Mastering Plastic Machining

Plastic machining is a multifaceted process that involves cutting, shaping, and finishing plastic materials to create various products. The type of plastic being machined, the tools used, temperature management, and surface finishing techniques all play a vital role in the outcome.

In this article, we'll explore advanced precision techniques for complex shapes, delve into the intricacies of tool selection, address temperature management during machining, discuss surface finishing methods, and identify common machining problems with popular plastics. So, let's dive into plastic machining and uncover the secrets to achieving superior results.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Precision Techniques for Complex Shapes

Precision machining techniques have evolved to meet the demands for complex shapes in plastic machining. These advanced methods ensure high accuracy and intricate designs. This accuracy comes from precision machines, which can create incredibly accurate molds supporting the shaping techniques below.

-

Blow molding is when the plastic is injected into the mold and expanded into the mold through blowing.

-

Compression molding is when plastic is heated and pressed down to fit the mold.

-

Extrusion molding is when the moldable plastic is pushed into a die (like a tube) to form a shape.

-

Injection molding is when melted plastics fit into a double-sided mold and are injected into a pressurized chamber.

-

Rotational molding is when melted plastic is put into a rotating chamber.

-

Thermoforming is when special thermoplastic sheets are heated to fit into a desired mold.

With thermoforming, thermoplastic sheets are pushed into a desired mold. The mold is made using precision machining techniques, allowing it to meet specific dimensional requirements.

Check out this link for more plastic fabrication processes.

Tool Selection for Ideal Machining

Selecting the appropriate tools for machining plastics is crucial to achieving precise and reliable results in various applications. Different plastic materials possess unique characteristics that require specific tooling considerations.

The mechanical properties and temperature resistance necessitate using specialized high-strength tools for high-strength plastics like acetal. Tool selection plays a vital role in achieving precision in complex applications.

Acrylic, a lightweight thermoplastic, requires tools that maintain superior optical quality and withstand extended UV exposure without discoloration. Optimal tool selection is essential to achieving the desired outcomes.

Acrylonitrile Butadiene Styrene (ABS), a popular plastic for machined components, benefits from carefully chosen tools that harness its good machinability and superior mechanical properties. This versatility opens up diverse applications across industries.

Tool selection considerations encompass material properties such as thermal resistance, formability, tensile strength, and chemical resistance. Manufacturers can streamline processes and produce high-quality end products by selecting tools that address these specific characteristics.

Factors like abrasion resistance, heat dissipation capabilities, and compatibility with specific plastic materials must be considered when selecting tools. Adhering to optimal tool selection principles ensures precise and reliable machining results for various plastic types.

Temperature Management

Temperature management is a crucial consideration when machining plastics. Plastic materials have a lower melting point than metals, requiring effective thermal regulation techniques during machining.

One common approach is using coolants to manage heat generation. Cooling directly at the cutting tool with plain water is a widely adopted practice. This helps lower the material's melting point, prevent clogging on the cutter, and reduce the risk of final rupture during milling.

Temperature control becomes even more critical when working with specific plastic materials like ABS, polycarbonate, and PTFE. These materials require careful heat generation and dissipation control to ensure dimensional stability and prevent material degradation.

Proper temperature management is essential for achieving tight tolerances, minimizing the risk of moisture absorption, and maintaining the machined plastic components' desired mechanical and chemical properties.

By addressing heat generation and control by selecting appropriate cooling techniques and temperature control measures, manufacturers can achieve precise and reliable results while maintaining the integrity of the plastic materials.

Learn More About These Materials

-

ABS

Acrylonitrile butadiene styrene is a durable, impact-resistant material commonly used in automotive components, consumer goods, and protective housings.

-

Cast Acrylic

Cast acrylic from Piedmont Plastics offers exceptional strength, optical clarity, and weather resistance, making it ideal for applications such as signage, retail displays, protective barriers, and architectural glazing.

-

Polycarbonate

Polycarbonate is a high-performance, impact-resistant thermoplastic known for its clarity, strength, and weatherability, making it suitable for applications such as eyewear lenses, bullet-resistant glass, construction materials, and automotive parts.

-

PTFE (Polytetrafluoroethylene)

PTFE plastic sheet and rod offer unmatched chemical resistance, high temperature performance, and low friction properties for industrial, electrical, and mechanical applications.

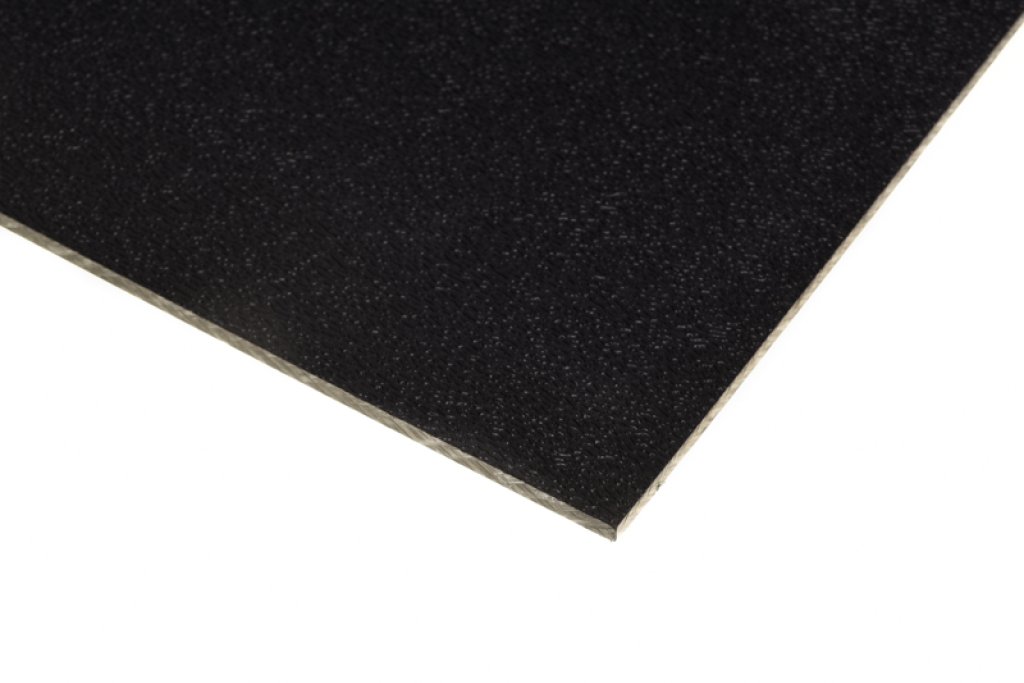

Surface Finishing of Machined Plastics

Surface finishing techniques, such as blasting, grinding, smoothing, and polishing, are vital in enhancing functionality and appearance. These techniques are necessary for achieving intricate shapes, holes, and undercut features that may be required when the number of components needed is not large enough to justify molding.

CNC machining processes, including CNC mills, lathes, drills, and waterjet cutters, are suitable for achieving the desired surface finishes on plastic components. These processes allow for precise control and accuracy, ensuring consistent results.

Designers and engineers must carefully consider material selection to achieve the desired surface finish. Different materials may require different surface finishing techniques and tools. Material properties such as thermal expansion, tensile strength, chemical resistance, and moisture absorption can impact the choice of surface finishing method.

Precision plastics machining and manufacturing services offer a wide range of capabilities to achieve the desired surface finishes for various applications. Some services include plastic CNC turning, 3D plastic machining, industrial laser engraving, drilling, and milling. These services and the appropriate surface finishing techniques enable manufacturers to meet their intended applications' dimensional tolerances, moisture resistance, and aesthetic requirements.

In conclusion, surface finishing is a critical aspect of machining plastics. Manufacturers can achieve the desired surface finishes by employing the right techniques and tools, ensuring functionality, longevity, and visual appeal.

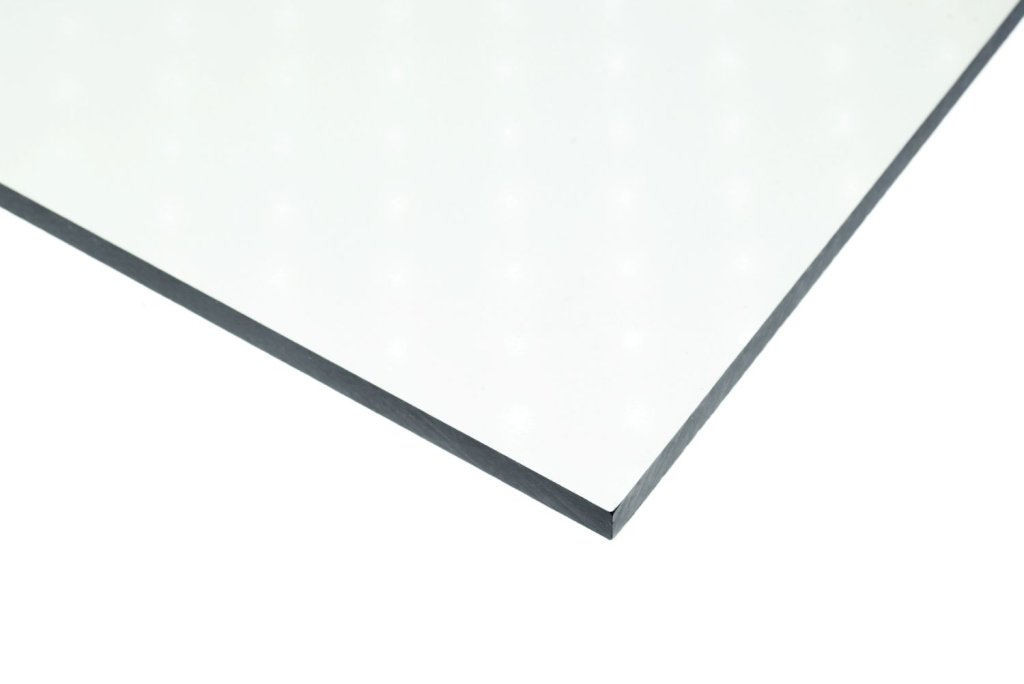

The Importance of Choosing The Right Material

When machining plastics such as ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, some difficulties can arise. One issue with ABS is its tendency to warp and shrink, which can lead to dimensional accuracy issues, especially during milling. This is due to its high thermal expansion and relatively low softening temperature.

Polycarbonate, on the other hand, is prone to melting and burning during machining processes. Its low softening temperature and poor heat dissipation require careful temperature control to prevent deformation and surface imperfections.

Both ABS and polycarbonate have a high moisture absorption rate, so controlling humidity conditions during machining is crucial to avoid changes in dimensions and mechanical properties.

Chatter marks are also a common issue when machining ABS and polycarbonate. Proper tool selection, feed rates, and cutting parameters are necessary to minimize vibration and achieve smooth surface finishes.

Additionally, achieving tight tolerances with these materials can be challenging due to their elastic nature. Careful consideration of cutting forces and appropriate machining strategies is needed to minimize part distortion and ensure dimensional stability.

Need Help?

If you have any questions, need further assistance, or would like to explore plastic machining solutions tailored to your needs, don’t hesitate to reach out to our expert team. Your success in plastic manufacturing is our priority, and we’re here to help. Contact us today for personalized guidance and support!

Contact Us Today