Cutting boards made from HDPE offer the ideal combination of durability, low moisture absorption, high tensile strength, and corrosion resistance, making this an ideal material for food prep surfaces.

HDPE Cutting Board

Durable, safe, and customizable, HDPE cutting boards are ideal for commercial and recreational kitchens.

-

Fabrication Support

Cut-to-Size, Routing

-

Local

Inventory Stocking

-

National

Inventory Access

Product Overview

Widely used for:

Performance Characteristics:

Typical Properties of HDPE Cutting Board

Common Properties

- Typical Thickness Size 0.25 in

- Typical Lengths 48 in

- Typical Widths 24 in

- Friendly Names Polyethylene Cutting Board, HDPE Sheet

- Common Profiles Sheet

Physical Properties

- Density 0.9g/cm^3

- Water Absorption 0.1% over 24 hours

- Moisture Absorption at Equilibrium 0.2%

- Linear Mold Shrinkage 0.005in/in

- Melt Flow 15g/10 min

Regulations

- FDA

- USDA

- 3-A Dairy

- NSF

- Canada AG

- RoHS Compliant

- REACH Compliant

Literature and Data Sheets

-

King CuttingBoard® King PlasticView

-

King CuttingBoard® XL King PlasticView

-

King CuttingColors® King PlasticView

-

Röchling Polystone® G and Polystone® P Röchling Engineering PlasticsView

-

VYCOM SANATEC® HDPE VycomView

-

VYCOM SANATEC® LITE HDPE VycomView

HDPE Cutting Board Material from Piedmont Plastics

HDPE is a popular choice for cutting boards thanks to its strength and durability. High-density polyethylene resists moisture, stains, and odors, making it ideal for food preparation in both commercial and residential settings. With its high impact resistance and easy-to-clean surface, HDPE provides a safe, long-lasting solution for a wide range of cutting board applications.

HDPE cutting boards are popular in restaurants, grocery stores, butcher shops, and commercial kitchens. They are also a great option for home kitchens, food trucks, and outdoor cooking areas. Because HDPE is non-porous and easy to clean, it helps prevent cross-contamination and keeps food processing sanitary. HDPE plastic sheets are also lightweight and easy to fabricate, which means they can be cut to size for custom applications.

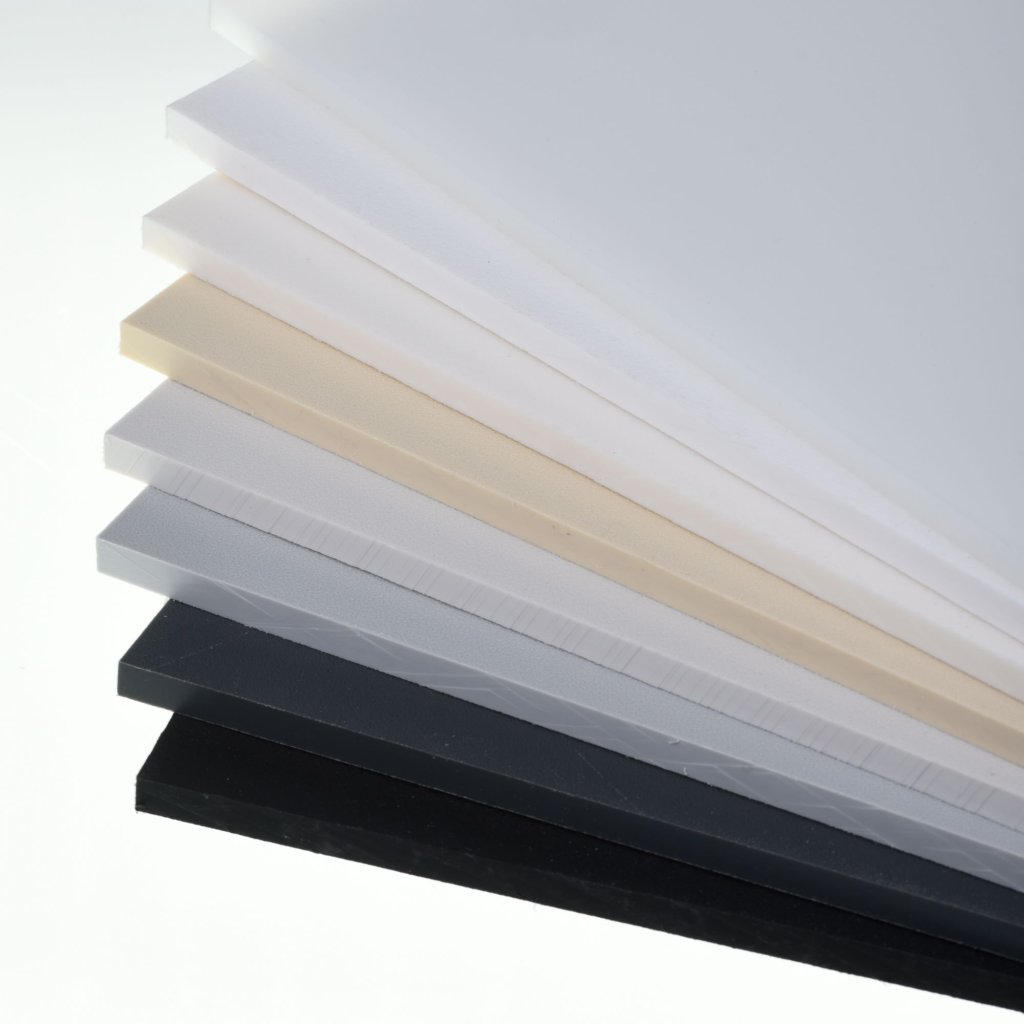

Available in a variety of colors and sizes, HDPE sheet is often color-coded to separate different types of food prep, such as raw meat and produce. These cutting boards are also gentle on knives, helping to extend the life of your blades.

If you're looking for a reliable and long-lasting cutting surface, HDPE cutting boards are an excellent choice. Piedmont Plastics is a leading plastic sheet distributor offering HDPE sheet in many sizes and thicknesses. Contact us today to order HDPE cutting board that meets your needs!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Key Features of HDPE Cutting Board

Here's why HDPE is the choice material for cutting boards:

Durability: HDPE is highly durable and resistant to chipping, making it less likely to contaminate food than wood and other traditional materials.

Safety: HDPE cutting boards are USDA compliant, dishwasher safe, and resist moisture, stains, and mildew, creating a dependable and food-safe environment.

Low Maintenance: HDPE is easy to clean and sanitize, which is crucial in food service facilities.

Bacteria Resistance: Because HDPE does not absorb harmful bacteria, it is ideal for environments where bacteria resistance is necessary.

Knife-Friendly: Since HDPE cutting boards do not dull knives, they work well in busy commercial settings.

These attributes make HDPE perfectly suited for cutting boards in various settings, including restaurants, grocery stores, and residential kitchens.

Benefits of Using HDPE for Cutting Boards

Common Industries for HDPE Cutting Board

HDPE cutting boards are used in several industries, including:

Food Service: Due to their durability, safety, and ease of maintenance, HDPE cutting boards are commonly used in restaurants, grocery stores, commercial and residential kitchens, and other food production facilities.

Meatpacking and Butchering: HDPE sheets are used as cutting boards in meatpacking and butchering industries because they are USDA compliant and withstand moisture, stains, and mildew.

Packaging: HDPE cutting board’s strength and resistance to bacteria absorption make it an ideal choice for food preparation and packaging applications.

Specialty Vehicles: HDPE cutting boards are also popular for specialty vehicles, providing a safe and durable surface for food preparation.

These industries rely on HDPE for its resistance to bacteria, acids, and odors, making it a top material for food preparation and service.

Why Buy HDPE Cutting Board from Piedmont Plastics?

At Piedmont Plastics, we offer only high-quality HDPE cutting board materials because we know your projects depend on reliable performance. No matter your industry, you can count on our deep product knowledge and wide material selection to help you succeed. Here’s why customers trust us as their go-to HDPE supplier:

Extensive Selection: We stock a wide variety of HDPE sheet in different sizes, thicknesses, and colors to support a broad range of applications.

Custom Cutting Services: With advanced CNC cutting and fabrication capabilities, we deliver precision-cut HDPE tailored to your exact specifications.

Expert Guidance: Backed by decades of experience, our team is ready to help you choose the right material for your unique application.

Nationwide Availability: With locations across North America, we make it easy to access HPDE and other performance plastics wherever you are.

Consistent Quality: We follow strict quality standards to ensure every HDPE product performs beyond expectations.

Ready to see the Piedmont difference for yourself? Contact us today to find the perfect HDPE material for your next project!

Talk to An Expert In

Columbus

460 Schrock Road

614-985-0745