Floating platforms face the ultimate test of endurance. Exposed to constant UV radiation, salt spray, wave impact, and structural stress, they demand materials that not only float but also survive.

Traditional materials, such as wood, steel, or untreated composites, fall short. Enter performance plastics: lightweight, corrosion-proof, and practically maintenance-free.

The Trouble with the Tide

Every floating system battles environmental forces. Saltwater corrodes steel, wood rots, and even treated metals degrade. Add in boat collisions, freezing temperatures, and sun exposure, and most conventional materials wear out too fast.

That’s why plastic, particularly the kind engineered for marine applications, is changing how we build floating structures.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

Top Plastic Products For Floats & Marine Applications

High-Density PE

High-Density Polyethylene (HDPE) continues to be the preferred material for creating durable, reliable floating platforms. It offers more than just buoyancy; it delivers the kind of performance engineers count on in unpredictable marine environments. In addition, its material properties are ideal for harsh, high-moisture conditions where other materials, such as wood, steel, or untreated composites, fail over time.

Here’s why HDPE continues to lead the industry:

Excellent Buoyancy: With a naturally low density (~0.95 g/cm³), HDPE maintains high flotation without absorbing water, making it perfect for sealed or rotationally molded float modules.

Superior UV Resistance: Formulations with stabilizers resist degradation from long-term sun exposure, a must-have for structures that spend decades on open water.

Corrosion and Chemical Resistance: Saltwater, algae, fuel residues, and agricultural runoff have minimal impact on HDPE, allowing it to retain its strength and form over time.

Impact Toughness: HDPE offers high tensile strength and exceptional impact resistance, even in cold temperatures. This makes it ideal for structures that may absorb impacts from boats, equipment, or waves.

Low Surface Friction: Its smooth surface helps prevent marine buildup, such as algae or barnacles, and allows for easy cleaning when needed, cutting down on maintenance labor and downtime.

Long-Term Stability: HDPE float modules can last 20–30 years in service, with minimal structural fatigue or deterioration.

Easy to Fabricate and Repair: HDPE can be welded, machined, or rotomolded into nearly any shape, and damaged components are often repairable in the field.

*Product specifications may not be precise. Please contact your local Piedmont Plastics sales rep for specific technical information.

UHMW-PE

Ultra-High-Molecular-Weight Polyethylene (UHMW-PE) excels where impact, friction, and abrasion are constant. Think of it as HDPE’s tougher cousin. This material is ideal for use in pile guides, rub rails, and wear pads, particularly where docks come into contact with chains, pilings, or boats.

With an ultra-low friction coefficient and self-lubricating properties, UHMW makes contact points last longer and operate more smoothly. Its high impact resistance means even heavy collisions from boats don’t leave a mark. Combined with HDPE, it forms a resilient one-two punch for durable platforms.

Marine-Grade PVC

While not used for flotation, marine-grade PVC excels in protection and performance around the waterline. Its resistance to sun, salt, and temperature swings makes it a smart choice for parts that endure constant abuse but require long-lasting performance.

Here’s where PVC proves its value:

Flexible bumpers and fenders absorb impact and bounce back without cracking.

UV-stable decking offers slip resistance and comfort underfoot in wet conditions.

Foam PVC panels provide a lightweight structure for signage and enclosures.

Low-maintenance durability means no rot, rust, or splintering, just long-term reliability.

Polycarbonate and ABS

Above the waterline, electronics need tough, protective casings. That’s where polycarbonate shines. It’s clear, impact-resistant, and weather-hardened, making it perfect for electrical covers and inspection panels.

ABS adds value in utility boxes and structural housings, providing tough, stable, and flame-resistant properties.

These plastics don’t just protect, they perform. They resist cracking in cold temperatures, softening in heat, and degradation from UV exposure. That’s important for systems like lighting, pumps, and sensors that live outdoors.

Where Floating Platforms Are Making Waves

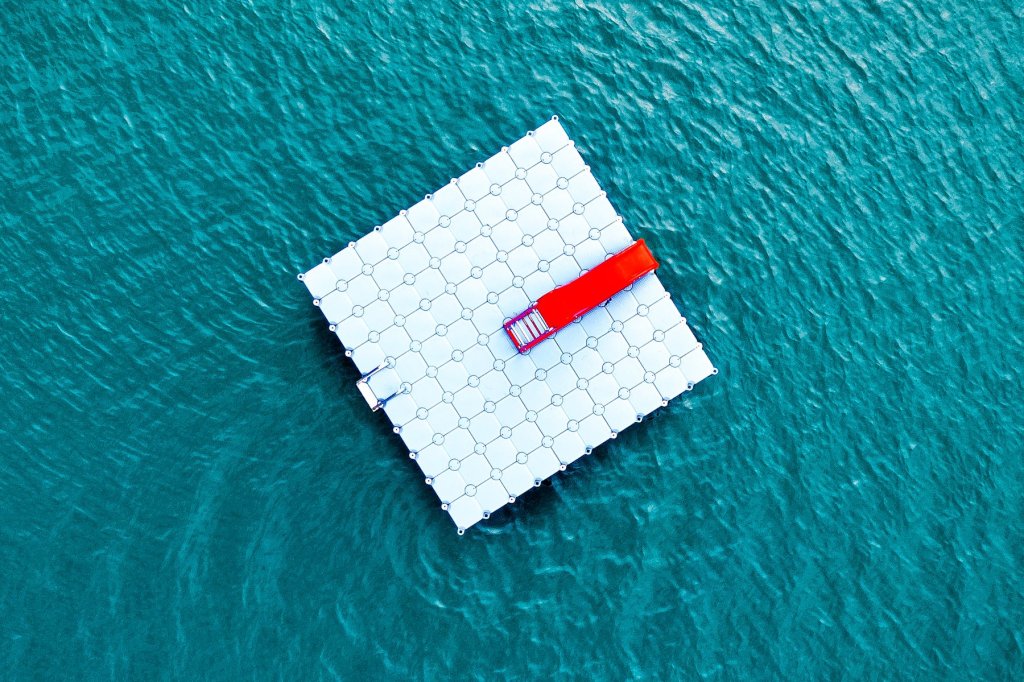

Floating platforms are no longer limited to marinas and docks; they’ve become essential infrastructure across industries that operate on or near water. Their modularity, flexibility, and resistance to environmental degradation make them a practical solution wherever stable, semi-permanent support structures are needed on the water.

Common Applications

- Marinas and Docks: Modular floats provide stable, low-maintenance access for boats and pedestrians.

- Aquaculture: HDPE collars and walkways support fish farming operations in saltwater and freshwater environments.

- Floating Solar Arrays: Buoyant platforms host photovoltaic panels on reservoirs and ponds, boosting energy efficiency.

- Industrial Equipment Access: Platforms support pumps, sensors, and pipelines in various industries, including water treatment, mining, and dredging.

- Walkways and Footbridges: Public parks and waterfronts use floating paths that adjust to changing water levels.

- Environmental Response: Floating booms and skimmer systems deploy quickly for oil spill containment and monitoring.

Reliable Materials for an Unforgiving Environment

Floating platforms aren’t just about buoyancy, they’re about resilience. Piedmont Plastics offers marine-grade HDPE, UHMW, PVC, and polycarbonate materials to meet your environmental and structural requirements. With decades of expertise and national supply reach, we help engineers and contractors choose materials that stand the test of time.

Dive Deeper

Need to keep your platform afloat for years to come? Send us a message to get started!

Get In Touch