What is Acrylic and Polycarbonate?

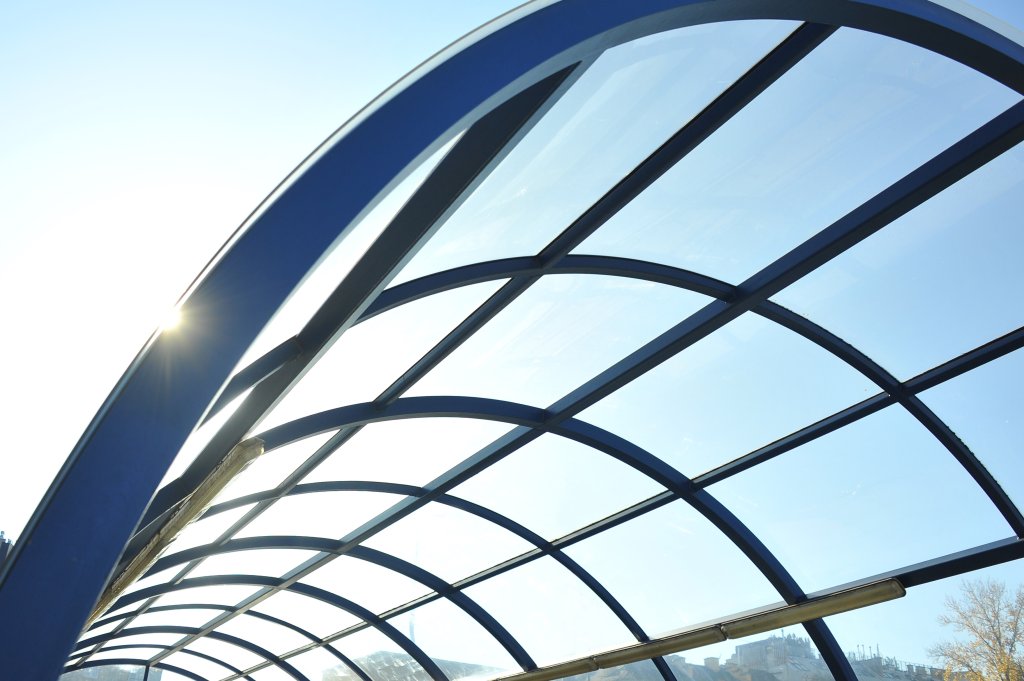

At Piedmont Plastics, acrylic sheeting and polycarbonate sheeting are two of the most popular types of products we sell. Because they have a similar look and are both a see-through plastic material for use in windows and similar applications, many customers lump them together. However, they have some key differences that you should understand as you select the right material for your project.

An Expert is just around the corner.

With over 100 years of combined product knowledge and industry experience. We are confident our plastics experts can help you find a solution for your application.

Acrylic and Polycarbonate – Strong, Versatile, and Lightweight Materials

Both acrylic and polycarbonate are incredibly strong, stronger than glass and about ½ the weight. They can both be completely clear and are easy to clean. When you first look at these products, it can be hard to tell the difference between them, but under the surface there are several properties that set them apart from each other.

Properties of Acrylic

Acrylic is sometimes called Plexiglass, but Plexiglass is just one of many brands of acrylic. This particular material has several benefits, including:

More affordable than both glass and polycarbonate.

Resists yellowing from the sun

Better clarity than glass transmitting 92% of light

Easier to machine and form

Shiny material that can be polished to a smooth finish

Has an impact resistance that is 17x that of glass

Available in a range of colors

In addition, acrylic is a thermoplastic that is formed and bent using heat. It can have clean glue joints for an improved overall look because glue bonds well with it. If you are looking for an affordable alternative to glass that is significantly stronger, acrylic could be the right fit.

Acrylic does have some cons to consider when choosing a plastic material. When compared to polycarbonate, it is a more rigid material. It also is more prone to cracking when drilled and chips more easily.

Properties of Polycarbonate

Polycarbonate plastics have many similar properties to acrylic. Some of the key differences include:

Higher cost, as much as 25% more expensive (depending on the grade)

Significantly stronger, with 250x the impact resistance of glass and 30x the strength of acrylic

Transmits 88% of light

Working temperature of 240 degrees, giving it a low level of flammability

Resists chips and cracking

Corrosion resistant when used in chemical applications

Will not crack even when the sheets are drilled in to

Can be formed without heating

If you are in need of bullet resistant materials or materials to use in a highly caustic environment, such as in a plant that works with acidic or other potent chemicals, then polycarbonate is probably the right fit.

Like acrylic, polycarbonate has some cons to consider. It is typically not a shiny material, but it can be polished. Although it resists cracking and chipping, it dents and scratches easily. It has good clarity, but it is not UV resistant and unless coated it will yellow over time. Acrylic is inherently UV resistant with as little as 3% degradation outdoors over a 10-year period.

Acrylic and Polycarbonte Products

-

Cast Acrylic

Piedmont Plastics is proud to be a leading supplier of acrylic sheet in North America.

-

Extruded Acrylic

A versatile and all-purpose acrylic sheet with multi-functional properties, Extruded Acrylic Sheet is a workhorse for a large variety of app...

-

Polycarbonate

Piedmont Plastics is an industry leading supplier of polycarbonate plastic sheet and products.

-

Specialty Polycarbonate Sheet

Piedmont Plastics carries specialty polycarbonate sheets that are FDA -compliant, highly optical, flame retardant, or laminated for bullet protection.

Which Material Works Best For Certain Applications?

So when would you choose acrylic for your application, and when would you choose polycarbonate? Acrylic is great as a window or in other substitutions for glass. It works well for retail displays and craft projects. These are applications where high impact resistance is not needed. Polycarbonate is the go-to choice for bullet-resistant applications, machine guards, heavy equipment windows and security glazing. It also works well as a mold for casting projects, because of the high heat resistance, and makes a great greenhouse glass material.

Still Need Assistance Choosing The Best Option?

If you are having trouble deciding between acrylic and polycarbonate, Piedmont Plastics is ready to help. Reach out to our knowledgeable sales team for help choosing the right product for your application.

Contact Us Today