When choosing a material for hull side windows, boat designers and engineers must decide between using acrylic or glass. Whether tempered or laminated, acrylic and glass are transparent materials that can tolerate high impact and weathering, making them both compelling options for boat builders.

What are the differences between acrylic and glass? Let’s dive in!

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience, we are confident our plastics experts can help you find a solution for your application.

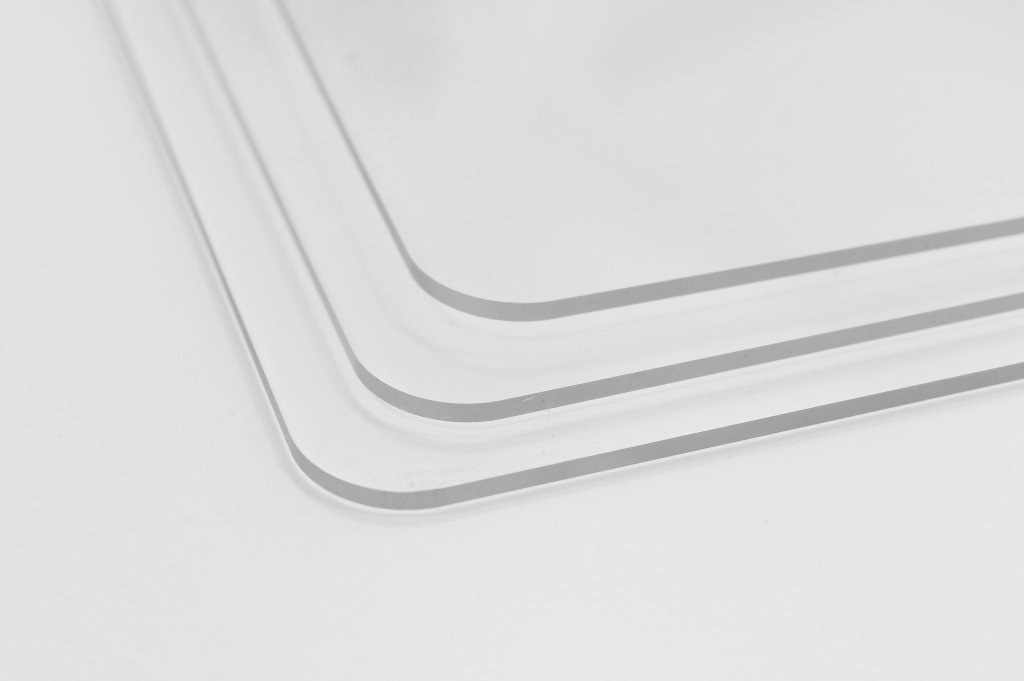

Engineers manufacture laminated glass using a method that involves layering float glass sheets with an adhesive polymer such as PVB, creating an extraordinarily strong assembly. However, advancements in polymer technology have made acrylic a superior alternative to glass.

Acrylic, a versatile polymer, offers better formability while maintaining terrific optical quality. Here are the key benefits of using acrylic:

Strength

Acrylic is 10 times stronger than glass, meaning it does not break due to high pressure or force. This impact resistance is particularly helpful for navigational and steering purposes. For this reason, engineers often use acrylic for boat windows and submarine portholes.

Weight

Acrylic is about half the weight of glass, making it an excellent material for boat windows. With the increasing emphasis on efficiency and environmental-consciousness, boat designers are focusing on reducing weight to enhance performance and fuel efficiency.

Cost

Acrylic is generally more affordable than high-quality glass, although the cost can vary depending on the type and thickness of the acrylic. While flat, unprocessed glass is less expensive than acrylic, tempered glass and acrylic are about equal in cost. Formed and/or laminated glass is much more expensive to manufacture.

Forming tools for glass windows are usually steel or ceramic, while acrylic windows only require fiberglass reinforced resin. This significantly impacts the tooling costs for window installation, making acrylic more affordable.

Formability

While glass can be molded into curved shapes, its limited malleability restricts the complexity of the final design, making intricate shapes difficult to form. Conversely, acrylic is versatile and can easily be shaped into more complex forms. This allows acrylic to maintain superb optical properties with minimal distortions.

Light Transmission

Up to 92% of light is transmitted through acrylic, while glass transmits only about 80-90% of light. Acrylic’s high level of clarity makes it an excellent material for applications where transparency is necessary, such as underwater viewing windows, hatch covers, and windshields.

Thermal Conductivity and UV Block

Acrylic has lower thermal conductivity compared to laminated glass, making it more effective for insulation applications like skylights and portlights. This also helps reduce heating and air conditioning costs.

Modern acrylic formulations can block up to 99% of UV rays and about 35% of infrared rays, depending on the tint. This capability protects the adhesives used to bond the window without needing a blackout strip called a Frit. It also prevents interior electronic components and upholstery from fading over time.

Piedmont Marine Grade® SB™ (Solar Block) is a cast acrylic sheet with approved protection against UV radiation. This helps prevent degradation of materials by blocking harmful UV rays. PMG® SB™ has been tested and approved by the Sika® Corporation for bonding and sealing Organic Windows Systems in the marine industry.

PMG® SB™ also has UV blocking (400 nm), which makes PMG® SB™ 62.5% better than standard acrylic glazing. In addition, the UV blocking (below 400 nm) blocks 100% of UV-A range radiation.

Scratch Resistance

Acrylic is softer and more prone to scratches than mineral glass. However, engineers are now applying silicate hard coatings to the exterior of acrylic, providing significantly enhanced scratch protection. In addition to reducing most scratches, this coating makes acrylic resistant to chemical attacks.

Nevertheless, as with glass, if the transparency is compromised, the entire window must be replaced. Certain chemicals can also damage acrylic, making it necessary to follow proper care and maintenance guidelines such as:

Using mild soap and water or cleaners specifically designed for acrylic

Avoiding cleaners with harsh chemicals such as ammonia, acetone, or alcohol

Storing acrylic sheets away from chemicals and damage-causing solvents

Ensuring that the storage area is dry and well-ventilated

Rinsing acrylic thoroughly with water if it contacts harmful chemicals

Inspecting acrylic surfaces regularly for indications of chemical damage, including discoloration or cracking

Using acrylic sheet with protective coatings to prevent chemical damage

Key Takeaways

Both acrylic and glass are valuable materials for boatbuilding, each offering their own advantages. Glass is known for its durability, scratch resistance, and ease of maintenance. However, it is typically more expensive than acrylic and presents challenges due to its weight and fragility during installation.

Acrylic is an optimal choice for boat windows due to factors such as clarity, strength, and lightweight properties. At the same time, it’s vital to keep in mind its susceptibility to scratches and chemical sensitivity. Despite those factors, with proper care and installation, acrylic windows can be a durable and efficient option for marine applications.

Want To Dive Deeper?

Acrylic is an ideal solution for cruisers and yachts in need of durable, cost-effective and high-quality window materials. Contact us today to learn more about our acrylic products!

Get In Touch