Piedmont Plastics supplies a wide range of performance plastics to a variety of machine shops ranging from job shops to contract manufacturing. Tight timetables and short turnaround times are the norm in this industry, and as a result, Piedmont offers a vast national inventory of machine grade plastics that help you get what you need quickly.

Common Plastics for Machine Shops

Whether you’re searching for a common plastic like acetal or nylon, or a higher performance plastic such as bearing grade PEEK or Torlon®, our vast experience, material knowledge, and strong supplier relationships make Piedmont the source machine shops depend on for plastic materials. Our CNC saws are just one value-added service offered, reducing yield loss and ensuring you receive the best overall solution for a particular job. Our customers operate everything from basic mills and lathes to the most sophisticated machining and turning centers. In addition, safety is a primary concern for many machine shops, and certain performance plastics, such as polycarbonate, do an exceptional job protecting operators from potential hazards and projectiles. There are a variety of industrial plastic materials and parts that can provide the greatest performance for machine shop equipment, and each have their own unique benefits.

Acetal has exceptional stiffness, strength, durability, lubricity, and a low moisture absorption rate. It offers a thinner, lighter, and more flexible design than traditional industrial products. It boasts excellent product fusion and a wide range of temperature performance levels. Acetal can be used for applications such as bearings and bushings, seals and gaskets, star wheels, , thrust washers, valve seats and wire harness fixtures.

Nylon has exceptional toughness, resistance to wear, and great tensile strength. It is lightweight and exhibits a low coefficient of friction and is chemically and thermally resistant. Nylon can be used in applications such as bearings and bushings, seals and gaskets, star wheels, thrust washers, and valve seats.

PTFE has a low coefficient of friction, excellent electrical properties, high chemical resistance, and stability in wide temperature ranges. PTFE is also FDA approved. PTFE can be used for applications such as conveyor systems, bearings and bushings, seals and gaskets, valve seats, and thrust washers.

UHMW is highly durable, cost-efficient, and versatile. It is commonly known for its extremely low coefficient of friction, inherent lubricity, superior impact strength and chemical resistance. Natural virgin UHMW has an extremely high molecular weight, making it extremely resistant to abrasion and moisture absorption. UHMW can also be used for applications such as chute liners, conveyor systems, star wheels, thrust washers, valves and fittings, and wear strips.

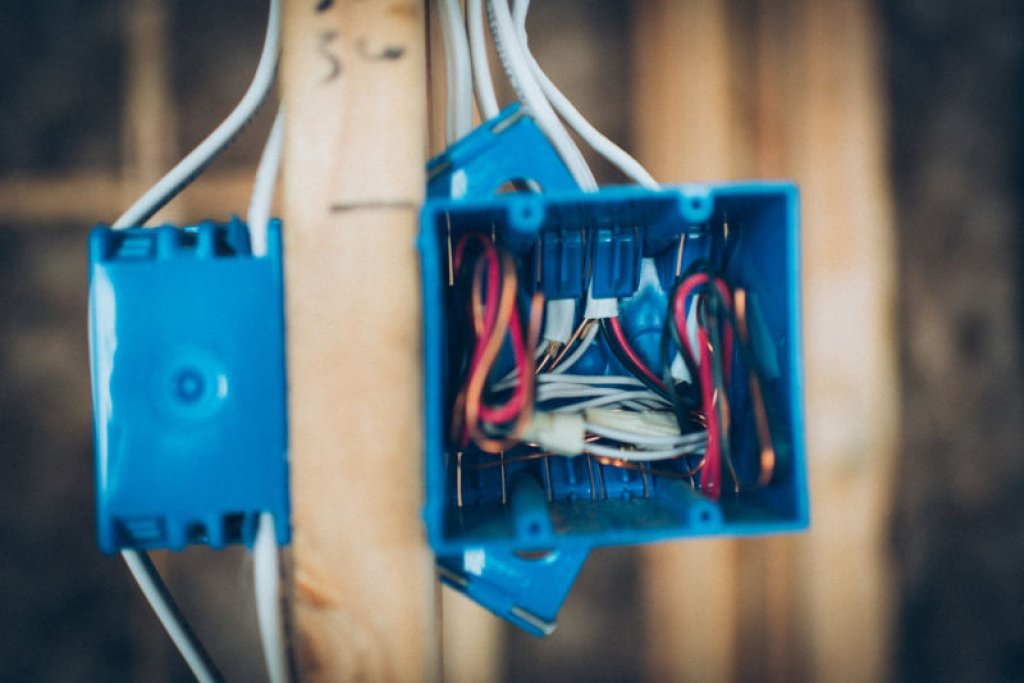

Polycarbonate is a transparent plastic material with exceptional impact resistance, toughness, low moisture absorption, dielectric properties, and flame retardance. Polycarbonate is 30 times stronger than acrylic, and over 200 times stronger than glass. It is lightweight, weighing six times less than glass. Polycarbonate is also a great insulator. Polycarbonate can be used in applications such as machine guards, heavy equipment glazing, and conveyor systems.

PVC Type I offers excellent resistance to impacts, corrosion, and chemicals. PVC is also an economical and highly machinable material, making it a great choice for a variety of applications such as valves and fittings, piping, cable insulators, tanks and air scrubbers. In addition, PVC Type I is offered in gray and white as standard colors, is easy to fabricate and is available in both sheets and rods of various sizes and thicknesses.