High-performance engineered plastics are essential components of power generation facilities. As the demand for clean and reliable sources of energy continues to grow, the use of plastic materials is likely to become even more widespread.

Performance plastics are increasingly being used in applications to help harness and transmit electricity from hydroelectric, nuclear, solar, thermoelectric, and wind facilities. Furthermore, the use of these engineered plastics continues to help support the development of the power generation industry.

Common Plastics for Power Generation Facilities

There are many different types of general engineered plastics that are used in power generation facilities, depending on the application. The specific type of plastic used in a particular application will depend on the requirements and conditions of the facility. Each material is unique and provides its own distinctive properties and characteristics.

Some of the most common engineered plastics used in power generation facilities include:

- High Density Polyethylene (HDPE)

- Polyvinyl chloride (PVC)

- PEEK (polyetheretherketon)

- Polypropylene

- Polycarbonate

- Nylon

- ULTEM

- TORLON

Benefits of Engineered Plastics In Power Generation Plants

High-performance engineered plastics are increasingly being used to replace traditional metal parts, offering a range of advantages over their metallic counterparts.

Overall, the use of plastic parts in power generation facilities offers a variety of benefits, including enhanced durability, resistance to corrosion, and cost-effectiveness.

One of the key advantages of using plastic parts in power generation facilities is their inherent strength, durability, and light weight. The combination of these benefits helps reduce the overall weight of equipment while also allowing applications to retain their structural integrity and performance characteristics when exposed to harsh conditions, thus reducing the need for costly repairs and maintenance.

Mechanical plastics are also highly resistant to corrosion and other forms of damage, which is a major benefit in power generation facilities. Because of this, plastics are able to withstand extreme temperatures, harsh chemical environments, and mechanical stresses, making them ideal for use in these demanding environments.

In addition to their durability and resistance to corrosion, plastic parts are also more cost-effective than metal parts. These materials are typically less expensive to produce, and extend the lifespan of equipment, which can help to reduce the overall cost of manufacturing and maintaining power generation equipment.

Plastic Applications for Power Generation

In power generation facilities, engineered plastics are used for a range of applications, including insulation, sealing, and protective coatings. These materials can withstand extreme temperatures, harsh chemical environments, and mechanical stresses, making them ideal for use in the demanding conditions found in power generation facilities.

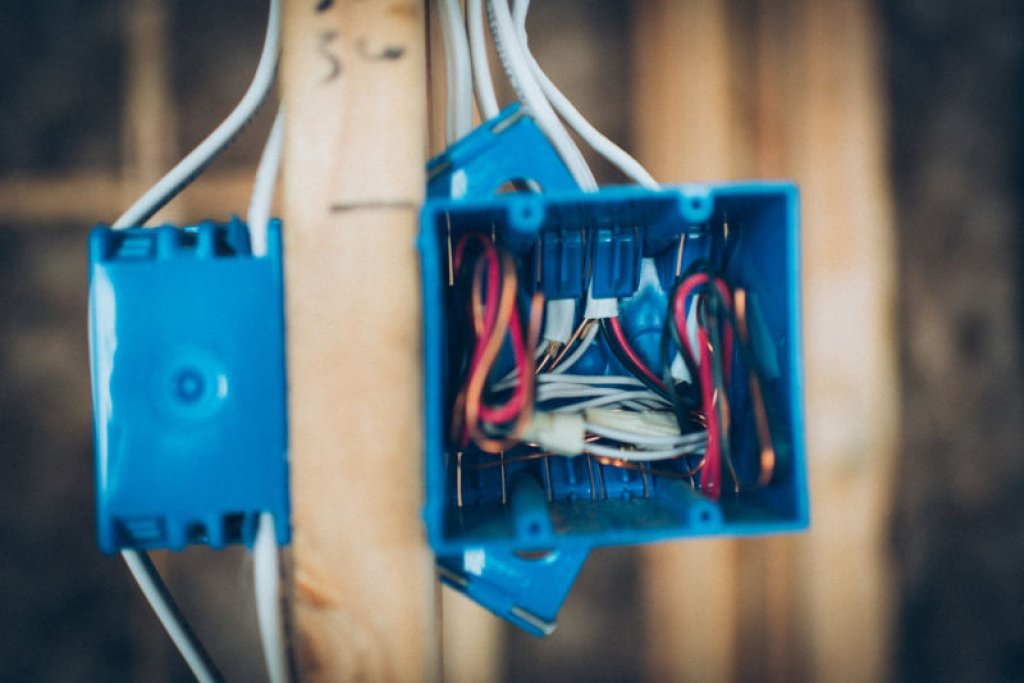

One of the most common uses for plastics in power generation plants is as insulation for electrical wiring and equipment. Engineered plastic parts provide an effective barrier against the transmission of heat and electricity, helping to improve efficiency and prevent electrical fires and other hazards.

Another important use for plastics in power generation is as a sealing material. These materials provide reliable, long-lasting seals that can prevent the escape of hazardous gases and liquids such as fossil fuels and natural gas.

In addition, clear protective barriers, machine guards, and face shields are installed using material like polycarbonate to improve safety for maintenance staff and workers.

Contact Piedmont Plastics

At Piedmont Plastics, we are dedicated to providing solutions for our industrial customers. Our team of dedicated industrial market experts are trained to aid you with the material selection process and provide fabrication assistance. Contact us today to get started!