Scratch-Resistant Surfaces

In engineering and product design, scratches are more than just a cosmetic issue. They can obscure visibility, erode perceived quality, and even impair function, especially in optical and electronic applications. That’s why scratch-resistant plastics have become essential in everything from car dashboards to medical equipment to smartphone screens.

This article explores the science, types, benefits, and real-world uses of these plastics. If you're a product designer or engineer looking to build durable, high-touch surfaces that stay looking new, this deep dive is for you.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Makes a Plastic Scratch-Resistant?

Not all plastics are inherently immune to scratches. Surface hardness, coatings, and self-healing capabilities set scratch-resistant materials apart.

Some plastics, like acrylic (PMMA), offer high surface hardness but can crack under impact. Others, like polycarbonate (PC), are incredibly strong and flexible but softer and more susceptible to scratching unless treated. Additionally, new additives, coatings, and hybrid blends have emerged in recent years to give standard plastics exceptional surface durability without sacrificing impact resistance or transparency.

Acrylic

Known for excellent clarity and decent scratch resistance, acrylic is one of the hardest common plastics. It offers optical quality that rivals glass while keeping a surface hardness of 4H to 5H on the pencil scale, strong enough to resist damage from fingernails, dust, and common abrasives.

This makes PMMA ideal for applications where visibility and surface finish are priorities, such as display cases, retail fixtures, and protective windows. While this material resists impacts, bumps, and drops better than glass, it doesn’t handle impact as well as polycarbonate, so it's better suited to lower-stress environments or paired with reinforcements.

Polycarbonate

Polycarbonate is famous for being virtually unbreakable; it’s 250 times more impact-resistant than glass. The trade-off is that it scratches easily in its raw form. To fix this issue, manufacturers apply ultra-thin, abrasion-resistant hard coats that improve polycarbonate’s scratch performance dramatically.

Hard-coated polycarbonate is commonly used in car headlights, machine guards, eyeglass lenses, and protective screens. These coatings give the material a glass-like surface without compromising its toughness, making it perfect for high-impact and high-clarity applications.

Advanced Formulations and Hybrid Systems

When basic plastics don’t cut it, advanced formulations step in. Engineers today turn to high-performance blends, additives, and layered systems that push the limits of scratch-resistant plastics. These innovations combine strength, clarity, and durability in ways standard polymers can't match.

Here are some of the most effective approaches:

-

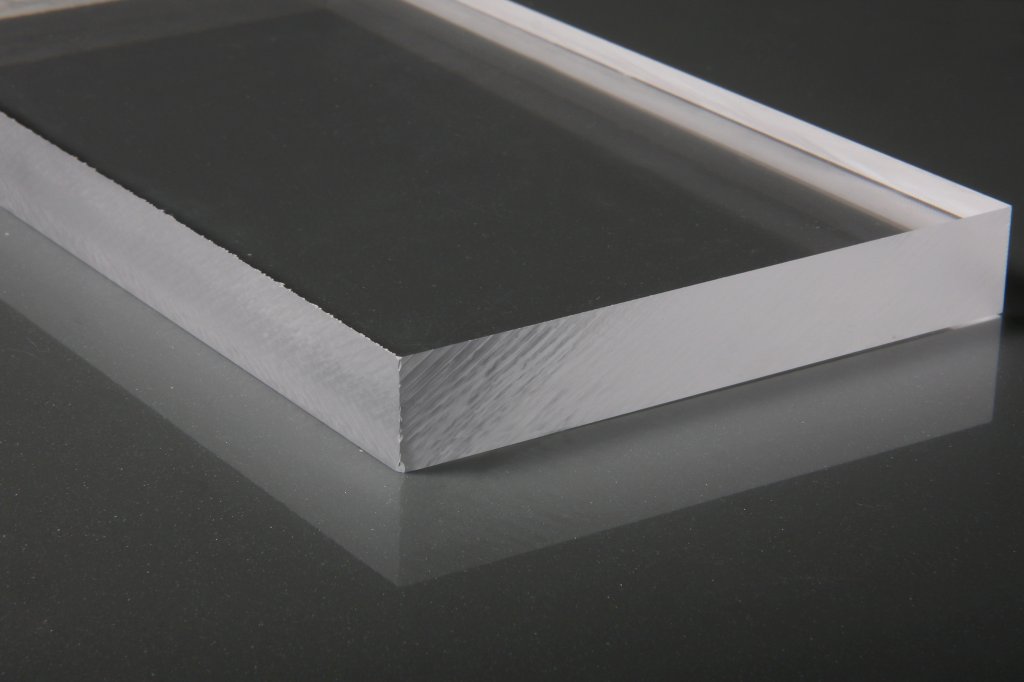

Co-Extruded Laminates

Co-extruded laminates such as PMMA over a PC core marry the hardness of acrylic with the impact resistance of polycarbonate.

-

Siloxane-Based Additive Packages

Siloxane-based additive packages are used in polypropylene and ABS to reduce surface marring and improve long-term wear performance.

-

Nano-Filler Reinforcements

Nano-filler reinforcements are microscopic particles added to the polymer matrix to increase surface hardness without sacrificing transparency.

-

Self-Healing Polymer Systems

Self-healing polymer systems incorporate microcapsules that release repair agents when scratched, enabling the material to restore itself over time.

Real-World Benefits of Scratch-Resistant Plastics

The advantages of using scratch-resistant plastics extend well beyond appearance. In high-traffic or high-touch environments, they deliver long-term performance and reliability.

First, they maintain clarity and surface smoothness over time, which is important for screens, lenses, and display panels. Second, they minimize maintenance, eliminating the need to polish out scuffs or replace panels prematurely. Third, they improve the user experience by keeping products looking newer longer.

In regulated industries like healthcare and transportation, these materials contribute to hygiene and safety by withstanding repeated cleaning without degrading. This durability helps support performance standards and extends the lifespan of critical equipment.

Where Are Scratch-Resistant Plastics Used?

Scratch-resistant plastics are everywhere once you know what to look for. They’re found in infotainment screens, instrument panels, and headlamp lenses in automotive design. Either hard-coated PC or PMMA helps these components resist wear from cleaning, sun exposure, and constant handling.

In electronics, scratch-resistant materials protect smartphones, tablets, and wearables from daily abuse. Some flexible screen protectors even use TPU to self-heal scratches, while others use multi-layer films to balance protection with clarity.

The medical industry also depends on plastics that can withstand sterilization and chemical cleaning. Clear, coated polycarbonate is used in incubators, diagnostic equipment, and face shields. These surfaces must remain clear and unscratched despite constant sanitization and use.

Plastics vs. Glass vs. Ceramics

Compared to standard plastics, scratch-resistant plastics last longer and look better. But how do they stack up against other materials?

Glass, especially tempered or Gorilla Glass, offers superior scratch resistance but is prone to shattering. It’s also heavier and harder to form into complex shapes.

Ceramics, like sapphire crystal, bring exceptional scratch resistance but are also extremely brittle and expensive. That’s why they’re often reserved for luxury watches and camera lenses.

Scratch-resistant plastics strike a balance between lightweight, moldable, and tough, with improved surface durability thanks to coatings or chemistry. In many applications, they’re the practical and cost-effective choice.

How Piedmont Plastics Adds Value

Choosing the right scratch-resistant plastic goes far beyond reading datasheets. Material properties, coatings, and blends vary widely by manufacturer, and real-world performance depends heavily on how a product is fabricated, finished, and used. That’s why working with a knowledgeable distributor like Piedmont Plastics makes all the difference.

As one of North America's leading suppliers of performance plastics, Piedmont offers:

Access to a broad range of scratch-resistant materials, including hard-coated polycarbonate (e.g. Tuffak® AR), premium acrylics (like ACRYLITE® or PLEXIGLAS® HC), and protective TPU films.

Expert guidance on matching materials to application needs, whether you’re designing a clear machine guard, a retail display, or a touch panel that needs long-term durability.

Custom fabrication services, such as CNC cutting, forming, and film lamination, to help bring scratch-resistant designs to life while ensuring optimal performance.

In-stock inventory and local availability, reducing lead times and making it easier to prototype or scale production quickly.

Whether you're developing a car dashboard, a medical monitor, or the next generation of wearable tech, choosing the right plastic isn’t just about meeting specs. It’s about exceeding user expectations.

Access More Information

Looking for further details on how Piedmont Plastics can help with your application? Contact our experienced sales team today!

Get In Touch