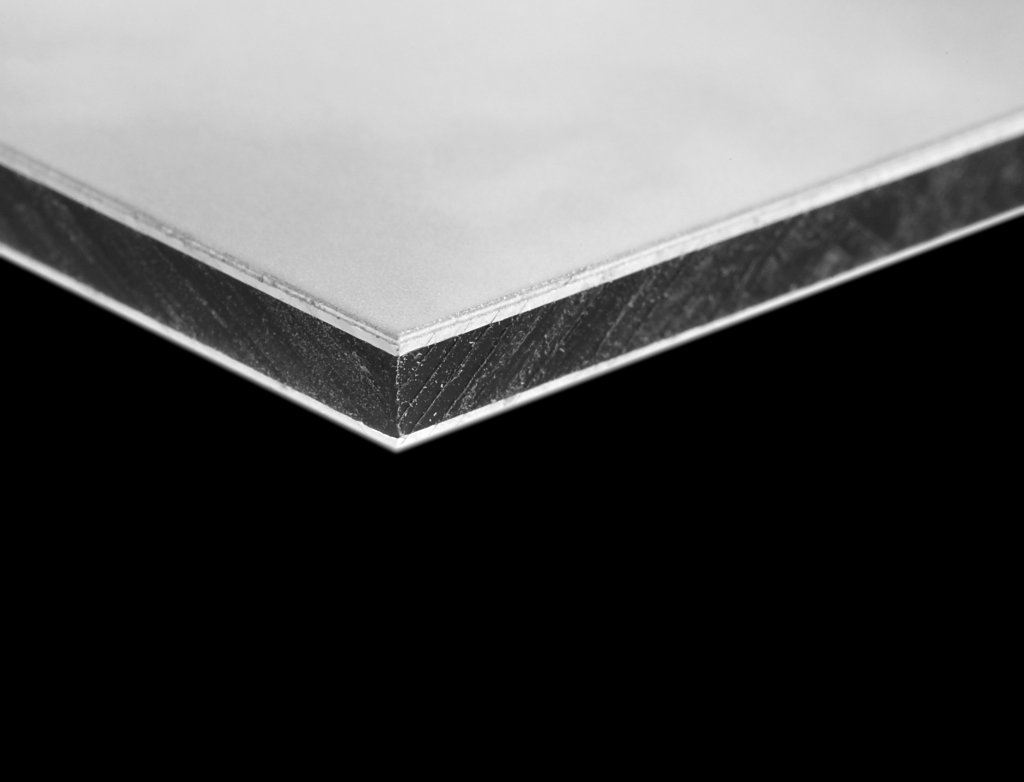

Aluminum composite material (ACM) is a three-layer panel material made of two thin layers of pre-finished aluminum bonded on either side of a polyethylene (PE) core. ACM panels are used in many indoor and outdoor applications due to their excellent dimensional stability, lightweight, strength, and durability. Piedmont Plastics offers aluminum composite panels in a wide choice of size, thickness, finish, and color. We also have fire grades available, and you can have your aluminum composite panels cut-to-size and machined into fabricated parts to meet your manufacturing needs.

All in all, Piedmont’s ACM can provide numerous solutions to many customers’ manufacturing needs.

Here’s more on how:

Ways To Use Aluminum Composite Panels

Between its aesthetic qualities and ability to be easily fabricated without sacrificing durability, ACM is a popular choice for material for a wide range of products. Some of its many uses include channel letters for signage, point-of-purchase displays, exhibition kiosks, digital and screen printing, performance sets, specialty vehicles, and building and construction applications like architectural cladding, insulation, and wall linings.

In manufacturing, ACM solves a lot of challenges by being simple to machine and fabricate. It bonds quickly and exhibits excellent dimensional stability. Panels can come in custom shapes and sizes, suitable for cutting, shearing, bending, punching, drilling and profiling. They can be cut to satisfy customer needs beforehand and can come in a wide range of colors—or, in some cases, be color-matched to fit a company’s branding or design requirements.

ACM readily accepts traditional inks and paints for signage and display applications, is digitally printable, and works well with PSA print media. Additionally, ACM meets UL compliance per UL879 as a component for sign accessories and may be used to construct type II electrical enclosures—all critical things to consider when planning exhibition hall displays.

When used in building, aluminum composite panels can add a modern touch to structures by allowing for shapes that would be considered an insurmountable design challenge decades ago. In addition, aluminum composite panels are significantly easier to work with when compared to more traditional materials such as steel, wood, and concrete.

Advantages of Aluminum Composite Material (ACM)

One of the most beneficial features of ACM is its versatility. ACM panels can be easily cut, routed, fabricated, mounted, and installed with everyday tools. ACM panels remain flat over time and are approximately half the weight of traditional aluminum. Because of this, ACM is considered more cost-effective than similarly gauged aluminum sheets.

As materials go, ACM is highly resistant to ultraviolet light, scratches, weather, and corrosion. This makes it perfect for a wide variety of applications. On top of that, ACM can be easily cleaned and maintained, allowing it to maintain a sleek and brilliant look. Where other materials may deteriorate over time, aluminum composite panels last much longer and provide end-users with more value for less cost.

Aluminum Composite Material Product Options

Piedmont Plastics offers several options for ACM products.

AluPOLY®

A part of Piedmont’s Sign Grade product line, AluPoly® is a standout ACM material option available in multiple grades, including Economy, Standard, Premium, HS, Digital, and Digital Plus. AluPOLY’s smooth surface can be coated or painted to match any color or pattern, made to look like wood or marble, and have either metallic or non-metallic finishes.

Piedmont Plastics stocks AluPOLY in your choice of gauges and aluminum skin thicknesses. Its protective film ensures a quality surface and superior adhesion that works well with most inks, paints, and pressure-sensitive media. As with other ACM options, AluPOLY is rigid and durable and can withstand the elements without warping.

DIBOND®

Considered an industry-standard material, DIBOND® aluminum composite material is made up of two pre-painted sheets of 0.012” aluminum with a solid polyethylene core. DIBOND sheet is among the flattest ACM panels available today is its high-quality surface is perfect for protecting digital and screen-printed graphics.

At about half the weight of a traditional aluminum sheet, DIBOND aluminum composite panels exhibit proven durability for sign usage, won’t bow or oil can, and can be routed and returned or roll-formed for added dimension or curves.

e-panel™

Two pre-painted sheets of 0.008” aluminum with a solid polyethylene core, e-panel™ is a top choice for flat panel applications. It is a popular digital and screen printing option, suitable for cold mounting graphics, and can be saw cut, routed, or punched.

epL-5™

This is the thinnest grade of ACM within the DIBOND product line. It is comprised of two pre-painted sheets of 0.005” aluminum with a solid PE core. Similar to e-panel, epL-5 is also most often used for flat panel applications only. It’s perfect for mounting graphics or printing and can be cut, routed, or punched.

Alucobond® PE

This ACM option consists of two sheets of smooth 0.020” nominal aluminum thermo-bonded to a polyethylene core. Alucobond panels provide flatness, formability and are resistant to simple wear and processing.

For More Information On Aluminum Composite Material

Our teams of knowledgeable plastics experts at Piedmont Plastics are ready to provide the solutions you need for your applications. Contact us today for more information on how ACM can be the optimal solution for your needs and how we can help serve you and your products.