Breaking Down Ballistic Plastics

Has safety been on your mind recently? Ballistic-grade plastics offer a compelling solution. These engineered materials are tough enough to resist ballistics yet versatile enough for use in windows, walls, shields, and more. While often associated with military use, these high-performance plastics are necessary in everyday civilian and industrial security applications.

Let’s take a closer look at ballistic-grade plastics, the most common types, and how they’re used to keep people and property safe without the weight, risk, or bulk of traditional materials.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

What Makes a Plastic "Ballistic"?

Ballistic-grade plastics are formulated to resist high-velocity impacts from bullets and other projectiles. Rather than shattering like glass or deforming like metal, these plastics are engineered to absorb and disperse energy on impact. Depending on thickness and composition, they can defend against everything from a 9mm round to high-powered rifle fire.

Unlike bullet-resistant glass or steel panels, ballistic plastics protect with a fraction of the weight and far more design flexibility. They meet performance standards like UL 752 and NIJ 0108.01, which classify levels of protection based on caliber and velocity.

Top Ballistic Plastics

Polycarbonate

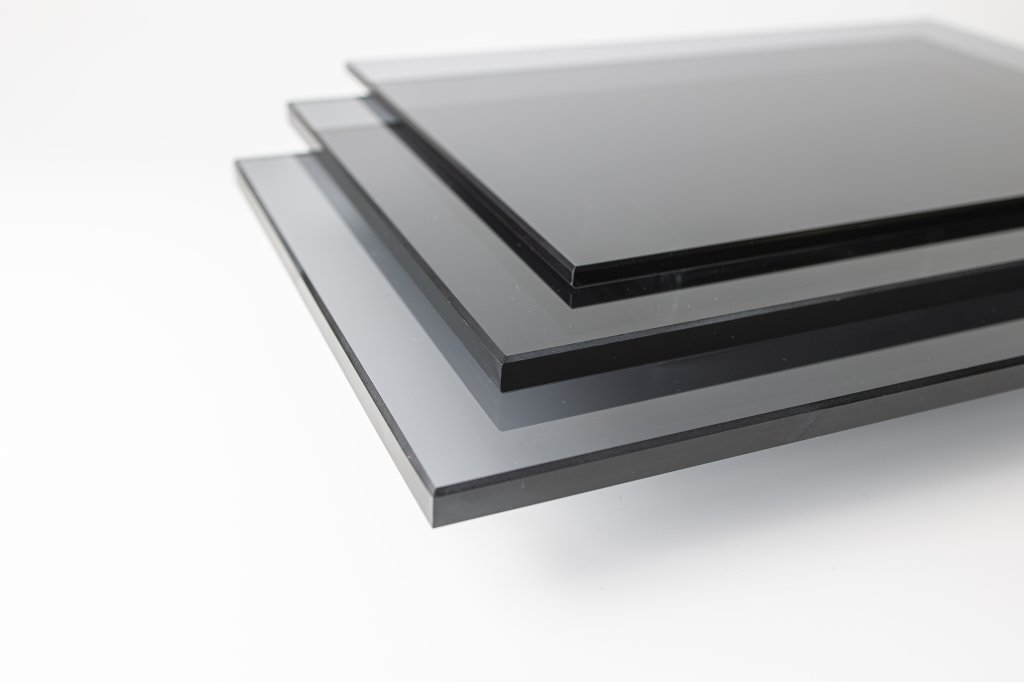

For good reason, polycarbonate is the most widely used transparent ballistic plastic. It’s up to 250 times stronger than glass and can take multiple hits without cracking. When layered or laminated, it bends instead of breaking, absorbing bullet impact without dangerous spall (fragments flying from the back side).

You’ll find ballistic-grade polycarbonate in bank teller windows, police riot shields, and armored vehicle glass. It’s light, incredibly strong, and can be combined with abrasion-resistant coatings to withstand wear and UV exposure. While not the clearest plastic (transparency is typically around 88%), it offers the best durability among transparent options.

Acrylic

If clarity is key, acrylic may be the better choice. It transmits over 90% of light and has a naturally glossy, scratch-resistant surface. On top of that, it doesn’t yellow with UV exposure and is easier to polish than polycarbonate. Special grades of acrylic can counter impacts by cracking in a controlled spiderweb pattern that slows and absorbs the projectile.

Acrylic is generally used in thicker monolithic sheets, effectively defending against handgun rounds. However, it’s typically a one-shot solution. After being hit, it cracks and may spall, which means it's best suited for areas with low threat levels like retail counters and reception barriers.

UHMW-PE

Ultra-high molecular weight polyethylene (UHMW-PE) is a top performer in opaque ballistic protection. Used in everything from body armor to vehicle panels, this fiber-based plastic is incredibly light and tough. Rather than stopping bullets by cracking or flexing, it traps them in a web of tightly packed fibers, dispersing the energy without breaking apart.

UHMW-PE is common in bulletproof vests, armored car doors, and high-performance riot shields. It floats in water, resists moisture and chemicals, and provides multi-hit protection. While it can’t be used for windows (it’s not transparent), its weight-to-strength ratio makes it invaluable for mobile and structural defense systems.

Strength That Goes Beyond Bullets

One of the biggest advantages of ballistic plastics is their versatility. These materials don’t just protect, they also support the form, function, and aesthetics of modern spaces.

In commercial and civic buildings, ballistic-grade plastics are used in glazing, lobbies, school entryways, and secure office partitions. They allow the creation of protective barriers that are discreet, clear, and welcoming, not imposing like metal or mesh.

In law enforcement and transit applications, ballistic shields and vehicle windows rely on the impact resistance and multi-hit durability of plastics like polycarbonate and UHMW-PE. For example, riot helmets, face visors, and tactical eyewear are often made from ballistic polycarbonate to protect against projectiles and shrapnel. You’ll even find these materials used in storm-prone regions as debris-resistant window panels because the physics of stopping a flying 2x4 isn’t so different from stopping a slow-moving round.

A Side-by-Side Comparison

Choosing the right ballistic plastic involves trade-offs between clarity, impact strength, cost, and reusability. Here’s a comparison of common materials:

Polycarbonate is best for durability and multi-hit protection. It's perfect for public buildings and high-traffic areas where both transparency and repeated impact resistance are important.

Acrylic is the go-to for settings where high clarity and aesthetics are critical, but the risk is lower. It’s easier to fabricate and polish, but it's not designed for repeated impact.

UHMW-PE dominates in opaque applications, offering top-tier strength-to-weight performance for armor panels and wearable protection, but it can’t be used where visibility is needed.

Benefits That Add Up

The Future of Protection

Ballistic-grade plastics represent the next generation of protective design: transparent where needed, durable where it counts, and customizable for every setting.

At Piedmont Plastics, we supply a wide range of ballistic-rated materials to meet your project’s exact needs, from UL 752-rated polycarbonate sheets to lightweight UHMW-PE composites. Whether building a safer storefront, upgrading a secure facility, or retrofitting a vehicle, we’re here to help you choose the right material for the job.

Create Your Order

Need help specifying materials for your next protective project? Contact us today for more information, and we’ll be happy to assist. Let’s build something stronger together!

Connect With Us