Deciding Between UHMW and HDPE

UHMW and HDPE are two indistinguishable thermoplastic polymers with differing industrial applications. Several key differences between UHMW (ultra-high molecular weight polyethylene) and HDPE (high-density polyethylene) make them suitable for specific uses.

This article will explore how the two polymers compare based on their production, industry, and general uses. You can determine which plastic best suits your needs by understanding the two polymers. Let's dive deeper into the similarities and differences between UHMW and HDPE to help you choose the best material for your needs!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

A Brief Overview

Plastics have become an integral part of our daily lives, revolutionizing various industries with their versatile properties and wide range of applications. These thermoplastic polymers have transformed the way we manufacture and use products, providing solutions to challenges in fields such as these:

Across these and many more applications, you'll find plastic in almost every industry. Two of these plastics include UHMW and HDPE.

Origins and Basic Properties

Ultra-high molecular weight polyethylene (UHMW) and high-density polyethylene (HDPE) are members of the polyethylene family, thermoplastic polymers commonly used in various industries. Below, you'll learn a bit more about the basics of these plastics.

UHMW, as its name suggests, has an ultra-high molecular weight. The molecular chains in UHMW are much longer than those found in other polyethylenes, resulting in its exceptional mechanical properties. UHMW is renowned for its outstanding wear resistance, impact strength, and chemical resistance, making it suitable for various industrial and consumer applications.

HDPE is also derived from polyethylene, but its molecular chains are shorter than UHMW's, making it much cheaper to produce (and less durable). HDPE offers excellent chemical, impact, and UV resistance, making it a preferred material for various applications, including packaging, pipe fittings, and outdoor equipment.

How UHMW and HDPE Are Made

The two follow the same manufacturing process, polymerization, which creates all polymers. During this process, smaller molecules (monomers) are chemically combined to create larger molecules (macromolecules). This means (without getting too technical) that UHMW and HDPE follow similar processes for creation. However, they differ based on the length of their polymer chains.

UHMW

The production of UHMW typically ends up as a gel or a fiber with an incredibly long set of molecular chains. The polymerization conditions are carefully controlled to achieve UHMW's ultra-high molecular weight characteristic, including temperature, pressure, and catalyst choice.

The result is a unique molecular structure with exceptionally long chains, giving UHMW outstanding mechanical properties.

HDPE

Like UHMW, HDPE starts with the polymerization of ethylene monomers but ends with shorter chains of Polyethene. The shorter molecular chains give HDPE its high-density characteristic, resulting in properties such as excellent chemical resistance, impact resistance, and UV resistance.

With these different strengths, each polymer has other advantages.

Key Advantages of UHMW

UHMW stands out for its:

High Strength and Durability: Renowned for its impressive strength-to-weight ratio. It can outlast other materials like HDPE, metals, wood, and other plastics.

Exceptional Wear Resistance: Highly resistant to abrasion, which makes it an excellent choice for applications where material needs to glide smoothly, like conveyor systems.

Excellent Chemical Resistance: UHMW exhibits excellent chemical resistance, making it suitable for corrosive chemical industries.

Low Water Absorption: Unlike other materials, it does not swell or degrade due to moisture exposure, ensuring its structural integrity and dimensional stability over time.

UV Resistance: It does not degrade or become brittle due to UV exposure, ensuring its longevity when continuously exposed to the sun.

Food Safety and FDA Approval: Its non-toxic and non-reactive properties ensure that it does not contaminate food or alter its taste or quality.

Key Advantages of HDPE

In turn, HDPE is valued for its:

Fair Impact Resistance: Its molecular structure and high molecular weight enable it to withstand some impacts and harsh environments without cracking or breaking.

Chemical Resistance: HDPE is impervious to acids, bases, solvents, and other aggressive chemicals.

UV Resistance: It can withstand prolonged exposure to sunlight without significant degradation or color fading.

Good Wear Resistance: HDPE's low coefficient of friction reduces wear and tear on surfaces. However, it's worth noting that UHMW is much better in this area.

Environmental Impact: HDPE and UHMW can both be recycled into new products, reducing waste and conserving natural resources.

Drawbacks and Limitations

While UHMW and HDPE offer numerous advantages, it is important to acknowledge these materials' potential weaknesses and limitations. Users can make informed decisions regarding their specific applications by understanding these challenges.

-

Water Absorption

UHMW has a small degree of water absorption while HDPE does not, which can affect its mechanical capabilities.

-

Impact and Wear Differences

UHMW is known for its greater impact strength and wear resistance compared to HDPE.

-

Formation Challenges

Due to its lower durability and wear resistance, HDPE is much easier to work with in regards to shape formation and machining. UHMW requires a bit more work here.

-

Heat Resistance

Neither UHMW nor HDPE resist high heat levels. On top of that, HDPE is flammable, making it less suitable for industries like aerospace.

By being aware of these limitations and challenges, users can make informed decisions about the suitability of UHMW and HDPE for their specific applications.

Practical Applications

UHMW and HDPE are widely used in various industries due to their exceptional mechanical properties and versatility. Let's explore some practical applications where industries commonly utilize UHMW and HDPE:

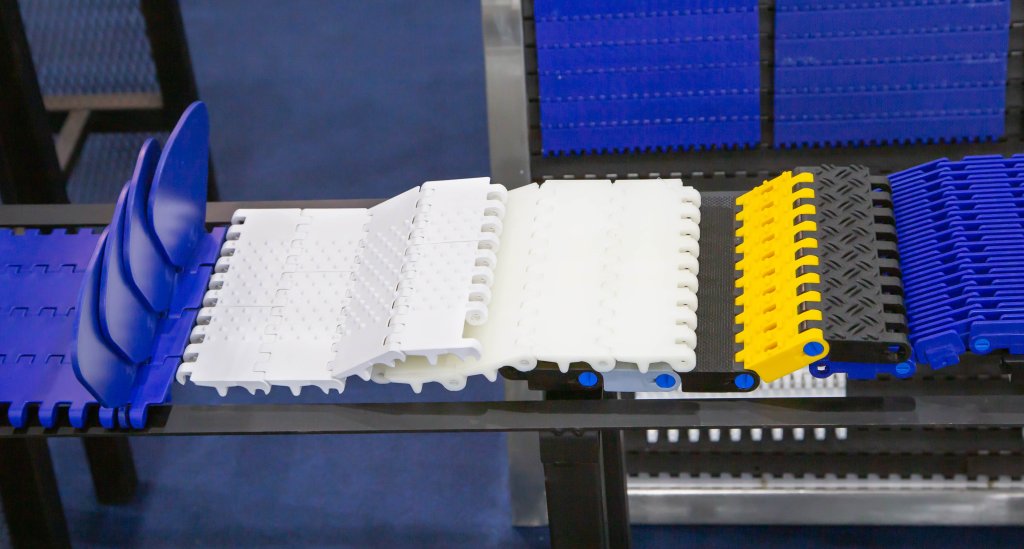

Conveyor Systems: UHMW and HDPE are ideal for conveyor systems used in food processing, packaging, and materials handling industries.

Outdoor Playground Equipment: UHMW and HDPE are commonly used to construct outdoor playground equipment due to their durability and resistance to harsh weather conditions.

Pile Wraps: In marine and coastal environments, UHMW is often used as pile guards to protect dock pilings, piers, and other marine structures from abrasion caused by boat impacts and tidal movements.

Pipe Fittings: UHMW is frequently used to manufacture pipe fittings such as flanges, valves, and connectors.

Polyethylene Liners: UHMW and HDPE liners are commonly used in industries that require chemical resistance, low friction, and abrasion resistance.

Medical Devices: UHMW and HDPE are widely used in the medical industry to produce orthotics, prosthetics, and other medical devices.

In addition to these practical applications, UHMW and HDPE are utilized in numerous other industries, such as automotive, agriculture, construction, and mining.

Safety and Environmental Concerns

Regarding sustainability and recycling potential, UHMW and HDPE have positive attributes that make them attractive options in various industries.

Polyethylene, the base polyethylene product from which UHMW and HDPE are derived, is known for its recyclability. This means that UHMW and HDPE can be recycled and transformed into new products, reducing the demand for virgin plastic materials and minimizing waste.

Check out our Reprocessed UHMW page for more details.

Making the Right Choice

UHMW and HDPE are highly versatile thermoplastic polymers with many benefits and applications. When choosing between the two, it is essential to evaluate the specific requirements of your project, such as impact resistance, coefficient of friction, chemical resistance, abrasion resistance, UV resistance, and tensile strength.

Additionally, considering the recyclability potential and availability of suitable recycling facilities in your area is important for sustainable decision-making. By weighing these factors, you can make an informed choice and select the material best suited for your needs and project requirements.

Receive Further Insights

To find out what plastic best meets your needs, contact our product experts at Piedmont Plastics today!

Get In Touch