What Are Duct Bank Spacers?

Duct bank spacers are essential components in underground conduit systems, providing structure and precision for organizing multiple electrical or communication lines in a secure configuration. By maintaining consistent spacing between conduits, these spacers prevent damage, interference, and misalignment during installation and concrete encasement.

Engineered for strength, accuracy, and ease of installation, plastic duct bank spacers simplify the layout process and ensure conduits remain properly aligned under load or environmental stress. Their non-conductive, corrosion-resistant construction makes them ideal for use across commercial, industrial, and utility infrastructure projects.

At Piedmont Plastics, we supply high-quality HDPE duct bank spacers and other performance plastic materials designed for long-term reliability in demanding underground environments. Learn more about the plastic products used in duct bank spacers and the benefits of these materials in the article below!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Why Duct Bank Spacers Matter

Electrical and telecommunication conduits must remain perfectly spaced and supported to ensure consistent performance once encased in concrete. Duct bank spacers act as the foundation of this system, locking conduits in place and ensuring uniform separation. Without proper spacing, conduits may warp, bend, or shift, which can lead to cable damage, misalignment, or difficulty during wire pulling and maintenance.

Spacers are particularly important in applications where large volumes of cable are routed underground, such as:

Data centers and hospitals where reliable power and communication are critical

Airports, rail systems, and utilities requiring long conduit runs and vibration resistance

Commercial buildings and industrial sites where multiple electrical feeds must be isolated and protected

Common Plastic Materials for Duct Bank Spacers

HDPE (High-Density Polyethylene)

HDPE is the most widely used material for duct bank spacers, and for good reason. It offers exceptional impact strength, moisture resistance, and flexibility, all while remaining lightweight and easy to fabricate.

Advantages of HDPE Spacers:

-

Non-conductive for enhanced electrical safety

-

Corrosion- and chemical-resistant for underground environments

-

High strength-to-weight ratio for easy handling

-

Excellent dimensional stability and load resistance

HDPE spacers also perform exceptionally well in both wet and dry conditions, maintaining their mechanical integrity even when exposed to temperature variations or soil pressure over time.

PVC (Polyvinyl Chloride)

PVC is another thermoplastic material sometimes used for duct bank spacers. It offers rigidity, ease of fabrication, and resistance to many environmental factors. However, PVC spacers can be more brittle at lower temperatures and may not offer the same long-term flexibility as HDPE.

When to choose PVC over HDPE:

In applications requiring very rigid conduit alignment

For projects with lower load requirements or shorter conduit runs

When compatibility with existing PVC conduit systems is important

HDPE vs. PVC: A Comparison

| Property | HDPE | PVC |

|---|---|---|

| Flexibility | High: resists cracking under stress | Moderate: more rigid, may become brittle in cold |

| Impact Strength | Excellent | Good |

| Temperature Resistance | Broad range (-40°F to 180°F) | Moderate (32°F to 140°F) |

| Chemical Resistance | Outstanding | Very good |

| Weight | Lightweight | Slightly heavier |

| Long-Term Durability | Excellent for decades-long performance | Good, but less flexible under load |

* Data is approximate and may be based on averages. Contact your local Piedmont Plastics sales representative for specific product specifications.

For most underground and concrete-encased conduit systems, HDPE spacers are the preferred choice due to their combination of toughness, flexibility, and corrosion resistance.

How Duct Bank Spacers Work

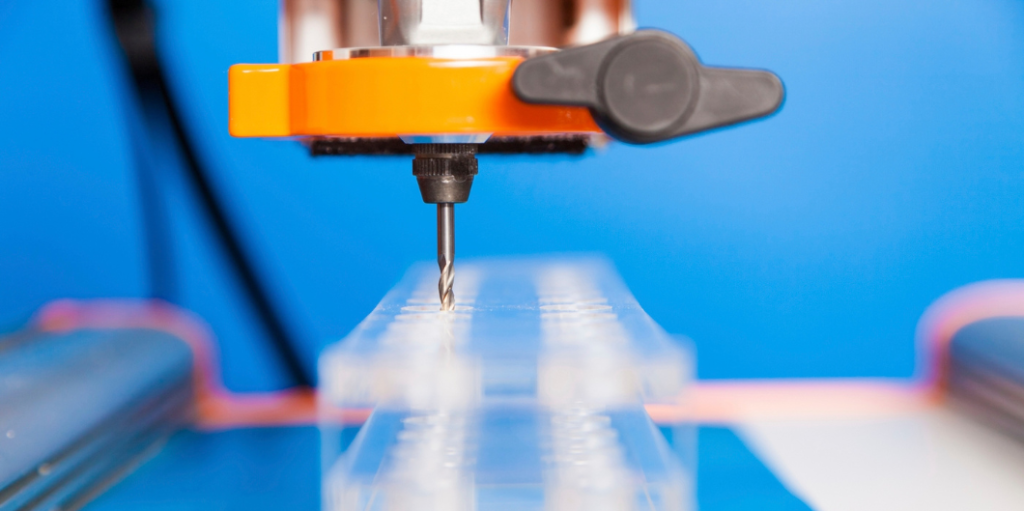

Most HDPE duct bank spacers are fabricated from solid plastic sheets, precisely routed with circular holes to hold conduits in fixed alignment. These holes are machined to match the conduit’s outer diameter, ensuring consistent spacing both vertically and horizontally throughout the duct bank. This one-piece, routed design provides a rigid and stable structure that maintains exact conduit positioning during installation and concrete encasement. Plus, it eliminates the need for interlocking or snap-together components.

This sheet-style design allows installers to:

Lay out conduit banks quickly and accurately

Maintain consistent spacing across all rows and columns

Secure conduits in place during the concrete pour without additional fasteners

Because HDPE and other plastics like PVC spacer sheets are non-conductive and moisture-resistant, they eliminate the need for grounding and minimize corrosion concerns common with metal alternatives.

Custom Fabrication and Routing Services

Our fabrication capabilities include:

By partnering with Piedmont Plastics, engineers and contractors can ensure their duct bank spacer solutions meet project specifications while saving time during on-site installation.

Long-Term Underground Performance

Underground electrical and communication systems operate in harsh environments exposed to moisture, soil pressure, chemical exposure, and temperature changes. HDPE and other performance plastics provide long-lasting stability and protection under these conditions.

Performance benefits include:

Resistance to corrosion, rust, and rot

High compressive strength for stable load support

Compatibility with standard PVC conduit systems

Low moisture absorption and dimensional stability

Reduced installation time and maintenance costs

These properties translate to decades of reliable performance, minimizing the need for costly replacements or repairs over the life of the installation.

Uses for Plastic Duct Bank Spacers

Plastic duct bank spacers are widely utilized in industries and facilities requiring secure underground power or data transmission, including:

- Utilities and power distribution networks

- Transportation infrastructure (highways, airports, and rail systems)

- Commercial and institutional facilities

- Data centers and telecommunications hubs

- Renewable energy installations

By providing consistent alignment, electrical insulation, and durability, plastic spacers help safeguard critical cabling systems across a broad range of environments.

Frequently Asked Questions About Duct Spacers

Below are a few FAQs about duct bank spacers!

Most duct bank spacers are made from HDPE, a non-conductive, corrosion-resistant plastic ideal for underground use. Other performance plastics such as PVC or ABS (Acrylonitrile Butadiene Styrene) may also be used, depending on project requirements. These materials provide excellent strength, durability, and electrical insulation for long-term performance in buried conduit systems.

Plastic duct bank spacers are lightweight, corrosion-resistant, and non-conductive, making them safer and easier to handle than metal alternatives. They won’t rust or deteriorate when exposed to soil, moisture, or chemicals, and they eliminate grounding concerns common with metallic components.

HDPE spacers offer greater flexibility, impact strength, and resistance to temperature variation, making them ideal for demanding or large-scale underground installations.

While more rigid, PVC spacers are suitable for shorter conduit runs or environments requiring tight, fixed alignment. HDPE generally provides superior long-term performance and durability for most underground applications.

Yes. Piedmont Plastics offers custom fabrication and routing services to create duct bank spacers in specific sizes and configurations. Our team can cut, route, and machine HDPE or PVC to match the exact conduit spacing and layout your project requires.

Duct bank spacers are commonly used in underground electrical and communication conduit systems found in utility and power distribution networks, transportation and infrastructure projects, data centers, hospitals, and manufacturing facilities, and commercial and industrial developments. They ensure conduits stay aligned and protected, even under soil pressure and concrete encasement.

When made from HDPE or PVC, duct bank spacers can last for decades without degradation. Their chemical resistance, low moisture absorption, and ability to withstand soil pressure make them a long-term, maintenance-free solution for underground electrical systems.

Partner with Piedmont Plastics

Piedmont Plastics supplies durable HDPE duct bank spacers and other plastic materials designed for precision, safety, and long-term performance in underground conduit systems. Our team works closely with engineers and contractors to develop solutions that meet exact project requirements, from prototype to full production.

Turn To The Experts

Contact your local Piedmont Plastics branch today to request a quote or learn more about our duct bank spacer materials and fabrication services!

Find Out More