discharge (ESD) Sensitivity Lowqualitative

- Breakdown Voltage 20kV/mm

Mechanical Properties

- Tensile Strength, Ultimate 20MPa

- Tensile Strength, Yield 12MPa

- Elongation at Break 600%

- Elongation at Yield 20%

- Modulus of Elasticity 200-1200MPa

- Gardner Impact 30J

- Falling Dart Impact 30J

- Instrumented Impact Total Energy 45J

Thermal Properties

- CTE, linear 150µm/m°C

- CTE, linear, Transverse to Flow 160µm/m°C

- Deflection Temperature at 0.46 MPa (66 psi) 58°C

- Deflection Temperature at 1.8 MPa (264 psi) 41°C

- Vicat Softening Point 92°C

- Flammability, UL94 HB

- Max Continuous Operating Temperature in F 140°F

- Minimum Operating Temperature in F -58°F

- Thermal Conductivity 0.4W/m·K

Regulations

- FDA

- USDA

- RoHS Compliant

- REACH Compliant

Get a Quote for Polyethylene Film from Piedmont Plastics

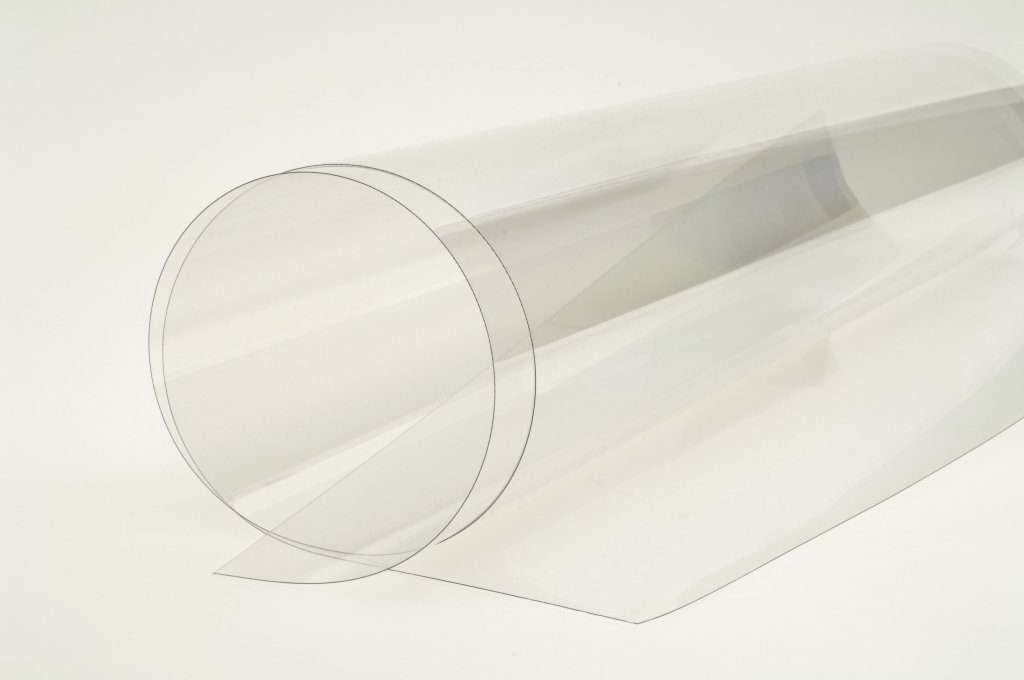

Polyethylene film (PE film) is a lightweight yet durable plastic sheeting supplied in convenient roll form. As one of the most widely used plastic films, it is available in both high-density (HDPE) and low-density (LDPE) grades. HDPE film is known for its strength, solvent resistance, and suitability for food storage and industrial applications, while LDPE film offers clarity, flexibility, and toughness, making it ideal for packaging and wrapping.

PE film is valued for its excellent tape adhesion and resistance to water, rot, wrinkles, and chemicals. It can also be reused multiple times and offers reliable protection against UV exposure for several years. Standard rolls are available in both clear and black to fit the needs of different projects.

Because of its balance of strength and flexibility, polyethylene film is used across many industries. In building and construction, it serves as a protective barrier for concrete curing, painting, and waterproofing. In pest control and extermination, it works as a containment layer. In agriculture, it is often used as a weed barrier or greenhouse covering. Packaging applications also rely on PE film for shrink bundling, pallet wraps, and produce bags.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of Polyethylene Film

Polyethylene film is engineered for strength, flexibility, and environmental resistance. Its physical properties vary by grade, but all PE films share dependable durability. Key features include:

Tape Adhesion and Durability: PE film offers excellent tape adhesion and lightweight durability, making it an ideal protective barrier for applications such as concrete curing, mortar work, pest control, waterproofing, painting, and renovations.

Chemical and Water Resistance: Resistant to water, rot, wrinkles, and many chemicals, PE film can be reused multiple times and is formulated to withstand UV degradation for several years.

Versatility: Available in both clear and black standard rolls, PE film is widely used in agriculture for weed barriers, greenhouse coverings, and other protective uses.

Toughness and Reliability: As a material, polyethylene is known for its toughness, flexibility, and dependable performance in demanding environments.

Low Moisture Absorption: In addition to its light weight, PE film has near-zero moisture absorption and is easy to process across different applications.

These features make polyethylene film a versatile, durable, and cost-effective solution for both commercial and household projects.

Benefits of Polyethylene Film

Common Applications for Polyethylene Film

PE film is used across industries due to its tape adhesion, lightweight durability, and weather resistance. Here are some common applications:

Building and Construction: In the building trades, PE film serves as a reliable protective barrier for concrete and mortar projects, as well as for waterproofing, painting, and general renovation work.

Agriculture: Farmers and gardeners rely on PE film for weed barriers and greenhouse coverings, where it delivers durability and protection against harsh environmental conditions.

Packaging: PE film plays a key role in packaging, appearing in industrial bags, shrink bundling, and protective wraps for soft goods.

Household and Commercial Products: PE film is incorporated into everyday products such as garment bags, blow molded bottles, large containers, and even injection molded housewares.

Food Handling and Storage: PE film is used for liners, storage bags, and other food-safe applications thanks to its solvent resistance.

Pest Control and Extermination: Serves as a containment barrier during fumigation, remediation, and pest treatment processes.

Together, these applications demonstrate the versatility and widespread importance of polyethylene film in sectors ranging from construction to healthcare.

Related Products

-

Polycarbonate Film

Polycarbonate film offers exceptional clarity, top-quality printing, high heat resistance, and easy thermoforming and molding capabilities.

-

Polyester

Piedmont Plastics supplies polyethylene terephthalate or polyester film (PET film), providing solutions for many applications and industries.

-

Rigid Vinyl Film

Rigid vinyl film is a type of durable PVC film for printing, packaging, and industrial applications. Piedmont Plastics supplies high-quality rigid vinyl film with excellent dimensional stability and performance.

Frequently Asked Questions about PE Film

Below are some commonly asked questions about PE film and how it performs in different applications.

HDPE film is stiffer, more chemical resistant, and less flexible, making it suitable for food storage and industrial liners. LDPE film is more flexible, clear, and tough, ideal for packaging and shrink bundling.

Yes, PE film is reusable and durable, particularly in applications such as drop cloths, covers, and greenhouse films.

Yes, many grades of PE film are stabilized to withstand UV exposure for several years, making them suitable for outdoor agricultural and construction use.

Yes, PE film provides excellent resistance to most common chemicals and solvents.

Yes, polyethylene resists water absorption, protecting it from moisture damage. Its strength and toughness also make it capable of handling the demands of gardening tasks.

Why Order Polyethylene Film from Piedmont Plastics?

At Piedmont Plastics, we understand that choosing the right polyethylene film is essential to the success of your project. That’s why we supply only high-quality PE film in both HDPE and LDPE grades, backed by expert guidance and a wide range of options to fit your exact needs.

Here’s why Piedmont Plastics is your trusted polyethylene film supplier:

Wide Product Selection: We carry polyethylene film in clear and black standard rolls, available in multiple grades, thicknesses, and widths to serve applications from packaging to construction.

Custom Cutting and Conversion Services: Our team can provide PE film tailored to your specifications, including custom roll widths and fabrication options for unique applications.

Trusted Expertise: With decades of experience, our specialists can guide you in selecting the right type of polyethylene film, whether you need flexible LDPE or robust HDPE.

Nationwide Availability: With branches across North America, Piedmont Plastics makes it easy to source PE film, no matter your location.

Consistent Quality: Every roll of polyethylene film we distribute meets strict performance standards, ensuring durability, flexibility, and long-lasting results.

Let Piedmont Plastics help you find the right polyethylene film for your application. Contact us today to speak with a trusted PE film distributor near you!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745