Modern and Reliable Solutions

Plastic is quickly becoming the more viable solution in modern plumbing systems compared to traditional metal piping. As plastic technology has improved and made polymers and thermoplastics more resistant to heat damage and easier to manipulate to fit a home, the need for costly materials like copper piping has diminished. Here's a closer look at some of the top plastic pipes for today's homes, their benefits and drawbacks, and the common uses for these various pipe materials.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Understanding ABS Pipes

ABS is a popular choice for plumbing. These pipes are black in color and slightly softer than PVC. This material is a traditional type of plastic, as it was one of the first styles used for plumbing in residential applications. Today, this plastic is primarily seen in vent and drain lines as well as outdoor applications.

ABS pipes are better at withstanding extreme temperatures, which is why ABS is the choice for outdoor applications when freezing temperatures are possible. It has high ductility, so it can sustain significant pressure before deforming. However, it’s usually not used to transport drinking water, it makes more noise when water flows through it, and it costs more than PVC.

Exploring CPVC Pipes

CPVC is a PVC pipe that has been treated with chlorine. The treatment makes the plastic more resistant to high water temperatures and pressures, so it can be used in residential hot water lines and industrial plumbing applications. CPVC does not corrode easily and takes less time to install than copper pipes, but it can be brittle. It also has a high thermal expansion coefficient, so it is often not ideal for outdoor uses where temperature variations are common.

Compared to the weaker PVC, one of the primary drawbacks of CPVC is the cost. It can be about double the cost compared to PVC. Thus, many plumbing jobs will turn to CPVC only when necessary and opt for PVC when it is strong enough for the application.

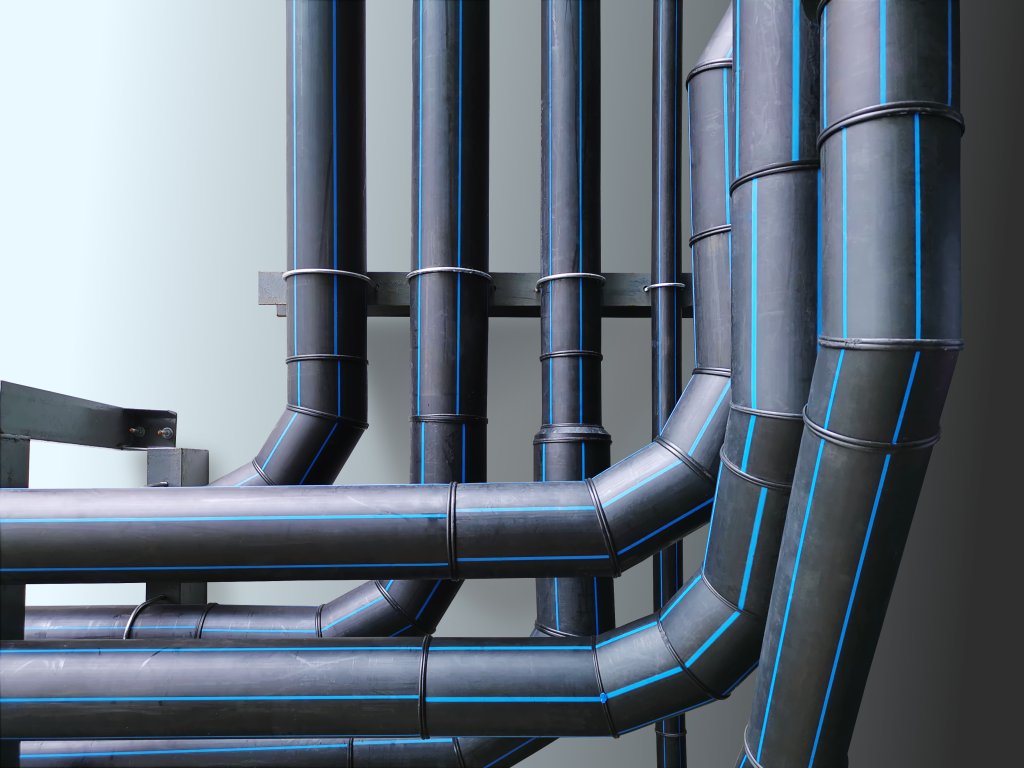

The Versatility of HDPE Pipes

High-density polyethylene, or HDPE, is a tough, durable plastic that works for almost every plumbing application. Its low coefficient of friction allows water to flow easily, which can reduce water pressure. HDPE is also particularly popular in agriculture and aquaculture. The pens on fish farms, for example, are often made from HDPE. This versatile material stands up under harsh environmental conditions, including extreme temperatures. The strong molecular bond of this polymer makes it impermeable when exposed to a wide range of chemical compounds.

HDPE is known for its tight bending radius and flexibility. It's also highly chemically stable and uses heat fusion joints to create a leak-free seal, an advantage over mechanically joined PVC and CPVC pipes. However, it's not ideal for direct burial and trenchless installation methods because of how soft it is.

Benefits of PEX Pipes

PEX is cross-linked polyethylene, a flexible plastic option for hot and cold water residential pipes. This lightweight material makes a flexible pipe that can easily run through the twists and turns of a residential plumbing system. It's suitable for cold and hot water and has few connections between the pipes. This design reduces the risk of leaks.

The main drawback of PEX is that it is not very UV resistant, so it doesn’t work well for outdoor applications. However, for indoor applications, it's an affordable option compared to copper, works well with hot water, and can easily be woven around the layout of your home's plumbing. These pipes also last around 40 years.

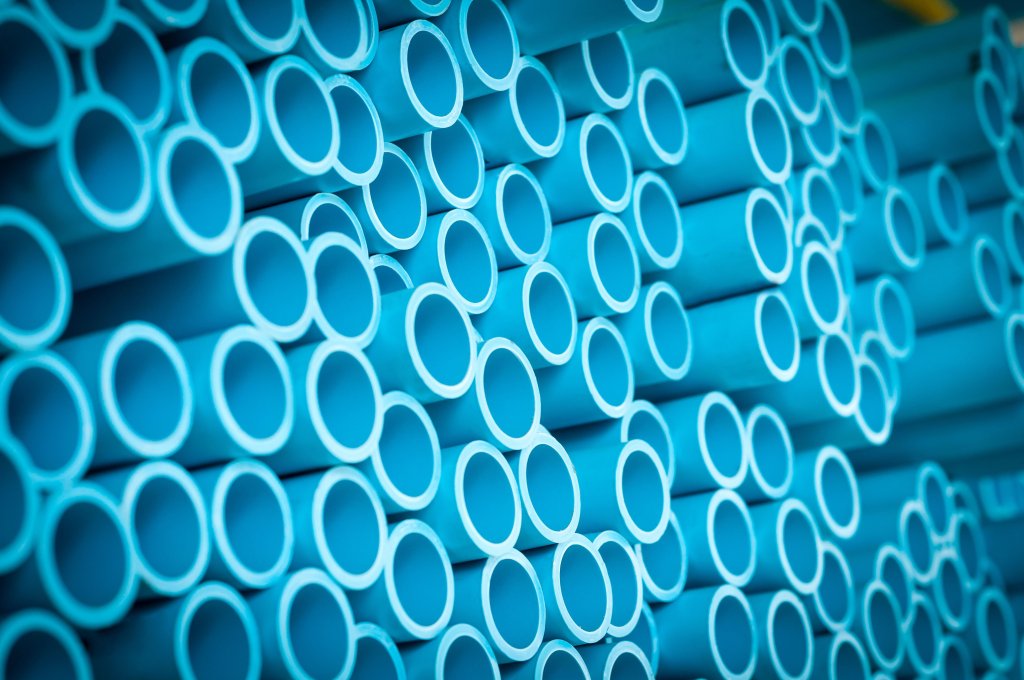

Polyvinyl Chloride (PVC) in Plumbing

PVC, the standard white piping most people think of when they think of plumbing, is still a common plumbing material. It's affordable, lightweight, and has a low coefficient of friction, so water flows freely. This plastic is the most common for main water lines but warps at high temperatures. Thus, alternative pipe material is necessary for hot water lines.

PVC isn't limited to the white plastic pipes most people think of for residential plumbing. Clear PVC hoses are another option for certain applications. It carries no taste or odor and can safely transport drinking water through a home. Again, the primary drawback to PVC is its tendency to warp at high temperatures. Also, it can leak at joints if not sealed correctly.

Comparing Plastic Pipes: Pros and Cons

As you consider the different plastic pipes available for your project, consider the pros and cons:

Heat Resistance

For hot water lines, you will need a material that resists damage at high temperatures. CPVC, PEX, and HDPE are all possible options here.

Ease of Installation

Some materials are easier to install than others. Of the different types of pipes mentioned here, PEX is the easiest to install due to its flexibility. HDPE is also easily shaped into the desired fit.

Corrosion Resistance

Corrosion resistance is a pro for almost all plastic pipes. They will not rust or corrode, even with extensive exposure to water. However, not all materials resist damage from outdoor elements, so that is a factor worth considering.

Non-reactive

All plastic pipes are non-reactive, which is not the case with metal piping. This is a benefit of using plastic, no matter the plastic you choose.

Low Heat Conductivity

Many types of plastic used for plumbing applications will not conduct heat, and thus the water inside the pipes maintains its temperature as it flows through your home, even without the need to insulate the pipe extensively.

For most situations, plastic is the go-to option for plumbing due to its affordability, corrosion resistance, and durability. Piedmont Plastics stocks a wide range of performance plastics, including PVC, CPVC, HDPE, and ABS, to meet the diverse needs of the plumbing industry. Our team is ready to offer tailored solutions to ensure your projects are completed efficiently and with the right materials for long-lasting performance.

Get In Touch

For more information about plastics for plastic plumbing, contact our knowledgeable sales team. We’d be happy to offer our expertise for your next project!

Contact Us